Abstract

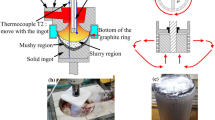

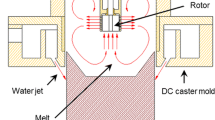

A fine and uniform microstructure is always desirable for aluminium billets produced by direct-chill (DC) casting. Although this is usually achieved by grain refiner addition during DC casting, in this paper we demonstrate a physical approach for grain refining DC cast billets. Intensive melt shearing is applied to DC casting by submerging a rotor–stator based high shear device in the sump of a conventional DC caster. It has been shown that DC casting with intensive melt shearing can achieve one order of magnitude grain size reduction without using chemical grain refiners. Such fine and equiaxed grain structure in the Al billets can be attributed to enhanced heterogeneous nucleation and growth under conditions with reduced temperature gradient and increased growth velocity.

Similar content being viewed by others

References

McCartney D G, Int Mater Rev 34 (1989) 247.

Quested T E, Mater Sci Technol 20 (2004) 1357.

Eskin G I, Ultrason Sonochem 1 (1994) 59.

Eskin G I, Ultrason Sonochem 8 (2001) 319.

Campanella T, Charbon C, and Rappaz M, Met Mater Trans A 35A (2004) 3201.

Li H T, Xia M, Jarry Ph, Scamans G M, and Fan Z, J Cryst Growth 314 (2011) 285.

Fan Z, Zuo Y B, and Jiang B, Mater Sci Forum 690 (2011) 141.

Fan Z, Zuo Y B, and Jiang B, Apparatus and method for liquid metals treatment, Application No.1015498.7, UK Patent, 2010.

Fan Z, Int Mater Rev 47 (2002) 49.

Zuo Y, Jiang B, and Fan Z, Mater Sci Forum 690 (2011) 137.

Jackson K A, Hunt J D, and Uhlmann D R, Seward T P, Trans TMS-AIME 236 (1966) 149.

Das A, Ji S, and Fan Z, Acta Materialia 50 (2002) 4571.

Hunt J D, Mat Sci Eng A 65 (1984) 75.

Zuo Y, Jiang B, and Fan Z, Mat Sci Eng 27 (2011).

Men H, Jiang B, and Fan Z, Acta Materialia 58 (2010) 6526.

Acknowledgments

The Author would like to thank the EPSRC and SAPA aluminium for their financial support which made the present work possible.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jones, S., Prasada Rao, A.K. & Fan, Z. Melt Conditioned Direct Chill (MC-DC) Casting of Al Alloys. Trans Indian Inst Met 66, 117–121 (2013). https://doi.org/10.1007/s12666-012-0235-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-012-0235-5