Abstract

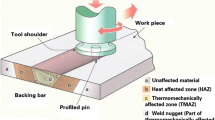

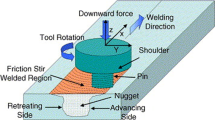

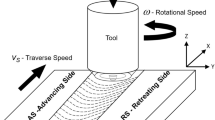

Magnesium alloys have gained considerable interest as a material for automotive and aerospace applications due to its low density, high specific strength and good castability. However, an issue is their corrosion properties. This restricts their practical applications. In this work, a comparative evaluation of corrosion behavior of friction stir welded AZ61A magnesium alloy weldments was investigated by immersion and salt spray corrosion tests. Extruded Mg alloy plates of 6 mm thick of AZ61A grade were butt welded using friction stir welding (FSW) process. The specimens were exposed to immersion and salt spray environments in order to characterize their corrosion rates. In addition, an attempt was made to develop an empirical relationship to predict the corrosion rate of the FSW joints in immersion tests and salt spray corrosion tests using response surface methodology. The corrosion morphology and pit morphology observation was carried out by optical microscopy. General corrosion was more prevalent on the immersion surface. However, the pits on the salt spray surface showed larger surface areas, larger volumes, and covered more area on the micrographs as compared to the pits on the immersion surfaces, due to the pit debris that trapped chloride ions within the pits. Finally, it concludes that the FSW AZ61A weldments are suitable for immersion conditions than salt spray environments.

Similar content being viewed by others

References

Modike B L, and Ebert T, Mater Sci Eng A 302 (2001) 37.

Zeng R C, Dietzel W, Zettler R, Chen J, and Kainer K U, Trans Non-Ferrous Met Soc China 18 (2008) s76.

Zeng R C, Zhang J, Huang W J, Dietzel W, Kainer K U, Blawert C, and Ke W, Trans Non-Ferrous Met Soc China 16 (2006) s771.

Nagasawa T, Otsuka M, Yokota T, and Ueki T, in: Magnesium Technology 2000, (eds) Kaplan H I, Hryn J, Clow B, TMS, Warrendale (2000) p. 383.

XU W, Liu J, and Zhu H, Mater Des 55 (2010) 2918.

Zhao M, and Wu S, Surf Coat Technol 200 (2006) 5407.

Song G, and Atrens A, Adv Eng Mater 1 (1999) 11.

ASTM G31-72 Standard Practices for Laboratory Immersion Corrosion Testing of Metals, ASTM, West Conshohocken (2004).

ASTM B-117 Standard Practice for Salt Spray Corrosion Testing of Metals, ASTM, West Conshohocken (2004).

Tunold R, Holton H M, Berge B H, Lasson A, and Steen-Hansen R, Corros Sci 17 (1977) 353.

Song G, and Atrens A, Adv Eng Mater 5 (2003) 837.

Song G, Atrens A, St John D, Nairn J, and Li Y, Corros Sci 39 (1997) 855.

Atrens A, Coade R, Allison J, Kohl H, Hochoertler G, and Krist G, Mater Forum 17 (1993) 263.

Song G, Atrens A, Wu X, and Zhang B, Corros Sci 40 (1998) 1769.

Ambat R, Aung N, and Zhao W, Corros Sci 42 (2000) 1433.

Merino M C, Pardo A, Arrabal R, Merino S, Casajus P, and Mohedano M, Corros Sci 52 (2010) 1696.

Hara N, Kobayashi Y, Kagaya D, and Akao N, Corros Sci 49 (2007) 166.

Schumtz P, Guiaumin V, Lilard R S, Lilard J A, and Frankela G S, J Electrochem Soc 150 (2003) B99.

Neil W C, Forsyth M, Howlettt P C, Hutchison C R, and Hinton B R W, Corros Sci 51 (2009) 387.

Lafront A M, Zhang W, Jin S, Tremblay R, Dube D, and Ghali E, Electrochim Acta 51 (2005) 489.

Zeng R-C, Chen J, Dietzel W, Zettler R, Jorge Dos Santos F, Lucia Nascimento M, and Ulrich Kainer K, Corros Sci 51 2009 1738.

Balasubraminan P, Zetler R, Blawert C, and Dietzel W, Mater Charact 60 (2009) 289.

Altun H, and Sen S, Mater Des 25 (2004) 637.

Song Y, Shan D, Chen R, and Han E-H, Corros Sci 52 (2010) 1830.

Aung N, and Zhou W, Corros Sci 52 (2010) 589.

Song G, and Xiu Z, Electrochim Acta 55 (2010) 4148.

Gao L, Zhang C, Zhang M, Huang X, and Sheng N, J Alloy Compd 468 (2007) 285289.

Acknowledgments

The authors would like to thank Centre for Materials Joining & Research (CEMAJOR), Department of Manufacturing Engineering, Annamalai University, Annamalai Nagar, for extending the facilities of the Materials Joining Laboratory and Corrosion Testing laboratory to carry out this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhanapal, A., Rajendra Boopathy, S. & Balasubramanian, V. Comparative Evaluation of Corrosion Behavior of Friction Stir Welded AZ61A Magnesium Alloy Weldments in Immersion Corrosion Tests and Salt Spray Corrosion Tests Using Response Surface Methodology. Trans Indian Inst Met 65, 275–287 (2012). https://doi.org/10.1007/s12666-012-0131-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-012-0131-z