Abstract

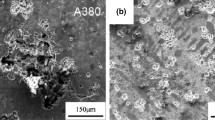

The present investigation deals with the hot tearing susceptibility of A206, A518, and A713 alloys. The hot tearing tests of the mentioned alloys were conducted at three different pouring temperatures using sand mold casting. Metallic cores designed to facilitate constrained radial contraction of the aforementioned alloys were used for casting. Macroscopic cracks were found in all the samples except in A518 alloy. It was observed that pouring temperatural and grain size have significant effect on crack susceptibility. Among the investigated alloys, A713 was found to be extremely prone to hot tearing. The microstructure characteristics of the alloys were studied using optical and scanning electron microscopy. Relationships between the pouring temperature, grain size and crack lengths of the alloys were also established.

Similar content being viewed by others

References

Li S, Hot Tearing in Cast Aluminum Alloys: Measures and Effects of Process Variables, PhD Thesis, Worcester Polytechnic Institute, Worcester (2010).

Phillion A B, Hot Tearing and Constitutive Behavior of Scanning Electronic-Solid Aluminium Alloys, PhD Thesis, The University of British Columbia, Vancouver (2007).

Eskin D G, Suyitno, and Katgerman L, Prog Mater Sci 49 (2004) 629.

Wang Y, Sun B, Wang Q, Zhu Y, and Ding W, Mater Lett 53 (2002) 35.

Eeghem J V, and Sy A D, AFS Trans 73 (1965) 282.

Davidson C, Viano D, Lu L, and John D S, Int J Cast Mater Res 19 (2006) 59.

Easton M, and St. John D Metall Mater Trans A 30 (1999) 1625.

Cao G, and Kou S, Metall Mater Trans A 37 (2006) 3647.

Karunakar B D, Rai R N, Patra S, and Datta G L, Int J Adv Manuf Technol 45 (2009) 851.

Elia F D, and Ravindran C, Trans Indian Inst Metals 62 (2009) 315.

Zhou Y Z, and Volek A, Scr Metal 56 (2007) 537.

Monroe C, and Beckermann C, Mater Sci Eng A 413 (2005) 30.

Cao G, and Kou S, Mater Sci Eng A 417 (2006) 230.

Li M, Wang H, Wei Z, and Zhu Z, Mater Design 31 (2010) 2483.

Gunde P, Schiffl A, and Uggowitzer P J, Mater Sci Eng A 15 (2010) 7074.

Zheng W, Li S, Tang B, Zeng D, and Guo X, J Rare Earth 24 (2006) 346.

Nasr Esfahani M R, and Niroumand B, J Mater Charact 61 (2010) 318.

Sabatino M D, and Arnberg L, Trans Indian Inst Metals 62 (2009) 321.

Clyn T W, and Davies G J, Br Foundrym 74 (1981) 65.

Acknowledgments

The authors were grateful to Mr. R.K. Harit, Mr. Bijendar Sharma and Mr. Balesh Sharma supporting staff in Foundry Engineering and Research Lab of Mechanical and Industrial Engineering Department, Indian Institute of Technology, Roorkee for the help while conducting the experiments for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Birru, A.K., Karunakar, D.B. & Mahapatra, M.M. A Study on Hot Tearing Susceptibility of Al–Cu, Al–Mg, and Al–Zn alloys. Trans Indian Inst Met 65, 97–105 (2012). https://doi.org/10.1007/s12666-011-0112-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-011-0112-7