Abstract

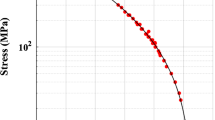

Creep behaviours for Alloy 617, such as creep properties, oxidation and creep fracture morphologies were investigated by a series of creep tests with different stress levels at 1223 K. Creep constants of A, n, m, and C were obtained at 1223 K for Alloy 617. To accurately predict the long-term creep life (or strength) for Alloy 617, a multi constant method with two C in the Larson-Miller (LM) parameter was newly proposed instead of the conventional one with a unique C. The conventional method did not thoroughly match with the creep rupture data, and revealed an overestimation for the prediction of the long-term creep strength. On the other hand, the multi constant method revealed a good agreement with the creep rupture data, and this method was more accurate than the conventional one. The multi constant analysis can be used to accurately predict the long-term creep rupture life of Alloy 617 above 105 h for 1173 K, 1223 K and 1273 K.

Similar content being viewed by others

References

Kim W G, Yin S N, Ryu W S and Chang J H, Proc of CREEP8, Eighth Int Conf on Creep and Fatigue at Elevated Temperature, PVP2007-26834, Texas (2007).

Kim W G, Yin S N, Ryu W S, Chang J H and Kim S J, Materials Science and Engineering A 483–484 (2008) 495.

Kim W G, Yin S N, Jung I H, and Kim Y W, Key Engineering Materials 385–387 (2008) 693.

Dewson S, and Li X, Proc of ICAPP 05, Paper No.5333, Seoul (2005).

ASME Boiler and Pressure Vessel Code, Section II, Materials Part D-Properties (2004).

Jang C, Lee D and Kim D, Int Journal of Press Vessels and Piping 85 (2008) 368.

Kim W G, Yin S N and Ryu W S, Key Engineering Materials 297–300 (2005) 2272.

Maruyama K and Yoshimi K, Proc of CREEP8, Eighth Int Conf on Creep and Fatigue at Elevated Temperature, PVP2007-26150, Texas (2007).

Schubert F, Bruch U, Cook R, Diehl H, Ennis P J, Jakobeit W, Penkalla H J, Heesen E T and Ulirich G, Nuclear Technology 66 (1984) 227.

Natesan K, Purohit A, and Tan S W, Materials Behavior in HTGR Environments, Report NUREG/CR-6824 ANL-02/37, Argonne National Laboratory (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, WG., Yin, SN., Kim, YW. et al. Creep behaviour and long-term creep life extrapolation of alloy 617 for a very high temperature gas-cooled reactor. Trans Indian Inst Met 63, 145–150 (2010). https://doi.org/10.1007/s12666-010-0020-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-010-0020-2