Abstract

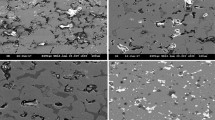

Sizing, also known as coining, is a post sintering near net shape metal forming operation performed on automobile brake and clutch liners to achieve improved physical and mechanical properties and close dimensional tolerances. Cu-15% Fe based composite pins were processed in the present investigation by powder metallurgy route with and without addition of mullite and graphite and both. Sizing of sintered pins was performed and tribological properties, such as; coefficient of friction (COF) and specific wear rate were studies under dry sliding conditions. Physical properties were also evaluated, which were found improved after sizing for all the compositions studied. Tribological properties, in particular specific wear rate, were found significantly deteriorated for the sized materials containing either mullite or graphite alone. However, composites that contained both mullite and graphite, showed slightly reduced, but more stabilized COF upon sizing. Specific wear rate of these sized pins was found minimal and exceptionally low compared to materials containing either mullite or graphite alone. There was little increase in the wear rate of sized pins compared to the as sintered pins containing both mullite and graphite, which was due to the development of microcracks after sizing. The tendency of microcracking could be minimized by optimization of the sizing pressure, so as to achieve both improved physical properties as well as tribological performance.

Similar content being viewed by others

References

Chapter 9-Sintered Friction Materials, in Powder Metallurgy-Practice and Applications: (eds) Sands R L and Shakespeare C R, George Newnes Ltd., London (1966) 198.

Upadhyaya G S (ed), Sintered Metallic and Ceramic Materials, Preparation, Properties and Applications, John Wiley & Sons Ltd., UK (2000) 800.

Locker K D, Powder Metallurgy 35(4) (1992) 253.

Chan D, and Stachowiak G W, J. Automobile Eng. 218Part D (2004) 953.

Friction and Wear of Aircraft Brakes, in ASM Handbook, (eds) Tatarzicki Y T, and Webb R T, ASM International, Materials Park, Ohio, 18 (1992) 582.

Teisanu Cristina, Tudor Andrei, Gheorghe Stefan, and Ciupitu Ion, Tribological Features of PM Iron-Copper based Material, The Annals of University “Dunarea De Jos” of Galati, Fascicle, Tribology ISSN 1221-4590 (2003) 168.

Technology of Metal Powders and their Products, in Treatise on Powder Metallurgy, Vol. 1, (ed) Goetzel Calus G, Interscience Publishers Inc., New York (1949) 663.

Fundamental Principles of Powder Metallurgy, (ed) Jones W D, Edward Arnold Ltd., London (1960) 606.

Eudier M, Powder Metallurgy, 18(35) (1975) 247.

Blau, Peter J, Composition, Functions, and Testing of Friction Brake Materials and their Additives, report no. ORNL/TM-2001/64 prepared by Oak Ridge National Laboratory, for The U.S. Deptt. of Energy, August 2001.

Hulskotte J.H.J., Schaap M and Visschedijk A.J.H., 10th International Specialized Conference on Diffuse Pollution and Sustainable Basic Management, Sept. 18–22, 2006, Turkey.

Venugopal P, Annamalai S, Kannan K S and Srinivasan Sriram, Jourrnal of Mechanical Working Tech. 13 (1986) 339.

Jha A K, and Kumar S, Journal of Mechanical Working Tech. 16 (1988) 145.

Xiong Xiang, Chen Jie, Yao Pingping, Li Shipeng and Huang Baiyun, Wear 262 (2007) 1182.

Stadler Zmago, Krnel Kristoffer, and Kosmac Tomaz, Journal of European Ceramic Soc, 27 (2007) 1411.

Vardavoulias M, Tresy C. Jouannt and Jeandin M, Wear 165 (1993) 141.

Suh N P, Wear, 44 (1977) 1.

Hamid Abdulhaqq A, Ghosh P K, Jain S C and Ray Subrata, Wear 265 (2008) 14.

Kurt Adem and Boz Mustafa, Materials and Design 26 (2005) 717.

Dhanasekaran S and Gnanamoorthy R, Materials and Design 28 (2007) 1135.

Moustafa S F, El-Badry S A, Sanad A M and Kieback B, Wear 253 (2002) 699.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jain, V., Saravanan, M., Anandani, R.C. et al. Effect of sizing on friction and wear properties of copper-iron based sintered composites. Trans Indian Inst Met 63, 43–54 (2010). https://doi.org/10.1007/s12666-010-0007-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-010-0007-z