Abstract

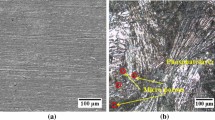

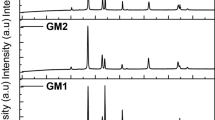

The MoS2 nanoflakes can be a novel candidate as a solid lubricant in fabricating friction material for automotive brake-pad disc systems. In this paper, an investigation has been made to analyze the effect of MoS2 nanoflakes on the mechanical and tribological behavior of the formulated copper-free low-metallic composite friction material. Three samples, namely S1, S2, and S3, have been fabricated containing different types of solid lubricant. Sample S1 had a solid lubricant as graphite, while samples S2 and S3 had graphite mixed with solid lubricant MoS2 with average flake sizes of 2 µm and 50 nm, respectively. Other components included steel, PAN, and aramid as reinforcing fibers; walnut powder, barium sulphate (BaSO4), and nitrile-butadiene rubber as fillers; phenolic resin as a binder; and FeO, Quartz, and MgO as abrasives. A pin-on-disc tribometer test (ASTM G-99) was conducted to carry out the wear test at a load of 60 N, sliding velocity of 2.09 m/s, and sliding distance of 6283 m at room temperature. A scanning electron microscope was used to study the micro-structural evolution of worn composite friction pin material. The results show that the nano-sized MoS2 solid lubricant influences the structural integrity of the formulated composites, which governs the friction and wear behavior. The graphite and MoS2-based friction composites S2 and S3 perform better than the conventional friction material (S1) containing graphite in terms of physical–mechanical, thermal, and tribological properties. The specific wear rate of the S1 sample is the highest (2.72 × 10–5 mm3/Nm) followed by S2 (1.84 × 10–5 mm3/Nm) and S3 (0.98 × 10–5 mm3/Nm) respectively. The graphite and MoS2-based friction specimens S2 and S3 showed adequate coverage of friction plateaus, reducing wear and abrasion of the counter disc.

Graphical Abstract

Similar content being viewed by others

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- CoF:

-

Coefficient of friction

- GCI:

-

Grey cast iron

- SEM:

-

Scanning electron microscope

- EDX:

-

Energy dispersive X-ray spectroscopy

- XRF:

-

X-ray fluorescence spectroscopy

- ρ :

-

Density of pin

- W 1 :

-

Initial pin weight

- W 2 :

-

Final pin weight

- NBR:

-

Nitrile-butadiene

- PoD:

-

Pin-on-disc

- P :

-

Porosity (%)

- w f :

-

Weight of the sample after soaking in water for 24 h

- w i :

-

Initial weight of the sample

- K a :

-

Specific wear rate

- F :

-

Force

- W :

-

Wear rate

- MoS2 :

-

Molybdenum disulfide

References

P.C. Verma, Automotive brake materials: Characterization of wear products and relevant mechanisms at high temperature, Ph.D. Thesis, University of Trento (2016)

S.M. Mulani, A. Kumar, H.N. Shaikh, A. Saurabh, P.K. Singh, P.C. Verma, A review on recent development and challenges in automotive brake pad-disc system. Mater. Today: Proc. 56(1), 447–454 (2022). https://doi.org/10.1016/J.MATPR.2022.01.410

P.C. Verma, L. Menapace, A. Bonfanti, R. Ciudin, S. Gialanella, G. Straffelini, Braking pad-disc system: wear mechanisms and formation of wear fragments. Wear 322–323, 251–258 (2015). https://doi.org/10.1016/J.WEAR.2014.11.019

M. Moazami-Goudarzi, A. Nemati, Tribological behavior of self-lubricating Cu/MoS2 composites fabricated by powder metallurgy. Transact. Nonferrous Metals Soc. China 28(5), 946–956 (2018). https://doi.org/10.1016/S1003-6326(18)64729-6

P.C. Verma, M. Alemani, S. Gialanella, L. Lutterotti, U. Olofsson, G. Straffelini, Wear debris from brake system materials: a multi-analytical characterization approach. Tribol. Int. 94, 249–259 (2016). https://doi.org/10.1016/j.triboint.2015.08.011

S. Venkatesh, K. Murugapoopathiraja, Scoping review of brake friction material for automotive. Mater. Today: Proc. 16, 927–933 (2019). https://doi.org/10.1016/j.matpr.2019.05.178

S.P. Jadhav, S.H. Sawant, A review paper: development of novel friction material for vehicle brake pad application to minimize environmental and health issues. Mater. Today: Proc. 19, 209–212 (2019). https://doi.org/10.1016/J.MATPR.2019.06.703

U. Olofsson, C. Piyush, M. Alemani, S. Gialannela, G. Straffelini, Characterisation of wear particles and tracks from disc brake materials: a multianalytical approach, in Eurobrake 2015. Dresden, 4–6 May 2015. https://doi.org/10.13140/RG.2.1.3188.6245.

M. Arman, S. Singhal, P. Chopra, M. Sarkar, A review on material and wear analysis of automotive Break Pad. Mater. Today: Proc. 5(14), 28305–28312 (2018). https://doi.org/10.1016/j.matpr.2018.10.114

G. Straffelini, P.C. Verma, I. Metinoz, R. Ciudin, G. Perricone, S. Gialanella, Wear behavior of a low metallic friction material dry sliding against a cast iron disc: role of the heat-treatment of the disc. Wear 348–349, 10–16 (2016). https://doi.org/10.1016/j.wear.2015.11.020

W. Song, J. Park, J. Choi, J.J. Lee, H. Jang, Effects of reinforcing fibers on airborne particle emissions from brake pads. Wear 484–485, 203996 (2021). https://doi.org/10.1016/J.WEAR.2021.203996

B. Rashid, Z. Leman, M. Jawaid, M.R. Ishak, F.M. Al-Oqla, Eco-friendly composites for brake pads from agro waste: a review, in Encyclopedia of Materials: Composites, vol. 3, ed. by D. Brabazon (Elsevier, 2017), pp. 209–228. https://doi.org/10.1016/B978-0-12-803581-8.10159-6.

S. Yashwhanth, M.M. Mohan, R. Anandhan, S.K. Selvaraj, Present knowledge and perspective on the role of natural fibers in the brake pad material. Mater. Today: Proc. 46, 7329–7337 (2021). https://doi.org/10.1016/J.MATPR.2020.12.995

V. An, E. Anisimov, V. Druzyanova, N. Burtsev, I. Shulepov, M. Khaskelberg, Study of tribological behavior of Cu–MoS2 and Ag–MoS2 nanocomposite lubricants. Springerplus 5(1), 72 (2016). https://doi.org/10.1186/s40064-016-1702-y

M.A. Ahdy, M.K. Ali, M. Mourad, A.M. Abd-El-Tawwab, Review of automotive brake lining materials and their tribological properties. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 236(7), 1445–1465 (2022). https://doi.org/10.1177/13506501211059812

N. Kalel, J. Bijwe, A. Darpe, Influence of amount of phenolic resin on the tribological performance of environment-friendly friction materials, SAE Technical Paper (2019). https://doi.org/10.4271/2019-01-2105

B. Bhatt, N. Kalel, M. Abdel-Latif, J. Bijwe, Influence of increasing amount of attapulgite on the performance properties of Cu-free brake-pads, SAE Technical Paper (2020). https://doi.org/10.4271/2020-01-1601

S. Zhao, Q. Yan, T. Peng, X. Zhang, Y. Wen, The braking behaviors of Cu-Based powder metallurgy brake pads mated with C/C–SiC disk for high-speed train. Wear 448–449, 203237 (2020). https://doi.org/10.1016/J.WEAR.2020.203237

J. Park, W. Song, J. Gweon, H. Seo, J.J. Lee, H. Jang, Size effect of zircon particles in brake pads on the composition and size distribution of emitted particulate matter. Tribol. Int. 160, 106995 (2021). https://doi.org/10.1016/j.triboint.2021.106995

D.K. Kolluri, X. Boidin, Y. Desplanques, G. Degallaix, A.K. Ghosh, M. Kumar, J. Bijwe, Effect of natural graphite particle size in friction materials on thermal localisation phenomenon during stop-braking. Wear 268(11–12), 1472–1482 (2010). https://doi.org/10.1016/j.wear.2010.02.024

S. Singh, N. Kalel, A. Darpe, R. Gilardi, J. Bijwe, Controlling the performance of copper-free brake-pads by varying size of graphite particles. SAE Technical Paper (2020). https://doi.org/10.4271/2020-01-1604

A. Saurabh, K. Joshi, A. Manoj, P.C. Verma, Process optimization of automotive brake material in dry sliding using taguchi and ANOVA techniques for wear control. Lubricants 10(7), 161 (2022). https://doi.org/10.3390/lubricants10070161

M. Leonardi, M. Alemani, G. Straffelini, S. Gialanella, A pin-on-disc study on the dry sliding behavior of a Cu-free friction material containing different types of natural graphite. Wear 442–443, 203157 (2020). https://doi.org/10.1016/J.WEAR.2019.203157

B. Bhatt, N. Kalel, S. Ameta, S. Mittal, J. Bijwe, Fe–Al alloy for eco-friendly copper-free brake-pads. Tribol. Int. 163, 107156 (2021). https://doi.org/10.1016/j.triboint.2021.107156

N. Kalel, B. Bhatt, A. Darpe, J. Bijwe, Copper-free brake-pads: a break-through by selection of the right kind of stainless steel particles. Wear 464–465, 203537 (2021). https://doi.org/10.1016/J.WEAR.2020.203537

F.F. Yusubov, Wear studies on phenolic brake-pads using taguchi technique. Tribol. Industry 43(3), 489–499 (2021). https://doi.org/10.24874/ti.1024.12.20.03

R. Yun, P. Filip, Y. Lu, Performance and evaluation of eco-friendly brake friction materials. Tribol. Int. 43(11), 2010–2019. https://doi.org/10.1016/j.triboint.2010.05.001

Y. Lyu, M. Leonardi, J. Wahlström, S. Gialanella, U. Olofsson, Friction, wear and airborne particle emission from Cu-free brake materials. Tribol. Int. 141, 105959 (2020). https://doi.org/10.1016/J.TRIBOINT.2019.105959

S.S. Karthikeyan, E. Balakrishnan, S. Meganathan, M. Balachander, A. Ponshanmugakumar, Elemental analysis of brake pad using natural fibres. Mater. Today: Proc. 16, 1067–1074 (2019). https://doi.org/10.1016/J.MATPR.2019.05.197

L.Y. Barros, P.D. Neis, N.F. Ferreira, R.P. Pavlak, D. Masotti, L.T. Matozo, J. Sukumaran, P. De Baets, M. Andó, Morphological analysis of pad–disc system during braking operations. Wear 352–353, 112–121 (2016). https://doi.org/10.1016/j.wear.2016.02.005

M. Federici, S. Gialanella, M. Leonardi, G. Perricone, G. Straffelini, A preliminary investigation on the use of the pin-on-disc test to simulate off-brake friction and wear characteristics of friction materials. Wear 410–411, 202–209 (2018). https://doi.org/10.1016/j.wear.2018.07.011

G. Straffelini, S. Verlinski, P.C. Verma, G. Valota, S. Gialanella, Wear and contact temperature evolution in pin-on-disc tribotesting of low-metallic friction material sliding against pearlitic cast iron. Tribol. Lett. 62, 36 (2016). https://doi.org/10.1007/s11249-016-0684-9

R. Agnihotri, S. Dagar, Mechanical properties of Al-SiC metal matrix composites fabricated by stir casting route. Res. Med. Eng. Sci. 2(5), 012070 (2017). https://doi.org/10.31031/RMES.2017.02.000549

R. Vijay, S. Manoharan, B.S. Rajan, S.K. Sarangi, K. Senthilkumar, S. Siengchin, T.S. Kumar, S. Karthikeyan, M. Chandrasekar, K. Yorseng, T. Ungtrakul, N. Rajini, Tribological characterization of cellulose fiber-reinforced polymer composites, in Tribology of Polymer Composites, ed. by S.M. Rangappa, S. Siengchin, J. Parameswaranpillai, K. Friedrich (Elsevier, 2021), pp. 95–113. https://doi.org/10.1016/B978-0-12-819767-7.00005-0.

K. Senthilkumar, S. Siengchin, T.S. Kumar, S. Karthikeyan, M. Chandrasekar, K. Yorseng, T. Ungtrakul, N. Rajini. Tribological characterization of cellulose fiber-reinforced polymer composites. In Tribology of Polymer Composites 2021 Jan 1 (pp. 95–113). Elsevier. https://doi.org/10.1016/B978-0-12-819767-7.00005-0.

M. Kumar, A. Kumar, Thermomechanical analysis of hybrid friction composite material and its correlation with friction braking performance. Int. J. Polym. Anal. Charact. 25(2), 65–81 (2020). https://doi.org/10.1080/1023666X.2020.1746543

Y. Zhao, L.Q. Ren, X. Tong, H. Zhou, L. Chen, Frictional wear and thermal fatigue behaviours of biomimetic coupling materials for brake drums. J. Bionic Eng. 5(1), 20–27 (2008). https://doi.org/10.1016/S1672-6529(08)60067-0

C. Pinca-Bretotean, R. Bhandari, C. Sharma, S.K. Dhakad, P. Cosmin, A.K. Sharma, An investigation of thermal behaviour of brake disk pad assembly with ansys. Mater. Today: Proc. 47, 2322–2328 (2021). https://doi.org/10.1016/J.MATPR.2021.04.296

A.M. Rajesh, S. Doddamani, K.N. Bharath, Dry sliding wear simulation of hybrid aluminum metal matrix composites. Adv. Compos. Hybrid Mater. 3, 120–126 (2020). https://doi.org/10.1007/s42114-020-00133-9

K.N. Hendre, B.D. Bachchhav, H.H. Bagchi, Frictional characteristics of brake pad materials alternate to asbestos. Int. J. Eng. Adv. Technol. 9(2), 694–698 (2019). https://doi.org/10.35940/ijeat.B3170.129219

A.M. Abdelbary, Methodology of testing in wear, in Wear of Polymers and Composites (Woodhead Publishing, Cambridge, 2014), pp.159–183. https://doi.org/10.1533/9781782421788.159

T. Singh, A. Patnaik, B. Gangil, R. Chauhan, Optimization of tribo-performance of brake friction materials: effect of nano filler. Wear 324–325, 10–16 (2015). https://doi.org/10.1016/j.wear.2014.11.020

R.C. Dante, Production processes for organic brake pads, in Handbook of Friction Materials and their Applications, (Woodhead Publishing, Cambridge, 2016), pp. 55–65. https://doi.org/10.1016/B978-0-08-100619-1.00004-3.

I. Khan, K. Saeed, I. Khan, Nanoparticles: properties, applications and toxicities. Arab. J. Chem. 12(7), 908–931 (2019). https://doi.org/10.1016/j.arabjc.2017.05.011

M.R. Vazirisereshk, A. Martini, D.A. Strubbe, M.Z. Baykara, Solid lubrication with MoS2: a review. Lubricants 7(7), 57 (2019). https://doi.org/10.3390/lubricants7070057

Z. Wan, X. Liu, Y. Shan, T. He, H. Wang, G. Chen, The effect of rigid particle on friction properties of automotive disk brake based on a local modeling. J. Tribol. 141(4), 041403 (2019). https://doi.org/10.1115/1.4042268

P. Zhang, L. Zhang, P. Wu, J. Cao, C. Shijia, D. Wei, X. Qu, Effect of carbon fiber on the braking performance of copper-based brake pad under continuous high-energy braking conditions. Wear 458–459, 203408 (2020). https://doi.org/10.1016/j.wear.2020.203408

M.G. Faga, E. Casamassa, V. Iodice, A. Sin, G. Gautier, Morphological and structural features affecting the friction properties of carbon materials for brake pads. Tribol. Int. 140, 105889 (2019). https://doi.org/10.1016/j.triboint.2019.105889

Acknowledgements

The authors thank the BITS Pilani Hyderabad campus central library for providing access to different journals and Central Analytical Laboratory (CAL) for SEM access.

Funding

The research has received partial funding from the Science and Engineering Research Board (SERB), Government of India, under the Accelerate Vigyan-Vritika scheme with file no. AV/VRI/2022/0013.

Author information

Authors and Affiliations

Contributions

AS: Visualization, Methodology, Investigation, Validation, Writing an original draft, Data curation. AM: Investigation, Data curation, Writing an original draft. TB: Methodology, Investigation. TRP: Investigation, Data curation. UB: Investigation, Data curation. PS: Methodology, Investigation, Writing review, and editing. AK: Investigation, Writing an original draft. PCV: Writing review and editing, Fund acquisition, Conceptualization, Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no known competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saurabh, A., Manoj, A., Boni, T. et al. Effect of MoS2 Nanoflakes on Mechanical and Tribological Behavior of Composite Friction Material Fabricated by Pressure-Assisted Sintering. Met. Mater. Int. 30, 697–713 (2024). https://doi.org/10.1007/s12540-023-01519-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01519-2