Abstract

The transition from fossil-fuel-based internal combustion vehicles to electric vehicles plays a key role to decarbonize road transport and mitigate climate change. Even though this transition is still in its infancy, it is important to consider not only its environmental benefits but also its potential side effects. Recent projections estimate that the current electric vehicle fleet is expected to increase from 2.4 million in 2020 to over 81 million in 2050, when more than half of all new cars sold are predicted to be battery-electric vehicles (BEVs). End-of-life (EOL) BEVs and their components (particularly the batteries) are far more challenging to manage than their fossil-fueled predecessors as they contain large amounts of chemical substances that constitute potential hazards to the environment and human health and safety. The paper discusses relevant topics for understanding future risks of transition to electric mobility in the Global South countries, which include the internationally used vehicle fluxes; waste management challenges for EoL BEV and its lithium-ion batteries (LIB); environmental and human health impacts of EoL LIBs disposal and policies and regulations for the e-vehicle life cycle. Recommendations to support the development of science-based policies to close regulation gaps of the used electric vehicle international trade flow, avoid pollution-shifting and guarantee a sustainable transition to e-mobility in the Global South countries are given. As a conclusion, an integrated approach from international and national stakeholders is fundamental to guarantee strong policies and regulations as well as to support the development of a sound management of EoL EV and LIBs in the Global South countries and help pave the way to a global circular economy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The urge to mitigate climate change and limit the global temperature increase to 1.5 °C as foreseen in the Paris Agreement has led the world to aim for a net-zero greenhouse gas emissions (GHG) by 2050 (Slowik et al. 2020). Considering that 25% of the GHG emissions comes from the transportation sector (Quinteros-Condoretty et al. 2021), the transition from fossil-fuel-based internal combustion vehicles to electric vehicles (EVs) plays a key role to decarbonize road transport. As a result, governments, vehicle manufacturers and civil society worldwide are acting to speed up this transition and phase-out internal combustion vehicles. As other alternatives such as green hydrogen powered engines are currently not suitable for the mass market, electric vehicles will in the foreseeable future form the backbone of efforts to decarbonize motorized private transport. It is expected that the annual global EV sales will grow from 2.4 million in 2020 to 81 million in 2050 (Slowik et al. 2020).

The electrification of private passenger transport began in the late 1990s with the introduction of mild hybrid vehicles (MHVs) that recuperate energy when breaking. These vehicles typically combined a small electric motor and battery with an internal combustion engine. Plug-in hybrid electric vehicles (PHEVs) can be considered the next evolutionary step in which batteries were improved and thus electric driving ranges increased while combustion engines were maintained for long-distance travel. Purely battery-powered electric vehicles (BEVs) are the ultimate goal of the e-mobility transition as they completely avoid local emissions and as electric engines are highly efficient. Moreover, electric engines require less maintenance than internal combustion engines or hybrid systems, which enhance the benefits for such transition.

Although EVs are mainly produced and consumed in the United States of America (USA), European countries, China, Japan, and South Korea, it is foreseen that the market will expand worldwide (Jones et al. 2020). Furthermore, used electric vehicles from the Global North have already started to enter the established international trade flow of used vehicles, as an example, the export of used EV from the EU increased 82% in the period from 2017 to 2020 (UNEP 2021). Many governments in the Global South promote the import of used EVs to decarbonize their vehicle fleets in an affordable way (i.e. Mauritius, after introducing policies to promote import of hybrid and electric vehicles, registered a sales uptake of used hybrid vehicles from 43 in 2009 to 14,754 until May 2020) (UNEP 2020). Nevertheless, the potentially grave negative environmental impacts of the disposal of used EV and their batteries in the destination countries of the Global South have not yet been investigated (Preeti and Sayali 2021). According to Castro et al. (2021), most published studies that aim to predict the future fleet of electrical vehicles worldwide do not investigate scenarios in developing countries of the Global South.

The transition towards electric mobility leads to significant reductions in local emissions, air pollution and potentially reduces the CO2 footprint of road transport. However, less focus is typically given to the environmental and health impacts electric vehicles have at the end of the product lifecycle.

To understand the environmental and health risks derived from the production and disposal of end-of-life (EoL) electric vehicles and their batteries, it is important to know their composition. The batteries in e-vehicles account for minimum 15% of the vehicle's weight and are at least 25 times heavier and 10 times larger in comparison to fossil fuel combustion engines (Besselink et al. 2010), and only increasing with size as greater driving range is sought after. Thus, this component should receive special attention. Lithium-Ion Batteries (LIBs) are currently the most common form of energy storage in EVs due to their high energy density when compared to other batteries available in the market (Wang et al. 2020b). LIBs contain high amount of scarce metals such as lithium and cobalt as well as toxic materials such as copper, nickel and lead and organic chemicals and toxic electrolytes, which if not properly handled its EoL may negatively impact the sustainability of electric mobility (Mayyas et al. 2018). Nickel is an example of heavy metal present in LIB. It can account for up to 14.84% of the battery mass (Winslow et al. 2018) and when leached into the soil it may lead to inhibition of plant growth (Bhalerao et al. 2015) and can cause health impacts such as cancer of the respiratory tract depending on the length of exposure and dose (Genchi et al. 2020).

Safe management of EoL LIBs requires a complex and well-structured waste management (treatment and recycle) system. However, most LIBs recycling companies are located in China, South Korea, the European Union (EU), Japan, Canada and, the USA (Melin 2019) and recycling capacities are limited or non-existent in most developing countries across Africa, Latin America, Oceania, and Asia (Gollakota et al. 2020), where the number of EVs may increase due to the expected rise of used EV trade. Thus, this waste stream could develop into major environmental and public health hazards, particularly in the Global South where recycling and disposal capacities are lacking, and environmental regulations and their enforcement are not yet in place.

To guarantee an adequate waste management system for end-of-life vehicles (ELV) and EoL LIB, policies and regulations are fundamental to establish the path to a circular economy approach (Maletz et al. 2018; Friege and Dornack 2019), to enhance reuse, recycling and appropriate disposal of EoL LIBs, as well as to promote the extended producer responsibility (EPR), and to create awareness of the society to properly dispose of EoL LIBs (Zhao et al. 2021); however, empirical understanding on which to base these policy changes still lags behind the current implementation of EV transport and infrastructure.

Thus, the goal of this paper is to discuss four key topics relevant for understanding future risks of transition to electric mobility in the Global South, namely (1) international used vehicle fluxes and its policies and regulations; (2) waste management challenges for EoL LIB including the environmental and human health impacts of EoL LIBs disposal and policies and regulations for the e-vehicle life cycle. In the end, recommendations for future research priorities for ensuring a more sustainable e-mobility transition are made.

Used vehicle global trade

A report by United Nations Environment Programme (UNEP), which investigated 146 countries, showed that between 2015 and 2018, 14 million used light-duty vehicles were exported worldwide, and around 80% of the vehicles went to low- and middle-income countries. The greatest exporters of used vehicles during that period were the EU, accounting for 54% of the exported vehicles, Japan (27%), and the USA (18%) (UNEP 2020). It is important to point out that the UNEP report did not include data on exports of used vehicles from South Korea, India, Thailand, China, or Canada, among others. Since 2019, China opened for export of used vehicles and the country aims to implement policies to promote such international trade (MOFCOM 2021).

The main destinations of used vehicles from the EU are West and North Africa; Japan exported mainly to Asia and East and Southern Africa, and the USA mainly to the Middle East and Central America. Africa imported the largest number in the period studied followed by Eastern Europe, Caucasus and Central Asia (EECCA), Asia–Pacific, the Middle East, and Latin America (LAC). Figure 1 shows the distribution of the main exporters and importers of used vehicles (UNEP 2020).

Distribution of exporters and importers of used vehicles (based on UNEP 2020)

According to Coffin et al. (2016), one of the reasons which justifies the more significant flow of used vehicles from high to low-income countries is the higher vehicle depreciation rate in high-income countries. Studies indicate that this higher depreciation rate is related to more stringent environmental policies (Storchmann 2004). Older vehicles tend to be more polluting, and therefore, governments seek to apply strict rules to reduce the older automobile fleet (Lepoutre 2020). In high-income countries, a combination of costly motor vehicle inspections, registration/road taxation, and high labour costs for service and repairs increases the overall maintenance costs of cars, leading to higher depreciation rate (Grubel 1980; UNEP 2020). Another relevant issue is the automobile’s industry planned obsolescence business strategy, which influences the consumers to change vehicles more frequently not only due to technical issues but also due to changes in the vehicle's style (Pineda and Salmoral 2017). In many cultures, vehicle’s ownership is associated with a social class and status, this notion, enforced by the vehicle industry marketing campaigns (Mattioli et al. 2020), is another driver for higher exchange rates of vehicles among high-income classes. Over the past two decades, several countries of the Global North have incentivized (through direct subsidies to buyers) the replacement of older vehicles by new cars. Recently, financial purchase incentives have focused on advancing the use of hybrid and battery electric vehicles (Hardman et al. 2021; Zhou et al. 2015). Thus, these factors lead to a high amount of disposable used vehicles available for export in high-income countries which can be sold at a better price in low-income countries (Roychowdhury 2018).

Furthermore, many high-income countries have legislative framework that establishes strict rules to scrape, recycle, and dispose ELV. In this sense, exporting used vehicles can be more profitable and cost-effective than scrapping, recycling and disposing them (Bernard 2015; Lepoutre 2020).

The price difference is another important factor for the import of used vehicles in low-income from high-income countries. Since the used vehicles have less value in high-income countries, it is more attractive to be sold at low-income countries, which have greater demand for low-cost cars (Kołsut 2020).

The international trade of used vehicles from high to low-income countries allows easier access to greater variety of vehicle types and brands at lower costs (Coffin et al. 2016) and fleet renovation in low-income countries (Roychowdhury 2018). However, when not well regulated, low-quality used vehicles can cause environmental, health, and road-safety problems in the destination country (UNEP 2020).

According to UNEP (2020), aiming to achieve cleaner vehicle fleets at more affordable costs, countries have been recently establishing incentives to import used hybrid electric (HEV) and EV vehicles. Even though the overall quantity is still low, the number of internationally traded used HEV and EV has been growing considerably (UNEP 2020). Examples of legislations to enforce import of used HEV and EV will be detailed in the following section. In addition, considering that used vehicles export countries, such as the Netherlands and Japan, have committed to phase out sales and registrations of new internal combustion engine cars and to set goals to establish a non-emission vehicle fleet (Wappelhorst 2021), it is expected that EV will enter the global trade flow of used vehicles from the high to low-income countries.

Characterization and prediction of international trade flow of used vehicles is extremely challenging due to difficulties to obtain reliable and compiled data, this is partially explained due to a lack of appropriate registration and the existence of grey and illegal markets for used vehicles (Kołsut 2020). For example, a recent evaluation of ELV in Europe found that 35% of the vehicles that left the registered stock were unaccounted for and with unknown whereabouts (Williams et al. 2020). The same report detected that these vehicles were probably exported without registration or dismantled and not reported in the EU (Williams et al. 2020). To overcome this data gap, different database can be analysed and crosschecked such as regional, national, and international import and export data, vehicle registration, de-registration as well as manufacturers, collectors, recyclers, and scrapper reports.

Lack of data on the volume, condition, and remaining lifespan of EVs being imported and exported, and the capacity for importing countries to handle EoL materials sustainably, limits the possibility to mitigate future environmental and health risks that may arise from the transition to e-mobility, particularly in the Global South.

Used vehicle global trade policies and regulations

Even though international trade of used vehicles is an established market, stronger and multilateral regulation is still required from importing and exporting countries (Roychowdhury 2018). Many importing countries from the Global South have limited or no regulations regarding standards to import used vehicles, whilst few Global North countries have restrictions on the export of used vehicles (UNEP 2020). In Africa, more than 60% of vehicles added annually to the continents fleet are used vehicles, 40 out of 54 countries were rated with weak and very weak regulatory environment for trade of used vehicles (UNEP 2020). Regulations for this market are fundamental to avoid that polluting and ELV cause environmental and safety hazards in the destination country (Roychowdhury 2018).

Nowadays, Global North countries in general do not have in place a robust system to avoid export of used vehicles that are at its EoL and have low environmental and safety performance (Scherger and Hornborg 2021). Strong export rules are necessary to guarantee appropriate verification, inspection, certification in a transparent manner before any vehicle is traded to avoid shifting waste burden to Global South countries (Roychowdhury 2018).

As an example, the EU, which is one of the main exporters of used vehicles to Global South countries (UNEP 2020), has no specific regulation that defines criteria regarding the environmental performance of used vehicles to be exported (Velten et al. 2020). A critical point regarding the European regulation is the need to have a clearer definition to distinguish used vehicles and ELV, owing to the fact that different rules apply for each category (Scherger and Hornborg 2021). The Correspondents' guidelines No 9, which represents the common understanding of all EU Member States on how Waste Shipment Regulation (WSR) should be interpreted aims to clarify the distinction between waste vehicles and used vehicles. According to the guidelines, used vehicles are not considered as waste if it is an operational used vehicle, a repairable used vehicle or if it is a vintage vehicle according to national provisions (European Comission 2011). The guidelines list several criteria and indicators to support the identification of ELV. However, the Correspondents' guidelines No 9 are not legally binding and leave space for different interpretations of when to define the vehicle as ELV or used vehicle. This interpretation gap may lead to export of ELV vehicles to Global South countries, which lack stringent import regulations (Scherger and Hornborg 2021). It is important to state that according to the EU WSR, exports of ELV from the EU destined for disposal are prohibited.

Regarding the regulation of importing used vehicles in the Global South, in general, there are four main approaches: a complete ban, a ban on vehicles beyond a certain age, higher tariffs for used vehicles, and an import license requirement to legally import a used vehicle (Coffin et al. 2016). Another instrument to regulate import of used vehicles is fiscal instruments. The most common fiscal measures adopted include incremental and fixed taxes on age, engine size, and emissions ratings. Lower duties or exemptions for specific low and no emissions vehicles, especially hybrid and electric vehicles are becoming more popular worldwide, including in developing vehicle markets, which are aiming to achieve cleaner vehicle fleet (UNEP 2020). Countries that had banned the import of all used vehicles, such as Egypt and Bhutan, are now allowing import of used hybrid EVs or BEVs (UNEP 2020). Examples of countries with import incentives for EV are shown in Table 1.

The above-mentioned incentives for the import of used HEV and BEV have accelerated the quantity of imported used EV. Mongolia, which is the main destination for used hybrid vehicles exported from Japan, tripled the importation of hybrid vehicles from 2012 to 2016 (UNEP 2020). The import of such vehicles is expected to continue growing, however the country lacks the capacity to treat, recycle and dispose end-of-life EV and their batteries. The most common route is to treat and to dispose them informally and irregularly causing air and soil pollution (Yu et al. 2017). Another aspect is that even though Mongolian legislation imposes higher taxes for import of used vehicles above 10 years, this has not been enforced and most of the imported used vehicles exceed the age limit. Often the vehicles arrive to the country with damaged batteries and it is common that dismantlers in Mongolia change the broken battery cell to extend the lifetime of the vehicles, whitout following the original producer procedures and under risky conditions for the workers (Yu et al. 2017).

Sri Lanka’s taxation scheme resulted in more than 100,000 hybrid vehicles and about 6,000 battery electric vehicles by end of 2017, being most of these imported as used vehicles. Interesting to note that even though a rise on BEV was observed between 2015 and 2017, the trend did not continue due to lack of charging infrastructure, concerns in battery life, and recycling (UNEP 2020). Sri Lanka has approved national solid waste management policies, however, most of the wastes generated and collected are disposed in open irregular dumpsites and there are no appropriate recycling capacities (Pariatamby et al. 2020). The example of Mongolia and Sri Lanka shows that even though Global South countries are supporting the import of used electric vehicles they have not yet evaluated the negative environmental impact that end-of-life electric vehicles and their batteries may cause when handled inappropriately.

In conclusion, importing and exporting countries need to act together to structure and promote a well-governed trade regulation for used vehicles to prevent dumping of ELV in the import countries and shifting of responsibility of disposal from the Global North to the South (Roychowdhury 2018). According to Roychowdhury (2018), regulation strategies include limitation of vehicle’s age; stringent inspection system with corresponding protocol in exporting and importing countries to avoid export of EoL vehicles; international cooperation to support development of scrappage and ELV management systems in importing countries, and involvement of different stakeholders along the waste management chain such as government, manufacturers, distributors, retailers, and recyclers (formal and informal). Global South countries must acknowledge the challenges to manage ELVs and their batteries and create strategies to develop adequate waste management systems.

End of life E-vehicles: management and future risks

Critical resources and components in electric vehicles and their batteries

End-of-Life (EoL) electric vehicles (EV) and their batteries contain significant amounts of materials that are hazardous for the environment and human health, but at the same time constitute a source of valuable secondary raw materials (Tarrar et al. 2021; Restrepo et al. 2019; Xu et al. 2016; Cucchiella et al. 2016). To guarantee proper recovery, reuse, and recycling of these materials, and to understand the potential environmental and health impacts of the disposal of electric vehicles and their batteries, it is important to understand their composition (Andersson et al. 2017).

Electrical vehicles are complex products, which can have an array of arrangements depending on, for example, its energy source, motor propulsion and auxiliary subsystems (Vidyanandan 2018). EVs can be categorized as Battery Electric Vehicle (BEV); Hybrid Electric Vehicle (HEV); Plug-in Hybrid Electric Vehicle (PHEV) and Fuel Cell Electric Vehicle (FCEV). BEVs are EVs in which batteries power electric motors as the only drive train. The batteries in BEVs typically have a mass of several hundred kilograms, and thus contain substantial amounts of their constituent materials. EVs that employ both an internal combustion engine (ICE) and an electrical power train to power the vehicle are known as HEV. In this case, mild and plug-in hybrid vehicles (MHVs/PHEVs) can be distinguished. Both use an ICE and an electrical power train, whereas MHVs only recuperate energy during the breaking process, on the other hand, PHEV can use electric propulsion over longer distances and can charge their batteries directly from an external power grid. FCEV refers to an EVs that uses a fuel cell, instead of batteries, or in combination with a battery or supercapacitor to power an electric motor (Un-Noor et al. 2017). These different arrangements influence EV composition; a key aspect is the battery size which depends on the electric driving range and other factors, and which is the smallest in MHVs (a few kilograms) and the largest in BEVs (up to several hundred kilograms).

The composition of vehicles is constantly changing, due to (a) the ever-growing amount of embedded electric and electronic systems and (b) constant advances in battery technologies (Cucchiella et al. 2016; Wang et al. 2020a). According to Restrepo et al. (2019) the composition of the resulting electric and electronic wastes is still poorly understood, which hinders the development of recycling and recovery strategies for critical materials present in ELVs.

Numerous batteries technologies and chemistries exist today for EV propulsion. Studies show that LIB offer several advantages over other available batteries, including lead-acid, nickel–cadmium, and nickel–metal hydride (Kotak et al. 2021). One of the most important advantages of LIB for its use in vehicles is their relatively higher energy density, which is a result of lithium being a very light metal (Mossali et al. 2020). Its relative electrochemical advantages include higher cell voltages, no required maintenance, and typically lower self-discharge rates when the battery is not in use (Quinteros-Condoretty et al. 2021). From 2010 to 2019, LIBs constituted more than 99% of the EV battery market (Slowik et al. 2020). Even though LIBs are the dominant battery technology in EVs as well as in portable electronic devices, they have several disadvantages, including their sensitivity to heat and pressure (resulting in fire and explosion hazards), their composition (use of toxic and rare materials, their considerable mass and size when used in EVs, and their high but rapidly decreasing costs (Steward et al. 2019).

Table 2 provides an overview of the metal content in common types of LIBs, which are classified according to their cathode chemistries, lithium–iron phosphate (LFP), lithium–manganese oxide (LMO) and nickel–manganese–cobalt (NMC) batteries (Winslow et al. 2018).

Even for a specific battery type, the exact amount of each battery component varies among different manufacturers and models (Winslow et al. 2018). As batteries typically range from more than 200 kg in small and compact cars to more than 500 kg in large sedans and sport utility vehicles (SUVs), it becomes clear that they contain considerable amounts of lithium and other mineral resources (Winslow et al. 2018). With the aim to deliver various types of vehicles (i.e. different sizes and utilities), as shown in Fig. 2, a general increase in battery weight can be seen coupled with the increased power (Ajanovic and Haas 2018).

By the year of 2050 it is expected that the demand of lithium will increase by 965% and of cobalt by 585% when compared to the production of 2017 mainly due to the growing low-carbon energy technologies (Sovacool 2021), posing a risk to the depletion of natural resources. Thus, it is fundamental to establish routes to guarantee recovery and recycling of these materials to avoid that they will be lost in landfills or in dumpsites, and to minimize extraction of raw materials.

Waste management challenges

It is expected that the annual global EV sales will grow from 1.4 million in 2017 to 21.5 million EV being sold in 2030, which consequently will cause an exponential growth of used batteries in future years (Dai et al. 2019). According to Dai et al. (2019), it can be estimated that the resultant waste derived from this EV boom would amount to 0.8 million metric tons by 2027. Richa et al. (2014) estimated that 0.33 to 4 million metric tons of LIBs from EV are expected to reach EoL between 2015 and 2040. In light of these numbers, it is clear that the vehicle sector is a significant source of waste due to its high volume and the presence of hazardous and critical materials in EoL EVs and their batteries (Cucchiella et al. 2016). Their inappropriate management can ultimately impact the sustainability to the e-mobility transition (Steward et al. 2019).

Waste management chains for EoL vehicles include activities, material, financial, and information flows between stakeholders such as vehicle users, collection centers, authorized dismantling facilities, shredders, recycling units, remanufacturing facilities, second-hand markets, and industrial landfills sites (Karagoz et al. 2020). All these actors must work in a dynamic and synchronized way to guarantee a successful closed loop system.

The waste management hierarchy concept, first defined by the European Council Directive 75/442/EEC on 15 July 1975, is comprised of reduction (prevention), reuse, recycle, recovery, and disposal. Reduction and prevention of waste generation should be priorities in waste management activities. To reduce the quantity of EoL EV vehicles generated, planned obsolescence in the industry of electric vehicles has to be diminished. Unfortunately, according to Pineda and Salmoral (2017), due to the fast development of technology present in electric cars, including software updates, a future with more obsolescence is foreseen.

Furthermore, in accordance with a circular economy concept, it is essential that EVs and their components are designed to allow reuse, safe recycling, and minimal disposal. For such, proper labelling and classification of the components and material used, standardization of formats and structure, as well as a design which allows simple disassembly of components are fundamental (Mossali et al. 2020). This is particularly important for the batteries, for which the concept of “battery passports” has been proposed to better inform recyclers about the composition and structure of battery cells and packages (Bai et al. 2020). Due to the fast development and constant changes in the composition and technologies of LIBs, it is extremely challenging to establish a robust governance that will cover all battery types available in the medium and long term.

The collection of EoL EVs and their components is a fundamental step in the waste management process. For EoL LIBs, which currently mostly originate from portable electric and electronic devices, the collection rate is still low, accounting for less than 20% in 2016 in the EU and estimated to be around 5% in North America (Larouche et al. 2020). Even though high collection rates are key to guarantee sequence of further waste management strategies, not many studies have been analyzing this area (Melin 2019). Research addressing collection aspects for the reverse logistic for EoL LIBs is relevant to investigate best practices and to avoid irregular destinations.

On the other hand, reuse and recycling alternatives for EoL LIBs have been extensively analyzed (Bobba et al. 2018; Pagliaro and Meneguzzo 2019; Casals et al. 2019; Kotak et al. 2021; Baars et al. 2021; Zhu et al. 2021).

To define the reuse and recycling step, it is important to understand the ageing process of the lithium-ion battery, which will be a key factor to define the best alternative in the waste management chain. LIBs’ degradation differs according to the materials used in the anode, cathode, electrolyte, separator, and collector and even depends on the fabrication process (Casals et al. 2019). Other factors that influence battery lifespan include the vehicle usage pattern, charging frequency, and general conditions of the road (Volan et al. 2021). LIBs from different types of EVs (BEV, PHEV, HEV) have different aging patterns (Baars et al. 2021). A LIB is generally replaced from EV when it has lost at least 20% of the initial capacity. Consequently, reused batteries usually start their second life with 80% or less of their original capacity (Casals et al. 2019). However, a battery can finish its first life due to ageing as well as from accidents. In any case, a technical battery assessment is fundamental to guarantee safety in its second life (Kotak et al. 2021).

If the battery is appropriate for reuse, it can be either directly reused, dismantled to the module, or dismantled to the cell level (Kotak et al. 2021). According to Kotak et al. (2021), direct reuse offers lower cost but reduces the alternatives for LIBs’ reuse, whilst dismantling until the cell level is the most versatile alternative but more costly due to technical modifications, testing, and implementation of new control systems. Possibilities to reuse EoL LIBs include different stationary electric energy storage systems (ESS), such as large-scale electricity and grid distribution and medium to small scale installations for energy management, power reliability, and transportation applications (Melin 2019). In Global South countries, a very promising strategy would be to reuse the batteries to guarantee energy access in rural areas. Considering the multiple alternatives to reuse EoL LIBs and the many life cycles it can have, the difficulty to trace and predict when, where, and how will be the final destination of EoL LIBs in Global South countries is highly amplified.

Advantages for reusing EV Batteries in the Global South include local independence from international battery manufacturing regions, local job creation, reducing the overall resource consumption for production of batteries, reducing the maintenance costs of electric vehicles when replacement of battery is required (GIZ 2021). Difficulties to reuse EV batteries are related to the many different (and constantly changing) types, chemistries, and designs of batteries which enhance the challenge to test and identify alternatives for reuse, low quantity of batteries available for larger solutions, and preference for new batteries (GIZ 2021).

In a circular economy perspective, after second (or even third) life vehicles and their components are recycled. In general, EoL vehicles have high recycling rates of bulk materials (steel and aluminium) and hazardous components. However, scarce metals embedded in the vehicles are prone to be lost to carrier metals, construction materials, and even to landfills (Andersson et al. 2017; Yano et al. 2019). According to Andersson et al. (2017), information of scarce metal recycling rates from ELV is still missing.

The main drivers for recycling of EoL LIBs from electric vehicles include the objective to diminish environment and safety hazards; reduce the carbon footprint of EVs; reduce EV costs related to raw material and landfill disposal; reduce reliance on mineral extraction; reduce reliance on specific suppliers and generate local economic activity (Beaudet et al. 2020).

Recycling of EoL LIBs is a complex cost and energy intensive industrial process (Mossali et al. 2020). Several technologies are available based on mechanical methods in combination with pyrometallurgical and/or hydrometallurgical methods (Makuza et al. 2021; Sobianowska-Turek et al. 2021). According to Kotak et al. (2021), the main recycling option is hydrometallurgical recycling, which is usually accompanied by a pre-processing method that can be mechanical or a pyrometallurgical method. The most sought metals in these processes are cobalt and nickel due to their economic and ecological value (Sobianowska-Turek et al. 2021). The efficiency of the recycling process depends on the technology adopted, and according to a review carried out by Melin (2019), lithium and cobalt recovery efficiencies are usually more than 90%.

Global recycling capacity of LIBs in 2016, was distributed in European Countries, Asia and North America. European countries host about 47% of the total capacity, and China alone hosts about 32% (Mayyas et al. 2018). It is fundamental to investigate and develop solutions that can be safely and effectively applied in Global South countries due to expected growth of such waste stream. An aspect that is important to consider is that so far, EoL LIBs may have not yet reached a considerable amount that makes it economically feasible to implement recycling industries in many Global South countries. For the short term, solutions where the battery could be safely reused and have its life extended are extremely relevant. In addition, structuring regional recycling hubs aiming to achieve economies of scale can be a solution. Such recycling hubs are an alternative not only to guarantee economic feasibility but also environmental protection and generation of income for the population.

The main technical and financial challenges to boost LIB recycling include the need to guarantee a high-quality material output and supplier reliability; competitive collection and recycling costs and revenues when comparing to raw material extraction; and low environmental footprint of the technologies (Beaudet et al. 2020).

Ideally, the amount of waste derived from EoL EV to be landfilled or incinerated would be minimum due to high rates of reuse and recycling (Mossali et al. 2020). The final disposal strategies of EoL LIBs around the world vary due to changes in number of EoL LIBs, market, legislative framework, and waste management infrastructure (Mrozik et al. 2021).

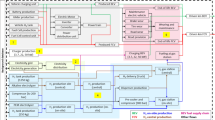

According to Mrozik et al. (2021), informal disposal or reprocessing occurs due to potential profits of recycling activities and if the official recycling or landfilling is very costly. Such informal and illegal disposal is more likely to occur in Global South countries due to lack of recycling and disposal facilities as well as deficits in environmental laws or their enforcement (Mrozik et al. 2021). Such informal and irregular practices pose a risk to the environment and human health. These risks will be detailed below. Figure 3 presents and overview of the LIB life-cycle.

The waste management chain for EoL EVs and LIBs in a circular economy perspective is a complex system, which requires social, technical, financial, and political efforts to be efficient and successful.

Environmental and health impacts of ELV and EoL LIB

As manufacture of electric vehicles and their batteries ramps up exponentially around the world, concerns around relevant environmental and health impacts are being raised. Environmental and health impacts may occur in different stages of LIB lifecycle (Christensen et al. 2021). Severe environmental impacts occurring in the mineral extraction phase such as local groundwater depletion during lithium mining observed Chile (Kaunda 2020) and urgent social issues such lack of safe working conditions and child labour in mining processes in the Democratic Republic of Congo (Sovacool 2021). With the goal to understand alternatives to ensure recovery and recycling of the critical materials in LIBs and thus minimize extraction, this paper will focus on the potential risks during EoL stage, looking at possible contaminations of air, soil, water, and human health hazards throughout the waste management chain of EoL LIBs.

According to Mrozik et al. (2021), in developing countries of the Global South, EoL LIBs are likely to be illegally recycled because revenue of LIBs content will be profitable at least to some degree and due to the costly fees for appropriate recycling and disposal. Illegal and informal recycling mainly occurs manually and without proper infrastructure and safety measures, it poses a risk to workers’ health (Ahirwar and Tripathi 2021). Study from Sobianowska-Turek et al. (2021) analysed the chemical safety data sheet of the compounds present in LIBs to evaluate the physicochemical and toxic properties of the substances. As a result, it was shown that cathodes and electrolytes used in LIBs can cause i.e. skin and/or eye irritation, are toxic to organs and may cause allergies and carcinogenic effects (Sobianowska-Turek et al. 2021). An example is the lithium hexafluorophosphate (LiPF6), a common organic solvent used in LIBs, which has harmful properties such as flammability and adverse effects to organs and tissues. LiPF6, in contact to water at higher temperatures can lead to the formation of hydrofluoric acid (HF) which can be fatal if swallowed or if in contact with skin (Sobianowska-Turek et al. 2021). This highlights the need to guarantee safety measures when handling EoL LIBs.

Regarding the disposal of EoL LIBs, according to Christensen et al. (2021), it is unlikely that in the Global North countries LIBs will be landfilled on a large scale, due not only to stringent environmental regulations but also to the valuable components of EoL LIBs. On the other hand, the majority of the developing nations in the Global South lack effective legislations and sophisticated waste management systems with capacities for dismantling and recycling high-tech designed batteries in a safe manner (Gollakota et al. 2020). In practice, EoL batteries in the global South are often recycled and disposed of informally, leading to environmental contamination and exposure of workers (Mrozik et al. 2021). When handled irregularly, EoL LIBs leach their contents into the ground and the leachate may infiltrate to deeper ground layers, polluting groundwater and can generate run-off to surface waters (Beaudet et al. 2020).

Leaching occurs due to a combination of biological and chemical degradation processes and percolation of rain in the waste mass (Kjeldsen et al. 2002). The resulting liquid (leachate) acts as a transportation medium for hazardous species (Winslow et al. 2018). LIB leachates will potentially carry various pollutants such as lithium, cobalt, nickel, chromium copper metals (in metallic, ionic or nanoparticle forms), additives, electrolyte degradation products, and dissolved gases (Christensen et al. 2021). Literature review from Mrozik et al. (2021) showed that the toxicity of heavy metals from LIBs includes attaching, blocking, and disturbing the conformational structure of carbohydrates, lipids, proteins or enzymes.

Kang et al. (2013) carried out leaching tests and life-cycle impact assessment to appraise abiotic resource depletion; human toxicity potential; freshwater ecotoxicity; terrestrial ecotoxicity caused by LIBs used in cell phones. As a result, it was shown that cobalt, copper, and nickel are the main contributors to the total hazard potential. It was also identified that metals such as cobalt, copper, nickel and lead, under simulated landfill conditions, would leach out concentrations that would exceed regulatory limits according to legislations from United States of America (Kang et al. 2013). Cobalt containing components can be carcinogenic to humans (Sobianowska-Turek et al. 2021). Copper effects include persistence, bioaccumulation, toxicity and trophic transfer and may lead to hazards such as DNA damaging (Ameh and Sayes 2019). When nickel is released into the environment, it binds strongly to small solid particles and thus may accumulate in the soil (Mrozik et al. 2021). At higher concentration, nickel is toxic to plants leading to inhibition of growth, photosynthesis, seed germination, sugar transport and induction of chlorosis, nacrosis and wilting (Bhalerao et al. 2015). Regarding health impacts, nickel may cause lung fibrosis, kidney and cardiovascular diseases and cancer of the respiratory tract (Genchi et al. 2020). Figure 4 exemplifies the potential environmental and health hazards of inappropriate handling of EoL LIBs.

Aiming to understand the overall situation of environmental contamination in recycling sites around the world, Houessionon et al. (2021) carried out a systematic review, which investigated the concentration of heavy metal levels in soil, water, and sediment collected in electronic waste recycling sites. The available studies revealed that these areas generally present heavy metals in the environment in higher concentrations than international standards. In addition, the study concludes that there are knowledge limitations regarding the environmental and human health risks derived from this contamination and thus should be further investigated. Houessionon et al. (2021) pointed out that there are geographical data gaps in areas like Africa, Oceania, Europa, America and even Asia (except China) and that there is still a need to carry out research in developing countries.

To minimize human health risks, capacity development for the workers and appropriate infrastructure is a fundamental aspect. Mapping and assessment of the risks associated with the informal refurbishing and recycling processes are necessary to apply adequate security measures. Regarding the mitigation of environmental risks, the first goal would be to avoid irregular dumping of EoL LIBs. A key aspect is to structure collection points, transportation system, and logistics to guarantee that the batteries will be collected and disposed in an environmentally friendly way. For such, a structured legislative framework, adequate technology combined with capacity development, environmental awareness, financial availability, and political-will are required.

ELV and EoL LIB policies and regulations

ELV is one of the fastest growing and most important waste streams due to its significant volumes and embedded materials (D’Adamo et al. 2020). Thus, aiming to protect the environment and promote a circular economy, countries have set legislations to regulate management of ELV. However, legislations on ELV are mostly limited to Global North Countries, and there is a need to develop and improve legal framework for ELV management and recycling for the Global South (Sakai et al. 2014).

A literature review from Karagoz et al. (2020) undertook an extensive content analysis of published studies on the ELV management, in the period from 2000 to 2019. As a result, the review collected 232 studies and classified them based on their purpose: “Regulations review”; “Network design”; “Recycling, production & planning”; “Literature survey”. The least number of papers (8.19%) were classified as “Regulations review” and the focus of these papers included only: Italy, European Union, Greece, England and United Kingdom, China, Germany, the USA, Japan, Australia, Denmark, Sweden, Turkey, and France (Karagoz et al. 2020). From this result, it is possible to indicate two research gaps: lack of research on polices and regulations regarding ELV and more specifically lack of research focus on Global South countries.

A study from Numfor et al. (2021) investigated the challenges and opportunities for ELV recycling in eight developing countries (Cameroon, Kenya, Nigeria, Egypt, India, Malaysia, Mexico, and South Africa), the study concluded that the greatest challenge encountered is poor policies and, in most cases, the absence of ELV management policy. This highlights the need to strengthen governance related to ELV management.

Regarding the existing regulations concerning EoL LIB, the EU recently published a new proposal for batteries and waste batteries. This new regulation has come into force on January 2022 and the Directive 2006/66/EC on batteries and accumulators should be repealed as of July 2023. The new directive addresses specifically the recycling rates for EoL LIBs. It determines rules on the carbon footprint of electric vehicle batteries, requires technical documentation to characterize the content of materials in EV batteries, specifies the minimum amount of recovered materials (cobalt, lead, lithium or nickel) that should be present in the LIB batteries. The need to have specific amount of recycled materials present in new LIBs, aims to close the loop for such resources. However, it adds complexity in the global material flux and to how the producers will comply to such goals considering that many used batteries are exported worldwide creating an outflow of recyclable material from the EU (Melin et al. 2021).

When looking to the legislative framework of EoL LIBs, in the Global North, extended producer responsibility (EPR) has been widely adopted as a mechanism to guarantee circularity of materials and resources from EoL LIBs. EPR is defined as an environmental policy approach in which a producer’s responsibility for a product is extended to the post-consumer stage of a product’s life cycle. This concept is based on the ‘polluter pays’ principle and aims to avoid environmental externalities in the product lifecycle as well as to shift the financial and/or organisational responsibility for treatment and disposal from the municipality to the producer. An important goal of EPR is to stimulate producers to incorporate environmental considerations in the design of their products (OECD 2001).

Another concept intrinsically connected to EPR is the shared responsibility concept. All actors in the product chain including consumers must participate in order to optimise EPR schemes effects. This is a challenging aspect since it requires environmental awareness from society and strong law enforcement (OECD 2001).

One practical example of how EPR is applied in the Global North is the Packaging Waste Programme in the United Kingdom (UK). Producers have to recover and recycle a specific percentage of their packaging waste each year (Gupt and Sahay 2015). Different share of responsibility is given for each stakeholder: sellers have 48% of responsibility, followed by packers/fillers (37%), converters (9%), and manufacturers (6%). The stakeholders can meet their recycling targets themselves or by collective schemes that fulfil all the obligations on their behalf for a fixed price (Gupt and Sahay 2015). In the case of packaging waste exported for recycling, compliance is proved by issuing of a Packaging Export Recovery Note (PERN), which can be issued only by accredited exporters. According to Gupt and Sahay (2015), the overall recovery rate increased by 68% and material-specific recycling rates increased by 45–137% from 1998 to 2004.

In the Global North, where there are already functioning EPR schemes, challenges appear when dealing with the increasing export of used products such as used vehicles (OECD 2014). This challenge becomes clear when looking in the collection rates of ELVs in European countries. EPR schemes in EU Member states, in the year of 2011, had a very low collection rate of ELV ranging from 45 to 13% based on what has been put on the market. This collection gap in the EPR scheme is mainly explained by ELV illegal dismantling and export practices (Monier et al. 2014). These exports create gaps in the product chain mainly because of used products exported to developing countries that do not have the capacity to guarantee safe recovery and recycling of the products leading to cross-border pollution problems (OECD 2014).

When looking to the legislative framework of Global South countries for EoL LIBs, according to Ferronato and Torretta (2019), one of the challenges faced by the developing countries in EoL batteries management includes lack of legislation to deal specifically with these waste fractions.

Global South countries are either in the process of designing EPR or have inefficient legislations or lack of legislation enforcement (Gupt and Sahay 2015). Implementing EPR for recycling systems in developing countries includes many challenges such as (1) difficulties to identify producers due to the large number of products assembled by small shops that could not bear the financial responsibility of EPR; (2) large number of repair businesses due to low labour costs and greater second-hand market; and (3) existence of illegal trade market which includes smuggling and imitation products (Kojima et al. 2009).

In developing countries, the lifespan of vehicles and batteries are widely extended and undergo many repair processes, which enhances the difficulty to track who should be responsible for the product after such changes. It is important to note that extended producer responsibility alone will not solve all problems of managing treatment and disposal of ELV and EoL LIB in developing countries. Other policy enforcements, such as tightening border controls to combat smuggled products and enforcing intellectual property rights also need to be in place (Kojima et al. 2009). In addition, a holistic approach to guarantee local capacity building, infrastructure, economic resources is required. Different actors such as research centres, non-governmental organisations, industry, local and international government, and workers of the informal sectors must all engage to allow a broad and assertive definition of the existing difficulties and together structure possible solutions.

It is always important to highlight that policies and regulations are fundamental to establish the path to a circular economy approach for ELV and EoL LIB management and to enhance reuse, recovery of resources, recycling and appropriate disposal of EoL LIBs (Zhao et al. 2021).

Conclusion and recommendations

The transition from fossil-fuel-based internal combustion vehicles to electric vehicles plays a key role to decarbonize road transport and mitigate climate change. As a result, governments, vehicle manufacturers and civil society worldwide are acting to speed up this transition and phase-out internal combustion vehicles. It is expected that used EVs will enter the already established international trade flow of used vehicles from Global North to Global South Countries. Nevertheless, to which extent and which environmental and health impacts that this increase in trade flow of used EV will cause in the destination countries are still unknown.

As seen in item 2.1, international global trade of used vehicles from Global North to Global South countries is an existing phenomenon that may enhance decarbonisation of Global South countries due to the growing trade flow of used EVs. Global South countries are already seeing that used EVs are an affordable opportunity make the transition to zero emission vehicle fleets (UNEP 2020). However, this market still lacks regulation to prevent dumping of EoL vehicles and thus lithium-ion batteries in the import countries and shifting of responsibility of disposal from the Global North to the South (Roychowdhury 2018). An example of such pollution shifting is the characteristic of vehicles imported in West Africa: the average age is of 12–16 years and around 20% of these used vehicles have malfunctioning engines (Agbo 2018). In addition, in general, Global South countries have deficient governance and infrastructure to deal with the increasing amount of EoL vehicles and LIBs. Aiming to support the development of science-based policies to close the regulation gap of the used electric vehicle international trade flow, avoid pollution-shifting and guarantee a sustainable transition to e-mobility in the Global South countries, recommendations for further investigation are itemized below.

-

Strategies for improvement of data availability of international fluxes of used vehicle trade

A key aspect that needs consideration is an urgent improvement of data availability of the international trade flow of used vehicles. Reliable and accurate database is fundamental to allow adherent policy and decision making for short, medium, and long term as well as predicting and assessing future scenarios. Thus, better tracking and registration mechanisms as well as strategies to diminish grey and illegal market of used vehicles are important to be developed. To structure this database, different sources (i.e. vehicle registration and de-registration databases, export and import of vehicles) have to be analysed and cross-checked.

-

Develop scenarios for future used e-vehicle international fluxes from Global North to Global South

Understanding and prediction of future used EV international fluxes and detailed case-study analysis is required. The development of scenarios for future volumes of international trade flows of used EV spanning from the Global North to the South must be carried out considering at least the age of the vehicles and its remaining lifespan; the expected quantity and quality of EoL LIBs generation in destination countries; the relevance of national export and import regulations; international agreements; and environmental and public health threats.

-

Understand the capacity of handling EoL EV and LIBs in the Global South

Development of strategies for handling EoL EVs and LIBs in the Global South are required to avoid loss of scarce resources, guarantee workers safety, and protect the environment. To develop such strategies, understanding of the actual capacity and situation of the management of EoL EV and LIBs in the Global South is required. Legislation and policies with adequate enforcement and engagement from different stakeholders, including the informal sector, must be created and supported. Capacity building and learning from successful cases is fundamental to accelerate the path to sustainable solutions. Furthermore, regional approaches, such as creation of consortiums, can allow more cost-efficient and safe management of EoL EV and LIBs. Research and development of second use and recycling technologies of EoL LIB for the context of Global South countries are recommended.

-

Assessment and prediction of environmental and health impacts associated to EoL EV and LIBs in the Global South

Determination and assessment of the possible environmental and health risks and impacts derived from the management of EoL EV and LIBs in Global South countries are important to support the development of technical strategies and policies to prevent future damages. To analyse the environmental risk, different environment compartments should be looked into (e.g. water, soil, and air pollution) as well as bioaccumulation of toxic substances in livestock and crops. Regarding the health risks, the different exposure pathways of the workers of the waste management system and surrounding community must be determined and investigated, aiming to understand the health hazards that may be caused by inappropriate handling of EoL LIBs and the possible measures to minimize the risks.

-

Investigation and evaluation of the international and national governance strategies for the global used vehicle trade flow

It is fundamental that exporting and importing countries share the responsibility and work together to improve regulation and control of this market to avoid the negative impacts of exporting polluting used vehicles. Clear definition of the role and responsibilities of each stakeholder is needed.

Further investigation of polices and regulations regarding EoL vehicle management in Global South countries as well as assessment of how they are being implemented is required. Policies such as the new EU Directive on batteries and waste batteries, which addresses specific recycling rates for EoL LIBs and requires technical documentation to characterize the content of materials in EV batteries, can serve as a model to structure an international framework. Nevertheless, it is important to consider the different countries’ realities when setting targets. An interesting strategy to develop the necessary legislative framework for managing EoL LIBs is to investigate the lessons learned and successful cases of similar waste streams in the destination countries. The role that different international players such as industry, non-governmental organizations (NGO), and research bodies could play to develop and apply a robust governance must be considered.

International and national policies and regulations are fundamental to establish the path to a circular economy approach for EVs and LIBs, to enhance reuse, recycling, and appropriate disposal of EoL LIBs whilst guaranteeing a just transition to electric mobility worldwide. Sound management of EoL LIBs not only enhances the sustainability of EV at the end-of-life stage, but also reduces the need for further extraction of precious and scarce metals, guaranteeing a closed-loop system for EV LIBs.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author upon request.

Change history

19 May 2023

A Correction to this paper has been published: https://doi.org/10.1007/s12665-023-10974-4

References

Agbo COA (2018) Recycle materials potential of imported used vehicles in Nigeria. Niger J Technol 3:118–129. https://www.researchgate.net/publication/228441415

Ahirwar R, Tripathi AK (2021) E-waste management: A review of recycling process, environmental and occupational health hazards, and potential solutions. Environ Nanotechnol Monit and Manag 15:100409. https://doi.org/10.1016/j.enmm.2020.100409

Ajanovic A, Reinhard H (2018) Electric vehicles: solution or new problem? Environ Dev Sustain 20:S7–S22. https://doi.org/10.1007/s10668-018-0190-3

Ameh T, Sayes CM (2019) The potential exposure and hazards of copper nanoparticles: a review. Environ Toxic Pharm 71:103220. https://doi.org/10.1016/j.etap.2019.103220

Andersson M, Söderman ML, Sandén BA (2017) Are scarce metals in cars functionally recycled? Waste Manag 60:407–416. https://doi.org/10.1016/J.WASMAN.2016.06.031

Bai Y, Muralidharan N, Sun YK, Passerini S, Whittingham MS, Belharouak I (2020) Energy and environmental aspects in recycling lithium-ion batteries: concept of battery identity global passport. Mater Today 41:304–315. https://doi.org/10.1016/J.MATTOD.2020.09.001

Baars J, Domenech T, Bleischwitz R, Melin HE, Heidrich O (2021) Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nature Sustain 4:71–79. https://doi.org/10.1038/s41893-020-00607-0

Beaudet A, Larouche F, Amouzegar K, Bouchard P, Zaghib K (2020) Key challenges and opportunities for recycling electric vehicle battery materials. Sustain 12:5837. https://doi.org/10.3390/su12145837

Bernard S (2015) North-south trade in reusable goods: Green design meets illegal shipments of waste. J Environ Econ Manag 69:22–35. https://doi.org/10.1016/j.jeem.2014.10.004

Besselink IJM, van Oorschot PF, Meinders E, Nijmeijer H (2010) Design of an efficient, low weight battery electric vehicle based on a VW Lupo 3L. The 25th World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium & Exhibition. https://www.researchgate.net/profile/Henk-Nijmeijer/publication/236609252_Design_of_an_efficient_low_weight_battery_electric_vehicle_based_on_a_VW_Lupo_3L/links/00b7d52cc625053e86000000/Design-of-an-efficient-low-weight-battery-electric-vehicle-based-on-a-VW-Lupo-3L.pdf. Accessed 25 Feb 2022

Bhalerao SA, Sharma AS, Poojari AC (2015) Toxicity of nickel in plants. Int J Pure and Appl Biosci 3:345–355

Bobba S, Podias A, Di Persio F, Messagie M, Tecchio P, Cusenza MA, Eynard U, Mathieux F, Pfrang A (2018) Sustainability assessment of second life application of automotive batteries (SASLAB). JRC Science Hub. https://publications.jrc.ec.europa.eu/repository/bitstream/JRC112543/saslab_final_report_2018_2018-08-28.pdf. Accessed 25 Feb 2022

Casals LC, García BA, Canal C (2019) Second life batteries lifespan: rest of useful life and environmental analysis. J Environmental Manag 232:354–363. https://doi.org/10.1016/j.jenvman.2018.11.046

Castro FD, Cutaia L, Vaccari M (2021) End-of-life automotive lithium-ion batteries (LIBs) in Brazil: prediction of flows and revenues by 2030. Resour Conserv Recycl 169:105522. https://doi.org/10.1016/j.resconrec.2021.105522

Christensen PA, Anderson PA, Harper GD, Lambert SM, Mrozik W, Rajaeifar MA, Wise MS, Heidrich O (2021) Risk management over the life cycle of lithium-ion batteries in electric vehicles. Renew Sustain Energ Rev 148:111240. https://doi.org/10.1016/j.rser.2021.111240

Coffin D, Horowitz J, Nesmith D, Semanik M (2016) Examining barriers to trade in used vehicles. U.S. International Trade Commission, Washington DC.

Cucchiella F, D’Adamo I, Rosa P, Terzi S (2016) Scrap automotive electronics: a mini-review of current management practices. Waste Manag and Res 34:3–10. https://doi.org/10.1177/0734242X15607429

D’Adamo I, Gastaldi M, Rosa P (2020) Recycling of end-of-life vehicles: assessing trends and performances in Europe. Technol Forecast Soc Change 152:119887. https://doi.org/10.1016/j.techfore.2019.119887

Dai Q, Spangenberger J, Ahmed S, Gaines L, Kelly JC, Wang M (2019) EverBatt: a closed-loop battery recycling cost and environmental impacts model (No. ANL-19/16). Argonne National Lab. https://www.osti.gov/servlets/purl/1530874. Accessed 25 Feb 2022

European Comission (2011) Correspondents' Guidelines No 9 on shipment of waste vehicles. https://ec.europa.eu/environment/pdf/waste/shipments/correspondents_guidelines9_en.pdf. Accessed 24 Feb 2022

Ferronato N, Torretta V (2019) Waste mismanagement in developing countries: a review of global issues. Int J Env Res Publ Health 16:1060. https://doi.org/10.3390/ijerph16061060

Friege H, Dornack C (2019) Abfall-und Kreislaufwirtschaft: Prioritäten für nachhaltiges Ressourcenmanagement. In: Englert M, Ternès A (Eds) Nachhaltiges Management - Nachhaltigkeit als exzellenten Managementansatz entwickeln. Springer Nature, Berlin, pp 593–611. https://doi.org/10.1007/978-3-662-57693-9_31

Genchi G, Carocci A, Lauria G, Sinicropi MS, Catalano A (2020) Nickel: human health and environmental toxicology. Int J Environ Res Publ Health 17:679. https://doi.org/10.3390/ijerph17030679

GIZ(=Deutsche Gesellschaft für Internationale Zusammenarbeit GmbH) (2021) Dealing with the end-of-life problem of electric vehicle batteries. GIZ. https://www.changing-transport.org/wp-content/uploads/202107_GIZTraCS_DealingwithEoLLiBs.pdf. Accessed 25 Feb 2022

Gollakota AR, Gautam S, Shu CM (2020) Inconsistencies of e-waste management in developing nations–facts and plausible solutions. J Environ Manag 261:110234. https://doi.org/10.1016/j.jenvman.2020.110234

Grubel HG (1980) International trade in used cars and problems of economic development. World Dev 8:781–788. https://doi.org/10.1016/0305-750X(80)90005-4

Gupt Y, Sahay S (2015) Review of extended producer responsibility: a case study approach. Waste Manag and Res 33:595–611. https://doi.org/10.1177/0734242X15592275

Hardman S, Fleming KL, Khare E, Ramadan MM (2021) A perspective on equity in the transition to electric vehicles. MIT

Hawkins AJ (2022) The Hummer EV’s battery weighs more than a Honda Civic. Available in: https://www.theverge.com/2022/2/16/22937491/hummer-ev-electric-truck-battery-weight-truck-bloat. Accessed on 31 Mar 2022

Houessionon MK, Basu N, Bouland C, Kedote NM, Fayomi B, Fobil NJ, Ouendo EM (2021) Knowledge, practices, and environmental and occupational health risks associated with electronic waste recycling in Cotonou, Benin. Occup Dis and Environ Med 9:33–48. https://doi.org/10.4236/odem.2021.92004

Jones B, Elliott RJ, Nguyen-Tien V (2020) The EV revolution: the road ahead for critical raw materials demand. Appl Energ 280:115072. https://doi.org/10.1016/j.apenergy.2020.115072

Kang DHP, Chen M, Ogunseitan OA (2013) Potential environmental and human health impacts of rechargeable lithium batteries in electronic waste. Environ Sci Technol 47:5495–5503. https://doi.org/10.1021/es400614y

Karagoz S, Aydin N, Simic V (2020) End-of-life vehicle management: a comprehensive review. J Mater Cycles Waste Manag 22:416–442. https://doi.org/10.1007/s10163-019-00945-y

Kaunda RB (2020) Potential environmental impacts of lithium mining. J Energy Nat ResLaw. 38(3):237–244. https://doi.org/10.1080/02646811.2020.1754596

Kjeldsen P, Barlaz MA, Rooker AP, Baun A, Ledin A, Christensen TH (2002) Present and long-term composition of MSW landfill leachate: a review. Critical Rev Environ Sci Technol 32:297–336. https://doi.org/10.1080/10643380290813462

Kojima M, Yoshida A, Sasaki S (2009) Difficulties in applying extended producer responsibility policies in developing countries: case studies in e-waste recycling in China and Thailand. J Mater Cycles Waste Manag 11:263–269. https://doi.org/10.1007/s10163-009-0240-x

Kołsut B (2020) The import of used cars to Poland after EU accession. Stud Ind Geogr Comm Pol Geogr Soc 34:129–143. https://doi.org/10.24917/20801653.342.9

Kotak Y, Marchante Fernández C, Canals Casals L, Kotak BS, Koch D, Geisbauer C, Trilla L, Gómez-Núñez A, Schweiger HG (2021) End of electric vehicle batteries: reuse vs. recycle. Energ 14:2217. https://doi.org/10.3390/en14082217

Larouche F, Tedjar F, Amouzegar K, Houlachi G, Bouchard P, Demopoulos GP, Zaghib K (2020) Progress and status of hydrometallurgical and direct recycling of Li-Ion batteries and beyond policy review. Materials 13(3):801. https://doi.org/10.38105/spr.e10rdoaoup

Lepoutre, E (2020) Used car market and heterogeneous environmental standards, from developed to developing countries. Dissertation, Université catholique de Louvain. http://hdl.handle.net/2078.1/thesis:27156

Makuza B, Tian Q, Guo X, Chattopadhyay K, Yu D (2021) Pyrometallurgical options for recycling spent lithium-ion batteries: a comprehensive review. J Power Sour 491:229622. https://doi.org/10.1016/J.JPOWSOUR.2021.229622

Maletz R, Dornack C, Ziyang L (2018) Source separation and recycling. Cham, Switzerland: Springer, Cham. https://doi.org/10.1007/978-3-319-69072-8

Mattioli G, Roberts C, Steinberger JK, Brown A (2020) The political economy of car dependence: a systems of provision approach. Energy Res Soc Sci. https://doi.org/10.1016/j.erss.2020.101486

Mayyas A, Steward D, Mann M (2018) The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries. Sustain Mat Technol. https://doi.org/10.1016/j.susmat.2018.e00087

Melin HE (2019) State-of-the-art in reuse and recycling of lithium-ion batteries–a research review. The Swed Energ Agency. https://www.energimyndigheten.se/globalassets/forskning--innovation/overgripande/state-of-the-art-in-reuse-and-recycling-of-lithium-ion-batteries-2019.pdf. Accessed 24 Feb 2022

Melin HE, Rajaeifar MA, Ku AY, Kendall A, Harper G, Heidrich O (2021) Global implications of the EU battery regulation. Science 373(6553):384–387. https://doi.org/10.1126/science.abh1416

MOFCOM (=Ministry of Commerce People’s Republic of China) (2021) Regular press conference of MOFCOM (April 1, 2021). MOFCOM. http://english.mofcom.gov.cn/article/newsrelease/press/202104/20210403050371.shtml. Accessed 14 Feb 2022

Mohan A, Sripad S, Vaishnav P, Viswanathan V (2020) Trade-offs between automation and light vehicle electrification. Nat Energy 5:543–549. https://doi.org/10.1038/s41560-020-0644-3

Monier V, Mudgal S, Hestin M, Cavé J, Gheoldus M, Acoleyen MV, Laureysens I, Watkins E, Fedrigo-Fazio D, Reisinger H, Weissenbach T, Oliva J, Porsch L (2014) Development of guidance on extended producer responsibility (EPR). Final Report. https://ec.europa.eu/environment/archives/waste/eu_guidance/pdf/Guidance%20on%20EPR%20-%20Final%20Report.pdf. Accessed 14 Feb

Mossali E, Picone N, Gentilini L, Rodrìguez O, Pérez JM, Colledani M (2020) Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. J Environ Manag 264:110500. https://doi.org/10.1016/j.jenvman.2020.110500

Mrozik W, Rajaeifar MA, Heidrich O, Christensen P (2021) Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energ Environ Sci 14:6099–6121. https://doi.org/10.1039/D1EE00691F

Numfor SA, Omosa GB, Zhang Z, Matsubae K (2021) A review of challenges and opportunities for end-of-life vehicle recycling in developing countries and emerging economies: a SWOT analysis. Sustain 13:4918. https://doi.org/10.3390/su13094918

OECD (2001) Extended producer responsibility—a guidance manual for governments. OECD. https://doi.org/10.1787/9789264189867-en

OECD (=Organisation for Economic Co-operation and Development) (2014) The state of play on extended producer responsibility (EPR): opportunities and challenges. OECD. https://doi.org/10.1787/9789264189867-en

Pagliaro M, Meneguzzo F (2019) Lithium battery reusing and recycling: a circular economy insight. Heliyon 5:e01866. https://doi.org/10.1016/j.heliyon.2019.e01866

Pariatamby A, Shahul Hamid F, Bhatti MS (2020) Sustainable waste management challenges in developing countries. Hershey PA, USA

Pineda JAS, Salmoral MP (2017) A juridical ‘theory’ of planned obsolescence. SSRN Electron J. https://doi.org/10.2139/ssrn.2966052

Preeti M, Sayali A (2021) Scientometric analysis of research on end-of-life electronic waste and electric vehicle battery waste. J Sci Res 10(2):37–46. https://doi.org/10.5530/JSCIRES.10.1.5

Quinteros-Condoretty AR, Golroudbary SR, Albareda L, Barbiellini B, Soyer A (2021) Impact of circular design of lithium-ion batteries on supply of lithium for electric cars towards a sustainable mobility and energy transition. Procedia CIRP 100:73–78. https://doi.org/10.1016/J.PROCIR.2021.05.012

Restrepo E, Løvik AN, Widmer R, Wäger P, Müller DB (2019) Historical penetration patterns of automobile electronic control systems and implications for critical raw materials recycling. Resour 8:58. https://doi.org/10.3390/resources8020058

Richa K, Babbitt CW, Gaustad G, Wang X (2014) A future perspective on lithium-ion battery waste flows from electric vehicles. Resour Conserv Recycl 83:63–76. https://doi.org/10.1016/j.resconrec.2013.11.008

Roychowdhury A (2018) Clunkered: combating dumping of used vehicles—a roadmap for Africa and South Asia. India Environment Portal. http://www.indiaenvironmentportal.org.in/files/file/Combating%20Dumping%20of%20Used%20Vehicles.pdf. Accessed 14 Feb 2022

Sakai et al. (2014) An international comparative study of end-of-life vehicle (ELV) recycling systems. J Material Cycl Waste Manag 16:1–20. https://doi.org/10.1007/s10163-013-0173-2

Scherger S, Alf Hornborg (2021) Clunkers for mobility? Dissertation, Lund University. http://lup.lub.lu.se/student-papers/record/9044233

Slowik P, Lutsey N, Hsu C (2020) How technology, recycling, and policy can mitigate supply risks to the long-term transition to zero-emission vehicles. International Council on Clean Transportation. https://theicct.org/publication/how-technology-recycling-and-policy-can-mitigate-supply-risks-to-the-long-term-transition-to-zero-emission-vehicles. Accessed 14 Feb 2022

Sovacool BK (2021) Who are the victims of low-carbon transitions? Towards a political ecology of climate change mitigation. Energ Res Soc Sci 73:101916. https://doi.org/10.1016/J.ERSS.2021.101916

Sobianowska-Turek A, Urbańska W, Janicka A, Zawiślak M, Matla J (2021) The necessity of recycling of waste li-ion batteries used in electric vehicles as objects posing a threat to human health and the environment. Recycling 6:35. https://doi.org/10.3390/recycling6020035

Steward D, Mayyas A, Mann M (2019) Economics and challenges of li-ion battery recycling from end-of-life vehicles. Procedia Manuf 33:272–279. https://doi.org/10.1016/J.PROMFG.2019.04.033

Storchmann K (2004) On the depreciation of automobiles: an international comparison. Transp 31:371–408. https://doi.org/10.1023/B:PORT.0000037087.10954.72

Tarrar M, Despeisse M, Johansson B (2021) Driving vehicle dismantling forward—a combined literature and empirical study. J Clean Prod 295:126410. https://doi.org/10.1016/J.JCLEPRO.2021.126410

Thomas CE (2015) Sustainable transportation options for the 21st century and beyond. A comprehensive comparison of alternatives to the internal combustion engine. https://doi.org/10.1007/978-3-319-16832-6

Toyota, M (2012) Toyota Prius Plug-in: your questions answered. Available at: https://mag.toyota.co.uk/toyota-prius-plug-in-your-questions-answered/ Accessed 31 Mar 2022.

Tracy D (2017) Here's What A Battery Researcher Told Us About The Tesla Roadster's Crazy Performance Claims. Available at: https://jalopnik.com/heres-what-a-battery-researcher-told-us-about-the-tesla-1820558723. Accessed 31 Mar 2021.

Un-Noor F, Padmanaban S, Mihet-Popa L, Mollah MN, Hossain E (2017) A comprehensive study of key electric vehicle (EV) components, technologies, challenges, impacts, and future direction of development. Energ 10:1217. https://doi.org/10.3390/en10081217

UNEP (2020) Used vehicles and the environment: A global overview of used light duty vehicles-flow, scale and regulation. UNEP. https://stg-wedocs.unep.org/handle/20.500.11822/34175. Accessed 14 Feb 2022

UNEP (=United Nations Environment Programme) (2021) Used vehicles and the environment: A global overview of used light duty vehicles-flow, scale and regulation. Update and Progress 2021. UNEP. http://airqualityandmobility.org/usedvehicles/usedvehicles_updatereport2021.pdf. Accessed 7 Mar 2022

Velten EK, Brauer C, Thie JE (2020) Used vehicle trade and fleet composition in Europe. Ecologic Institute. https://www.researchgate.net/profile/Eike-Velten/publication/351124817_Used_Vehicle_Trade_and_Fleet_Composition_in_Europe/links/60895053a6fdccaebdf2ad2b/Used-Vehicle-Trade-and-Fleet-Composition-in-Europe.pdf. Accessed 25 Feb 2022

Vidyanandan KV (2018) Overview of electric and hybrid vehicles. Energ Scan 3:7–14. https://www.researchgate.net/publication/323497072

Volan T, Vaz CR, Uriona-Maldonado M (2021) Scenarios for end-of-life (EOL) electric vehicle batteries in China. Revista De Gestão 28:335–357. https://doi.org/10.1108/REGE-12-2020-0143

Wang L, Wang X, Yang W (2020a) Optimal design of electric vehicle battery recycling network–from the perspective of electric vehicle manufacturers. Appl Energ 275:115328. https://doi.org/10.1016/j.apenergy.2020.115328

Wang L, Hu J, Yu Y, Huang K, Hu Y (2020b) Lithium-air, lithium-sulfur, and sodium-ion, which secondary battery category is more environmentally friendly and promising based on footprint family indicators? J Clean Prod 276:124244. https://doi.org/10.1016/j.jclepro.2020.124244

Wappelhorst S (2021) Update on government targets for phasing out new sales of internal combustion engine passenger cars. International Council on Clean Transportation. https://theicct.org/publication/update-on-government-targets-for-phasing-out-new-sales-of-internal-combustion-engine-passenger-cars. Accessed 14 Feb 2022

Williams R, Keeling W, Petsinaris F, Baron Y, Mehlhart G (2020) Supporting the evaluation of the directive 2000/53/EC on end-of-life vehicles. European Commission. https://ec.europa.eu/environment/pdf/waste/elv/ELVD%20Evaluation-Final%20report%20Aug2020-rev1.pdf. Accessed 25 Feb 2022

Winslow KM, Laux SJ, Townsend TG (2018) A review on the growing concern and potential management strategies of waste lithium-ion batteries. Resour, Conserv and Recycl 129:263–277. https://doi.org/10.1016/J.RESCONREC.2017.11.001

Xu G, Yano J, Sakai SI (2016) Scenario analysis for recovery of rare earth elements from end-of-life vehicles. J Mater Cycl Waste Manag 18:469–482. https://doi.org/10.1007/s10163-016-0487-y

Yano J, Xu G, Liu H, Toyoguchi T, Iwasawa H, Sakai SI (2019) Resource and toxic characterization in end-of-life vehicles through dismantling survey. J Mater Cycl Waste Manag 21:1488–1504. https://doi.org/10.1007/s10163-019-00902-9

Yu J, Wang S, Toshiki K, Serrona KR, Fan G, Erdenedalai B (2017) Latest trends and new challenges in end-of-life vehicle recycling. In: Hester RE, Harrison RM (ed) Environmental impacts of road vehicles. The Royal Society of Chemistry, London, pp 174–213. https://doi.org/10.1039/9781788010221-00174

Zhao Y, Pohl O, Bhatt AI, Collis GE, Mahon PJ, Rüther T, Hollenkamp AF (2021) A review on battery market trends, second-life reuse, and recycling. Sustain Chem 2:167–205. https://doi.org/10.3390/suschem2010011

Zhou Y, Wang M, Hao H, Johnson L, Wang H, Hao H (2015) Plug-in electric vehicle market penetration and incentives: a global review. Mitig Adapt Strateg Glob Change 20:777–795. https://doi.org/10.1007/s11027-014-9611-2