Abstract

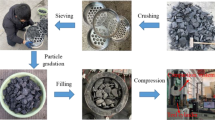

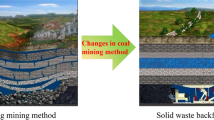

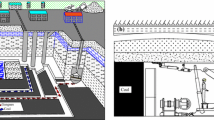

In recent years, solid waste backfill mining has developed rapidly and widely used to control surface subsidence and reduce accumulation of solid waste. As crushed materials are used to backfill goafs, the particle size of backfill materials becomes a key factor influencing the control of surface subsidence. To analyse the influences of particle size of backfill materials on surface subsidence, the compaction properties of crushed gangue backfill materials (CGBM) with different particle sizes were tested by using the YAS5000 testing machine and a self-made compacting device. Moreover, based on the strain hardening behaviour of CGBM in the process of compaction, a method of simulating CGBM using double-yield model was put forward. By employing this method in simulation, the influence of particle size of CGBM on surface subsidence was studied. The research results are demonstrated as follows: with the increase in particle size of the backfill materials, these maximum values such as the maximum surface subsidence, horizontal movement, inclination, curvature, and horizontal deformation increased gradually. Little difference was found in the surface subsidence and movement while using CGBM with particle sizes in the ranges of 2.5–16 and 2.5–50 mm with uniform gradation. However, both values were obviously smaller than those using CGBM with particle sizes of 20–31.5 and 31.5–50 mm. In terms of samples with particle sizes of 2.5–50 mm, the gradation of particles was uniform. By using large particles to form frame structures and small particles to fill fractures, such structures with strong anti-deformation abilities produced a small amount of deformation under the load from overlying strata. Therefore, this structure exerted a good controlling effect on surface deformation.

Similar content being viewed by others

References

Belem T, Benzaazoua M (2008) Design and application of underground mine paste backfill technology. Geotech Geol Eng 26:147–174. doi:10.1007/s10706-007-9167-y

Brake SS, Dannelly HK, Connors KA (2001) Controls on the nature and distribution of an alga in coal mine-waste environments and its potential impact on water quality. Environ Geol 40:458–469. doi:10.1007/s002540000181

Cui XM, Gao YG, Yuan DB (2014) Sudden surface collapse disasters caused by shallow partial mining in Datong coalfield, China. Nat Hazards 74:911–929. doi:10.1007/s11069-014-1221-5

Fan GW, Zhang DS, Wang XF (2014) Reduction and utilization of coal mine waste rock in China: a case study in Tiefa coalfield. Resour Conserv Recy 83:24–33. doi:10.1016/j.resconrec.2013.12.001

Guo GL, Zhu XJ, Zha JF, Wang Q (2014) Subsidence prediction method based on equivalent mining height theory for solid backfilling mining. Trans Nonferrous Metal Soc China 24:3302–3308. doi:10.1016/S1003-6326(14)63470-1

Guo WB, Tan Y, Bai EH (2017) Top coal caving mining technique in thick coal seam beneath the earth dam. Int J Min Sci Technol 27:165–170. doi:10.1016/j.ijmst.2016.11.005

Jirina T, Jan S (2010) Reduction of surface subsidence risk by fly ash exploitation as filling material in deep mining areas. Nat Hazards 53:251–258. doi:10.1007/s11069-009-9425-9

Junker M, Witthaus H (2013) Progress in the research and application of coal mining with stowing. Int J Min Sci Technol 23:7–12. doi:10.1016/j.ijmst.2013.01.002

Li M, Zhang JX, Miao XX (2014) Experimental investigation on compaction properties of solid backfill materials. Min Technol 123:193–198. doi:10.1179/1743286314Y.0000000066

Loupasakis C, Angelitsa V, Rozos D, Spanou N (2014) Mining geohazards-land subsidence caused by the dewatering of opencast coal mines: the case study of the Amyntaio coal mine, Florina, Greece. Nat Hazards 70:675–691. doi:10.1007/s11069-013-0837-1

Mohammad N, Reddish DJ, Stace LR (1997) The relation between in situ and laboratory rock properties used in numerical modelling. Int J Rock Mech Min Sci 34:289–297. doi:10.1016/S0148-9062(96)00060-5

Oparin VN, Potapov VP, Giniyatullina OL, Andreeva NV, Schastlivtsev EL, Bykov AA (2014) Evaluation of dust pollution of air in Kuzbass coal-mining areas in winter by data of remote earth sensing. J Min Sci 50:549–558. doi:10.1134/S1062739114030168

Orejarena L, Fall M (2010) The use of artificial neural networks to predict the effect of sulphate attack on the strength of cemented paste backfill. Bull Eng Geol Environ 69:659–670. doi:10.1007/s10064-010-0326-7

Palarski J (1989) The experimental and practical results of applying backfill. In: Hassani FP, Scoble MJ, Yu TR (eds) Innovations in mining backfill technology. Balkema, Rotterdam, pp 33–37

Pappas DM, Mark C (1993) Behavior of simulated longwall gob material. Bureau of Mines, Report of Investigations, pp 23–35

Skierszkan EK, Maye KU, Weis D, Beckie RD (2016) Molybdenum and zinc stable isotope variation in mining waste rock drainage and waste rock at the Antamina mine, Peru. Sci Total Environ 550:103–113. doi:10.1016/j.scitotenv.2016.01.053

Unver B, Yasitli NE (2006) Modelling of strata movement with a special reference to caving mechanism in thick seam coal mining. Int J Coal Geol 66:227–252. doi:10.1016/j.coal.2005.05.008

Wang JA, Shang XC, Ma HT (2008) Investigation of catastrophic ground collapse in Xingtai gypsum mines in China. Int J Rock Mech Min Sci 45:1480–1499. doi:10.1016/j.ijrmms.2008.02.012

Xu ZQ (2001) Study of several problems concerning selection of physical and mechanical parameters of rock used for numerical analysis. MS thesis, J Univ Sci Technol B 16–17

Xuan DY, Xu JL (2014) Grout injection into bed separation to control surface subsidence during longwall mining under villages: case study of Liudian coal mine, China. Nat Hazards 73:883–906. doi:10.1007/s11069-014-1113-8

Xuan DY, Xu JL, Wang BL, Teng H (2016) Investigation of fill distribution in post-injected longwall overburden with implications for grout take estimation. Eng Geol 206:71–82. doi:10.1016/j.enggeo.2016.04.007

Yavuz H (2004) An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int J Rock Mech Min Sci 41:193–205. doi:10.1016/S1365-1609(03)00082-0

Zhang JX, Zhou N, Huang YL, Zhang Q (2011) Impact law of the bulk ratio of backfilling body to overlying strata movement in fully mechanized backfilling mining. J Min Sci 47:73–84. doi:10.1134/S1062739147010096

Zhang JX, Jiang HQ, Deng XJ, Ju F (2014) Prediction of the height of the water-conducting zone above the mined panel in solid backfill mining. Mine Water Environ 33:317–326. doi:10.1007/s10230-014-0310-8

Zhang JX, Zhang Q, Spearing AJS, Miao XX, Guo S, Sun Q (2017) Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int J Min Sci Technol 27:17–27. doi:10.1016/j.ijmst.2016.11.014

Acknowledgements

This research was supported by the Fundamental Research Funds for the Central Universities (2017XKZD13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, M., Zhang, J., Huang, Y. et al. Effects of particle size of crushed gangue backfill materials on surface subsidence and its application under buildings. Environ Earth Sci 76, 603 (2017). https://doi.org/10.1007/s12665-017-6931-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-017-6931-z