Abstract

Background

The bioeconomy relies strongly on the availability of biomass, including biogenic waste, residues and by-products. The cost of supply often represents a significant proportion of the total value of the resource. However, there is limited insight into the current supply costs of wastes, residues and by-products. This includes straw, which is the most important agricultural by-product in Germany. Despite its importance, standardised information on supply costs or market prices, as well as their temporal and spatial variation, is missing.

Aim

Therefore, there is an urgent need for the temporal and spatial monitoring of individual cost components within total supply costs. This is essential to identify the most cost-effective options for the utilisation of agricultural by-products. Therefore, this study focuses on the case of straw to develop a model capable of visualising and mapping regional supply costs over time.

Method

We use an activity-based costing approach to calculate and monitor regional supply costs, defined as the monetary expenditure required to make straw available at the farm level. Our methodology combines typical technical and operational aspects of straw collection and transport with regional wage statistics, yield data, farm sizes, fuel prices and labour costs. We also consider storage costs and opportunity costs associated with nutrient replacement and conduct sensitivity analyses to measure their impact. To validate our calculations, we compare them with actual straw prices. To establish a reliable cost monitoring system, we propose an approach to assess the quality of input data.

Result

In 2011, the regional supply costs for straw varied from 45.72 EUR/Mg[FM] to 92.92 EUR/Mg[FM], showing a wide range. Over the years, the German average supply cost for straw increased from 56.78 EUR/Mg[FM] in 2010 to 58.79 EUR/Mg[FM] in 2020, with a peak of 61.24 EUR/Mg[FM] in 2018. This suggests that the temporal impact on mass-specific costs is relatively moderate compared to the spatial distribution of supply costs. The sensitivity analysis highlights storage time and costs, straw yield and wage levels as the main drivers of supply costs. Doubling the storage period from 3 to 6 months increases total costs by 20%. On average, the costs explain 75% of the straw price across all federal states, depending on annual price and cost levels. The quality assessment of input data shows that currently 68% of the data cannot be automatically extracted for continuous monitoring. Detailed results are available in a corresponding data publication: https://doi.org/10.5281/zenodo.8145082.

Conclusion

In the absence of standardised market prices, the model presented provides an approach to estimating the supply costs of straw, expressed in terms of the monetary cost to farmers of mobilising straw. This cost information could be a valid database for further techno-economic assessments or models to evaluate the economic feasibility of straw valorisation. Due to the modular structure of the model, the future development of supply costs can be considered if the input data are adapted to future scenarios.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

To mitigate climate change, it will be necessary to move towards a sustainable economy and replace fossil resources with renewable resources such as biomass [1]. The limited land available for biomass cultivation is mainly used for food production, so biogenic residues, wastes and by-products are of great importance for the transition to a bioeconomy [2].

In Germany, straw has the highest potential among residues, wastes and by-products and already covers 34–20% of the total mobilisable technical biomass potential of residues, wastes and by-products [3], and will be the case study in this study. The extent to which this mobilisable technical straw potential could be made available for different uses, such as as a building material [4], or as an energy source, for example as a co-digestate in biogas plants [5], depends among other things, on costs. Therefore, this study deals with the issue of straw supply costs.

In techno-economic analyses of biomass valorisation concepts, e.g. by Schubert [6] or Lepage et al. [7], it is pointed out that the supply costs of the raw material (e.g. straw) have a significant influence on the economic evaluation of the value chain. Despite the importance of supply costs for the successful implementation of a bio-based transformation towards a sustainable economy, they are often only superficially addressed. For example, Karras et al. [8] have shown that in techno-economic analyses there is a mismatch in spatial and temporal resolution between the sources cited and the study areas considered. One problem, especially residues, wastes and by-products, is the lack of a standardised market on which the resources are traded. For example, the straw trade in Germany is highly regionalised and business relationships are mostly bilateral. [9] For larger trade volumes, individual contracts are usually concluded with several farmers [10]. As a result, there are no valid market prices for straw that reflect the balance between supply and demand. In particular, regional straw prices are not always available.

The supply curve in straw markets is determined by the willingness of farmers to supply straw. Townsend et al. [11] mentioned that farmer’s decisions are affected by the price offered, in addition to the need to return crop residues to maintain soil health, the ability to fit straw-making activities into the farm’s timetable, access to markets or contract details. Several studies have investigated the willingness of farmers to supply at a regional level through surveys. Zyadin et al. [12] showed in two regions of Poland that 60% of the farmers are not willing to supply straw for bioenergy use, due to several socio-economic factors, including low straw prices in Poland and the lack of confidence in bioenergy supply chains. For a region in Italy, Giannoccaro et al. [13] showed that 57% of farmers are willing to participate in the feedstock market and 45% already sell their straw. They also derive a straw price by asking about the willingness to accept a certain price. These straw prices are higher than the observed market prices. Therefore, they conclude that estimating the prices using cost-based methods is not appropriate and farmer’s preferences should also be taken into account when estimating prices. Unfortunately, survey-based determination of farmer’s preferences is only a snapshot within the study area and is relatively time-consuming in the survey methodology.

Therefore, instead of time-consuming regional surveys, it may be useful to use cost-based approaches to determine the cost of straw supply from the farmer's perspective over a longer period and at a national level. In this context, activity-based costing is used to monetise all steps in the straw mobilisation process at the farm level. Existing work, e.g. at the EU level through the S2Biom project [14] or at the national level through the straw price calculator (Strohpreis-Rechner) of the Chamber of Agriculture Niedersachsen (Landwirtschaftskammer Niedersachsen) [15], can already provide straw supply costs at farm level. However, the S2Biom project and the straw price calculator do not consider temporal effects. To take into account the temporal effects of straw mobilisation, temporal supply costs are necessary. As mentioned by Brosowski et. al [16], straw availability in Germany is variable and to answer the question of how much straw is available in a given region and at what cost, temporal effects need to be included.

Therefore, in this paper we develop a modelling approach including activity-based costing to answer the following questions: 1) What are the supply costs of straw from a farmer's perspective in Germany? 2) What are the main drivers of supply costs on the farm? 3) What are the trends over time? 4) Are there regional cost differences?

The spatial resolution is at the county level [NUTS-3] for Germany. The evaluation of supply costs for the historical period 2010–2020 is included to identify temporal developments. Finally, the model should provide a kind of minimum price from the farmer's point of view for the mobilisation of straw at the farm level. These results address the cost driver aspects in the willingness to participate or supply straw as a bio-based resource. Potential users of straw will thus be able to identify regions, where the individual costs of straw supply are in line with their willingness to pay for straw as a raw material. This overcomes one of the barriers to straw mobilisation by farmers.

Looking only at the history or current point in time of supply costs makes the calculated supply costs obsolete in the future. This reduces the time period over which the supply cost dataset can contribute to the scientific discourse. For this reason, activity-based costing approaches for determining the supply costs of straw or the supply costs of biogenic residues and wastes as well as by-products should ideally be established as continuous monitoring. For this purpose, the individual input parameters must be easy to update and have a suitable data quality. To evaluate the presented model concerning the quality of the input data, a data quality assessment is presented, which allows an evaluation of the quality based on a score. From this, it can be deduced to what extent the presented method can be transferred to continuous monitoring.

To some extent, it is necessary to make statements about the future in the present. For example, in the discussion about the future use of biomass, biogenic residues and waste, and by-products, several studies determine the availability of biomass for the future, e.g. 2050, under defined assumptions [17, 18]. Prussi et al., [19] conclude that feedstock costs and prices are an important puzzle within biomass mobilisation. This highlights the need to be able to estimate future supply costs based on assumptions. Similar to what is available for biomass potentials. Therefore, straw supply cost models should be able to calculate future supply costs under defined assumptions. The supply cost model presented provides the ability to manipulate input data by individual assumptions to determine future supply costs under the assumptions made.

The model results are validated by comparison with existing studies using Activity Based Costing. However, as explained above, supply costs only represent supply-side costs and neglect the demand side. Therefore, a comparison with non-standardised market straw prices is also made to answer the question of what percentage of straw prices can be explained by the supply cost model, because from the farmer's point of view, the supply costs determined here from the following model are only a kind of minimum compensation for the farmer for mobilising straw at the farm gate.

Methods and Material

This chapter defines the system boundaries, the calculation elements and data sources as well as the validation data, the sensitivity analysis and the approach to assess the data quality of the input for the supply cost model.

Definition and System Boundary

In this paper, supply costs are defined as the monetised effort to make the residual biomass available from the farmer's perspective. Accordingly, the supply costs presented here can be understood as a minimum compensation to be paid to the farmer for mobilising the straw from the field. Consequently, the supply costs should not be understood as market prices resulting from the balance between supply and demand. The scope of the supply chain is limited to the road-side (farm-gate), illustrated inside the green box of Fig. 1. This means, that actual possible financial benefits from digestate recirculation are not included. It also excludes the cost of growing the main crop of which the straw is a by-product.

The model is applied to straw, the most relevant by-product in Germany according to their mobilisable technical biomass potential [3].

Calculation Elements of Straw Supply Costs

The following section presents the data, which is used to feed the model and calculate the supply costs. Official statistics, databases, literature assumptions and expert assessments, are the basis for the calculation and will be assessed in a separate section according to their data quality. The first step is to define supply chains for straw supply up to the farm gate. Figure 2 shows the two assumed supply chains. A supply chain with lower technical equipment for smaller farms and a supply chain with higher technical equipment. The main distinguishing criterion is the type of straw bale. Round bales are assumed for the supply chain with lower equipment and square bales for the farms with higher equipment, as square bales are state of the art [10, 20]. In Addition, the storage was assumed to be on the one hand in existing buildings that are currently not in use or on the other hand in separate storage halls.

To define the relevant supply chain on NUTS-3 levels in Germany the specific farm area is used to allocate. The farm area per county for different size categories and the number of farms inside these size categories are obtained from the regional statistics [22]. The national average farm area (Anat) is the average of the weighted specific farm area (Aspec) over all counties (i) (2). The weighting factor (f) is the number of farms (F) per category (j) (1)

The supply chain with higher equipment is allocated to all counties with a specific farm area above or equal to national average. This method is applied to the years from 2010–2020. The county-specific data on the NUTS-3 level is available for the years 2010, 2016 and 2020. The yearly trend from higher NUTS level [federal state – NUTS-2] is used to interpolate the missing years 2011–2015 and 2017–2019 according to the method described in Naegeli de Torres et al., 2022 [23].

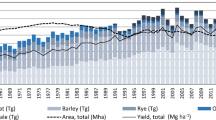

After assigning the supply chain, the matching KTBL table from the “Fieldwork calculator” [21] needs to be identified. The KTBL tables are distinguished according to straw yield per ha. Therefore, the straw yields (Ystraw) are derived from corn yields (Ycorn) (wheat, rye, oat barley, triticale) published by the Regional statistic [24]. The corn-to-crop relations per fruit type (g) are extracted from the German fertiliser guideline [25] and correspond to the assumptions of the DBFZ resource database [3]. The assumed technical removal rate (Rtech) of 33% from Weiser et al., 2014 [26] expresses the factor of straw which remains on the field due to technical restrictions (3).

The corresponding KTBL tables include information about the working and technical effort for the collection and transport of the straw to the farm gate as well as information for spreading fertilizer to substitute the removed nutrients. Additional specific storage costs extracted from the “Straw Price Calculator” of the Chamber of Agriculture of Niedersachsen are included. An overview of the selection criteria and cost data is illustrated in Fig. 3.

The supply costs (Csupply) are the sum of collection costs (Ccoll), transport costs (Ctrans), storage costs (Cstore) and opportunity costs (Copp) as costs for the removed nutrients (4).

To calculate the working effort inside the different steps of the supply chain the NUTS-specific wage of the farm worker (W) needs to be calculated (5). The wage is the product of the gross wage (Wfarm), the NUTS-specific wage level in reference to the per capita income (CI) and the share of non-wage costs (NWC).

The collection, transport and fertilizer costs are determined on the one hand by the working effort depending on the time demand (TD) and the wage of the farm worker. On the other hand, the technical effort is based on the fuel price (FP) next to the variable (Cvar) and fix (Cfix) costs (6, 7, 8).

The collected straw needs to be stored and the storage costs depend on specific storage costs (sCstore) according to the cost per fruit type, the density of the straw bales (BD) and the storage time (Tstore) (9).

The last part of the costs are the opportunity costs to value the losses of the nutrient removal. Therefore, the straw value as a product of nutrient content (NC) and Nutrient price (NP) is extended by the fertilizer costs to replace the nutrients on the field (10). The humus balance in the soil is not taken into account in the model because we assume that the humus needed to maintain soil quality could be balanced by good agricultural practice [27] (e.g. smart selection of intercropping could replace soil incorporation of straw [28] or leaving straw on the field in subsequent years). We are only interested in the monetary effort the farmer has to collect the straw if he decides to remove all technically available straw from the field.

Sensitivity

The sensitivity of the supply cost model is calculated by changing the input values according to their standard deviation (SD) and defined percentages by which the input data changes. Therefore, the SD is calculated for the different input data and expresses the rate of change of the input values in positive and negative directions. The positive or negative SD is multiplied by the initial values and the model run is repeated to assess the relative change in total supply cost according to the relative change in input variables. As already mentioned, in addition to the SD, the same input values are changed at constant percentages of 5%, 10%, 15% and 20% in negative and positive directions to identify the most sensitive values. Only input parameters that are subject to temporal or type-specific fluctuations were considered and the storage time, as the storage time is an assumption that is not based on any source-based information. No sensitivities were calculated for the data from the KTBL data repository.

Model Validation

The model is validated against researched straw prices and existing literature values to verify that the model produces plausible results. Straw prices are obtained by personal request from the “Market Information Office – East” and the State Office for Agriculture Hessen and are available for 7 federal states [29, 30]. Literature values for supply costs of straw are taken from the S2Biom-project at the European level [14], a literature review of supply costs and prices used in European studies by Karras et al. [8] and the straw price calculator of the Chamber of Agriculture Niedersachsen [15].

Data Quality

Another objective of the model is to establish dynamic data processing to allow an easy updating of the model. The focus of the data processing is therefore on establishing automated data handling. This enables monitoring the supply costs with less effort in the future. Ideally, data should be accessed via API interfaces, or downloadable data tables that are kept up to date. The use of literature values or expert assessment should be kept to a minimum and only used where automated data is not available.

To provide an overview of the underlying inputs, the data are assessed for their quality, to provide robust and valid supply cost data. Data quality has several dimensions as introduced by Wang and Strong [31] in 1996, such as reliability, relevance, completeness or actuality. A method for assessing data quality in the context of environmental studies is provided by Weidema and Wesneas for Life-Cycle-Assessments with the “pedigree matrix” [32]. They relate the data quality of input data to five indicators and propose a score from one to five with ascending scoring. For the supply cost model, we have adopted this idea and adapted the data quality indicators to our objectives. The aim is to assess the quality of the input data used to calculate the supply costs within each calculation element. Table 1 shows the data quality indicators and the possible scores.

The first data quality indicator addresses the temporal scope of the input data and the time covered by the input data. The regional scope assesses the spatial resolution of the input data and how it fits with the spatial resolution of the supply cost model. The reliability of the input data depends on the source from which it comes and is adopted from Edelen & Ingwersen, 2016 [33], who extend the “pedigree matrix” from Weideman and Wesneas [32]. Reliable sources include measurements with a described measurement method. Expert assessments appear to be less reliable because they are subjective and therefore contain uncertainties. The last data quality indicator concerns how the data have been processed to assess the future effort to update the data.

After assessing each data quality indicator for each calculation element, the minimum score per indicator and category is extracted. In contrast to Weidema and Wesneas [32] where only the highest score per category is relevant, in our assessment only the lowest score is relevant due to inverted scales.

Results

Detailed results are available in a separate data publication in the Zenodo repository [34] (https://doi.org/10.5281/zenodo.8145082).

Supply Cost

The model was implemented in R 4.0.4 and the visualisation of the results was mainly done in R using the “ggplot2” package. The API requests from Destatis and the regional statistics [35] were specified in the script and executed directly in the R environment. Data inputs beyond the API were read as CSV or Excel files.

Regional Supply Costs

Overall, the supply costs of straw varied between 92.92 EUR/Mg[FM] in Cottbus for the year 2011 and the supply costs in the county of Landkreis Mecklenburgische Seenplatte in 2010 with 45.72 EUR/Mg[FM]. Figure 4 shows the regional supply costs for the years 2010, 2018 and 2020. The high costs in 2018 for the districts of Spree-Neiße and Potsdam-Mittelmark resulted from the very low straw yield of 1.42 and 1.60 Mg[FM]/ha, respectively. The straw yield influenced the model because the work and technical inputs per ha were determined by the yield categories. Furthermore, to obtain Mg-specific values, the ha-specific results were divided by the straw yield. Therefore, a high straw yield reduced the Mg-specific costs and a low straw yield increased the costs. The regional effect between East Germany (former GDR) and West Germany could be explained by the wage level. Using our method for regionalising wages, the average working costs per ha across all years and districts in East Germany (Sachsen, Brandenburg, Thuerignen, Mecklenburg-Vormpommern and Sachsen-Anhalt) were about 20.00 EUR. In western Germany, the average working costs per ha were more than 35.00 EUR. As shown in Fig. 5, the temporal effect over the period 2010–2020 was not strong in terms of mass-specific costs.

Composition of Supply Costs—Drivers

As mentioned above and in Fig. 5, the time effects were not very strong. If we assume an average straw yield of 3.46 Mg[fm]/ha and an average farm size of 78.71 ha, of which 70.7% was arable land [36], which was cultivated with cereals, the supply costs at farm level varied over the years up to 806.02 EUR. The main drivers of the variation over time were wage rates, nutrient prices and the yearly straw yield. The temporal effects of fuel prices weren't strong, as the fuel price only represents between 3.7% and 13.0% of the total costs. The main driver of technical costs was the cost of machinery, which included depreciation and repair costs. Within the opportunity costs, the straw value dominated. Fertiliser application costs accounted for only 4.9 to 28.4% of opportunity costs and only 1.3 to 6.3% of total costs.

Sensitivity

Due to the modular structure of the model, it was possible to look at the individual elements of the calculation separately and to change their values. Figure 6 shows the results of the sensitivity analysis. The straw yield and the technical removal rate had the greatest influence on the total costs. Both input parameters reacted identically in the sensitivity analysis, due to their identical function within the system of equations. Storage costs and duration as well as wage levels also had a strong influence on total costs. Storage costs and duration behave in the same way. On the other hand, the price of fuel for the machines had less influence on the supply costs. Detailed percentages and SDs are given in Table A1 (Annex 1 – Sensitivity Analysis). When the input values were varied according to their standard deviation, it was found that storage costs varied the most and therefore had a strong impact on the results.

Storage time was also changed. By default, the storage time was set at three months and the storage accounted for an average of 22.2% of the total cost. If we assume that the storage time is doubled to six months, the share increases to 36.4% of the total cost. The supply costs increased on average by 20.3% to a total cost of 72.07 EUR/Mg[FM] as an average for all years and at the NUTS-3 level. The neglect of storage (storage time = 0 months) led to a reduction of the total costs by 20.3%.

Validation

Compared to existing work, our model added the time component to the supply costs. The S2Biom project also calculated the supply costs in EUR/Mg[DM] for cereal straw at the NUTS-3 level but kept the costs constant over time [14]. The range of road-side costs for cereal straw in Germany in the S2Biom database was between 32.07 EUR/Mg[FM] and 34.72 EUR/Mg[FM], assuming a dry matter content of the straw of 86% [37]. These costs were on average 56.5% of the costs of our approach. The S2Biom approach did not include the storage costs. When we neglected storage costs in our model, the average supply costs of the S2Biom approach corresponded to 71.2% of our model results.

Extracted straw costs and prices for supply for road-side delivery were also collected in the literature review by Karras et al., 2022 [8]. Road-side supply costs ranged from 21.98 EUR/Mg[FM] to 52.78 EUR/Mg[FM], which is more in line with our results for the upper part of the range.

The Chamber of Agriculture of Niedersachsen provided a “Straw Price Calculator”, which like our model, included the collection costs, the transport costs to the farm-gate, the storage costs and the value of straw in terms of nutrient prices. They also included a 50.0% profit margin on the straw value. [15] They updated their model regularly but did not include regional effects except for manual changes to selected input parameters for regional assumptions. To compare the results with our model, we looked at the calculated straw price for 2019. The straw price calculator gave a straw price of 71.60 EUR/Mg[FM] when selecting round bales and a storage period of three months in an old building. We modelled an average supply cost of 60.54 EUR/Mg[FM] in 2019 with a maximum regional cost of 79.85 EUR/Mg[FM] and a minimum regional cost of 49.88 EUR/Mg[FM]. If we add a 50% profit margin to our straw value, the total cost of supply in 2019 would be 66.07 EUR/Mg[FM].

Figure 7 shows the calculated supply costs in combination with the annual average straw prices, which were available on request for Sachsen-Anhalt, Sachsen, Thueringen, Brandenburg, Mecklenburg-Vorpommern and Hessen [29, 30]. It can be seen that the modelled temporal effects in the supply costs indicated the fluctuation of straw prices over the years, but couldn't explain them in their totality. Furthermore, the costs explained only a part (from 50% up to 123%, on average 75%) of the straw prices. Prices are influenced more by straw scarcity than by production costs [13]. The price peaks in the time series can therefore be explained by extreme weather events (heat and drought) in 2012 and 2018 [38], which limited the supply of straw [39]. As a result, straw became scarcer and competition for straw increased, leading to higher prices. This increased competition can be attributed to the competition for uses in the straw market. Competing uses of straw such as animal bedding and feeding, are one of the main competing uses, together with incorporation into the soil or burning on the field [40]. For example, livestock farmers can pay higher prices than other straw users [41]. However, as shown in Fig. 7 the modelled costs have also increased significantly in 2011 and 2018, especially in Brandenburg and Sachsen-Anhalt, due to lower straw yields.

Data Quality

To establish a long-term cost monitoring system, data quality was assessed for each cost element and aggregated by category to identify the potential for improvement in the input data to the monitoring system. The results are shown as a circular bar chart in Fig. 8. This representation of the input data shows at first glance the weaknesses of the input data. Input data with a low score can be a good starting point to review and improve the input data of the model. In the case of straw supply costs the farm structure stands out as the only input category with a high data quality score, as the farm area data were mostly available as time series at NUTS-3 level and can be processed by official statistics via API request. The other input categories, with the isolated exception of the spatial resolution indicator, had low-quality scores, as the extracted literature values were partly based on assumptions or referred to sources with a different temporal or spatial scope. In addition, the other categories contained individual input data that could not be directly integrated into the model via copy & paste or API.

A closer look at the individual calculation elements is shown in Table 2. 42% of the calculation elements referred to a reliable data source where the data measurement was documented. 12% of the calculation elements referred to assumptions that were not explained. Data obtained through API requests also accounted for 42%. This can be explained by the fact that data from official statistics contain a description of the collection method. Most of the calculation elements (82%) didn't refer to NUTS 3 level data, such as the desired spatial resolution of the output. They referred to other NUTS levels, such as federal or national data. 48% of the calculation elements were available for the whole time series 2010–2020 or at least contained several data within this period. The calculation elements with the lowest score across all indicators were data on nutrient content, specific storage costs and technical extraction rate.

Discussion

The model presented has successfully highlighted regional variations and temporal trends in straw supply costs from a farmer’s perspective. This allowed potential straw users to locate regions according to their willingness to pay. As presented in the results the North-East of Germany has the lowest supply costs, due to larger farm structures and corresponding economies of scale, as well as low wage levels. According to Brosowski et al. [16], the North-East of Germany, in particular, Mecklenburg-Vorpommern is also the region with the highest technical and mobilisable straw potential. Thus, the North-Eastern of Germany appears to be the region in which energy or material utilisation pathways for straw could be promising.

The data quality assessment presented here can help to stabilise these results over time and establish a monitoring system for the current regional supply costs. The data quality indicator gives a first impression of how the input data of the calculation elements fit the desired output of the supply cost model. The score indicates which input data needs to be examined in more detail to improve the input data in the future. Combined with the SD of the input variables, the potential for improvement can be better identified. For example, storage costs are relevant because storage costs have a relatively low data quality score combined with a high SD. In addition, the model is sensitive to a change in storage costs. In contrast, according to the sensitivity analysis, the wage level also has a large impact on the results, but the wage level has a higher data quality score. Accordingly, future improvements in input data should therefore be related to storage costs rather than wage levels.

However, it is advisable to use local surveys to determine not only farmers' supply costs but also their willingness to supply. This is because the cost of mobilise straw from the farmer's perspective is only one driver of the farmer's willingness to supply straw. Other drivers include the extent to which farmers prefer to incorporate straw into the soil to maintain soil quality [55], or how much straw is used on the farm for other internal uses and is not available as surplus for sale [12]. Competing uses in the regions of interest, such as livestock farms using straw as bedding and fodder, or mushroom and strawberry cultivation [40], could increase the demand and thus the scarcity and ultimately price of straw. Therefore, an extension of our work could be to combine our maps with maps of soil quality and maps of livestock farms or strawberry and mushroom farms to further narrow down the regions to be considered for an on-site survey.

Another factor influencing the willingness to supply straw are the details of the contract and the structure of the supply chain. This means, for example, that a contractor acting as an intermediary between the farmer and the straw end-user could increase farmers' confidence in a straw market [41]. In this case, the contractor may use modern baling and collection techniques and have increased efficiency than individual farmers. In addition, there may be economies of scale, which could reduce supply costs. Particularly in southern Germany, where our approach assumes somewhat lower technical equipment for straw collection at the individual farm level, the integration of contractors could lead to lower supply costs. Logically, the design of the defined supply chain and its players therefore influences on the cost structure.

To implement such considerations, our model has been designed in a modular way, so that input parameters and assumptions can be changed, e.g. the values for the variables of collection and transport costs as input parameters can be lowered. In addition, individual cost elements could be excluded if, for example, storage costs within the supply chain are no longer incurred by the farmer but by the end user. In our case, this would reduce farmer costs by around 22%. In general, this makes it relatively easy to apply the model to other areas to get an overview of supply costs without having to go into the field.

Another advantage of the modular design is the ability to incorporate future scenarios. In the case of fuel and raw material prices, the prices currently affected by the war in Ukraine were used in further model calculations. The average fuel price in 2022 was 79.94% higher than the annual average fuel price in 2020 [47]. Applying this cost increase to the fuel cost input data, the total cost increased from 58.79 EUR/Mg[FM] in 2020 to 60.82 EUR/Mg[FM], an increase of 3.45%. This underlines the small impact of fuel costs on supply costs. Raw material and nutrient prices increase between 147% for DAP fertiliser and 237% for potassium chloride. The average cost increase in 2022 compared to 2020 is 22.89% [50]. This highlights the ability of the model to use known cost drivers to determine the impact on farmer straw supply costs under future assumptions.

Our sensitivity analyses have emphasised that changes in input factors, such as storage costs and straw yield, have a significant impact on the model results. In particular, the yields identified within the NUTS-3 geographical divisions play a significant role in determining the supply costs per unit of mass. As mentioned in the validation section of this study the straw prices are determined by the scarcity of straw [13]. Scarcity is determined by the supply of straw as expressed by the straw yield, which is an input parameter in the model presented. The validation against straw prices showed that our model does not fully explain the straw price increase, but it does indicate of the rising or falling cost of supply. The average coverage of our model at the straw prices used for validation is 75%. Our cost approach does not currently take into account farmers' expected returns, which may be included in straw prices. To further reduce the gap between prices and our costs, the results of the willingness to supply and willingness to accept surveys could be used to obtain expected profits and implement them in our model.

Finally, our model highlighted the farmer's point of view and his monetary effort to collect, transport and store the straw on the farm, taking into account the opportunity costs associated with nutrient extraction through straw removal. These results help to better understand the cost driver of straw mobilisation. To extend the model to include the perspective of the straw user and his supply costs, the model would have to be extended to include transport and logistics from the farm to the plant. To do this, transport costs and logistics concepts would have to be defined in further steps and added to the existing supply costs (on the farm side).

Conclusion

The straw supply cost model presented provides detailed information on the minimum compensation required by a farmer to supply straw. Therefore, it could be a missing piece of the puzzle in finding the best location for business cases based on a certain amount of straw at a certain cost. It could narrow down the regions of interest for a detailed analysis of the market environment, thus reducing the effort in finding a location. In addition, the results could be used as input values for feedstock costs in techno-economic assessments, as our feedstock costs are available for a defined period and a wider geographical area, in contrast to more elaborate willingness-to-pay methods for estimating a price. However, it should be noted that the actual local straw prices paid are higher than the supply costs calculated by the model.

By extending the model to a monitoring system, it can ensure that the decision support tools are up to date. Rapid and continuous updating of the model can be achieved through the integration of modern data collection methods facilitated by API requests. Currently, 42% of the input data is accessible via an API, with a further 16% available in Excel or CSV files, which are updated regularly. Expanding automated data integration has the potential to further refine the model and create a monitoring system that can be easily updated. The combination of data quality assessment and sensitivity analysis plays a crucial role in developing and improving the model in line with the input data used. This approach to data quality assessment can be applied to other monitoring systems where different input data are aggregated to provide a quick overview of data model deficiencies.

The modular framework that underpins the supply cost calculation can be used to predict future supply costs under specific scenarios. As a result, the model serves not only as a historical cost monitoring tool but also as a planning tool for estimating future straw expenditures. In this way, this cost monitoring initiative provides a building block in a robust basis for subsequent techno-economic assessments or models aimed at assessing the economic viability of straw valorization.

Data Availability

The datasets/results generated and analysed during the current study are available as a dataset in the Zenodo repository [https://doi.org/10.5281/zenodo.8145082].

The databases of the calculation elements used to calculate the results are listed in Table 2, where the data quality of the calculation elements is assessed.

Abbreviations

- \({{\text{C}}}_{{\text{i}},{\text{t}}}^{{\text{supply}}}\) :

-

Total supply costs in NUTS-3 region per year, EUR/ha, EUR/Mg

- \({{\text{C}}}_{{\text{i}},{\text{t}}}^{{\text{coll}}}\) :

-

Costs for collection effort in NUTS-3 region per year, EUR/ha, EUR/Mg

- \({{\text{C}}}_{{\text{i}},{\text{t}}}^{{\text{trans}}}\) :

-

Costs for transport effort in NUTS-3 region per year, EUR/ha, EUR/Mg

- \({{\text{C}}}_{{\text{i}}}^{{\text{store}}}\) :

-

Storage costs in NUTS-3 region, EUR/ha, EUR/Mg

- \({{\text{sC}}}_{{\text{g}}}^{{\text{store}}}\) :

-

Specific storage costs per fruit type, EUR/m3

- \({{\text{C}}}_{{\text{i}},{\text{t}}}^{{\text{opp}}}\) :

-

Opportunity Costs (Straw value and fertilizer spread) in NUTS-3 region per year, EUR/ha, EUR/Mg

- Cvari :

-

Variable machine costs in NUTS-3 region, EUR/ha, EUR/Mg

- Cfixi :

-

Fix machine costs (broken down by ha) in NUTS-3 region, EUR/ha, EUR/Mg

- Aj,t :

-

Agricultural area per year, ha

- Fj,t :

-

Number of farms per year

- fj,t :

-

Weighting factor per year

- \({{\text{A}}}_{{\text{i}},{\text{t}}}^{{\text{spec}}}\) :

-

Specific farm area in NUTS-3 region per year, ha

- \({{\text{A}}}_{{\text{t}}}^{{\text{nat}}}\) :

-

National average of specific farm area per year, ha

- TDi :

-

Time demand for worker in NUTS-3 region, h/ha

- FDi :

-

Fuel Demand in NUTS-3 region, l/ha

- NC:

-

Nutrients Content, kg/Mg

- FPt :

-

Price fuel per year, EUR/l

- NPt :

-

Price Nutrients per year, EUR/Mg

- Wi,t :

-

Total wage farm worker in NUTS-3 region per year, EUR/h

- Wfarm :

-

Gross wage farm worker, EUR/h

- CIt :

-

Per capita Income per year, EUR

- WC:

-

Wage Cost, EUR/h

- NWC:

-

Non-Wage Cost, EUR/h

- \({{\text{Y}}}_{{\text{i}},{\text{t}}}^{{\text{straw}}}\) :

-

Straw yield (By-product) in NUTS- 3 region per year, Mg/ha

- \({{\text{Y}}}_{{\text{i}},{\text{t}}}^{{\text{corn}}}\) :

-

Corn yield (Main product) in NUTS- 3 region per year, Mg/ha

- RtCg :

-

Residue-to-Crop relation, %

- Rtechi :

-

Technical removal rate, %

- BD:

-

Density of the straw bales, Mg/m3

- coll:

-

Collection effort

- trans:

-

Transport effort [to farm gate]

- fert:

-

Fertilizer effort

- t:

-

Year of interesst (2010–2020)

- i:

-

Single NUTS3 region (County)

- n:

-

Total amount of NUTS3 regions

- j:

-

Farm category (< 5 ha, 5-10 ha, 10-20 ha, 20-50 ha, 50-100 ha, 100-200 ha, > 200 ha)

- k:

-

Total amount of different farm categories

- g:

-

Fruit type of cereals (wheat, rye, oat, barley, triticale)

- m:

-

Total amount of different fruit types

References

Federal Ministry of Food and Agriculture (BMEL), Federal Ministry of Education and Research (BMBF): National Bioeconomy Strategy, Berlin. https://www.bmel.de/SharedDocs/Downloads/EN/Publications/national-bioeconomy-strategy.pdf?__blob=publicationFile&v=2 (2020). Accessed 7 March 2023

Fehrenbach, H., Giegrich, J., Köppen, S., Wern, B., Pertagnol, J., Baur, F., Hünecke, K., Dehoust, G., Bulach, W., Wiegmann, K.: BioRest: Verfügbarkeit und Nutzungsoptionen biogener Abfall- und Reststoffe im Energiesystem (Strom-, Wärme- und Verkehrssektor). (BioRest: Availability and utilisation options of biogenic waste and residues in the energy system (electricity, heat and transport sectors)). ifeu, IZES, Öko-Insitut, Dessau-Roßlau. https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2019-09-24_texte_115-2019_biorest.pdf (2018). Accessed 7 March 2023

DBFZ: Resource Database. webapp.dbfz.de. https://datalab.dbfz.de/home/?lang=en#Resource%20Database. Accessed 30 July 2021

Chaussinand, A., Scartezzini, J.L., Nik, V.: Straw bale: a waste from agriculture, a new construction material for sustainable buildings. Energy Procedia. (2015). https://doi.org/10.1016/j.egypro.2015.11.646

Meyer, A., Ehimen, E.A., Holm-Nielsen, J.B., Walker, P., Thomson, A., Maskell, D.: Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenerg. (2018). https://doi.org/10.1016/j.biombioe.2017.05.013

Schubert, T.: Production routes of advanced renewable C1 to C4 alcohols as biofuel components – a review. Biofuels Bioprod. Bioref. (2020). https://doi.org/10.1002/bbb.2109

Lepage, T., Kammoun, M., Schmetz, Q., Richel, A.: Biomass-to-hydrogen. A review of main routes production, processes evaluation and techno-economical assessment. Biomass Bioenerg. (2021). https://doi.org/10.1016/j.biombioe.2020.105920

Karras, T., Brosowski, A., Thrän, D.: A review on supply costs and prices of residual biomass in techno-economic models for Europe. Sustainability. (2022). https://doi.org/10.3390/su14127473

Pfeiffer, A., Mertens, A., Brosowski, A., Thrän, D.: Der Strohmarkt in Deutschland. Marktschreier 4.0. (The straw market in Germany). Deutsches Biomasseforschungszentrum (DBFZ), Leipzig (2019)

VERBIO Vereinigte BioEnergie AG: High-tech for the straw harvest. VERBIO deploys two new tractors and straw balers from New Holland [Press release]. (2021). https://www.verbio.de/en/press/news/press-releases/detail/hightech-fuer-die-strohernte-verbio-setzt-zwei-neue-traktoren-und-strohpressen-von-new-holland-ein/. Leipzig, Schwedt. Accessed 19 Jul 2022

Townsend, T.J., Sparkes, D.L., Ramsden, S.J., Glithero, N.J., Wilson, P.: Wheat straw availability for bioenergy in England. Energy Policy. (2018). https://doi.org/10.1016/j.enpol.2018.07.053

Zyadin, A., Natarajan, K., Igliński, B., Iglińska, A., Kaczmarek, A., Kajdanek, J., Pappinen, A., Pelkonen, P.: Farmers’ willingness to supply biomass for energy generation. Evidence from South and Central Poland. Biofuels. (2017). https://doi.org/10.1080/17597269.2016.1225647

Giannoccaro, G., de Gennaro, B.C., de Meo, E., Prosperi, M.: Assessing farmers’ willingness to supply biomass as energy feedstock: Cereal straw in Apulia (Italy). Energy Econ. (2017). https://doi.org/10.1016/j.eneco.2016.11.009

S2BIOM-Project: S2BIOM cost supply. (2016). https://s2biom.wenr.wur.nl/web/guest/data-downloads. Accessed 15 Nov 2022

Harms, R.: Strohpreis-rechner. Mindestpreisberechnung nach nährstoffkosten. (Straw price calculator - straw price calculator minimum price calculation according to nutrient costs). (2022). https://www.lwk-niedersachsen.de/lwk/news/39294_Strohpreis-Rechner. Accessed 9 Nov 2022

Brosowski, A., Bill, R., Thrän, D.: Temporal and spatial availability of cereal straw in Germany—Case study: Biomethane for the transport sector. Energ. Sustain. Soc. (2020). https://doi.org/10.1186/s13705-020-00274-1

Searle, S., Malins, C.: A reassessment of global bioenergy potential in 2050. GCB Bioenergy. (2015). https://doi.org/10.1111/gcbb.12141

Ruiz, P., Nijs, W., Tarvydas, D., Sgobbi, A., Zucker, A., Pilli, R., Jonsson, R., Camia, A., Thiel, C., Hoyer-Klick, C., Dalla Longa, F., Kober, T., Badger, J., Volker, P., Elbersen, B.S., Brosowski, A., Thrän, D.: ENSPRESO - an open, EU-28 wide, transparent and coherent database of wind, solar and biomass energy potentials. Energ. Strat. Rev. (2019). https://doi.org/10.1016/j.esr.2019.100379

Prussi, M., Panoutsou, C., Chiaramonti, D.: Assessment of the feedstock availability for covering EU alternative fuels demand. Appl. Sci. (2022). https://doi.org/10.3390/app12020740

Noordhof, J.: LU trend-report: pressen 2019. LOHNUNTERNEHMEN 06. (2019). https://lu-web.de/redaktion/news/trend-report-pressen/. Accessed 11 Nov 2022

Kuratorium für Technik und Bauwesen in der Landwirtschaft (KTBL): KTBL-Feldarbeitsrechner. (KTBL fieldwork calculator). https://daten.ktbl.de/feldarbeit/home.html (2021). Accessed 15 November 2021

Regionalstatistik: Landwirtschaftliche Betriebe und deren landwirtschaftlich genutzte Fläche (LF) nach Größenklassen der LF. Tabelle: 41141–05–01–4 - Agrarstrukturerhebung / Landwirtschaftszählung. (Agricultural holdings and their utilised agricultural area by size class). https://www.regionalstatistik.de/genesis/online?operation=find&suchanweisung_language=de&query=41141-05-01-4#abreadcrumb (2022). Accessed 4 July 2022

Naegeli de Torres, F., Karras, T., Semella, Sebastian: Modellierung von Zeitreihen regionaler landwirtschaftlicher Anbauflächen. (Modelling of time series of regional agricultural croplands). In: Das Leibniz-Institut für ökologische Raumentwicklung e. V. (ed.) Dresdner Flächennutzungssymposium (DFNS). (Dresden Land Use Symposium). Dresdner Flächennutzungssymposium (DFNS), Dresden, 14.06. - 15.06. (2022)

Regionalstatistik: Erträge ausgewählter landwirtschaftlicher Feldfrüchte - Jahressumme - regionale Tiefe: Kreise und krfr. Städte. Tabelle: 41241–01–03–4 -Erntestatistik. (Yields of selected agricultural crops - annual total - regional depth: counties and independent cities). https://www.regionalstatistik.de/genesis//online?operation=table&code=41241-01-03-4&bypass=true&levelindex=0&levelid=1668027998409#abreadcrumb (2022). Accessed 9 November 2022

Federal Ministry of Food and Agriculture (BMEL): Verordnung über die Anwendung von Düngemitteln, Bodenhilfsstoffen, Kultursubstraten und Pflanzenhilfsmitteln nach den Grundsätzen der guten fachlichen Praxis beim Düngen. Düngeverordnung - DüV (Fertiliser regulation) (2017)

Weiser, C., Zeller, V., Reinicke, F., Wagner, B., Majer, S., Vetter, A., Thraen, D.: Integrated assessment of sustainable cereal straw potential and different straw-based energy applications in Germany. Appl. Energy. (2014). https://doi.org/10.1016/j.apenergy.2013.07.016

Soyez, K., Reinhold, J.: Verwertung von Bioabfall - Recyclingpotenzial für die Humusreproduktion. Chem. Ing. Tec. (2012). https://doi.org/10.1002/cite.201100247

Björnsson, L., Prade, T.: Sustainable cereal straw management: Use as feedstock for emerging biobased industries or cropland soil incorporation? Waste Biomass Valor. (2021). https://doi.org/10.1007/s12649-021-01419-9

Marktinformation Ost (MIO): Preisverlauf für futtermittel. (Price trend for animal feed). (2023). https://www.lallf.de/oekologischer-landbau-handelsklassen-foerderung-mio/mio-marktinformation/mio-oeffentlicher-bereich/ [time series - personal request]. Mail recevied 3 Jan 2023

Landesbetrieb Landwirtschaft Hessen: heu & stroh - marktinformation & preise. (Hay & straw - market information & prices), Kassel. (2020). https://llh.hessen.de/unternehmen/marktinformation-und-preise/futtermittel/futtermittel-heu-stroh/ [time series - personal request]. Mail recevied 10 January 2020

Wang, R.Y., Strong, D.M.: Beyond accuracy: what data quality means to data consumers. J. Manag. Inf. Syst. 12, 5–33 (1996)

Weidema, P.B., Wesnaes, M.S.: Data quality management for life cycle inventories-an example of using data quality indicators. J. Clean. Prod. (1996). https://doi.org/10.1016/S0959-6526(96)00043-1

Edelen, A., Ingwersen, W.: Guidance on Data Quality Assessment for Life Cycle Inventory Data. Version 1. EPA/600/R-16/096. National Risk Management Research Laboratory, Cincinnati (2016)

Karras, T.: Straw supply costs for Germany – NUTS3 | 2010-2020 | farm-side. Version 1.0. Data set (2023). https://doi.org/10.5281/zenodo.8145082

Federal Statistical Office (Destatis): Anwenderdokumentation „Webservice/API“. Version 4.3. (User documentation "Webservice/API), Wiesbaden. https://www-genesis.destatis.de/genesis/misc/GENESIS-Webservices_Einfuehrung.pdf (2021). Accessed 15 November 2022

Federal Statistical Office (Destatis): Agricultural holdings, utilised agricultural area: Germany, years, types of land use. GENESIS-Tabelle: 41271–0003. Land use survey. https://www-genesis.destatis.de/genesis//online?operation=table&code=41271-0003&bypass=true&levelindex=0&levelid=1689626668678#abreadcrumb (2023). Accessed 17 July 2023

Krause, T., Mantau, U., Mahro, B., Noke, A., Richter, F., Raussen, T., Bischof, R., Hering, T., Thrän, D., Brosowski, A.: Nationales Monitoring biogener Reststoffe, Nebenprodukte und Abfälle in Deutschland. Teil 1 : Basisdaten zu Biomassepotenzialen. (National monitoring of biogenic residues, by-products and waste in Germany Part 1 : Basic data on biomass potentials). https://www.openagrar.de/receive/openagrar_mods_00065538 (2020). Accessed 9 November 2022

Deutscher Wetterdienst (DWD): German Climate Atlas - year 2012. https://www.dwd.de/EN/climate_environment/climateatlas/climateatlas_node.html (2023). Accessed 3 March 2023

Brosowski, A., Bill, R., Thrän, D.: Temporal and spatial availability of cereal straw in Germany—Case study. Biomethane for the transport sector. Energ. Sustain. Soc. (2020). https://doi.org/10.1186/s13705-020-00274-1

Smerald, A., Rahimi, J., Scheer, C.: A global dataset for the production and usage of cereal residues in the period 1997–2021. Sci. Data. (2023). https://doi.org/10.1038/s41597-023-02587-0

Helliwell, R., Seymour, S., Wilson, P.: Neglected intermediaries in bioenergy straw supply chains: Understanding the roles of merchants, contractors and agronomists in England. Energy Res. Soc. Sci. (2020). https://doi.org/10.1016/j.erss.2019.101387

Federal Statistical Office (Destatis): Agricultural holdings, utilised agricultural area: Länder, years, types of land use, size classes of the utilised agricultural area. GENESIS-Tabelle: 41271–0013. Land use survey. https://www-genesis.destatis.de/genesis//online?operation=table&code=41271-0013&bypass=true&levelindex=0&levelid=1668027437727#abreadcrumb (2022). Accessed 9 November 2022

Federal Statistical Office (Destatis): Gross hourly earnings in agriculture: Germany, reference month (until 09/2010), selected activities in agriculture, groups of farm labour, sex. GENESIS-Tabelle: 62311–0001. Survey of earnings in agriculture. https://www-genesis.destatis.de/genesis//online?operation=table&code=62311-0001&bypass=true&levelindex=0&levelid=1668028131211#abreadcrumb (2022). Accessed 9 November 2022

Regionalstatistik: Lohn- und Einkommensteuerpflichtige, Gesamtbetrag der Einkünfte, Lohn- und Einkommensteuer - Jahressumme - regionale Tiefe: Kreise und krfr. Städte. Tabelle: 73111–01–01–4 - Lohn- und Einkommensteuerstatistik. (Wage and income taxpayers, total amount of income, wage and income tax - annual total - regional depth: counties and independet cities). https://www.regionalstatistik.de/genesis//online?operation=table&code=73111-01-01-4&bypass=true&levelindex=0&levelid=1689280942319#abreadcrumb (2022). Accessed 11 November 2022

Landwirtschaftskammer Niedersachsen: Leitfaden zur Verdienst- bzw. Arbeitskostenermittlung in der Landwirtschaft und im Gartenbau. (Guide to determining earnings or labour costs in agriculture and horticulture). Fachbereich 3.4, Oldenburg. https://www.lwk-niedersachsen.de/lwk/news/38236_Das_kostet_eine_Arbeitskraft_in_Landwirtschaft_und_Gartenbau (2021). Accessed 09.11.

Federal Statistical Office (Destatis): Consumer price index: Germany, years. GENESIS-Tabelle: 61111–0001. https://www-genesis.destatis.de/genesis//online?operation=table&code=61111-0001&bypass=true&levelindex=0&levelid=1668028329041#abreadcrumb (2022). Accessed 9 November 2022

Federal Statistical Office (Destatis): Preise - Erzeugerpreise gewerblicher Produkte (Inlandsabsatz) Preise für leichtes Heizöl, Motorenbenzin und Dieselkraftstoff. Diesel Großverbraucher. (Prices - Producer prices of industrial products (domestic sales) Prices for light heating oil, motor gasoline and diesel fuel- Diesel bulk consumer). https://www.destatis.de/DE/Themen/Wirtschaft/Preise/Erzeugerpreisindex-gewerbliche-Produkte/Publikationen/Downloads-Erzeugerpreise/erzeugerpreise-preisreihe-heizoel-pdf-5612402.html (2022). Accessed 9 November 2022

Renke Harms: Strohpreis-Rechner. (Strawprice calculator). Landwirtschaftskammer Niedersachsen, Oldenburg (2022)

Kuratorium für Technik und Bauwesen in der Landwirtschaft (KTBL): Faustzahlen für die Landwirtschaft. (Agriculture key figures), 15th edn. Kuratorium für Technik und Bauwesen in der Landwirtschaft(KTBL), Darmstadt (2018)

INDEX Mundi: DAP fertilizer Monthly Price - US Dollars per Metric Ton. 15 years. https://www.indexmundi.com/commodities/?commodity=dap-fertilizer&months=180 (2022). Accessed 9 November 2022

INDEX Mundi: Potassium-Chloride fertilizer Monthly Price - US Dollars per Metric Ton. 15 years. https://www.indexmundi.com/commodities/?commodity=potassium-chloride&months=180 (2022). Accessed 9 November 2022

INDEX Mundi: Urea fertilizer Monthly Price - US Dollars per Metric Ton. 15 years. https://www.indexmundi.com/commodities/?commodity=urea&months=180 (2022). Accessed 9 November 2022

Deutsche Bundesbank: Euro foreign exchange reference rate of the ECB / EUR 1 = USD … / United States. Euro foreign exchange reference rates published by the European Central Bank. Monthly average. https://www.bundesbank.de/dynamic/action/en/statistics/time-series-databases/time-series-databases/745582/745582?listId=www_sdks_b01012_2&tsId=BBEX3.M.USD.EUR.BB.AC.A02&dateSelect=2023 (2022). Accessed 19 July 2023

Bickhardt, T.: Hinweise zu Getreidestroh und Nährstoffwert. (Notes on cereal straw and nutritional value). https://llh.hessen.de/unternehmen/unternehmensfuehrung/analyse-strategie-und-finanzen/hinweise-zu-getreidestroh-und-naehrstoffwert/ (2017). Accessed 9 November 2022

Glithero, N.J., Ramsden, S.J., Wilson, P.: Barriers and incentives to the production of bioethanol from cereal straw: A farm business perspective. Energy Policy. (2013). https://doi.org/10.1016/j.enpol.2013.03.003

Funding

Open Access funding enabled and organized by Projekt DEAL. This study was funded by DBFZ—Deutsches Biomasseforschungszentrum gGmbH.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Tom Karras. The first draft of the manuscript was written by Tom Karras and reviewed and edited by Daniela Thrän. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare no relevant financial or non-financial conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of Novelty

We provide an activity-based costing calculation from the farmer's perspective of straw supply considering regional and temporal aspects for Germany within one model. The model approach can be used to integrate scenario-based assumptions to derive future supply costs.

Highlights

• Straw supply costs from the framer’s activity-based perspective

• Cost model on regional resolution and temporal development

• Data quality assessment of input data used for the model

Annex 1 – Sensitivity Analysis

Annex 1 – Sensitivity Analysis

Table A1

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Karras, T., Thrän, D. The Costs of Straw in Germany: Development of Regional Straw Supply Costs between 2010 and 2020. Waste Biomass Valor (2024). https://doi.org/10.1007/s12649-024-02528-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12649-024-02528-x