Abstract

This works aims to evaluate a process to convert residual medical Cannabis sativa stalks into medium chain length polyhydroxyalkanoate (mcl-PHA), using chemical pretreatment and enzymatic hydrolysis to obtain sugars as a carbon source for a fermentation process with Pseudomonas aeruginosa. Chemical composition analysis revealed a content of structural polysaccharides of 57.64%. Thermochemical pretreatments with 2% sulfuric acid or 2% sodium hydroxide were capable of partially removing hemicellulose and lignin, as well as increasing cellulose crystallinity. Pretreated biomass was subjected to hydrolysis using commercial cellulase cocktails Celluclast® 1.5 L and Cellic® CTec3. Acid pretreatment showed an adverse effect on hydrolysis yield of holocellulose, decreasing to 39.5%; compared to 44.4% of untreated biomass. Alkaline pretreatment increased degree of hydrolysis up to 73.3%. Shake flask fermentation of hydrolysate with Pseudomonas aeruginosa produced cell growth of 1.65 g/L and a mcl-PHA titer of 0.41 g/L. Extracted polymer presented characteristic FTIR bands for PHAs, glass transition temperature of − 50.8 °C, melting temperature of 48.9 °C, possibly allowing its use in the biomedical industry. The developed process represents a potential way to valorize Cannabis waste stalks, using alkaline pretreatment, enzymatic hydrolysis with Celluclast® 1.5 L and fermentation with Pseudomonas aeruginosa. Further work should focus on improving yield of the obtained polyhydroxyalkanoate in fermentation, in order to improve industrial feasibility of the entire process and, in turn, increasing revenue of the medical Cannabis industry.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of novelty

Our research presents a novel approach by exploring the utilization of waste Cannabis stalks, an underutilized biomass, as a feedstock for the production of medium-chain-length polyhydroxyalkanoates (mcl-PHAs). Notably, this study marks the first attempt to valorize the polysaccharides from Cannabis biomass in Colombia, irrespective of the cultivar. By addressing the environmental ramifications of neglected waste management practices, our findings not only contribute to mitigating ecological damage but also offer a sustainable solution for the burgeoning Cannabis industry. This innovative research opens new avenues for waste valorization, environmental sustainability, and economic growth in Colombia's agricultural sector.

Introduction

Cannabis sativa L. is an annual C3 herbaceous and dicotylenodous angiosperm plant. It can be classified in two distinct groups. Marijuana, which is mainly used recreationally due to its intoxicating properties; but may have medicinal properties, and hemp, important for its medicinal value, fiber and seed, which are used in several products [1]. This plant presents different important molecules for research like cannabinoids, terpenoids, nitrogenous compounds, non-cannabinoid phenols, flavonoids and steroids. There are more than 125 individual cannabinoids with the majority being Δ9-tetrahydrocannabinol (THC) and cannabidiolic acid (CBDA), mainly present in the female cannabis flower [2]. Active components in Cannabis sativa mimic the effects of endocannabinoids, such as anandamide (ANA) and 2-arachidonoylglycerol (2-AG), activating cannabinoid receptors CB1 and CB2, potentially having activity as analgesic, neuroprotective, antiemetic, anticonvulsant, anti-inflammatory and antispasmodic. Therapeutic potential has been shown in cancer, epilepsy, sclerosis, neuropathic and chronic pain, spinal cord injury, Parkinson’s and Alzheimer’s diseases, post-traumatic stress disorder and anxiety, schizophrenia and pulmonary disease [3].

Thanks to these therapeutic properties, global Cannabis market increased in value from USD 8.28 billion in 2017 to around USD 9 billion in 2020, and it is projected to reach a value of nearly USD 50 billion by 2028. The South American Cannabis market could increase from USD 125 million in 2018 to USD 776 million by 2027 [3]. In Colombia, medical Cannabis industry has also been thriving, and it is expected that by 2030, 1558 hectares will be dedicated to the cultivation of Cannabis [4]. For medical purposes, only the flowers and leaves of the Cannabis plant are used for the extraction of cannabidiol (CBD) oil. The remaining biomass, including the stalks, fibers and shives, represent around 70% of the plant’s dried weight [5]. For instance, a 500 m2 (or 0.05 ha), with 10 plants/m2 in average, producing six crop cycles per year, would produce 2250 kg of waste biomass [2]. Even when it is source of cellulose and biomaterials, a big portion of this biomass ends up as a low-value residue [6], which is usually discarded or burned, and is not only wasteful but also polluting, producing large amounts of carbon dioxide, nitrogen oxides, hydrogen sulfides, soot, among others [7].

Industrial hemp is considered an excellent source of fermentable sugars, for its conversion into bioproducts. Like other lignocellulosic biomass, because of its recalcitrance, it needs to undergo a pretreatment step, which can be chemical, mechanical, thermal, biological, among others. This is done in order to remove hemicellulose and/or lignin, improving cellulose accessibility without formation of inhibitory compounds such as hydroxymethylfurfural (HMF) and furfural [8]. Dilute acid pretreatment is characterized by its simplicity and low cost, while alkali pretreatment is beneficial for preventing sugar degradation. For these reasons, alkali and acid pretreatment are amongst the most common pretreatment methods for lignocellulosic biomass [9]. Following pretreatment, enzymatic hydrolysis with cellulases is performed, converting polysaccharides into free sugars which can be used as feedstock for fermentation [10]. Extensive research has been made on the transformation of Cannabis polysaccharides into value added products, including biological conversions into bioethanol [11], biogas [12], succinic acid [13, 14], lactic acid [15] and polyhydroxybutyrate [16]; as well as chemical conversions into furfural [17], levoglucosan and levoglucosenone [18].

One possible product of biological conversion is polyhydroxyalkanoate (PHA); a class biodegradable polyesters synthetized as energy storage by microorganisms, especially bacteria; on conditions of a limited essential nutrient such as nitrogen, phosphorus or oxygen [19]. Medium chain length polyhydroxyalkanoates (mcl-PHAs) are soft and elastomeric [20], which make them suitable for applications such as the construction of scaffolds for tissue engineering, drug delivery, adhesives for medical applications, packaging and films [21]. So far, PHA production has relied on first generation feedstocks, such as whey, molasses, sugarcane, sweetcorn and vegetable oils; which raises food prices when they are used in the polymer industry [22], while also being highly expensive [23]. mcl-PHAs are mainly synthetized by Pseudomonas species using two metabolic pathways. The first one consists on the β-oxidation of aliphatic carbon sources such as fatty acids, and the second one implicates the de novo synthesis of fatty acids from unrelated sources such as glucose, gluconate and ethanol [24]. These pathways can be used to find alternative and cheap substrates for PHA production that don’t compete with human food [20] and improve the sustainability and economic feasibility of the production process [25].

In this study, a process for the conversion of residual stalks from a medical Cannabis cultivar into mcl-PHA is evaluated. For this purpose, the stalks were subjected to acid and alkaline pretreatment, analyzing the changes that occur in biomass. Pretreated biomass was enzymatically hydrolyzed with different conditions to achieve a high concentration of reducing sugars. This hydrolysate was finally used as a substrate for Pseudomonas aeruginosa in a batch fermentation process for the production of mcl-PHA. The product was characterized for functional groups and using thermal methods.

Materials and methods

Reagents and Bacterial Strain

Cellic® CTec3 (Novozymes) was donated by Universidad Nacional and Celluclast® 1.5 L (Novozymes) was obtained from Univar Solutions. Enzymatic activity was determined to be 223 FPU/mL and 67 FPU/mL, respectively [26]. Pseudomonas aeruginosa ATCC9027 was obtained from the Laboratory of Microbiology and Parasitology of Universidad del Cauca. The strain was conserved in a stock solution of 30% glycerol at -20 °C. Residual Cannabis sativa stalks, were supplied by Corporación Flora Vital SAS Zomac (Cauca, Colombia). Stalks were dried in an oven at 60 °C for 6 days, milled and sieved through 1 mm. Solid reagents were purchased from Carlo Erba and solvents were purchased from Sigma Aldrich.

Characterization of Biomass

Determination of total solids, ash and extractive was achieved following methodology of the National Renewable Energy Laboratory [27,28,29]. Structural components were determined according to Van Soest detergent methodology [30]. Nitrogen content was determined using a standardized Kjeldahl methodology using a protein conversion factor of 6.25 [31, 32].

Thermochemical Pretreatments

Biomass was pretreated with either 2% w/v sodium hydroxide (NaOH) or 2% v/v sulfuric acid (H2SO4) solution. 5% solids suspension of the biomass were prepared and taken into an autoclave at 121 °C and 15 psi for 30 min. Later, solids were extensively washed with distilled water until wash water resulted on neutral pH. Solids were then dried at 105 °C for 12 h, they were then taken into a desiccator and weighted to determined recovered solids.

Combined severity factor (CSF) of acid pretreatment was calculated following Eq. 1 [33] and Eq. 2 for alkaline pretreatment [34]. Where t is pretreatment time (min), T is pretreatment temperature (°C), pH is measured pH of pretreatment slurry before pretreatment and COH- is the concentration hydroxyl ions (mol/L).

Pretreated samples were investigated using Fourier Transform Infrared Spectroscopy with attenuated total reflectance (FTIR-ATR) (Thermo Fisher Scientific Nicolet™ iS™ 10 FTIR Spectrometer). Spectra were taken between 4000 cm−1and 500 cm−1, 8 cm−1 resolution and 32 scans. Each spectrum was taken by triplicate, normalized, averaged and baseline corrected. Spectra were then used to determine changes in crystallinity as Lateral Order Index (LOI), according to Eq. 3, where A1430 is the absorbance 1420 cm−1 y A898 is the absorbance at 896 cm−1 [35]. Pretreated biomass was also analyzed for its content in cellulose, hemicellulose and lignin, using detergent methodology as described before, in order to determine their recovery in relation to untreated biomass.

Enzymatic Hydrolysis

For enzymatic hydrolysis studies, 5% w/v suspensions of either untreated or pretreated biomass were prepared in pH 5.0, 50 mM citrate buffer, enzymatic loading was initially 20 FPU/g biomass of either Celluclast 1.5 L or Cellic CTec3 (from now on enzymes A and B, respectively). Reactions were performed in reflux conditions at 50 °C, 75 rpm, for 72 h. Sample aliquots of 1 mL were taken at 4, 8, 12, 24, 36, 48, 60 and 72 h. These samples were centrifuged and stored at 8 °C until reducing sugars analysis. Determination of reducing sugars was performed spectrophotometrically [36]. Additional experiments were performed using mixtures of 10 FPU/g of each enzyme used. Sequential two-step hydrolysis experiments consisted in 36 h long hydrolysis with 10 FPU/g of one enzyme, solid separation and resuspension in 10 FPU/g of the other enzyme. Hydrolysis yield was calculated according to Eq. 4.

PHA Production

P. aeruginosa strain was first scanned for its ability to produce PHA in Agar Plate Count (APC) medium supplemented with 15 g/L glucose and 0.1% Nile Red staining (0.1% in acetone). PHA production was observed as brown spots against bright green in a negative control. A two-step preculture was used to adapt bacteria to the used media as follows. From nutrient agar cultures, a single colony was transferred into 10 mL MSM media with a composition described in literature [37], with 0.75 g/L ammonium chloride (NH4Cl) instead of ammonium sulphate and 15 g/L of either glucose (model substrate) or diluted hydrolysate as a carbon source for a C/N mass ratio of 20, and incubated for 24 h. Subsequently, 1 mL of this culture was transferred into another 10 mL MSM media and incubated for 18 h [38]. This culture was used as a 1% v/v inoculum for 250 mL shake flask with 200 mL MSM media, which was incubated at 30 °C and 200 rpm for 72 h in an orbital shaker [39]. Cell growth was quantified with 10 mL aliquots, cell pellets were centrifuged at 3600 rpm for 20 min and drying at 80 °C for 12 h while liquid was used to quantify reducing sugars as described before.

Extraction and Purification of PHA

PHA production was quantified gravimetrically at 24, 48 and 72 h of fermentation. Cell pellets were first extracted with methanol for 1 h; then, cells were separated by filtration and subjected to 10 cycles of Soxhlet extraction with chloroform. Extract was concentrated using rotatory evaporation and was then added into 10 mL of chilled ethanol, which caused precipitation of the product and allowed its separation by centrifugation [40]. The product was air dried and stored at 8 °C until its characterization. For purification, PHA was redissolved in chloroform and precipitated using chilled ethanol as described before.

Analysis of Product

Extracted product was characterized using thermal methods and FTIR-ATR using the same conditions previously described for biomass analysis [41]. Differential scanning calorimetry (DSC) was performed. Sample was first heated from 25 °C up to 180 °C with a ramp of 5 °C/min to erase thermal history of the polymer. It was then cooled down to -60 °C and heated again to 180 °C with a 10 °C/min ramp. Resulting thermogram was used to determine the glass transition temperature (Tg) and the melting temperature (Tm) [41].

Data Analysis

All experiments were performed in triplicate, data was analyzed using Microsoft Excel 365 and Minitab 1919. Statistical difference was determined by Fisher comparison tests with α = 0.05 or in the case of pairwise comparison, Student’s t test was performed, again with α = 0.05.

Results and Discussion

Characterization of Biomass

Determined chemical composition of the examined Cannabis stalk can be found in Table 1, along with a comparison to other studies. Holocellulose (cellulose + hemicellulose) comprise 57.7% of dry weight, meaning that over half of total biomass can be potentially exploited for the production of sugars. These values are very similar to other reports [32, 42], but low in comparison to reports of 70.2% [5] and 67.4% [16]. Lignin content is relatively low, compared to studies on industrial hemp which report more than 20% [43, 44]. This low lignin content is beneficial for latter hydrolysis. Many factors could be influencing the chemical composition of Cannabis biomass, including cultivar [8]; fertilization regime, which affects cellulose and hemicellulose content [45]; and plant maturity, which increases lignin deposition [46]. High extractive content is also remarkable, it is likely due to the strictly medical purpose of the used hemp, which means a particularly high content of oils and proteins.

Effect of Pretreatments

Both pretreatments had a quantifiable effect on biomass composition, acid pretreatment was capable of removing a big portion of hemicellulose and a fraction of lignin, but around 20% of initial cellulose was removed as well. Alkaline pretreatment mostly removed lignin and a small fraction of hemicellulose. Remarkably, alkaline pretreatment retained cellulose almost in its totality. This is consistent with what is expected from literature, with H2SO4 damaging lignin structure and dissolving hemicellulose and NaOH hydrolyzing and dissolving lignin [47]; the former can be observed in Table 2.

Changes in biomass were analyzed by FTIR too, obtained spectra are showed in Fig. 1. Important changes in band intensity are those ocurring at 1734 cm−1, a band which is reduced or dissapears with acid and alkaline pretreatment respectively, and is related to carbonyl bond elongation in hemicellulose and lignin. The band at 1597 cm−1 is characteristic of C = C bond elongation and the band at 1240 cm−1 is related to the bending of C-OH bonds in lignin and hemicellulose [48] and the reduction in their intensity indicates their removal with pretreatment. An increase in the 3340 cm−1 band was observed with acid pretreatment, which has been asociated with an increase in cellulose proportion [48]. On the contrary, there is a reduction in the intensity of this band with alkaline pretreatment, an indicative of a reduction in hydrogen bonding, which could be caused by a process called mercerization, meaning, the conversion of type I cellulose into type II cellulose [49].

LOI of untreated biomass was determined to be 0.93 and it increased to 1.26 with acid pretreatment and to 1.20 with alkaline pretreatment. This increase in crystallinity has been observed in other works with hemp biomass [48, 50, 51]. Pretreatments increase LOI by partially removing amorphous hemicellulose, lignin and cellulose, as well as the causing recrystallization of para-crystalline and amorphous cellulose after water penetration [50, 52]. Unlike results from existing studies [48, 50], acid pretreatment did not cause a bigger increase crystallinity than alkaline pretreatment did. This could be due to high solid removal with acid pretreatment, which is a result of treatment severity [53], namely, high temperature, acid concentration and/or time.

Enzymatic Hydrolysis

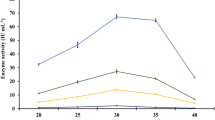

Figure 2 shows the kinetics of enzymatic hydrolysis along 72 h. Untreated and acid pretreated biomass reached 90% of the final hydrolysis yield by 36 h, while alkaline pretreated biomass took 60 h to reach this value. Using different times of pretreatment on hemp biomass, much shorter times have been shown to be necessary to reach this high degree of hydrolysis, like 12 h [14, 53] or 24 h [13]. This could indicate that pretreatment can be improved, in order to speed up hydrolysis. Acid pretreatment resulted in a higher concentration of reducing sugars over untreated biomass: 10.7 mg/mL and 8.2 mg/mL at 72 h, respectively for enzyme A and 14.1 mg/mL and 11.5 mg/mL for enzyme B. However, it had a negative effect on hydrolysis yield, due to higher initial holocellulose content in acid pretreated biomass. The observed reduction on hydrolysis yield was from 31.5% in untreated biomass to 29.8% (enzyme A) and from 44.4 to 39.5% (enzyme B). This effect is something no other previous study has reported. Existing literature has found H2SO4 pretreatment to be highly effective for increasing hydrolysis yield. For instance, pretreatment with 1% H2SO4, for 30 min at 160 °C, allowed to achieve 98.7% cellulose hydrolysis [44] and pretreatment with 2% H2SO4, for 10 min at 180 °C resulted in 64.0% glucose yield [48].

Acid pretreatment CSF was 1.66, a value lower than the optimal CSF for acid pretreatments determined in literature. It has been found that increasing CSF from 1.35 to 2.06 causes an increase glucan saccharification yield up to 68% [54]. Similarly, another study found that 2.17 is the optimal CSF value to achieve maximal fermentable sugar production, from a variety of hemp cultivars [33]. The higher values in these references could indicate that the reason for the negative effect of acid pretreatment is due to insufficient severity, which could result only partial disruption of lignin without really eliminating it, in turn, causing recondensation of lignin and its absorption with cellulose to occur [48], as well as the formation of pseudo-lignin; two processes that are known to occur with dilute acid pretreatments and that have a negative effect on cellulase activity [55, 56]. These phenomena, added to the increase in crystallinity, contribute to the decrease on hydrolysis yield with acid pretreatment. This is supported by the fact that alkaline pretreatment presented a similar CSF value of 1.80, but it did succeed on improving enzymatic hydrolysis, which is explained by its effectiveness with partial removal of lignin, avoiding its non-productive binding to cellulases [57].

Alkaline pretreatment caused a 2.3-fold increase in hydrolysis yield with enzyme A and a 1.4-fold increase with enzyme B. The effectiveness of this type of pretreatment has been proven before on hemp biomass. Gunnarson et al., (2015) found that pretreatment with NaOH at 121 °C and enzymatic hydrolysis, glucan conversion efficiency of 68,4% was achieved [14]. However, better efficiencies like 99.5% [48] and 96.3% [44] have been reported; an indication that pretreatment can still be improved.

Seeing how alkaline pretreatment was most effective, it was selected to run additional testing. First, the effect of mixing both enzymes on equal concentration can be seen in Table 3. It was expected that accessory enzymes in each cocktail would cause a synergistic action on the different biomass components, allowing to reach a higher degree of hydrolysis; however, none of these additional experiments caused a significant difference on hydrolysis yield to when enzyme A alone is used. Sequential experiments also allowed to test the effect of product inhibition on cellulase activity. It was previously determined that separation and resuspension of biomass in new enzyme solution is an effective method to increase sugar production from 40 g/L to 46 g/L (from hemp hurd), by means of preventing enzymatic feedback inhibition [16]. In this study, this approach did not cause significant changes on hydrolysis yield, meaning that this process is not limited by inhibition of enzyme activity. Instead, this limit is caused by a lack of biomass digestibility due to remaining hemicellulose and/or lignin, preventing enzyme access to cellulose [58]. The observed increase in crystallinity is also likely to play a role limiting hydrolysis.

As it can be seen in Fig. 3, hydrolysis yield variers linearly when enzyme concentration is increased with from 10 FPU/g to 20 FPU/g. Further increasing enzyme loading to 25 FPU/g did not improve hydrolysis yield; reinforcing the idea that biomass digestibility should be improved. When varying solid loading, hydrolysis yield experiences no significant changes from 2.5 to 10.0%. However, at 15% loading, a significant reduction in hydrolysis yield is observed, which could be due to limited mass transfer and inefficient mixing caused by the high solid content [59].

Fermentation

Alkaline Cannabis hydrolysate was tested as a carbon source for the growth of P. aeruginosa. Figure 4 shows cell growth and carbon source consumption on fermentations. Cultures took 24 h to reach stationary growth phase and no lag phase was observed neither with model substrate or hydrolysate, which likely indicates that the used two-step preculture method used was successful in allowing cells to adapt to culture media. Higher CDW was evident all along the 72 h of fermentation with glucose, reaching a final value of 1.65 g/L; while fermentation using hydrolysate reached CDW of 1.75 g/L, which represented no statistically significant difference. This corresponds to a yield of 0.14 g of biomass/g consumed sugars, for both fermentations, meaning that biomass grew with similar efficiency from either carbon source.

Sugars consumption in both fermentations was similar, they were consumed rapidly at first, then slowed down after 12 h and were not fully consumed, reaching final concentrations of 3.02 g/L and 2.63 g/L using hydrolysate and glucose respectively. PHA production was detected at 24 h and continued to increase until the end of fermentation (Fig. 5) where 0.41 g/L of PHA could be extracted. This is in accordance to Rosas-Rojas, et al., (2007), who determined that Pseudomonas aeruginosa ATCC9027 accumulates PHA in early exponential phase [60]. Surprisingly, PHA production with glucose as a substrate was lower than with hydrolysate, reaching 0.32 g/L and 0.41 g/L (which corresponds to yields of 0.035 and 0.026 g PHA/g sugar), respectively. Hossain, et al., (2022), have determined higher accumulation of PHA using lignocellulose hydrolysate (0.47 g/L and 0.61 g/L) over glucose (0.61 g/L) [61]. Authors attribute this to the presence of toxins and/or inhibitors such as extractives, pectin and oligosaccharides, which cause physiological stress, repress growth and enhance accumulation of PHA. This is a possible explanation for the higher production of PHA also found in this work, given that although PHA is mainly synthetized as a strategy for energy and carbon reserve [62], it serves other functions, such as protection against exogenous stress factors [63]. Nevertheless, the presence of these inhibitors was not determined in this study and the cause for this increase in mcl-PHA production should be investigated, as it is important for its replication and application in biorefinery processes of lignocellulosic materials.

Table4 shows a comparison of results obtained by different authors on the production of mcl-PHA using lignocellulosic biomass as a carbon source. mcl-PHA production in this work is comparable to some of these reports [39, 64]; but others result in a mcl-PHA production over 3 times fold [65,66,67]. What these studies have in common is the successful incorporation of the liquid fraction of the NaOH pretreatment of biomass into the fermentation broth (consisting of low molecular weight lignin and lignin aromatics), either alone or in addition to the sugar fraction, using different strategies in order to avoid inhibition. This could represent a viable alternative to be used for increasing PHA production).

Mass Balance

Figure 6 shows the mass balance of the complete process for the upcycling of residual Cannabis stalks into mcl-PHA. Pretreatment and enzymatic hydrolysis steps are effective in the conservation of sugars from biomass. Fermentation step and extraction of polymer represent the biggest lost in mass yield, and this is the step that should be targeted the most in order to improve the viability of the process. To achieve this, the use of all fractions of the biomass is important and different approaches can be used for it. On one hand, genetic engineering is a valuable tool to design strains capable of metabolizing different components of lignocellulose, like it has been done with Pseudomonas putida engineered to catabolize glucose, xylose, arabinose, p-coumaric acid and acetic acid [68]. A series of modifications to improve incorporation of p-coumaric acid into mcl-PHA in P. putida caused a 200% increase in mcl-PHA titer [69]. Similarly, microbe consortia of engineered E. coli and P. putida have been used effectively for metabolizing both glucose and xylose, the most abundant sugars in lignocellulosic biomass [70, 71]. Alternatively to genetic engineering tools, an adaptation approach to toxic media with wild type P. putida, have also been shown to be effective for the production of mcl-PHA, causing the microorganism to prepare by synthesizing enzymes, switching metabolic pathways and building up biomass [67]. Finally, coproduction of another valuable bioproduct can improve the economy of the process. For the case of P. aeruginosa, rhamnolipids are an important coproduct of fermentation along with PHA and its extraction and purification has been researched and reviewed before [72]. All of these strategies should be considered as options when trying to improve the viability of the fermentation process.

It is also important to note that the chloroform extraction method was only used in this study for its technical performance. Realistically, it cannot be employed industrially given concerns regarding human and environmental toxicity [73]. Downstream processing of PHA containing cells has been extensively reviewed [74,75,76] and regarding economic performance and sustainability, some methods are highlighted, including extraction with green solvents like dimethyl carbonate (DMC) and methylene carbonate, and mechanical extraction, like high pressure homogenization. These methods need to be applied to this biomass, looking for similar performance to the benchmark method of chloroform extraction.

Product Characterization

Identity of the extracted product was confirmed to be PHA by means of FTIR. Relevant bands were found at 2959 cm−1, 2921 and 2851 cm−1; characteristic of asymmetrical elongations of methyl (CH3) and methylene (CH2) groups and symmetrical elongations of CH2 groups, in that order. A band at 1731 cm−1, indicative of PHA presence, corresponds to carbonyl (C = O) bond elongation on ester groups. Bands on 1644 and 1731 cm−1 are related to amide bonds (-CO-N) from bacterial proteins remaining in the polymer [77]. This was confirmed after purification of PHA was performed, which caused a reduction in the absorbance of both amide bands in relation to the ester carbonyl group band, as can be observed in Fig. 7. Also, ester carbonyl is also displaced to a lower wavenumber (1728 cm−1) after purification, indicating higher crystallinity of the polymer [78].

Another typical PHA band was found at 1375 cm−1 and is related to bending of terminal CH3 groups. Bands at 1259 and 1162 cm−1 relate to elongation of C-O-C and C-O groups, respectively. Finally, bands from 1037 cm−1 to 699 cm−1 correspond to elongation of C-O and C-C bonds in the amorphous phase of the polymer [79, 80]. Data from these FTIR spectra allow for correct identification of the obtained product as PHA.

DSC analysis revealed that the produced polymer presents a glass transition temperature (Tg) of -50.8 °C and a melting temperature (Tm) of 48.9 °C. PHA produced by Rosas-Rojas et al., (2007) [60] using Pseudomonas aeruginosa ATCC9027 (the exact same strain as in this work) presented a lower Tg -56.5 °C and a higher Tm of 73.0 °C [60]; suggesting that carbon source plays a significant role in the thermal properties of the polymer produced by this strain. Determined thermal properties resemble those of PHA produced by P. putida grown on lauric acid (Tg = -44 °C and Tm = 53.0 °C) [81] or γ-butyrolactone (Tg = -45.7 °C and Tm = 50.1 °C) [82]. This could be an indicator of the molecular structure of the obtained PHA. In terms of common use polymers, polyethylenglycol (PEG) presents similar thermal properties: Tg = -66,0 °C; Tm = 66,0 °C [83]; and so does polycaprolactone (PCL): Tg = -60,0 °C; Tm = 60,0 °C [84]. These two polymers are commonly used in the biomedical industry, meaning that the properties of the produced polymer could be modified so that it can be used too.

Conclusion

A process for the conversion of residual Cannabis stalks into mcl-PHA was developed. Starting biomass contained over half its dry weight as structural polysaccharides. Acid pretreatment had a detrimental effect on hydrolysis yield, which was likely a due to low pretreatment severity. On the other hand, alkaline pretreatment allowed to reach a high degree of hydrolysis (73.3%), proving to be a better option for further optimization. Celluclast 1.5 L proved to be a better alternative to Cellic CTec3, releasing a higher amount of reducing sugars. Fermentation process represented the biggest loss in mass conversion, producing a mcl-PHA titer of 0.41 g/L (13 g of polymer for every 469 g of reducing sugars in solution). We suggest that the incorporation of lignin resulting from alkaline pretreatment into the fermentation broth can result in a substantial increase in mcl-PHA production, taking appropriate measures to avoid growth and PHA production inhibition. The determined characteristics of the extracted polymer suggest that it could be employed in medical industry.

Data Availability

We confirm that all relevant data is provided within the article. If any additional information is required, please contact the corresponding author.

References

Rehman, M., et al.: Evaluation of hemp (Cannabis sativa L.) as an industrial crop: A review. Environ. Sci. Pollut Res. 28, 52832–52843 (2021). https://doi.org/10.1007/s11356-021-16264-5

Robertson, K.J., Brar, R., Randhawa, P., Stark, C., Baroutian, S.: Opportunities and challenges in waste management within the medicinal cannabis sector. Ind. Crops Prod. 197, 116639 (2023). https://doi.org/10.1016/j.indcrop.2023.116639

Suárez-Jacobo, Á., Díaz Pachecho, A., Bonales-Alatorre, E., Castillo-Herrera, G.A., García-Fajardo, J.A.: Cannabis Extraction Technologies: Impact of Research and Value Addition in Latin America. Molecules 28(7), 2895 (2023)

Ramírez, J.M.: La Industria Del Cannabis Medicinal en Colombia. Fedesarrollo, pp. 1–61, (2019)

Marrot, L., et al.: Valorization of Hemp Stalk Waste through Thermochemical Conversion for Energy and Electrical Applications. Waste and Biomass Valorization, no. November. (2021). https://doi.org/10.1007/s12649-021-01640-6

Yakti, W., Förster, N., Müller, M., Mewis, I., Ulrichs, C.: Hemp Waste as a Substrate for Hermetia illucens (L.) (Diptera: Stratiomyidae) and Tenebrio molitor L. (Coleoptera: Tenebrionidae) Rearing. Insects (2023). https://doi.org/10.3390/insects14020183

Su, S., Gao, Y., Zhou, X., Xiong, X., Wang, Y., Lyu, L.: Structure of Waste Hemp Stalks and Their Sound Absorbing Properties. Polymers 14(22), 4844 (2022). https://doi.org/10.3390/polym14224844

Ji, A., Jia, L., Kumar, D., Yoo, C.G.: Recent advancements in biological conversion of industrial hemp for biofuel and value-added products. Fermentation (2021). https://doi.org/10.3390/fermentation7010006

Pérez Aguilar, J.A., Franco, J.M., Benítez Benítez, R.: Waste biomass from the Cannabis industry, an alternative for obtaining products of high added value. Rev. Colomb Biotecnol. 25(1), 92–103 (2023). https://doi.org/10.15446/rev.colomb.biote.v25n1.102648

Gomez, F.P., Hu, J., Clarke, M.A.: Cannabis as a feedstock for the Production of Chemicals, Fuels, and materials: A review of relevant studies to date. Energy and Fuels. 35(7), 5538–5557 (2021). https://doi.org/10.1021/acs.energyfuels.0c04121

Zhao, J., Xu, Y., Wang, W., Griffin, J., Roozeboom, K., Wang, D.: Bioconversion of industrial hemp biomass for bioethanol production: A review. Fuel (2020). https://doi.org/10.1016/j.fuel.2020.118725

Asquer, C., Melis, E., Scano, E.A., Carboni, G.: Opportunities for Green Energy through emerging crops: Biogas valorization of cannabis sativa l. residues. Climate (2019). https://doi.org/10.3390/cli7120142

Kuglarz, M., Alvarado-Morales, M., Karakashev, D., Angelidaki, I.: Integrated production of cellulosic bioethanol and succinic acid from industrial hemp in a biorefinery concept. Bioresour Technol. 200, 639–647 (2016). https://doi.org/10.1016/j.biortech.2015.10.081

Gunnarsson, I.B., Kuglarz, M., Karakashev, D., Angelidaki, I.: Thermochemical pretreatments for enhancing succinic acid production from industrial hemp (Cannabis sativa L). Bioresour Technol. 182, 58–66 (2015). https://doi.org/10.1016/j.biortech.2015.01.126

Gandolfi, S., Pistone, L., Ottolina, G., Xu, P., Riva, S.: Hemp hurds biorefining: A path to green l-(+)-lactic acid production. Bioresour Technol. 191, 59–65 (2015). https://doi.org/10.1016/j.biortech.2015.04.118

Khattab, M.M., Dahman, Y.: Production and recovery of poly-3-hydroxybutyrate bioplastics using agro-industrial residues of hemp hurd biomass. Bioprocess. Biosyst Eng. 42(7), 1115–1127 (2019). https://doi.org/10.1007/s00449-019-02109-6

Brazdausks, P., et al.: Effect of aluminium sulphate-catalysed hydrolysis process on furfural yield and cellulose degradation of Cannabis sativa L. shives. Biomass Bioenerg. 89, 98–104 (2016). https://doi.org/10.1016/j.biombioe.2016.01.016

Rizhikovs, J., et al.: Pretreated hemp shives: Possibilities of conversion into levoglucosan and levoglucosenone. Ind. Crops Prod. 139, 111520 (2019). https://doi.org/10.1016/j.indcrop.2019.111520

Jaramillo-Sánchez, R., Alcaraz-Zapata, W.: Limitations on production methods for PHAs obtention: A systematic review, DYNA, vol. 87, no. 215, pp. 193–203, (2020). https://doi.org/10.15446/dyna.v87n215.84238

Reddy, V.U.N., Ramanaiah, S.V., Reddy, M.V., Chang, Y.C.: Review of the developments of bacterial medium-chain-length polyhydroxyalkanoates (mcl-PHAs). Bioengineering. 9(5), 1–24 (2022). https://doi.org/10.3390/bioengineering9050225

Silva, J.B., Pereira, J.R., Marreiros, B.C., Reis, M.A.M., Freitas, F.: Microbial production of medium-chain length polyhydroxyalkanoates, Process Biochem, vol. 102, no. January, pp. 393–407, (2021). https://doi.org/10.1016/j.procbio.2021.01.020

Govil, T., et al.: Lignocellulosic feedstock: A review of a sustainable platform for cleaner production of nature’s plastics. J. Clean. Prod. 270, 122521 (2020). https://doi.org/10.1016/j.jclepro.2020.122521

Al-Battashi, H.S., et al.: Lignocellulosic biomass (LCB): A potential alternative biorefinery feedstock for polyhydroxyalkanoates production. Rev. Environ. Sci. Biotechnol. 18(1), 183–205 (2019). https://doi.org/10.1007/s11157-018-09488-4

Mozejko, J., Karolina, C., Paulina, S.: Pseudomonas species as producers of eco-friendly polyhydroxyalkanoates. J. Polym. Environ. 27(6), 1151–1166 (2019). https://doi.org/10.1007/s10924-019-01422-1

Surendran, A., Lakshmanan, M., Chee, J.Y., Sulaiman, A.M., Van Thuoc, D., Sudesh, K.: Can Polyhydroxyalkanoates Be Produced Efficiently From Waste Plant and Animal Oils? Front. Bioeng. Biotechnol, vol. 8, no. March, pp. 1–15, (2020). https://doi.org/10.3389/fbioe.2020.00169

Adney, B., Baker, J.: Measurement of cellulase activities: Laboratory Analytical Procedure (LAP). no. January (2008)

Sluiter, A., et al.: Determination of total solids in biomass and total dissolved solids in liquid process samples. Lab. Anal. Proced., pp. 1–9, (2008)

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D.: Determination of Ash in Biomass. Lab. Anal. Proced., pp. 1–5, (2005)

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D.: Determination of Extractives in Biomass. Lab. Anal. Proced., pp. 1–9, (2008)

Vaz, S.: Analytical Techniques and Methods for Biomass, 1st edn. Springer Cham (2016)

Väisänen, T., Kilpeläinen, P., Kitunen, V., Lappalainen, R., Tomppo, L.: Effect of steam treatment on the chemical composition of hemp (Cannabis sativa L.) and identification of the extracted carbohydrates and other compounds, Ind. Crops Prod, vol. 131, no. February, pp. 224–233, (2019). https://doi.org/10.1016/j.indcrop.2019.01.055

Keiller, B.G., Potter, M., Burton, R.A., van Eyk, P.J.: Elucidating the degradation reaction pathways for the hydrothermal carbonisation of hemp via biochemical compositional analysis. Fuel (2021). https://doi.org/10.1016/j.fuel.2021.120450

Das, L., et al.: Comparative evaluation of Industrial Hemp cultivars: Agronomical practices, Feedstock characterization, and potential for Biofuels and Bioproducts. ACS Sustain. Chem. Eng. 8, 6200–6210 (2020). https://doi.org/10.1021/acssuschemeng.9b06145

Wang, C., et al.: Impact of Alkaline pretreatment Condition on enzymatic hydrolysis of sugarcane bagasse and pretreatment cost. Appl. Biochem. Biotechnol. 193(7), 2087–2097 (2021). https://doi.org/10.1007/s12010-021-03530-y

Karimi, K., Taherzadeh, M.J.: A critical review of analytical methods in pretreatment of lignocelluloses: Composition, imaging, and crystallinity. Bioresour Technol. 200, 1008–1018 (2016). https://doi.org/10.1016/j.biortech.2015.11.022

Hernández-López, A., Sanchez Felix, D.A., Sierra, Z.Z., Bravo, I.G., Dinkova, T.D., Avila-Alejandre, A.X.: Quantification of reducing sugars based on the qualitative technique of Benedict. ACS Omega. 5(50), 32403–32410 (2020). https://doi.org/10.1021/acsomega.0c04467

Jiang, X.J., Sun, Z., Ramsay, J.A., Ramsay, B.A.: Fed-batch production of MCL-PHA with elevated 3-hydroxynonanoate content. AMB Express (2013). https://doi.org/10.1186/2191-0855-3-50

Cerrone, F., Choudhari, S.K., Davis, R., Cysneiros, D.: Medium chain length polyhydroxyalkanoate (mcl-PHA) production from volatile fatty acids derived from the anaerobic digestion of grass, Appl. Microbiol. Biotechnol, vol. 42, no. October, pp. 1115–1127, (2013). https://doi.org/10.1007/s00253-013-5323-x

Davis, R., et al.: Conversion of grass biomass into fermentable sugars and its utilization for medium chain length polyhydroxyalkanoate (mcl-PHA) production by Pseudomonas strains. Bioresour Technol. 150, 202–209 (2013). https://doi.org/10.1016/j.biortech.2013.10.001

Rigouin, C., et al.: Production and characterization of two medium – chain – length polydroxyalkanoates by engineered strains of Yarrowia lipolytica. Microb. Cell. Fact. (2019). https://doi.org/10.1186/s12934-019-1140-y

Souza, H.K.S., Matos, M., Reis, M.A.M., Covas, J.A., Hilliou, L.: Can Biomass Mastication Assist the Downstreaming of Polyhydroxyalkanoates Produced from Mixed Microbial Cultures? Molecules 28(2), 767 (2023). https://doi.org/10.3390/molecules28020767

Muangmeesri, S., et al.: Holistic valorization of hemp through reductive Catalytic Fractionation. ACS Sustain. Chem. Eng. 9(51), 17207–17213 (2021). https://doi.org/10.1021/acssuschemeng.1c06607

Barta, Z., Kreuger, E., Björnsson, L.: Effects of steam pretreatment and co-production with ethanol on the energy efficiency and process economics of combined biogas, heat and electricity production from industrial hemp. Biotechnol. Biofuels (2013). https://doi.org/10.1186/1754-6834-6-56

Das, L., et al.: Industrial hemp as a potential bioenergy crop in comparison with kenaf, switchgrass and biomass sorghum. Bioresour. Technol. (2017). https://doi.org/10.1016/j.biortech.2017.08.008

Frankowski, J., Wawro, A., Batog, J., Burczyk, H.: New Polish Oilseed Hemp Cultivar Henola–Cultivation, Properties and utilization for Bioethanol Production. J. Nat. Fibers. 00(00), 1–13 (2021). https://doi.org/10.1080/15440478.2021.1944439

Liu, M., et al.: Effect of harvest time and field retting duration on the chemical composition, morphology and mechanical properties of hemp fibers. Ind. Crops Prod. 69, 29–39 (2015). https://doi.org/10.1016/j.indcrop.2015.02.010

Kucharska, K., Rybarczyk, P., Hołowacz, I., Łukajtis, R., Glinka, M., Kamiński, M.: Pretreatment of lignocellulosic materials as substrates for fermentation processes. Molecules. 23(11), 1–32 (2018). https://doi.org/10.3390/molecules23112937

Zhao, J., Xu, Y., Wang, W., Griffin, J., Wang, D.: Conversion of liquid hot water, acid and alkali pretreated industrial hemp biomasses to bioethanol. Bioresour Technol. 309, 123383 (2020). https://doi.org/10.1016/j.biortech.2020.123383

Kljun, A., Benians, T.A.S., Goubet, F., Meulewaeter, F., Knox, J.P., Blackburn, R.S.: Comparative analysis of crystallinity changes in cellulose i polymers using ATR-FTIR, X-ray diffraction, and carbohydrate-binding module probes. Biomacromolecules. 12(11), 4121–4126 (2011). https://doi.org/10.1021/bm201176m

Abraham, R.E., Vongsvivut, J., Barrow, C.J., Puri, M.: Understanding physicochemical changes in pretreated and enzyme hydrolysed hemp (Cannabis sativa) biomass for biorefinery development. Biomass Convers. Biorefinery. 6(2), 127–138 (2016). https://doi.org/10.1007/s13399-015-0168-4

Stevulova, N., et al.: Properties Characterization of Chemically Modified Hemp Hurds. Materials (2014). https://doi.org/10.3390/ma7128131

Bokhari, S.M.Q., Chi, K., Catchmark, J.M.: Structural and physico-chemical characterization of industrial hemp hurd: Impacts of chemical pretreatments and mechanical refining. Ind. Crops Prod. 171, 113818 (2021). https://doi.org/10.1016/j.indcrop.2021.113818

Kuglarz, M., Gunnarsson, I.B., Svensson, S.E., Prade, T., Johansson, E., Angelidaki, I.: Ethanol production from industrial hemp: Effect of combined dilute acid/steam pretreatment and economic aspects. Bioresour Technol. 163, 236–243 (2014). https://doi.org/10.1016/j.biortech.2014.04.049

Kamireddy, S.R., Li, J., Abbina, S., Berti, M., Tucker, M., Ji, Y.: Converting forage sorghum and sunn hemp into biofuels through dilute acid pretreatment. Ind. Crops Prod. 49, 598–609 (2013). https://doi.org/10.1016/j.indcrop.2013.06.018

Wan, G., et al.: How Pseudo-lignin Is Generated during Dilute Sulfuric Acid Pretreatment. J. Agric. Food Chem. (2019). https://doi.org/10.1021/acs.jafc.9b02851

Yuan, Y., et al.: Recent advances in understanding the effects of lignin structural characteristics on enzymatic hydrolysis. Biotechnol. Biofuels 14(1), 205 (2021). https://doi.org/10.1186/s13068-021-02054-1

Geun, C., Meng, X., Pu, Y., Ragauskas, A.J.: The critical role of lignin in lignocellulosic biomass conversion and recent pretreatment strategies: A comprehensive review. Bioresour Technol. 301, 122784 (2020). https://doi.org/10.1016/j.biortech.2020.122784

Luo, X., et al.: Promoting enzymatic hydrolysis of lignocellulosic biomass by inexpensive soy protein. Biotechnol. Biofuels (2019). https://doi.org/10.1186/s13068-019-1387-x

Zhao, J., Xu, Y., Wang, W., Griffin, J., Wang, D.: High ethanol concentration (77 g/L) of Industrial Hemp Biomass Achieved through optimizing the relationship between ethanol Yield/Concentration and solid loading. ACS Omega. 5(34), 21913–21921 (2020). https://doi.org/10.1021/acsomega.0c03135

Rojas-Rosas, O., Villafaña-Rojas, J., López-Dellamary, F.A., Nungaray-Arellano, J., González-Reynoso, O.: Production and characterization of polyhydroxyalkanoates in Pseudomonas aeruginosa ATCC 9027 from glucose, an unrelated carbon source. Can. J. Microbiol. 53(7), 840–851 (2007). https://doi.org/10.1139/W07-023

Hossain, M.A., et al.: Upcycling agricultural waste to biodegradable polyhydroxyalkanoates by combined ambient alkaline pretreatment and bacterial fermentation. Ind. Crops Prod. (2021). https://doi.org/10.1016/j.indcrop.2022.114867

Kumar, V., Kumar, S., Singh, D.: Microbial polyhydroxyalkanoates from extreme niches: Bioprospection status, opportunities and challenges. Int. J. Biol. Macromol. (2020). https://doi.org/10.1016/j.ijbiomac.2019.09.253

Koller, M., Maršálek, L., de Sousa, M.M., Dias, Braunegg, G.: Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. New Biotechnol. 37, 24–38 (2017). https://doi.org/10.1016/j.nbt.2016.05.001

Bellary, S., Patil, M., Mahesh, A., Lali, A.: Microbial conversion of lignin rich biomass hydrolysates to medium chain length polyhydroxyalkanoates (mcl-PHA) using Pseudomonas putida KT2440. Prep Biochem. Biotechnol. 0(0), 1–10 (2022). https://doi.org/10.1080/10826068.2022.2036999

Liu, Z.H., et al.: Cooperative valorization of lignin and residual sugar to polyhydroxyalkanoate (PHA) for enhanced yield and carbon utilization in biorefineries. Sustain. Energy Fuels. 3(8), 2024–2037 (2019). https://doi.org/10.1039/c9se00021f

Arreola-Vargas, J., Meng, X., Wang, Y., Ragauskas, A.J., Yuan, J.S.: Enhanced medium chain length-polyhydroxyalkanoate production by co-fermentation of lignin and holocellulose hydrolysates. Green. Chem. 23(20), 8226–8237 (2021). https://doi.org/10.1039/D1GC02725E

Mohammad, S.H., Bhukya, B., September: Biotransformation of toxic lignin and aromatic compounds of lignocellulosic feedstock into eco-friendly biopolymers by Pseudomonas putida KT2440. Biores. Technol. (2022). https://doi.org/10.1016/j.biortech.2022.128001

Elmore, J.R., et al.: Engineered Pseudomonas putida simultaneously catabolizes five major components of corn stover lignocellulose: Glucose, xylose, arabinose, p-coumaric acid, and acetic acid. Metab. Eng. (2020). https://doi.org/10.1016/j.ymben.2020.08.001

Salvachúa, D., et al.: Metabolic engineering of Pseudomonas putida for increased polyhydroxyalkanoate production from lignin. Microb. Biotechnol. 13(1), 290–298 (2020). https://doi.org/10.1111/1751-7915.13481

Liu, Y., Yang, S., Jia, X.: Construction of a ‘nutrition supply–detoxification’ coculture consortium for medium-chain-length polyhydroxyalkanoate production with a glucose–xylose mixture. J. Ind. Microbiol. Biotechnol. 47(3), 343–354 (2020). https://doi.org/10.1007/s10295-020-02267-7

Qin, R., Zhu, Y., Ai, M., Jia, X.: Reconstruction and optimization of a Pseudomonas putida-Escherichia coli microbial consortium for mcl-PHA production from lignocellulosic biomass. Front. Bioeng. Biotechnol. (2022). https://doi.org/10.3389/fbioe.2022.1023325

Yadav, B., Talan, A., Tyagi, R.D., Drogui, P.: Concomitant production of value-added products with polyhydroxyalkanoate (PHA) synthesis: A review. Bioresour Technol. 337, 125419 (2021). https://doi.org/10.1016/j.biortech.2021.125419

Pérez-Rivero, C., López-Gómez, J.P., Roy, I.: A sustainable approach for the downstream processing of bacterial polyhydroxyalkanoates: State-of-the-art and latest developments. Biochem. Eng. J. 150, 107283 (2019). https://doi.org/10.1016/j.bej.2019.107283

Haque, M.A., Priya, A., Hathi, Z.J., Qin, Z.H., Mettu, S., Lin, C.S.K.: Advancements and current challenges in the sustainable downstream processing of bacterial polyhydroxyalkanoates. Curr. Opin. Green. Sustain. Chem. 36, 100631 (2022). https://doi.org/10.1016/j.cogsc.2022.100631

Kurian, N.S., Das, B.: Comparative analysis of various extraction processes based on economy, eco-friendly, purity and recovery of polyhydroxyalkanoate: A review. Int. J. Biol. Macromol. (2021). https://doi.org/10.1016/j.ijbiomac.2021.06.007

Koller, M.: Established and advanced approaches for recovery of microbial polyhydroxyalkanoate (PHA) biopolyesters from surrounding microbial biomass. EuroBiotech J. 4(3), 113–126 (2020). https://doi.org/10.2478/ebtj-2020-0013

Sathiyanarayanan, G., et al.: Production and characterization of medium-chain-length polyhydroxyalkanoate copolymer from Arctic psychrotrophic bacterium Pseudomonas sp. PAMC 28620. Int. J. Biol. Macromol. 97, 710–720 (2017). https://doi.org/10.1016/j.ijbiomac.2017.01.053

Rodrigues, A.M., et al.: Polyhydroxyalkanoates from a mixed Microbial Culture: Extraction optimization and polymer characterization. Polym. (Basel). 14(11), 1–22 (2022). https://doi.org/10.3390/polym14112155

Choonut, A., Prasertsan, P., Klomklao, S., Sangkharak, K.: Study on mcl-PHA production by Novel Thermotolerant Gram-positive isolate. J. Polym. Environ. 28(9), 2410–2421 (2020). https://doi.org/10.1007/s10924-020-01779-8

Gumel, A.M., Annuar, M.S.M., Heidelberg, T.: Growth kinetics, effect of carbon substrate in biosynthesis of mcl-PHA by Pseudomonas putida Bet001. Brazilian J. Microbiol. 45(2), 427–438 (2014). https://doi.org/10.1590/S1517-83822014000200009

Liu, Q., Luo, G., Zhou, X.R., Chen, G.Q.: Biosynthesis of poly(3-hydroxydecanoate) and 3-hydroxydodecanoate dominating polyhydroxyalkanoates by β-oxidation pathway inhibited Pseudomonas putida. Metab. Eng. 13(1), 11–17 (2011). https://doi.org/10.1016/j.ymben.2010.10.004

Wang, H.H., Zhou, X.R., Liu, Q., Chen, G.Q.: Biosynthesis of polyhydroxyalkanoate homopolymers by Pseudomonas putida. Appl. Microbiol. Biotechnol. 89(5), 1497–1507 (2011). https://doi.org/10.1007/s00253-010-2964-x

Brandrup, J., Immergut, E.H., Grulke, E.A.: Polymer Handbook, 4th edn. John Wiley and Sons, New York (1999)

Kipper, M.J., Shen, E., Determan, A., Narasimhan, B.: Design of an injectable system based on bioerodible polyanhydride microspheres for sustained drug delivery. Biomaterials (2002). https://doi.org/10.1016/S0142-9612(02)00181-3

Acknowledgements

Authors thank the project Jóvenes Investigadores e Innovadores en el Departamento del Cauca, Universidad del Cauca, Vice Rectory of Research and all allied entities for the funds provided to Pérez Aguilar for the development of this study.

Funding

Open Access funding provided by Colombia Consortium. Author Pérez Aguilar received a grant from the project Jóvenes Investigadores e Innovadores en el Departamento del Cauca, funded by the Ministry of Science and Technology.

Author information

Authors and Affiliations

Contributions

PA, JA performed laboratory work, data analysis and wrote the paper manuscript. Remaining authors aided in research planning, assistance and logistics; as well as reviewing and approving the submitted manuscript.

Corresponding author

Ethics declarations

Competing interests

authors declare that there are no known competing interests with the publication of this work.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pérez Aguilar, J.A., Franco, J.M., Otero, I.D. et al. Production of Medium Chain Length Polyhydroxyalkanoate from Waste Cannabis sativa Biomass. Waste Biomass Valor 15, 4221–4233 (2024). https://doi.org/10.1007/s12649-024-02431-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-024-02431-5