Abstract

Purpose

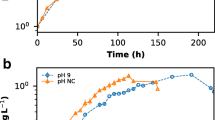

Herein, we examined C. necator for its production of bioplastic under mixotrophic fermentation. The mixotrophic process utilized dual carbon sources of mixed CO2 and glucose for the production of PHB.

Methods

C. necator was optimized through adaptive laboratory evolution under a mixed carbon sources of CO2 and glucose. The isolated mutant was then studied for its ability to co-utilize glucose and CO2 carbon sources for growth and for PHB production. Experimental design based on central composition design was implemented to optimize PHB production under mixotrophic fermentation. Parameters effecting PHB accumulation including CO2 and glucose substrate ratio, cell dosage and aeration were studied.

Results

Under optimized mixotrophic batch process, 0.22 g/L of PHB and 28% PHB content was reached from mixed carbon sources. Further CO2 and glucose co-feeding strategy optimization in mixotrophic fed-batch, PHB titer was elevated to 0.41 g/L.

Conclusion

Overall, this study offered a promising alternative for CO2 valorization through the mixotrophic conversion of CO2 and glucose to PHB by C. necator, which could provide basis in future Bio-CCU technology development for climate change mitigation.

Graphical Abstract

Similar content being viewed by others

Data Availability

Data is available upon request.

References

Federsel, C., Jackstell, R., Beller, M.: State-of-the-art catalysts for hydrogenation of carbon dioxide. Angew. Chem. Int. Ed. 49(36), 6254–6257 (2010)

Tee, K.L., Grinham, J., Othusitse, A.M., González-Villanueva, M., Johnson, A.O., Wong, T.S.: An efficient transformation method for the bioplastic-producing Knallgas bacterium Ralstonia eutropha H16. Biotechnol. J. (2017). https://doi.org/10.1002/biot.201700081

Fukui, T., Chou, K., Harada, K., Orita, I., Nakayama, Y., Bamba, T., Nakamura, S., Fukusaki, E.: Metabolite profiles of polyhydroxyalkanoate-producing Ralstonia eutropha H16. Metabolomics. 10(2), 190–202 (2014)

Yu, J.: Fixation of carbon dioxide by a hydrogen-oxidizing bacterium for value-added products. World J. Microbiol. Biotechnol. 34(7), 89 (2018)

Liu, Q., Wu, L., Jackstell, R., Beller, M.: Using carbon dioxide as a building block in organic synthesis. Nat. Commun. 6(1), 5933 (2015)

Zhang, L., Jiang, Z., Tsui, T.H., Loh, K.C., Dai, Y., Tong, Y.W.: A review on enhancing Cupriavidus necator fermentation for poly(3-hydroxybutyrate) (PHB) production from low-cost carbon sources. Front. Bioeng. Biotechnol. (2022). https://doi.org/10.3389/fbioe.2022.946085

Alagesan, S., Minton, N.P., Malys, N.: (13)C-assisted metabolic flux analysis to investigate heterotrophic and mixotrophic metabolism in Cupriavidus necator H16. Metabolomics 14(1), 9 (2018)

Jawed, K., Irorere, V.U., Bommareddy, R.R., Minton, N.P., Kovács, K.: Establishing mixotrophic growth of Cupriavidus necator H16 on CO2 and volatile fatty acids. Fermentation 8(3), 125 (2022)

Serafim, L.S., Lemos, P.C., Albuquerque, M.G., Reis, M.A.: Strategies for PHA production by mixed cultures and renewable waste materials. Appl. Microbiol. Biotechnol. 81(4), 615–628 (2008)

Li, M., Wilkins, M.: Fed-batch cultivation and adding supplements to increase yields of polyhydroxybutyrate production by Cupriavidus necator from corn stover alkaline pretreatment liquor. Bioresour. Technol. 299, 122676 (2020)

Kim, S., Jang, Y.J., Gong, G., Lee, S.M., Um, Y., Kim, K.H., Ko, J.K.: Engineering Cupriavidus necator H16 for enhanced lithoautotrophic poly(3-hydroxybutyrate) production from CO2. Microb. Cell Fact. 21(1), 231 (2022)

Tang, R., Weng, C., Peng, X., Han, Y.: Metabolic engineering of Cupriavidus necator H16 for improved chemoautotrophic growth and PHB production under oxygen-limiting conditions. Metab. Eng. 61, 11–23 (2020)

Kanno, M., Carroll, A.L., Atsumi, S.: Global metabolic rewiring for improved CO2 fixation and chemical production in cyanobacteria. Nat. Commun. 8, 14724 (2017)

Liang, F., Lindberg, P., Lindblad, P.: Engineering photoautotrophic carbon fixation for enhanced growth and productivity. Sustain. Energy Fuels 2, 2583–2600 (2018)

Unrean, P., Champreda, V.: Optimized pulse-feeding fed-batch fermentation for enhanced lignin to polyhydroxyalkanoate transformation. Biotechnol. Prog. (2023). https://doi.org/10.1002/btpr.3302

Wang, B., Liu, Z., Tao, S., Ren, Y., Gao, W., Liu, X., Yang, B.: Preparation and properties of CO2 micro-nanobubble water based on response surface methodology. Appl. Sci. 11(24), 11638 (2021)

Brojanigo, S., Parro, E., Cazzorla, T., Favaro, L., Basaglia, M., Casella, S.: Conversion of starchy waste streams into polyhydroxyalkanoates using Cupriavidus necator DSM 545. Polymers 12(7), 1496 (2020)

Dalsasso, R.R., Pavan, F.A., Bordignon, S.E., Aragão, G.M.F., Poletto, P.: Polyhydroxybutyrate (PHB) production by Cupriavidus necator from sugarcane vinasse and molasses as mixed substrate. Process Biochem. 85, 12–18 (2019)

Aramvash, A., Moazzeni Zavareh, F., Gholami Banadkuki, N.: Comparison of different solvents for extraction of polyhydroxybutyrate from Cupriavidus necator. Eng. Life Sci. 18(1), 20–28 (2017)

Kacmar, J., Carlson, R., Balogh, S.J., Srienc, F.: Staining and quantification of poly-3-hydroxybutyrate in Saccharomyces cerevisiae and Cupriavidus necator cell populations using automated flow cytometry. Cytometry A 69(1), 27–35 (2006)

Aramvash, A., Zavareh, F.M., Banadkuki, N.G.: Comparison of different solvents for extraction of polyhydroxybutyrate from Cupriavidus necator. Eng. Life Sci. 18, 20–28 (2018)

Kuttiraja, M., Douha, A., Valéro, J.R., Tyagi, R.D.: Elucidating the effect of glycerol concentration and C/N ratio on lipid production using Yarrowia Lipolytica SKY7. Appl. Biochem. Biotechnol. 180(8), 1586–1600 (2016)

Unrean, P., Tee, K.L., Wong, T.S.: Metabolic pathway analysis for in silico design of efficient autotrophic production of advanced biofuels. Bioresour. Bioprocess. 6(1), 49 (2019)

Blunt, W., Dartiailh, C., Sparling, R., Gapes, D.J., Levin, D.B., Cicek, N.: Development of high cell density cultivation strategies for Improved medium chain length polyhydroxyalkanoate productivity using Pseudomonas putida LS46. Bioengineering 6(4), 89 (2019)

Keunun, P., Rakkarn, T., Yunu, T., Paichid, N., Prasertsan, P., Sangkharak, K.: The production of polyhydroxybutyrate by two-step fermentation and the application of polyhydroxybutyrate as a novel substrate for a biolubricant. J. Polym. Environ. 26(6), 2459–2466 (2018)

Możejko, J., Ciesielski, S.: Pulsed feeding strategy is more favorable to medium-chain-length polyhydroxyalkanoates production from waste rapeseed oil. Biotechnol. Prog. 30(5), 1243–1246 (2014)

Poblete-Castro, I., Rodriguez, A.L., Lam, C.M., Kessler, W.: Improved production of medium-chain-length polyhydroxyalkanoates in glucose-based fed-batch cultivations of metabolically engineered Pseudomonas putida strains. J. Microbiol. Biotechnol. 24(1), 59–69 (2014)

Yang, Y.H., Brigham, C.J., Budde, C.F., Boccazzi, P., Willis, L.B., Hassan, M.A., Yusof, Z.M., Rha, C., Sinskey, A.J.: Optimization of growth media components for polyhydroxyalkanoate (PHA) production from organic acids by Ralstonia eutropha. Appl. Microbiol. Biotechnol. 87, 2037–2045 (2010)

Acknowledgements

This study was supported by National Research Council of Thailand (Grant Number N42A650256).

Funding

This study was funded by National Research Council of Thailand (Grant Number N42A650256).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Unaha, D., Jaihao, P., Unrean, P. et al. Optimizing Bioplastic Production of C. necator Under Mixotrophic Fermentation with CO2 and Glucose. Waste Biomass Valor 15, 2857–2867 (2024). https://doi.org/10.1007/s12649-023-02330-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02330-1