Abstract

A significant amount of paper residue has continuously been discarded worldwide. This rsidue encompasses a high-cellulose content that can be converted into value-added chemicals. Hydrolysis can be applied as an effective method to produce chemicals from lignocellulosic materials. This work presents a study on biomass waste valorization that uses acid hydrolysis to convert the cellulose residue into raw materials. Commercial cardboard waste was used as a lignocellulosic material source to produce fermentable sugar. The original material was crushed to about 1 mm pieces before being submitted to the hydrolysis reaction. It was found 4.8 mg of calcium ion (Ca2+) per gram of cardboard by means of a complexometric method using direct titration. The calcium ion acted as an inhibitor for the action of yeasts during the fermentation process, and then Ca2+ ions were removed by calcium sulfate decantation. A low-cost ionic liquid (n-butylammonium acetate) was used to enhance the hydrolysis reactional media. The fermentable sugar was obtained by two-step cellulose hydrolysis. Sugar content was assessed by both the Fehling test and the 3,5-dinitro-salicylic acid (DNS) method. Without ionic liquid, the maximum sugar concentration was 6.09 and 0.85 g/L, respectively, to 10% and 35% sulfuric acid concentrations. In the presence of ionic liquid, the corresponding sugar concentrations were 6.56 and 5.68 g/L. The whole reaction conversion achieved 30%, which must be considered significant for cellulose encompassed in the cardboard waste. The high amount of sugar obtained by acid hydrolysis of cardboard waste using ionic liquid points to a proper recovery and discarding for cardboard waste. Results show paper residues as an alternative source to sugar production, which is feasible to be converted into bioenergy and biofuel.

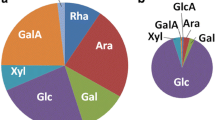

Graphical Abstract

Similar content being viewed by others

Data Availability

Data and materials were obtained during the study by the authors. No data, text, or theories by others are presented. The datasets generated during the current study are not publicly available due to copyright restrictions, but they are available from the corresponding author on a representative request.

References

Wong, S.L., Ngadi, N., Abdullah, T.A.T., Inuwa, I.M.: Current state and future prospects of plastic waste as source of fuel: a review. Renew. Sustain. Energy Rev. 50, 1167–1180 (2015)

Santos, R.G., Rocha, C., Felipe, F., Cezario, F., Correia, P., Rezaei-Gomari, S.: Tire waste management: an overview from chemical compounding to the pyrolysis-derived fuels. J. Mater. Cycles Waste Manage. 22, 628–641 (2020)

Ullah, K., Sharma, V.K., Dhingra, S., Braccio, G., Ahmad, M., Sofia, S.: Assessing the lignocellulosic biomass resources potential in developing countries: a critical review. Renew. Sustain. Energy Rev. 2015(51), 682–698 (2015)

Poliakoff, M., Licence, P.: Green chemistry. Nature 450, 810–812 (2007)

Manian, A.P., Braun, D.E., Široká, B., Bechtold, T.: Distinguishing liquid ammonia from sodium hydroxide mercerization in cotton textiles. Cellulose 29, 4183–4202 (2022)

Taha, M., Foda, M., Shahsavari, E., Aburto-Medina, A., Adetutu, E., Ball, A.: Commercial feasibility of lignocellulose biodegradation: possibilities and challenges. Curr. Opin. Biotechnol. 38, 190–197 (2016)

Sun, Y., Cheng, J.: Hydrolysis of lignocellulosic materials for ethanol production: a review. Biores. Technol. 83, 1–11 (2012)

Szczodrak, J., Fiedurek, J.: Technology for conversion of lignocellulosic biomass to ethanol. Biomass Bioenerg. 10(5–6), 367–375 (1996)

Santos, R.G., Alencar, A.C.: Biomass-derived syngas production via gasification process and its catalytic conversion into fuels by Fischer Tropsch synthesis: a review. Int. J. Hydrogen Energy 45(36), 18114–18132 (2020)

Hahn-Hagerdal, B., Galbe, M., Gorwa-Grauslund, M.F., Liden, G., Zacchi, G.: Bio-ethanol – the fuel of tomorrow from the residues of today. Trends Biotechnol. 24, 12 (2006)

Balat, M., Balat, H., Öz, C.: Progress in Bioethanol Processing. Prog. Energy Combust. Sci. 34, 551–573 (2008)

FAOSTAT (2019). FAO - Food and Agriculture Organization of the United Nations. Available in: http://www.fao.org/faostat/en/#data/GF.

IEA (2020). Key World Energy Statistics. Available in: https://www.iea.org/reports/key-world-energy-statistics-2020.

Cabalova, I., Kacik, F., Geffert, A., Kacikova, D.: The effects of paper recycling and its environmental impact. In: Broniewicz, E. (ed.) Environmental management in practice, pp. 329–350. InTech (2011)

Ndiribe, C.C.: The nature fit concept of waste reduction: Prospects for engineering a clean future. Res. Environ. Sustain. 14, 100127 (2023)

CEPI (2006). Confederation of European Paper Industries. Special Recycling 2005 Statistics- European Paper Industry Hits New Record in Recycling. Available in: http://www.erpa.info/images/Special_Recycling_2005_statistic.

DEEP (2020). Corrugated Cardboard Recycling. Department of Energy & Environmental Protection. Available in: https://portal.ct.gov/DEEP/Reduce-Reuse-Recycle/Corrugated-Cardboard.

Dubey, A.K., Gupta, P.K., Garg, N., Naithani, S.: Bioethanol production from waste paper acid pretreated hydrolyzate with xylose fermenting Pichia stipites. Carbohyd. Polym. 88(3), 825–829 (2012)

Pauly, M., Keegstra, K.: Cell-wall carbohydrates and their modification as a resource for biofuels. Plant J. 54, 559–568 (2008)

De Oliveira, D.M., De Bomfim, A.S.C., Benini, K.C.C.D.C., Cioffi, M.O.H., Voorwald, H.J.C., Rodrigue, D.: Waste paper as a valuable resource: an overview of recent trends in the polymeric composites field. Polymers 15, 426 (2023)

Yilmaz U, Tutuş A, Sönmez S (2021). An overview of the waste paper recycling system. Current Studies in Agriculture, Forestry and Aquaculture Sciences. Editor: İsmet Daşdemir. Duvar Publishing, Turkey.

Simão, L., Hotza, D., Raupp-Pereira, F., Labrincha, J.A., Montedo, O.R.K.: Wastes from pulp and paper mills: a review of generation and recycling alternatives. Cerâmica 64(371), 443–453 (2018)

Zabed, H., Sahu, J.N., Boyce, A.N., Faruq, G.: Fuel ethanol production from lignocellulosic biomass: an overview on feedstocks and technological approaches. Renew. Sustain. Energy Rev. 66, 751–774 (2016)

Hamelinck, C.N., Hooijdonk, G., Faaij, A.P.C.: Ethanol from lignocellulosic biomass: techno-economic performance in short- middle- and long-term. Biomass Bioener. 28, 384–410 (2005)

Ogeda, T.L., Petri, D.F.S.: Biomass enzymatic hydrolysis. Quim. Nova 33(7), 1549–1558 (2010)

Laca, A., Laca, A., Díaz, M.: Hydrolysis: from cellulose and hemicellulose to simple sugar. Second and third generation of feedstocks. Chapter 8, 213–240 (2019)

Sindhu, R., Kuttiraja, M., Binod, P., Sukumaran, R.K., Pandey, A.: Bioethanol production from dilute acid pretreated Indian bamboo variety (Dendrocalamus sp.) by separate hydrolysis and fermentation. Indust. Crops Prod. 52, 169–176 (2014)

Taneda, D., Ueno, Y., Ikeo, M., Okino, S.: Characteristics of enzyme hydrolysis of cellulose under static condition. Biores. Technol. 121, 154–160 (2012)

Wang, L., Templer, R., Murphy, R.J.: High-solids loading enzymatic hydrolysis of waste papers for biofuel production. Appl. Energy 99, 23–31 (2012)

Morales-Dela Rosa, S., Campos-Martin, J.M., Fierro, J.L.G.: Complete chemical hydrolysis of cellulose into fermentable sugars via ionic liquids and antisolvent pretreatments. Chem Sus Chem 7(12), 3467–3475 (2014)

Hubbe, M.A.: Recycling paper recycling. A new classic handbook on recycling. BioResources 9(2), 1828–1829 (2014)

Zugenmaier, P. (ed.): Crystalline cellulose and cellulose derivatives: characterization and structure. In: Cellulose derivatives, pp. 175–206. Springer, Berlin, Heidelberg (2008)

Damayanti, D., Supriyadi, D., Amelia, D., Saputri, D.R., Devi, Y.L.L., Auriyani, W.A., Wu, H.S.: Conversion of lignocellulose for bioethanol production. Applied in bio-polyethylene terephthalate. Polymers 13, 2886 (2021)

Bergmeyer, H.U., Grabl, M.: Methods of enzymatic analysis, 3rd edn. Verlag Chemie, Weinheim (1983)

Nill, J., Karuna, N., Jeoh, T.: The impact of kinetic parameters on cellulose hydrolysis rates. Process Biochem. 74, 108–117 (2018)

Clark, T.A., Mackei, K.L.: Fermentation inhibitors in wood hydrolysates derived from the softwood Pinus radiate. J. Chem. Technol. Biotechnol. 34, 101–110 (1984)

Fengel, G., Wegener, G.: Wood and cellulose chemistry. Walter de Gruyter, Berlin (1984)

Gírio, F.M., Fonseca, C., Carvalheiro, F., Duarte, L.C., Marques, S., Bogel-Łukasik, R.: Hemicelluloses for fuel ethanol: a review. Biores. Technol. 101(13), 4775–4800 (2010)

Rossell, C.E.V.: Conversion of lignocellulose biomass (bagasse and straw) from the sugar-alcohol industry into bioethanol Industrial Perspectives for Bioethanol. Ed Telma. Franco. Cap. 8, 123–142 (2006)

Mosier, N., Wyman, C., Dale, B., Elander, R., Lee, Y.Y., Holtzapple, M., Ladisch, M.: Features of promising technologies for pre-treatment of lignocellulosic biomass. Biores. Technol. 96, 673–686 (2005)

Esteghlalian, A., Hashimoto, A.G., Fenske, J.J., Penner, M.H.: Modeling and optimization of the dilute-sulfuric-acid pre-treatment of corn stover poplar and switchgrass. Bioresour. Technol. 59, 129–136 (1997)

Liu, C.-Z., Wang, C., Stiles, A.R., Guo, C.: Ionic liquids for biofuel production: opportunities and challenges. Appl. Energy 92, 406–414 (2012)

Xu, J., Liu, B., Hou, H., Hu, J.: Pre-treatment of eucalyptus with recycled ionic liquids for low-cost biorefinery. Biores. Technol. 234, 406–414 (2017)

Holbrey, J.D., Seddon, K.R.: Ionic liquids. Clean Prod. Processes 1, 223–236 (1999)

Bian, J., Peng, F., Peng, X.-P., Xiao, X., Peng, P., Xu, F., Sun, R.-C.: Effect of [Emim]Ac pretreatment on the structure and enzymatic hydrolysis of sugarcane bagasse cellulose. Carbohyd. Polym. 100, 211–217 (2014)

Gunny, A.A.N., Arbain, D., Nashef, E.M., Jamal, P.: Applicability evaluation of deep eutectic solvents-cellulase system for lignocellulose hydrolysis. Biores. Technol. 181, 297–302 (2015)

Zhuo, K., Du, Q., Bai, G., Wang, C., Chen, Y., Wang, J.: Hydrolysis of cellulose catalyzed by novel acidic ionic liquids. Carbohyd. Polym. 115, 49–53 (2015)

Amarasekara, A.S.: Acidic Ionic Liquids. Chem. Rev. 116, 6133–6183 (2016)

Jordan, J.H., Easson, M.W., Condon, B.D.: Cellulose hydrolysis using ionic liquids and inorganic acids under dilute conditions: morphological comparison of nanocellulose. RSC Adv. 10, 39413–39424 (2020)

Maki-Arvela, P., Anugwom, I., Virtanen, P., Sjoholm, R., Mikkola, J.P.: Dissolution of lignocellulosic materials and its constituents using ionic liquids: a review. Ind. Crops Prod. 32, 175–201 (2010)

Lee, K.M., Ngoh, G.C., Chua, A.S.M., Yoon, L.W., Ang, T.N., Lee, M.G.: Comparison study of different ionic liquid pretreatment in maximizing total reducing sugars recovery. BioResources 9, 1552–1564 (2014)

Parveen, F., Patra, T., Upadhyayula, S.: Hydrolysis of microcrystalline cellulose using functionalized Bronsted acidic ionic liquids—a comparative study. Carbohyd. Polym. 135, 280–284 (2016)

Kulshrestha, A., Pancha, I., Mishra, S., Kumar, A.: Deep eutectic solvents and ionic liquid assisted hydrolysis of microalgal biomass: a promising approach towards sustainable biofuel production. J. Mol. Liq. 335, 116264 (2021)

Lara-Serrano, M., Angulo, F.S., Negro, M.J., Morales-Delarosa, S., Campos-Martin, J.M., Fierro, J.G.: Second-Generation bioethanol production combining simultaneous fermentation and saccharification of IL-pretreated barley straw. ACS Sustain. Chem. Eng. 6(5), 7086–7095 (2018)

Lopes, A.M.C., Bogel-Łukasik, R.: Acidic ionic liquids as sustainable approach of cellulose and lignocellulosic biomass conversion without additional catalysts. Chemsuschem 8(6), 947–965 (2015)

Lei, Z., Dai, C., Chen, B.: Introduction: Ionic Liquids. Chem. Rev. 117(10), 6633–6635 (2017)

Andrade Neto, J.C., Cabral, A.S., Oliveira, L.R.D., Torres, R.B., Morandim-Giannetti, A.A.: Synthesis and characterization of new low-cost ILs based on butylammonium cation and application to lignocellulose hydrolysis. Carbohyd Poly 143, 279–287 (2016)

ISO 536:2019. Paper and board - Determination of grammage. Test methods and quality specifications for paper and board (2019).

Fehling, H.: The quantitative determination of sugar and starch by means of copper sulfate. Ann. Chem. Pharm. 72(1), 106–113 (1849)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31(3), 426–428 (1959)

Hao, X., Wen, P., Wang, J., Wang, J., You, J., Zhang, J.: Production of xylooligosaccharides and monosaccharides from hydrogen peroxide-acetic acid-pretreated poplar by two-step enzymatic hydrolysis. Biores. Technol. 297, 122349 (2020)

Hao, X., Xu, F., Zhang, J.: Effect of pre-treatments on production of xylooligosaccharides and monosaccharides from corncob by a two-step hydrolysis. Carbohyd. Polym. 285, 119217 (2022)

Deshavath, N.N., Mukherjee, G., Goud, V.V., Veeranki, V.D., Sastri, C.V.: Pitfalls in the 3.5-dinitrosalicylic acid (DNS) assay for the reducing sugars: Interference of furfural and 5-hydroxymethylfurfural. Int. J. Biol. Macromol. 156, 180–185 (2020)

Ziaei-Rad, Z., Fooladi, J., Pazouki, M., Gummadi, S.N.: Lignocellulosic biomass pre-treatment using low-cost ionic liquid for bioethanol production: An economically viable method for wheat straw fractionation. Biomass Bioenergy 151, 106140 (2021)

Bian, J., Peng, P., Peng, F., Xiao, X., Xu, F., Sun, R.-C.: Microwave-assisted acid hydrolysis to produce xylooligosaccharides from sugarcane bagasse hemicelluloses. Food Chem. 156, 7–13 (2014)

Boonchuaya, P., Techapun, C., Leksawasdi, N., Seesuriyachan, P., Hanmoungjai, P., Watanabe, M., Takenaka, S., Chaiyaso, T.: An integrated process for xylooligosaccharide and bioethanol production from corncob. Biores. Technol. 256, 399–407 (2018)

Acknowledgements

The authors gratefully acknowledge suggestions from Dr. Bruna Pratto for experimental preparation.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

ESdS: cardboard characterization and pre-treatment, acid hydrolysis and ionic liquid synthesis. GPP: cardboard characterization, acid hydrolysis and pre-treatment, and NMR analysis. LMA: acid hydrolysis and sugar determination. MSP: acid hydrolysis and sugar determination. ACL: experimental supervision, result discussion, and review of the manuscript draft. RBT: experimental suggestions and review of the manuscript draft. RGdS: general supervision, experimental assistance, analysis and discussion of results, and final manuscript writing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declared that they have no conflict of interest.

Ethics Approval and Consent to Participate

All of the authors approved the manuscript submission.

Consent for Publication

The authors agree with the manuscript submission.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

da Silva, E.S., Policarpo, G.P., Antonio, L.M. et al. Sugar Production from Cardboard Waste by Two-Step Acid Hydrolysis Using Ionic Liquid. Waste Biomass Valor 15, 2637–2649 (2024). https://doi.org/10.1007/s12649-023-02300-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02300-7