Abstract

This work aimed to use linoleic acid extracted from melon seed oil for the development of biological compounds, and to use the ash of melon seed cake for fried oil treatment. Eight active compounds were developed using linoleic acid and the elucidation of their structure was established according to elemental analysis and spectral data. The developed compounds were tested for their antibacterial activity. The melon seed cake was carbonized for the treatment of fried oils. The melon seed oil was rich in linoleic acid (61.4%) and it contains several fatty acids including lauric, myristic, palmitic, palmitoleic, stearic, oleic, linolenic, arachidic, and paulinic in concentrations of 0.2%, 0.73%, 11.7%, 0.11%, 10.3%, 14.1%, 0.49%, 0.19%, and 0.1%, respectively. The extracted linoleic acid showed a high refractive index (1.471), iodine value (122.3 g I2/100 g), saponification (184.42 mg KOH/g), low peroxide value (3.9 meq/kg oil), polymer content (1.00%), polar contents (1.95%), and moisture content (42 g/kg). The melon seed ash was rich in several metals including magnesium (743.5 mg/kg), calcium (137 mg/kg), sodium (12.95 mg/kg), potassium (1040 mg/kg), chromium, manganese, iron, copper, zinc, cadmium, and mercury in concentrations of 0.072, 40.88, 19.29, 3.334, 8.21, 0.005, 0.005 mg/kg, respectively, as well as arsenic (0.09 mg/kg), lead (0.044 mg/kg), phosphorus (1222 mg/kg) and selenium (0.13 mg/kg) which they improved the physic-chemical properties of fried oils. Linoleic acid was used for the development of 9 compounds with antimicrobial activity against Gram-positive and Gram-negative bacteria. Additionally, the melon seed ash improved the chemical characteristic of used cotton and sunflower oils. Therefore, the linoleic acid extracted from melon seed oil is a promising source for the development of antibacterial agents and the leftover cake is promising for the production of adsorbent material suitable for fried oils treatment.

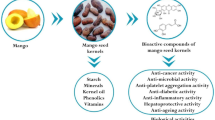

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

Melon seeds are considered a waste can be used to extract oil rich with linoleic acid which can be used for the synthesis of bioactive compounds with potent antimicrobial activity. Moreover, Melon seeds ash can be used to improve the properties of used frying oil. As the prepared compounds composed of antimicrobial hetero cycles appended to linoleate moiety and the latter is commonly used for paints and polymer formation. Thus, the new prepared compounds are thought to be promising if they are used for production of hospital and food factories painting in order to decrease microbial load. Moreover, those compounds could be used for production of antimicrobial plastics which used as food packaging. Thus, this work provides new ideas for innovation in sustainable development in terms of safely reusing waste and biomass with great importance to food industry and food safety.

Introduction

Food by-products and food waste are considered major socioeconomic and environmental problems generated throughout different stages including the harvest, post-harvest, food processing or distribution, and storage [1]. In addition, high quantities of food waste are created as household waste like spoiled or unused food. The impact on the environment due to food waste is mostly related to the decomposition processes and the production of fluids some gases like methane which are responsible for the greenhouse effect, and sludge (fluids) which contaminate the groundwater, springs, and soil [2].

Additionally, the increase in unused food by-products decreases the efficiency of food production and reduces the sustainability of production. These food waste and by-products are well known as a rich source of beneficial compounds such as phenolics, fibers, pigments, vitamins, proteins, fatty acids, and sugars which possess valuable biological effects such as anti-bacterial, anti-inflammatory, antioxidant, cardioprotective, and anticancer beside others [3]. Despite this fact, the vast majority of these compounds are still not exploited at the industrial level for the production of new promising compounds.

The global production of melon (Cucumis melo L.) has dramatically increased due to its high economic and nutritional value. The edible part of the plant is the fruit while the peels and seeds are discarded. Melon seeds contain moister, crude protein, crude fat, crude fiber, carbohydrates, and ash at ratios of 4.5, 25.0, 25.0, 23.3, 19.8, and 2.4%, respectively [4]. Moreover, Jacob et al. [5] reported that the seeds contain iron, zinc, manganese, and calcium at concentrations of 144.7, 21.05, 22.73, and 0.10 mg/100 g, respectively; besides sodium, potassium and phosphorus. The extracted melon seeds oil was found to be rich in linoleic, oleic acids, and flavonoids which are the predominant antioxidant phenolic compounds [6]. The uses of extracted melon seeds oil have been reported for medical applications, biodiesel production, synthesis of detergents, and margarine manufacture [7]. Linoleic acid, the predominant fatty acid in melon seeds oil, is the precursor for arachidonic acid biosynthesis and consequently; some prostaglandins, leukotrienes, and thromboxane [8]. Industrially, linoleic acid is widely used in oil paints and varnishes due to its high reactivity with oxygen in the air and the formation of a crosslinked stable film called linoxyn [9]. It is also very popular in the production of cosmetic products due to its anti-inflammatory, skin whitening, and moisturizing activities [10].

It is well known that deep-fat fried in the presence of moisture, oxygen, free radicals, and trace elements resulted in several physic-chemical reactions including hydrolysis, thermo-oxidation, isomerization, and polymerization [11]. This leads to the decomposition of frying oils and the formation of non-volatile monometric/polymeric oxidative products increasing color, foaming, density, viscosity, and free fatty acids content, and consequently; the induction of off-flavor of the fried food and the frying medium [12]. Besides impairing sensory quality, deterioration of frying oil can eventually cause adverse health effects to the consumer [13]. Previous reports indicated that treatment with different adsorbents can improve the used oil quality. Hidayatullah and Bangash [14] showed that activated charcoal or MgO improves the quality of Silybum marianum oil. Moreover, treatment with a combination of several adsorbents improved fried oil. Diatomaceous earth, lime, and natural zeolite reduced the total polar materials, free fatty acids, turbidity, viscosity, conjugated dienes, color, and peroxide value of fried oil [15]. The current study was conducted to use linoleic acid extracted from melon seeds for the preparation of new bioactive compounds, to evaluate their antibacterial efficiency and the use of melon seeds meal as an adsorbent agent for the treatment of used oils.

Materials and Methods

Materials

Melon seeds were obtained from Agriculture Research Center, Plant Protection Research Institute, Giza. Hydrazine hydrate, ethyoxycarbonyl isothiocyanate, malononitrile, and malononitrile dimer were purchased from Aldrich Chemical Co.

Chemicals and Reagents

Mercuric acetate was purchased from Arcos Organics, Fisher Scientific Company (Belgium). Triethylamine, thiourea, hydroxylamine hydrochloride, and ammonium hydroxide were purchased from the British Drug House (BDH). Sodium nitrite, potassium hydroxide, bromine, sodium bicarbonate, and anhydrous sodium sulfate were purchased from El-Nasr Pharmaceutical Chemical Co. (ADWIC), Egypt. Dimethylformamide (DMF), dry benzene, diethyl ether, benzene, dry dioxane, and pyridine were purchased from Aldrich Chemical Co. Ethanol, methanol, petroleum ether, and carbon tetrachloride were BDH reagents, nitric acid, hydrochloric acid, and acetic acid were purchased from El-Nasr Pharmaceutical and Chemical Co. (ADWIC), Egypt.

Melon Seeds Oil Extraction

Firstly, 1000 g melon seeds were grinned and dried overnight at 50 °C and moisture content was determined. Oil was extracted with n-hexane (3 L) in a Soxhlet Apparatus at a condensation rate of 5 or 6 points per second for 6 h at a temperature of 79 °C. The solvent was then evaporated to dryness using a rotary evaporator and the obtained melon seeds oil was weighted and kept for analysis [16].

Quality Parameters and Fatty Acids Composition of the Extracted Oil

Refractive index, free fatty acids, iodine value, peroxide value, and Saponification value of the extracted melon seed oil were carried out [17]. Also, polar and polymer contents were determined according to Waltking and Wessels [18], and viscosity was estimated according to Saguy et al. [19]. The fatty acid composition of the extracted melon seeds oil was determined by GC–MS after esterification [17]. The mass spectrum of GC–MS was interpreted using the database of National Institute of Standard and Technology (NIST) having more than 62,000 patterns by comparing the mass spectrum of the unknown components with those of the known elements stored in the NIST library. The name, molecular weight and chemical structure of the test material were ascertained [20].

Oil Hydrolysis

Melon seeds oil (417 g) was hydrolyzed using a high-pressure reactor at 250 °C and 2 MPa in distilled water (1 L), the reaction was left to cool to room temperature to separate the fatty layer from the non-fatty one. The separated fatty layer was dried over anhydrous sodium sulfate and filtered off. Formation of free fatty acids was confirmed using 1H NMR spectrum and TLC [16]. In the TLC method, plates (20 × 20 cm) were coated with a slurry of silica gel (60 g) in water (15 g/kg), left to dry, then it was activated at 110 °C for 1 h. Standard spots of known fatty acid and another spot of oil (individually) were spotted on the activated thin layer plates, at the baseline (2 cm from the bottom). The fatty acids mixture of the hydrolyzed fat was also spotted on the same line. The developing solvent consisted of n-hexane, diethyl ether, and acetic acid at a volumetric ratio of 80:20:1, respectively. The developing jar was lined on three sides with filter paper wetted with the same developing solvent. The plates were developed till the solvent reached the front line (15 cm from the start line). The spots of different components separated by TLC were then visualized by iodine vapor. The fatty acids were considered formed when the withdrawn sample showed only one spot with no tail and with a rate of flow similar to that of the known fatty acid spot but not the oil spot. However, the formation of fatty acids was confirmed by 1H NMR using a Bruker AVANCE 400 NMR spectrometer operating at 9.4 T observing the 1H nuclei at 400.13 MHz according to the method described by Barison et al. [21]. In brief, aliquots of fatty acids mixture (approximately 200 μL was directly transferred into NMR tubes (5 mm) and the volume was completed to 600 μL using CDCl3 containing 0.05% TMS. The spectra of 1H NMR were recorded at room temperature (~ 20 °C) by pooling eight averages, and laxation delay of 1 s, a spectral width of ∼ = 9.0 ppm and 64 K data points, providing a digital resolution of 0.05 Hz using a multinuclear direct detection probe (5 mm) on the NMR instrument. The 1H NMR spectra were processed by applying an exponential multiplication of the FIDs by a factor of 0.3 Hz prior to Fourier transform with zero-filling to 64 K. The relaxation delay for use in the acquisition of quantitative 1H NMR spectra was determined by T1 measurements with the aid of the pulse sequence inversion recovery, with similar parameters as for 1H spectra and changing τ values from 0.1 to 20 s. The 1H NMR chemical shifts are expressed in ppm related to the TMS signal at 0.00 ppm as internal reference, and the analyses were performed in duplicate.

Linoleic Acid Extraction Using Supercritical CO2 Extractor

Linoleic acid was extracted individually in a pure form [22] from the fatty acid mixture (363.65) of the extracted melon seeds oil using a supercritical CO2 extractor at 26.0 MPa, 313 K. The obtained linoleic acid (216.58 g) was confirmed according to its elemental analysis, melting points, GC–MS and mass spectra (MS) of its methyl ester which detect the corresponding molecular ion peak (293 M+).

Organic Synthesis and Reactions

Synthesis of Methyl Octadeca-9,12-dienoate(methyl linolate) (1)

The method described previously [16] was used for the synthesis of methyl linolate. In brief, sulphuric acid (5 mL) was added to a mixture of octadic-9,12-dienoic acid (70.1 g, 250 mmol) in absolute methanol (100 mL). The reaction mixture was refluxed with stirring for 8 h. Then, it was left to cool. The mixture was washed with water till neutralization, then the methyl ester was separated by extraction with diethyl ether, and then the solvent was evaporated under reduced pressure (Box 1, supplementary file).

Synthesis of Octadeca-9,12-dienehydrazide (2)

A mixture of octadic-9,12-dienoate (1) (2.94 g, 10 mmol) and hydrazine hydrate (0.49 mL, 10 mmol) in dry benzene (30 mL) was heated under reflux for 7 h. and the reaction mixture was allowed to cool, then poured over acidified ice-cold water. The precipitated product was filtered off, washed with water, and recrystallized from ethanol (Box 2, supplementary file).

Synthesis of 5-(Heptadeca-8,11-dienyl)-1H-1,2,4-triazole-3-amine (3)

Thiourea (0.76 g, 10 mmol) was added to a solution of fatty acid hydrazide (2.94 g, 10 mmol) and mercury acetate (0.5 mL), and the mixture was heated under reflux for 7 h, and then it was left to cool to room temperature. The solvent was evaporated under reduced pressure, and the remaining solid was washed with water, dried, and finally recrystallized from pyridine to afford the corresponding triazolamine (Box 3, supplementary file).

Synthesis of Diazonium Salt of the Aminotriazole (4)

A suspension of aminotriazole 3 (3.185 g, 10 mmol) in glacial acetic acid (30 mL) was heated to produce a clear solution then cooled to 0–5 °C, and nitric acid (90 mL) was added. A solution of sodium nitrite (3.5 g, 50 mmol) in water (10 mL) was poured gradually with stirring, and the reaction mixture was left in an ice chest overnight. The formed solid was collected by filtration, washed with ethanol, and dried to afford the corresponding diazonium nitrate (4), which was used directly for the next preparation without further purification.

Synthesis of 4-Amino-7-(heptadeca-8,11-dienyl)-[1,2,4]triazolo[5,1-c] [1,2,4]Triazine-3-carbonitrile (6)

The diazotized 5-amino-1,2,4-triazole 4 (3.62 g, 10 mmol) was added to a cold solution of malononitrile (0.66 g, 10 mmol) in ethanol (50 mL), and the presence of sodium acetate trihydrate (5g). The addition was carried out with rapid stirring at 0–5 °C over 30 min, the mixture was stirred for a further 10 h, kept in an ice chest for 12 h, and finally diluted with water. The solid precipitate was collected by filtration, washed with water, dried, and finally recrystallized from ethanol to afford the corresponding coupling product 6 (Box 4, supplementary file).

Synthesis of 2,4-Diamino-8-(heptadeca-8,11-dienyl)-1,2,4-triazolo[1,5-c] pyrido[2′,3′-e]-1,3,4-triazine-3-carbonitrile (9)

The diazonium salt of 4 (3.62 g, 10 mmol) was added to a cold solution of malononitrile dimmer (1.31 g, 10 mmol) in ethanol (50 mL) in the presence of sodium acetate trihydrate (5 g). The addition was carried out with rapid stirring at 0–5 °C for 30 min. After complete addition, the reaction mixture was stirred for a further 10 h, then kept in an icebox for 12 h, and finally diluted with water. The solid precipitate was collected by filtration, washed with water, dried, and finally recrystallized from EtOH/DMF to afford the corresponding coupling product 9 (Box 5, supplementary file).

Synthesis of 7-(Heptadeca-8,11-dienyl)2,3,5-triaminopyrido{4,3-d}pyrimidine{5,6-e}triazolo{5′,1′-c}triazine (11)

Urea (0.6 g, 10 mmol) was added to a solution of 9 (4.34 g, 0.01 mmol) in ethanol (25 mL) and triethyl orthoformate (2.22 g, 0.015 mmol). The mixture was heated under reflux for 8 h, and allowed to cool to room temperature. The solvent was removed under reduced pressure, and the remaining solid was poured onto ice water. The solid product was collected by filtration, washed with water, dried, and finally recrystallized from DMF (Box 6, supplementary file).

Synthesis of 2,4-Diamino-8-(heptadeca-8,11-dienyl)-1,2,4-triazolo[1,5-c]pyrimido[5′,4′-e]-1,3,4-triazine (13)

Urea (0.6 g, 10 mmol) was added to a solution of 6 (3.95 g, 0.01 mmol) in ethanol (25 mL) and triethyl orthoformate (2.22 g, 0.015 mmol). The mixture was heated under reflux for 8 h, and allowed to cool to room temperature. The solvent was removed under reduced pressure, and the remainder was poured onto ice water. The solid product was collected by filtration, washed with water, dried, and finally recrystallized from ethanol (Box 7, supplementary file).

Synthesis of 3-Amino-7-(heptadeca-8,11-dienyl)-1,2,4-triazolo[5,1-c]-pyrazino[4,3-e] 1,2,4-Triazine (15)

Hydroxylamine hydrochloride (0.69 g, 10 mmol) was added to a solution of 4-Amino-7-(heptadeca-9,12-dienyl)-[1,2,4]triazolo[5,1-c] [1,2,4]triazine-3-carbonitrile (6) (3.97 g, 0.01 mmol) in ethanol (30 mL). The mixture was heated under reflux for 7 h, then it was allowed to cool to room temperature. The solvent was evaporated under reduced pressure, and the crude product was washed with water, dried, and finally recrystallized from ethanol to produce compound 15 (Box 8, supplementary file).

Synthesis of Ethyl Amino-N′-(octadic-9,12-dienoyl) Methanethiocarbamate (16)

A solution containing acid hydrazide (2) (1.46 g, 5 mmol) and the appropriate isothiocyanate (0.5 g, 5 mmol) in ethanol (20 mL) was heated under reflux for 3 h, then it was left at room temperature overnight. The separated product was filtered off, washed with ethanol, dried, and recrystallized from EtOH (Box 9, supplementary file).

Synthesis of Ethyl-3-(heptadeca-8,11-dienyl)-5-mercabto 4H-1,3,4-triazole-4-carboxylate (17)

A suspension of the appropriate thiosemicarbazide 16 (4.25 g, 10 mmol) in sodium hydroxide solution (5%, 5 mL) was heated under reflux for 7 h. The reaction mixture was allowed to cool, and then adjusted to pH 6 with 10% hydrochloric acid, the formed precipitate was filtered off, washed with water, dried, and recrystallized from DMF (Box 10, supplementary file).

Synthesis of 5-(Heptadeca-8,11-dienyl)-1,2-dihydro-[1,2,4]triazolo[3,4-c][1,2,4] Triazol-3-one (19)

The appropriate triazolethion 17 (0.4 g, 1 mmol) was reacted with hydrazine hydrate (2 mmol) in absolute ethanol (15 mL). The mixture was heated under reflux for 7 h, the solvent was evaporated under reduced pressure, then it was acidified with 10% hydrochloric acid until neutralization, the formed solid was washed with water, dried, and recrystallized from EtOH to afford the corresponding product 19 (Box 11, supplementary file).

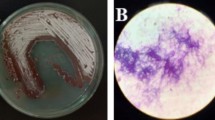

Antibacterial Activity

The prepared compounds (100 µg/mL) were tested in vitro for their antibacterial activity in diethyl ether as solvent. Four bacterial species (two-Gram positive and two-Gram negative) namely Staphylococcus Epiderm, Enterococcus fesalis, Enterobacter cloacae, and Flavo-Bacterium were used, and the test was done according to the disk diffusion method [22]. Inhibition zone diameter (IZD), in mm/mg compound, was measured and taken as the criterion for antimicrobial activity. The antibiotics Vancomycin rifampin, Penicillin G, Gentamycin cephalosporin cefotaxime Imipenem, and Normal flora Natpathegen, were used as references to evaluate the potency of the tested compounds under the same condition.

Preparation of Melon Seeds Waste Ash

Melon seeds ash was prepared from melon ground seed cake (541 g). Where ground cake was placed in a crucible, carbonized in a furnace at 600 °C for 12 h, kept in a desiccator till reached room temperature, weighted (56.8 g), and stored in glass screw-capped bottles [23].

Determination of Chemical Elements of Melon Seeds Waste Ash

Metals of melon seeds ash were extracted by the acid digestion method and Ca, Mg, Zn, Fe, Cu, and Mn were determined using an Atomic absorption spectrometer [24]. The phospho-vanadomolybdate colorimetric method was applied to detect P content using a spectrophotometer; whereas, the flame photometer was used for K and Na analysis [25]. All the determinations were carried out in triplicate (mg/100 g) and reported as mean mineral content.

Frying Protocol

A known amount (2000 mL) of refined sunflower oil and cottonseed oil were placed individually in a domestic stainless steel pan fryer (24 cm diameter × 14 cm height) and heated at 180 °C ± 5. Then, 150 g potato chips (2 mm thickness × 40 mm width × 50 mm length); previously soaked in a sufficient quality NaCl solution (10% w/v) for 10 min, were fried for about 10 min. The frying processes were conducted four times a day, and the frying period was 4 h/day. The used oil was left to cool after each frying process, and no fresh oil was added. The frying processes of sunflower oil and cottonseed oil were repeated individually for six consecutive days, and the total continuous frying period was 24 h. In the end, oil samples were left to cool down and then stored at − 5 °C for analysis [23].

Treatment with Adsorbents

The adsorbent materials (Melon seeds ash and Magnesol XL) were individually added to both samples of used sunflower oil and used cottonseed oil at a 3% level, then mechanically stirred using a super-mixer (Gemmy Industrial Crop, Japan) for 15 min. at 150 rpm, and filtered through Whatman No.1 filter paper. These adsorption treatments were repeated three times for each sunflower oil and cottonseed oil after the end of the heating period (24 h) [23].

Chemical Characteristics of the Used Oils and the Treated Used Oils

Sunflower and cottonseed oils were used individually for frying processes, the two oils had been analyzed before and after the frying process, and the used oils were also treated with two different adsorbents (Magnisole and melon seeds ash), then, the chemical characteristics of those treated oils were reported. Free fatty acid and peroxide values of the used oils and treated used oils were determined according to AOAC [17]. Insoluble polar and polymer components were determined according to Waltking and Wessels [18], the induction period (IP) was measured according to Firestone et al. [26] using a metrohm 679 Rancimat, and viscosity was determined according to Saguy et al. [19] using Brookfield DVIII model digital rheometer at 30 °C using spindle no. 27 at 250 rpm. However, color index (CI) was detected by using a Lovibond Tintometer Apparatus. Each oil sample was performed three times for each test and the averages were calculated.

Results and Discussion

Moisture, Oil Yield, and Oil Quality

The moisture content in the ground melon seeds was found to be 42 g/kg (4.2%) and the oil yield extracted with n-hexane was 417 g/kg (41.7%). The results of the physical and chemical properties of the extracted melon seed oil are listed in Table 1. These results showed that refractive index, iodine value, and saponification are relatively high and indicated that the physical properties of the oil are similar to the oils rich in linoleic acid [27]. The iodine value is well known as a measure of the unsaturation degree of the fat. In the current study, the iodine value of melon seed oil (122.3 g I2/100 g) was higher than the recorded value of Cucumis melo var. saccharinus (109.6 g I2/100 g) and honeydew melon seed oil (153.4 g I2/100 g) as reported by De Mello et al. [28] and Yanty et al. [4], respectively. Moreover, the saponification value which is referring to the mean molecular mass was lower (184.42 mg KOH/g) than those reported for honeydew melon seed oil (210.2 mg KOH/g) and cottonseed oil (189–198 mg KOH/g), coconut oil (248–265 mg KOH/g) and Cucumis melo var. saccharinus seed oil (210.62 mg KOH/g) [4, 28], respectively. Additionally, the percentage of free fatty acid reported here in was 0.61% as acid value and was lower than that of honeydew melon seed oil (2.5%), pumpkin (1.44%), and watermelon (1.41%) seed oils [29]. The current data showed that the peroxide value of melon seed oil (3.9 meq/kg) was lower than 10 meq/kg suggesting that this oil is highly stable and non-susceptible to oxidative rancidity [17].

Fatty Acids Composition

The GC–MS analysis of fatty acids composition of the extracted melon seeds oil after esterification with methanol (Table 2). Linoleic acid was the major fatty acid and represented 61.4% of the total fatty acids. Moreover, lauric acid (C12:0), myristic acid (C14:0), palmitic acid (C16:0), palmitoleic acid (C16:1), stearic acid (C18:0), oleic acid (C18:1), linolenic acid (C18:3), arachidic acid (C20:0), and paulinic acid (C20:1) were presented at concentrations of 0.2%, 0.73%, 11.7%, 0.11%, 10.3%, 14.1%, 0.49%, 0.19%, and 0.1%, respectively. Thus, melon seeds could be regarded as a rich source of linoleic acid. The high content of linoleic acid reported in the current study was similar to that reported previously [27, 30,31,32]. However, linoleic acid concentration in our study was lower than the concentration found in Cucumis melo var. inodorus [4], C. melo hybrid AF-522, and was higher than the concentration found in C. melo var. saccharinus [28]. Taken together, the current GC–MS results and the previous data indicated the high variability in the profile of fatty acids in melon-seed oils [6].

Oil Hydrolysis

Oil hydrolysis is the operation by which the water reacts with the oil to yield fatty acids and glycerol [33]. Oil molecules could be easily hydrolyzed to free fatty acids mixture and glycerol in a high-pressure reactor at 250 °C and 2 MPa [16]. In the current study, the extracted melon seeds oil (417 g) was hydrolyzed into a free fatty acid mixture (363.65 g) and glycerol. The complete oil hydrolysis and formation of free fatty acids was confirmed according to TLC where the formed fatty acids mixture showed a unique spot with no tail and with the rate of flow (Rf value) similar to that of known fatty acids but not the oil. These results were in agreement with those reported previously [34].

Linoleic Acid Extraction Using Supercritical CO2 Extractor

A pure linoleic acid was extracted individually from a fatty acid mixture (363.65 g) of the extracted melon seeds oil using a supercritical CO2 extractor at (26.0 MPa, 39.85 °C). The applied method yielded 216.58 g of linoleic acid represented 97% of the present linoleic acid as confirmed by its elemental analysis, where the percentages of the calculated elements were: C, 77.90; H, 11.50; O, 11.41%, and the found elements percentages were: C, 77.88; H, 11.52%. Moreover, its melting point was recorded as (− 5.0°C), the mass spectra (MS) of its methyl esters showed the corresponding molecular ion at 294 (M+), and it was also confirmed according to GC–MS. These results suggested that the supercritical CO2 extractor is efficient for the extraction of linoleic and confirmed the previous reports [35].

Organic Synthesis

Methyl ester of linoleic acid was found to be a suitable starting material for the synthesis of a variety of heterocyclic systems pendant to a long-chain fatty residue of industrial and biological potency. Treatment of methyl octadec-9,12-dienoate (1) with hydrazine hydrate afforded the corresponding octadec-9,12-dienehydrazide (2) (Fig. 1, Scheme 1). The IR spectrum of the later product showed bands at ν 3291, 3223, and 1535 cm−1 due to NH2, NH, and C=O functions, respectively. Its mass spectrum revealed a peak at m/z 293 (M+) corresponding to its molecular ion. The 1H NMR spectrum of the same product revealed the appearance of signals due to NH at δ 8.09 and NH2 at δ 3.01, in addition to aliphatic protons at δ 0.93–1.95 and ethylenic protons in the region δ 5.34–5.40. All the data of the synthesized compounds were confirmed by the published data [36,37,38].

Octadec-9,12-dienehydrazide (2)

5-(Heptadec-8-enyl)-1H-1,2,4-triazol-3-amine (3)

When the acid hydrazide derivative (2) was treated with thiourea, in the presence of mercuric acetate under reflux, it afforded a product identified as 5-(heptadec-8,11-dienyl)-1H-1,2,4-triazol-3-amine (3) (Fig. 1, Scheme 2). The IR spectrum of the later product showed two absorption bands at ν 3260–3234 and 3013 cm−1 due to NH2 and NH groups, respectively. Moreover, the 1H NMR revealed characteristic D2O-exchangeable signals at δ 8.20 and 4.21 due to NH and NH2 protons, respectively. Moreover, its mass spectrum showed a fragment ion peak corresponding to its molecular ion at m/z 317.

4-Amino-7-(heptadeca-8,11-dienyl)-[1,2,4]triazolo[5,1-c][1,2,4] Triazine-3-carbo-nitrile (6)

The diazotized aminotriazole (4) (prepared by the diazotization of the aminotriazole 3) coupled with malononitrile to afford a product identified as 4-amino-7-heptadec-8,11-dienyl-[1,2,4]triazolo[5,1-c][1,2,4]triazine-3-carbonitrile (6) (Fig. 1, Scheme 3). The structure of the isolated product was established based on its elemental analysis and spectral data. For example, its IR spectrum showed a band at ν 3685–3545 due to the NH2 group and a strong absorption band at ν 2222 cm−1 corresponding to C≡N absorption. Its 1H NMR spectrum showed a D2O exchangeable signal at δ 4.17 due to NH2 protons, in addition to aliphatic protons at δ 0.94–1.92 and ethylenic protons at δ 5.36–5.42.

2,4-Diamino-8-(heptadeca-8,11-dienyl)-1,2,4-triazolo[1,5-c]pyrido[2′,3′-e]-1,3,4-triazine-3-carbonitrile (9)

The triazole diazonium nitrate 4 (prepared by the diazotization of the aminotriazole 3) coupled with malononitrile dimmer, in ethanol, buffered with sodium acetate, furnished a product identified as 2,4-diamino-8-heptadec-8,11-dienyl-1,2,4-triazolo[1,5-c]pyrido[2′,3′-e]-1,3,4-triazine-3-carbonitrile (9). The IR spectrum of product 9 showed absorption bands at ν 3733–3688 and 3632–3590 cm−1 due to two NH2 groups and another band at ν 2220 cm−1 characteristic for C≡N absorption. The 1H NMR spectrum of the same product revealed D2O-exchangeable signals at δ 4.13 and 4.33 due to two NH2 protons, in addition to aliphatic protons at δ 0.95–1.94 and ethylenic protons at δ 5.33–5.41. Compound 9 is assumed to be formed because of intramolecular cyclization of the acyclic non-isolable intermediates 7 and 8 (Fig. 1, Scheme 4).

7-(Heptadeca-8,11-dienyl)2,3,5-triaminopyrido{3,4-d}pyrimidine{5,6-e}triazolo {5′,1′-c}triazine (11)

When compound 9 was treated with urea in ethanol, in the presence of triethyl orthoformate, it afforded the condensed ring system 11. The structure of the later product was confirmed according to its elemental analysis and spectral data. For example, its IR spectrum showed three absorption bands in the regions ν 3988–3901, 3862–3802, and 3800–3721 cm−1 due to three NH2 groups. The 1H NMR spectrum compound 11 revealed three D2O-exchangeable signals at δ 4.05, 4.21, and 4.49 due to three NH2 protons, in addition to aliphatic protons at δ 0.95–1.94 and ethylenic protons at δ 5.33–5.42. Moreover, its mass spectrum revealed a peak corresponding to the molecular ion at m/z 502. The formation of compound 11 is assumed to take place via the addition of the amino group in compound 9 to the urea carbonyl carbon followed by the elimination of the water molecule and addition of the urea amino group to the nitrile group in compound 9 to afford the final product 11 as shown in Fig. 1, scheme 5.

4-Diamino-8-(heptadeca-8,11-dienyl)-1,2,4-triazolo[1,5-c] pyrimido [5′,4′-e]-1,3,4-triazine (13)

Treatment of 4-amino-7-heptadec-8,11-dienyl-[1,2,4]triazolo[5,1-c][1,2,4] triazine-3-carbonitrile (6) with urea in ethanol, and in the presence of triethyl orthoformate, furnished a single product identified as 2,4-diamino-8-(heptadec-8,11-dienyl)-1,2,4-triazolo[1,5-c]pyrimido[5′,4′-e]-1,3,4-triazine (13) (Fig. 1, Scheme 6). The IR spectrum of compound 13 exhibits two absorption bands at ν 3898–3833 and 3688–3611 cm−1 due to two NH2 groups and showed no nitrile absorption. In addition, its 1H NMR spectrum revealed two D2O-exchangeable signals at δ 4.00 and 4.15 two NH2 protons, and aliphatic protons at δ 0.94–1.93 in addition to ethylenic protons at δ 5.36–5.43. Its MS spectrum revealed a peak corresponding to its molecular ion at m/z 436.

3-Amino-7-(heptadeca-8,11-dienyl)-1,2,4-triazolo[5,1-c]-pyrazino [4,3-e] 1,2,4-traizine (15)

Compound 6 reacted with hydroxylamine (liberated in situ from hydroxylamine hydrochloride and sodium carbonate), in refluxing ethanol, and afforded a product identified as 3-amino-7-(heptadec-8,11-dienyl)-1,2,4-triazolo[5,1-c]-pyrazino[4,3-e]1,2,4-traizine (15), as shown in Fig. 1, scheme 7. The IR spectrum of 15 showed absorption bands at ν 3492–3420 and 3230 cm−1 due to NH2 and NH groups, respectively. Its 1H NMR spectrum revealed a broad (D2O-exchangeable) signal at δ 8.66 due to NH proton and another one at 4.24 due to NH2 protons, in addition to aliphatic protons at δ 0.96–1.95 and ethylenic protons at δ 5.33–5.42. The mass spectrum of the same product showed a fragment ion at m/z 419 corresponding to its molecular ion. The formation of compound 15 is assumed to take place via the addition of the amino group in hydroxylamine to the nitrile group in compound 6 to afford the acyclic non-isolable intermediate 14, which underwent intramolecular cyclization via elimination of water molecule, to afford the final product 15 (Fig. 1, Scheme 7).

5-(Heptadeca-8,11-dienyl)-1,2-dihydro-[1,2,4]triazolo[3,4-c][1,2,4] Triazol-3-one (19)

Condensation of the acid hydrazide 2 with methoxycarbonyl isothiocyanate in ethanol, afforded the corresponding thiosemicarbazide 16 (Fig. 1, Scheme 8). The IR spectrum of ethyl amino N′-(octadeca-9,12-dienoyl) methanethiocarbamate (16) showed bands at ν 1700, 1630, and 1325 cm−1 due to two C=O groups and one C=S absorption, respectively. Treatment of the thiosemicarbazide 16 with sodium hydroxide furnished the corresponding triazole derivative 17. The IR spectrum of product 17 showed only one carbonyl absorption band at ν 1684 cm−1, in addition to other bands at ν 3425 and 1277 due to NH and C=S respectively. Treatment of the triazolthione 17 with hydrazine hydrate, afforded 5-(heptadeca-8,11-dienyl)-1,2-dihydro-[1,2,4] triazolo[3,4-c][1,2,4] triazol-3-one (19) (Scheme 8). The IR spectrum of compound 19 revealed bands at ν 3392, 3224, and 1720 cm−1 due to two NH and one C=O group, respectively. Its 1H NMR spectrum showed two D2O-exchangeable signals at δ 6.21 and 7.32 characteristic for protons of two NH groups, in addition to aliphatic protons at δ 0.95–1.94, and ethylenic protons at δ 5.33–5.42. Moreover, its mass spectrum revealed a molecular ion peak at m/z 358.

Antibacterial Activity

The antimicrobial activity was assayed using 100 µg/mL of the tested compounds and diethyl ether as a solvent against Gram +ve and Gram −ve bacteria. The results (Table 3) showed that all the synthesized compounds exhibited antimicrobial activity, and since these compounds are appended to a long-chain fatty acid, they can easily penetrate the lipoprotein cell membrane, thus being used as pharmaceuticals. Moreover, as this long-chain fatty acid possesses two unsaturated centers, the prepared compound can undergo a polymerization process, providing a new antimicrobial polymer that can be used to produce antimicrobial kitchenware. In addition, linoleic acid is commonly used in the production of paints, so the prepared compounds can be used to produce antimicrobial paints that can be used to coat the walls of hospitals and food factories to reduce the microbial load. These results also suggested that linoleic acid derivatives are promising for the development of antibacterial agents [39].

Elemental Analysis of Melon Seeds Ash

The atomic absorption spectrometer analysis of melon seeds ash revealed that the ash contains alkali earth metal (magnesium and calcium) in concentrations of 743.5 and 137 mg/kg, respectively; alkali metal (sodium and potassium) in concentration of 12.95 and 1040 mg/kg, respectively; transition metal (chromium, manganese, iron, copper, zinc, cadmium, and mercury) in concentrations of 0.072, 40.88, 19.29, 3.334, 8.21, 0.005, 0.005 mg/kg, respectively; metalloid (arsenic) in a concentration of 0.09 mg/kg, and lead in a concentration of 0.044 mg/kg, in addition to nonmetal (phosphorus, selenium) in concentrations of 1222 and 0.13 mg/kg, respectively. These results showed that the metal content of melon seed ash is lower than those reported in the previous studies in sweet melon [6].

Due to the higher nuclear charge of the alkaline earth metals, their tendency to form complexes with Lewis bases is high. Moreover, transition metals could easily form multiple coordination bonds with several negative ions or neutral molecules having lone pairs of electrons, due to the presence of vacant d orbitals, which afforded complex compounds with a high molecular weight. Thus, Alkali earth metals and transition metals can clarify used oil through the formation of multiple coordination bonds with different alcohols, aldehydes, ketones, acids, ions, and so many other degradable oil products. On the other hand, phosphorus and selenium are known for their high reactivity toward oxygen and formation of water-soluble compounds P4O6, P4O10, SeO2, and SeO3 depending on the available oxygen amount, consequently, they forced the used oil to get rid of peroxides.

Effect of Melon Waste Ash on the Chemical Characteristics of Fresh and Used Oils

The results of the effect of melon seed ash on the chemical characteristics of fresh and used cotton and sunflower oils compared to Magnisole are depicted in Fig. 2. These results showed that frying of both oils increased the red color (Fig. 2A), free fatty acids (Fig. 2B), peroxide value (Fig. 2C), viscosity (Fig. 2D), polar content (Fig. 2F), polymer content (Fig. 2G), and free oxidized fatty acids (Fig. 2H) but decreased the induction period (Fig. 2E) significantly compared to the fresh oils. Treatment with melon seed ash or Magnisole improved all the tested parameters in both oils. These results were similar to those reported in the literature on fried niger seed oil using different levels of MgO, bleaching earth, bentonite, silica gel, and ash [11], palm oil using HZSM-5/SBA-15 micro-mesoporous materials [40], and rapeseed oil using tea polyphenols [41]. The improvement in free fatty acids reported herein may be due to the specific adsorption affinity of the adsorbent for small molecular materials [40]. However, the peroxide value which mainly increased due to the thermo-oxidation reaction between the oil and the atmospheric oxygen [41] was improved due to the formation of molecules with a specific adsorption capacity towards peroxides as the oxidation products [42].

Conclusion

Pure linoleic acid was extracted from melon seed oil using the supercritical CO2 extractor technique. The results showed that the melon seed oil is rich in linoleic acid (61.4%) and the physical properties of the extracted oil revealed that the refractive index, iodine value, and saponification were high suggesting the rich content of linoleic acid in the oil. Moreover, the chemical properties of the oil showed that the oil has a low peroxide value, low moisture content, and low level of trace elements suggesting that this oil can be used for non-food applications. The oil also was hydrolyzed to a free fatty acid mixture (41.7%) and glycerol. The melting point of the extracted linoleic acid was − 5.0 °C and its methyl esters showed the corresponding molecular ion at 294 (M+). Linoleic acid was used successfully as starting material for the synthesis of several heterocyclic long-chain fatty acids with potent antibacterial activity against Gram-positive and Gram-negative bacteria. The elements analysis of the melon ash showed the presence of high concentrations of P, K, Mg, and Mn, moderate concentrations of Na, Zn, Cu, and Fe, and trace concentrations of Pb, Cd, Hg, Cr, and Se. The use of melon ash did not affect fresh cottonseed and sunflower oils; however, it was effective in inducing a significant improvement in the chemical characteristics of the fried oils. It could be concluded that melon oil is a promising agent for the production of high-value derivatives for medical and food applications and also the melon cake is promising for the production of adsorbent material to be used in the improvement of fried oils.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code Availability

The codes used during the current study are available from the corresponding author on reasonable request.

References

Mirabella, N., Castellani, V., Sala, S.: Current options for the valorization of food manufacturing waste: a review. J. Clean. Prod. 65, 28–41 (2014)

Vidović, S., Vladić, J., Nastić, N., Jokić, S.: Subcritical and supercritical extraction in food by-product and food waste valorization. Ref. Mod. Food Sci. (2020). https://doi.org/10.1016/B978-0-08-100596-5.23014-X

Karimi, E., Jaafar, H.Z., Ahmad, S.: Phytochemical analysis and antimicrobial activities of methanolic extracts of leaf, stem and root from different varieties of Labisa pumila Benth. Molecules 16(6), 4438–4450 (2011). https://doi.org/10.3390/molecules16064438

Yanty, N.A.M., Lai, O.M., Osman, A., Ghazali, H.M.: Physicochemical properties of Cucumis melo var. Inodorus (honeydew melon) seed and seed oil. J. Food Lipids 15, 42–55 (2008). https://doi.org/10.1111/j.1745-4522.2007.00101.x

Jacob, A.G., Etong, D.I., Tijjani, A.: Proximate, mineral and anti-nutritional compositions of melon (Citrullus lanatus) seeds. Br. J. Res. 2, 142–151 (2015)

Mallek-ayadi, S., Bahloul, N., Kechaou, N.: Chemical composition and bioactive compounds of Cucumis melo L. seeds: Potential source for new trends of plant oils. Process Saf. Environ. Prot. 113, 68–77 (2018)

Nyakuma, B.B., Roozbahani, F., Oladokun, O., Dodo, Y.A., John, T., Ivase, P.: Kinetic analysis of melon seeds husk using non-isothermal thermogravimetric analysis. Mater. Today Proc. 5(11), 23249–23257 (2018)

Whelan, J., Fritsche, K.: Linoleic acid. Adv. Nutr. 4(3), 311–312 (2013)

Izzo, F.C., Källbom, A., Nevin, A.: Multi-analytical assessment of bodied drying oil varnishes and their use as binders in armour paints. Heritage 4, 3402–3420 (2021)

Ahmad, A., Ahsan, H.: Lipid-based formulations in cosmeceuticals and biopharmaceuticals. Biomed. Dermatol. (2020). https://doi.org/10.1186/s41702-020-00062-9

Nuru, Z., Getachew, P.: Improving the quality of used frying niger seed oil with adsorbent treatment. Heliyon 7(4), e06748 (2021). https://doi.org/10.1016/j.heliyon.2021.e06748

Manjunatha, S.S., Mathews, A.T., Patki, P.E.: Modelling the kinetics of mass transfer and change in colour during deep fat frying of green peas (Pisum sativum L) at different frying temperatures. Heat Mass. Transf. 55(11), 3087–3102 (2019)

Que, D.E., Chao, H.R., Hsu, Y.C., Cui, K., Chen, S., Tayo, L.L., Young, L.H.: Emission of carbonyl compounds from cooking oil fumes in the night market areas. Aerosol Air Qual. Res. 19(7), 1566–1578 (2019)

Hidayatullah, I.K., Bangash, F.K.: Quality improvement of used fried Silybum marianum oil by treatment with activated charcoal and magnesium oxide. J. Chem. Soc. Pak. 29(6), 564–568 (2007)

Yilmaz, E., Bulut, E.: Frying oil refreshing capacity of a new adsorbent mixture. Acad. Food J. 10, 24–29 (2012)

Soliman, H.M., Basuny, A.M., Arafat, S.M.: Utilization of stearic acid extracted from olive pomace for production of triazoles, thiadiazoles and thiadiazines derivatives of potential biological activities. J. Oleo Sci. 64(9), 1019–1032 (2015)

AOAC Association of Official Agriculture Chemists: Official methods of analysis of 18 th ed. AOAC, Washington (2005)

Waltking, A.E., Wessels, H.: Chromatographic separation of polar and non-polar components of frying oils. JAOAC 64, 1329–1330 (1981)

Saguy, I.S., Shami, A., Weinberg, P., Garti, N.: Utilization of jojoba oil for deep fat frying of foods. LWT 29(7), 573–577 (1996)

Olajuyigbe, A.A., Amah, G.H., Adebawo, O.O., Olajuyigbe, O.O.: Extraction and GC–MS analysis of the fatty acids in commonly consumed melon seed varieties in Nigeria. GSC Biol. Pharm. Sci. 7(3), 077–092 (2019)

Barison, A., da Silva, C.W., Campos, F.R., Simonelli, F., Lenz, C.A., Ferreira, A.G.: A simple methodology for the determination of fatty acid composition in edible oils through 1H NMR spectroscopy. Magn. Reson. Chem. 48(8), 642–650 (2010). https://doi.org/10.1002/mrc.2629

Soliman, H.M., El- Shattory, Y.: Isolation of pure individual fatty acids from chicken skin using supercritical CO2 extractor or cooling centrifuge. J. Oleo Sci. 69(8), 859–864 (2020)

Basuny, A.M., Arafat, S.M., Soliman, H.M.: Effectiveness of olive-waste ash as an adsorbent material for the regeneration of fried sunflower oil. Curr. Sci. Int. 3(4), 311–319 (2014)

Soriano, S., Netto, A.D.P., Cassella, R.J.: Determination of Cu, Fe, Mn and Zn by flame atomic absorption spectrometry in multivitamin/multimineral dosage forms or tablets after an acidic extraction. J. Pharm. Biomed. Anal. 43, 304–310 (2007)

Oliveira, A.P., Martins, D.L., Martins, M.L., Villa, R.D.: Determination of Na and K in Brazilian solid dietary sweeteners by flame photometry. Int. Food Res. J. 23(5), 2216–2219 (2016)

Firestone, D., Stier, F.R., Blumenthal, M.M.: Regulation of frying fats and oils. Food Technol. 45, 90–94 (1991)

Milovanović, M., Pićurić-Jovanović, K.: Characteristics and composition of melon seed oil. J. Agric. Sci. 50(1), 41–47 (2005)

De Mello, M.L.S., Bora, P.S., Narain, N.: Fatty and amino acids composition of melon (Cucumis melo var. saccharinus) seeds. J. Food Compos. Anal 14, 69–74 (2001)

El-Adawy, T.A., Taha, K.M.: Characteristics and compositions of different seed oils and flours. Food Chem. 74, 47–54 (2001)

Egbuonu, A.C.C., Aguguesi, R.G., Samuel, R., Ojunkwu, O., Onyenmeri, F., Uzuegbu, U.: Some physicochemical properties of the petroleum ether-extracted watermelon (Citrullus lanatus) seed oil. Asian J. Sci. Res. 8(4), 519–525 (2015)

Gómez-García, R., Campos, D.A., Aguilar, C.N., Madureira, A.R., Pintado, M.: Valorization of melon fruit (Cucumis melo L.) by-products: phytochemical and biofunctional properties with emphasis on recent trends and advances. Trends Food Sci. Technol. 99, 507–519 (2020)

Silva, M.A., Albuquerque, T.G., Alves, R.C., Oliveira, M.B.P.P., Costa, H.S.: Melon seeds oil, fruit seeds oil and vegetable oils: a comparison study. Ann. Med. 51(S1), 166 (2019). https://doi.org/10.1080/07853890.2018.1561973

Pinto, J.S., Lanças, F.M.: Hydrolysis of corn oil using subcritical water. J. Braz. Chem. Soc. 17(1), 85–89 (2006)

Aziz, M., Husson, F., Kermasha, S.: Optimization of the hydrolysis of safflower oil for the production of linoleic acid, used as flavor precursor. Int. J. Food Sci. (2015). https://doi.org/10.1155/2015/594238

Bimakr, M., Rahman, R.A., Taip, F.S., Adzahan, N.M., Sarker, M.Z., Ganjloo, A.: Supercritical carbon dioxide extraction of seed oil from winter melon (Benincasa hispida) and its antioxidant activity and fatty acid composition. Molecules 18(1), 997–1014 (2013)

Long, D.A.: Infrared and Raman characteristic group frequencies. Tables and charts George Socrates John Wiley and Sons, Ltd, Chichester, Third Edition. J. Raman Spectrosc. 35, 905–905 (2004). https://doi.org/10.1002/jrs.1238

Stuart, B.H.: Infrared spectroscopy: fundamentals and applications. Wiley, Hoboken (2004). https://doi.org/10.1002/0470011149

Lakowicz, J.R., Masters, B.R.: Principles of fluorescence spectroscopy, third edition. J. Biomed. Opt. 13(2), 029901 (2008). https://doi.org/10.1117/1.2904580

Casillas-Vargas, G., Ocasio-Malavé, C., Medina, S., Morales-Guzmán, C., Del Valle, R.G., Carballeira, N.M., Sanabria-Ríos, D.J.: Antibacterial fatty acids: an update of possible mechanisms of action and implications in the development of the next-generation of antibacterial agents. Prog. Lipid Res. 82, 101093 (2021). https://doi.org/10.1016/j.plipres.2021.101093

Soprano, R.A.L., Andrade, G.R.S., Costa, L.P., de Souza, M.J.B., de Souza, A.M.G.P., Gimenez, I.F.: Ordered micro-mesoporous carbon from palm oil cooking waste via nanocasting in HZSM-5/SBA-15 composite: preparation and adsorption studies. J. Hazard Mater. 362, 53–61 (2019)

Gao, H.X., Yu, J., Chen, N., Zeng, W.C.: Effects and mechanism of tea polyphenols on the quality of oil during frying process. J. Food Sci. 85(11), 3786–3796 (2020)

Nadia, A., Subekti, S., Manan, A., Wahyudin, P.: The effectiveness of activated carbon as adsorbent in the oil purification process fish by-product of the fish canning industry. Ecotoxicol. Environ. Saf. 441(1), 012151 (2020)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). Not applicable.

Author information

Authors and Affiliations

Contributions

This work was carried out in collaboration between the authors: MAA-W and HMS: conceptualization, methodology, software, data curation. HMS: writing-original draft preparation. MAA-W: visualization, investigation, supervision, software, validation and writing- reviewing and editing. The authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

The protocol of the current study was approved by the ethics Animal Care and Use Committee of the National research Center, Dokki, Cairo, Egypt (approval # 12050305/2019).

Consent for Publication

Not applicable.

Consent to Participate

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Soliman, H.M., Abdel-Wahhab, M.A. Synthesis of Antibacterial Bioactive Compounds Using Linoleic Acid Extracted from Melon Seeds Oil and Evaluation of Its Waste Meal Ash for Fried Oil Regeneration. Waste Biomass Valor 15, 487–499 (2024). https://doi.org/10.1007/s12649-023-02161-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02161-0