Abstract

The analysis of the chemical composition of biomass plays an important role in all steps of the life cycle of biomass, especially in thermal conversion processes. Electrothermal vaporization (ETV) coupled with inductively coupled plasma optical emission spectrometry (ICP-OES) is a promising approach for biomass analysis as almost no sample preparation is required, samples can be analysed quickly, and the release of elements from the sample can potentially be quantified with temperature resolution. In this work, the concentration of seven important side and trace elements is determined in beechwood, torrefied wood, wheat straw, miscanthus, and spruce bark. For comparison and validation of the ETV setup, four additional methods of analysis are applied to determine the elemental concentration. Chemical fractionation analysis (CFA) is conducted to investigate the chemical association form. In addition, microwave pressure digestion is carried out with two different acid solutions (HNO3 and HBF4). X-ray fluorescence (XRF) analysis is performed to determine the ash composition of all samples. The spread between most of the results of the different measurement techniques is with less than 20 % well within the expected range for heterogeneous biomass samples. Large deviations, such as the sulphur concentration in the XRF analysis, can be explained by the method used. The ETV results are in very good agreement with the CFA and microwave pressure digestion results. As these methods are well established, ETV analysis has proven to be suitable for the analysis of side and trace elements in biomass.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

This paper demonstrates the first successful validation of the analysis of different biomass fuels in an ETV-ICP-OES system that is required for the temperature-resolved analysis of biomass samples.

Introduction

Biomass is currently the largest source of renewable energy in the world [1]. With a rising demand for renewable energies and limited availability of sustainable biomass, more advanced methods of biomass utilization need to be implemented. This does not only include cleaner and more efficient thermal conversion processes, but also ash utilization and the use of biomass as a sustainable carbon source for chemical processes. Biomass and ash composition is crucial in all these processes, since there are limits on certain elemental concentrations, both from the process side and from regulation [2,3,4].

There are multiple methods of analysis available for investigating the composition of solid biomass samples [5,6,7,8,9,10,11]. These methods vary in complexity, cost, duration, hazardousness, possible sample size, and accuracy. Since biomass is usually a highly heterogeneous sample even within one batch, analysis of multiple samples can give a more accurate picture of the sample at hand [12]. Hence, cost and duration influence the overall accuracy, because a cheaper or quicker method can analyse more samples in the same time or for the same costs. Thus, depending on the application and elements of interests, different methods of analysis are suitable.

The elemental analysis of solid biofuels is largely regulated in standardized protocols [6, 7, 11]. The protocols can be divided into X-ray fluorescence spectroscopy (XRF) and wet chemical analysis methods. The determination of the elemental composition by XRF is regulated in ISO 16696 [11]. While XRF requires only little sample preparation, the standard recognises the challenge of determining very low elemental concentrations or elemental concentrations in inhomogeneous samples. The suggested fused bead method to overcome these challenges is only applicable to non volatile components [11].

As an alternative to XRF, wet chemical analysis methods can be used. DIN EN ISO 16967 standardises the analysis of aluminium (Al), calcium (Ca), iron (Fe), magnesium (Mg), phosphorous (P), potassium (K), sodium (Na), and titanium (Ti) in solid biofuels [6]. In a first step, the solid biomass samples are solved in a microwave pressure digestion. The protocol requires hydrofluoric acid (HF), which is a powerful contact poison. The handling of hydrofluoric acid makes this method of analysis dangerous, time-consuming and expensive, as many safety protocols must be followed. In theory, HF is needed to break down the silicate matrix of the biofuels. Compared to coal, biomass contains fewer silicates. Moreover, Zimmermann et al. found that a fluoroboric acid (HBF4) based digestion protocol can sufficiently break down the silicate matrix and returns comparable results [13]. The resulting solution of the microwave pressure digestion can then be analysed using Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Flame Atomic Absorption Spectrometry (FAAS), or Flame Emission Spectroscopy (FES) [6].

The determination of the chlorine and sulphur content is standardised in DIN EN ISO 16994. In general, the same microwave pressure digestion can be utilized, but neither hydrochloric acid (HCl) nor sulphur containing acids can be used. It mus be considered, that some volatile chlorine compounds can evaporate from the digestion. Moreover, the protocol limits the detection method to ICP-OES or Ion Chromatography (IC) [7, 14]. Thus, for wet chemical analysis advanced equipment is necessary. Overall, the standardised protocol for wet chemical analysis is a time consuming and expensive procedure that requires hazardous chemicals but returns accurate results.

Another factor that needs to be taken into account are systematic errors that can occur due to various factors, including weighing errors, pipetting errors, and contamination. Weighing errors can be caused by environmental factors such as temperature and air currents. In addition, the detection limit of the balance plays a significant role when the sample mass is small. Pipetting errors can occur due to imprecise handling, user error, or when the pipette is not exactly calibrated for the liquid at hand. Contamination is another source of systematic error and can be caused by improper handling of the sample, use of contaminated equipment, or exposure to dust or moisture. Longer and more elaborate procedures are more prone to systematic errors due to the increased likelihood of mistakes in handling and measurement. In general, the mentioned errors are likely to be higher than the detection limits and accuracies of an XRF or ICP-OES system.

Electrothermal vaporization (ETV) is a promising approach for the analysis of biomass samples. The samples are vaporised in a resistively heated furnace under an inert atmosphere. The resulting aerosol is then led into an Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES). ETV analysis has several advantages over wet chemical analysis methods, among them a wide range of detectable elements, rapid analysis, little sample preparation, and the potential to quantify the release patterns from biomass with temperature resolution. However, since the ETV method relies on reference materials for calibration and every element needs to be carefully tuned, extensive validation is required to achieve reliable results.

ETV analysis in general has long been established [15, 16]. It is an accepted method for the analysis of trace elements in materials science [17,18,19]. Resano et al. estimate the precision of ETV-ICP-OES methods to 5–15% and the usual working range of the determination of elemental concentrations up to 10,000 mg/kg [20]. The upper working range is primarily limited by plasma and spectrometer overload. High concentrations can thus either not be analysed or the heating rate has to be reduced [21]. While plant materials have been analysed in an ETV-ICP-OES by Detcheva et al., their investigations focus on trace elements with significantly lower concentrations [22]. The most recent works in ETV-ICP-OES analysis by Hommel et al. investigate the potassium and sulphur release from coal [23]. However, coal contains significantly lower amounts of potassium and due to the origin, the matrix differs from a typical biomass matrix.

The focus of this work lies on the validation of an ETV method for the analyses of side elements in biomass. To minimise matrix effects, plant based reference materials are used for calibration. While aqueous standards are usually used for calibration, reference materials with a similar matrix show a similar release behaviour, which is important for temperature resolved measurements. Since some of the investigated elemental concentrations exceed the usual working range of ETV-ICP-OES systems, validation of the results is necessary [20]. In contrast to the existing literature, the concentration of the elements investigated, the sample type, and the calibration materials differ in this work.

For the validation of the ETV system, five biomass samples are analysed in the ETV and by four other methods. First, a chemical fractionation analysis (CFA) is performed. CFA is a method adapted from Zevnehoven et al. to determine the chemical associated form of the analysed elements [24]. By comparing the results of the CFA and the ETV system, it can be shown whether the bonding type of the element has an influence on the release behavior and thus on the detectability using an ETV setup. Furthermore, the analysis methods complement each other, because the solid products of the CFA can be analysed in the ETV system. The concentration in the liquid leachate and the solid residue should add up to the concentration in the raw biomass.

In addition, two microwave pressure digestions with different acid solutions are analysed. Microwave pressure digestion is fully commercially available and widely used [6, 25]. The results of the microwave pressure digestion can therefore be used as a benchmark in the validation process.

X-ray fluorescence (XRF) analysis is used to have a solid sample method as a reference. XRF and the other methods can analyse numerous elements. Therefore, the elements studied and discussed must be reduced to the relevant elements that can be analysed with all the methods used.

The elements present in biomass can be categorized in main-, minor-, and trace-elements. The main elements carbon, hydrogen, and oxygen are almost completely released during combustion. The minor elements are responsible for most of the ash-related problems, as they make up the majority of the bottom and fly ash in combustion processes [2]. For a better understanding of these processes, the analysis of the minor elements is therefore of central importance. In this work, the primary focus lies on the determination of the minor elements in biomass.

As there is no uniform definition of the minor elements in literature, nitrogen (N), silicon (Si), chlorine (Cl), potassium (K), sodium (Na), calcium (Ca), magnesium (Mg), sulphur (S), and phosphorus (P) are considered minor elements of biomass. All side elements except nitrogen, chlorine and silicon are analysed in all methods of analysis. The liquid sampling methods can not determine chlorine and nitrogen, because the used acids contain these elements. Silicon could form components that are volatile at room temperature with some of the acids, so it can not be accurately quantified by all methods and is therefore excluded from the comparison. In addition to the minor elements, the concentration of zinc (Zn), usually considered a trace-element, is analysed [2].

The biomass samples investigated are selected on the basis of their origin and expected composition to cover a wide range of solid biomass samples. Two stalk-like biomass samples are investigated. Straw is an agricultural residue and its thermal conversion is usually a challenge [26]. The other stalk-like biomass sample is miscanthus, an energy crop. Pretreated biomass are represented by torrefied wood. Bark is chosen because it usually has higher concentrations of minor elements than the core wood [27]. Beechwood is a conventional wood and regularly used in thermal conversion processes [28].

The results are used to validate electrothermal vaporization as a method for the detailed analysis of different types of biomass and different elements. The results are also used to compare the concentration of the seven elements studied in the different types of biomass and the five methods of analysis.

Experimental

This section describes the procedures employed for the analysis of biomass in this work, as well as optimisation protocols for the analysis using electrothermal vaporization.

Samples

In all analysis samples from the same batch are taken. Beechwood is supplied in milled form from J. Rettermaier & Söhne GmbH + Co KG, Germany under the brand name Lignocel HB 120. Spruce bark is sourced from Metsä Fibre Oy, Finland. Torrefied wood pellets are supplied form from TorrCoal Technology B.V., Netherlands and milled before analysis. It consists of various woody biomass types that are torrified at 285 °C to 450 °C and pressed into pellets [29]. Miscanthus is grown, harvested and milled by Forschungszentrum Jülich, Germany. Wheat straw is taken from personal sampling.

The moisture content of all biomass samples is determined by thermogravimetric moisture measurements (Touch Moisture 611-3453, VWR International BV, Belgium). For CFA analysis, samples are dried at 108 °C overnight and their residual moisture is measured in a thermogravimetric analyser. For ETV, samples are not dried but instead kept at room conditions, due to the fact that moisture after drying would not remain constant during the extended time required for weighing multiple samples, thus falsifying weights. Instead, dry basis concentrations are calculated based on the routine thermogravimetric moisture measurements. Those samples that are not pre-milled are milled to pass a 0.5 mm sieve. Except for the difference in moisture content, the same biomass samples are used in all measurements.

Wet Chemical Analysis Methods

Microwave Pressure Digestion

Conventionally, precise analysis of ash elemental composition in biomass is performed by microwave pressure digestion. A small sample (either raw biomass or ash) is hydrolysed and oxidised in the presence of an oxidising acid at high temperature and pressure, thereby dissolving all inorganic constituents while breaking down the sample matrix. In this work, nitric acid (65% HNO3) and hydrochloric acid (32% HCl) are used along with tetrafluoroboric acid (50% HBF4) as a fluorinating agent, according to a method by Zimmermann et al. [13]. Furthermore, a set of digestion experiments omitting fluoride are performed, using only HNO3, to assess whether this safer and more convenient protocol yields comparable results to the conventional method.

For HBF4 digestion, approx. 250 mg of raw sample are placed into a PTFE-lined pressure vessel, to which 7 mL of 65% HNO3, 3 mL of 32 % HCl and 2 mL of 50% HBF4 are added. For HNO3 digestion, approx. 100 mg of sample and 10 mL of 65% HNO3 are used. The vessel is sealed and loaded into a ETHOS.lab temperature-controlled microwave system (MLS Mikrowellen-Labor-Systeme GmbH, Germany). The temperature is set to ramp to 180 °C within 60 min, followed by 240 min hold time. After cooling, the solution is transferred quantitatively into a 100 mL PP volumetric flask and diluted with demineralised water. Elemental concentrations of the resulting solution are determined using liquid sampling ICP-OES.

A SPECTRO ARCOS 2 ICP-OES spectrometer from SPECTRO Analytical Instruments GmbH, Germany, set up in a side-on plasma configuration is used. For liquid sampling measurements, sample solutions are fed into the nebulizer via a peristaltic pump from a CETAC ASX-560 autosampler (Teledyne Technologies Inc., USA). For solid sampling measurements, the ETV is connected directly to the plasma torch via PTFE tubing approx. 70 cm in length and 4 mm in inner diameter. Measurement conditions for ETV-ICP-OES experiments are listed in Table 1.

Chemical Fractionation Analysis (CFA)

The procedure for CFA is based on works by Zevenhoven, Werkelin et al. [24, 30], as well as past works at the Chair of Energy Systems [31, 32]. Through subsequent leaching of solid biomass samples in water (H2O), 1 M ammonium acetate solution (NH4Ac) and 1 M hydrochloric acid (HCl), minor elements are fractionated into four groups. These are water-soluble salts (e.g. K+, Na+, Cl−), organically associated ions (e.g. Mg2+, Ca2+), acid-soluble salts (e.g. Ca and Mg carbonates and sulfates) and inert minerals (e.g. silicates, oxides) [24]. The leaching method by Werkelin et al. employs a single H2O leaching step, followed by three NH4Ac and two HCl lechings, with solvent volumes of 5 to 10 mLs per gram of sample [30]. This procedure is adapted as follows to allow for better suspension of the sample in the solvent as well as to ensure complete leaching (see also Fig. 1):

-

1.

2 × in 20 mL/g H2O, room temperature, stirring, 24 h

-

2.

3 × in 20 mL/g 1 M NH4Ac, room temperature, stirring, 24 h and

-

3.

2 × in 20 mL/g 1 M HCl 80 °C, stirring, 24 h

A sample of 5 g is placed in an Erlenmeyer flask along with a stir bar, to which 100 mL of the respective solvent is added. A watch glass is placed on top to limit evaporation and stirring is turned on for 24 h. In the case of HCl leaching, the flask is placed in a 80 °C oil bath and fitted with a reflux condenser. After leaching, the sample is filtered through a filter paper in a Büchner funnel using vacuum filtration. In the case of samples with a high proportion of colloidal matter, centrifugal separation is performed to prevent clogging of the filter. The flask is rinsed three times with approx. 20 mL of H2O to recover all of the sample, each time pouring it through the funnel to wash the filter cake, thus ensuring no solutes are retained. After drying for approx. 10 min on the filter, the sample is transferred back into the flask and the procedure is repeated for the next leaching step. The leachate was transferred quantitatively into a volumetric flask and diluted to the respective volume of 250 mL or 500 mL, depending on the expected concentration of the analyte. After the final H2O and NH4Ac steps, a small sample of the leached solids is taken and dried at 108 °C for analysis of residual elemental concentrations in ETV.

Solid Sampling Methods

Electrothermal Vaporization (ETV)

An ETV 4000 from Spectral Systems GmbH, Germany, equipped with the AD-50 autosampler is used for the ETV analysis. It is fit with graphite Maxi-Tubes Improved and the corresponding graphite Maxi, premium quality sample boats are used, as supplied by the manufacturer.

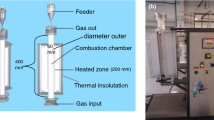

A schematic setup of the ETV system is shown in Fig. 2. The sample is introduced into the resistively heated furnace in a graphite boat. An optical pyrometer is integrated in the door of the furnace and reads the temperature of the sample boat. The graphite tube of the furnace is held in position by two graphite contacts. The temperature is adjusted by changing the electrical power conducted through the furnace. During operation, the power is automatically regulated so that the temperature read by the pyrometer corresponds to the set temperature. The vaporised sample is transported out of the furnace tube by an argon carrier stream, which is referred to as “Argon 2” by the manufacturer. Tetrafluoromethane (CF4) is added into the carrier gas stream as a modifying gas. The modifying gas enables the evaporation of compounds with high boiling temperatures, prevents the formation of carbides, and promotes nucleation to form a dry aerosol [22]. After the furnace tube the bypass argon flow “Argon 1” dilutes the sample gas and helps the formation of a dry aerosol that is then led into the ICP-OES. The “Argon 3” stream cools the metal housing and ensures that all graphite parts are under a protective inert atmosphere [33]. The internal pyrometer of the ETV unit is calibrated weekly with an external reference pyrometer supplied by Spectral Systems GmbH, Germany. The resulting linear correction function is programmed into the ETV temperature controller.

Parameters for ETV experiments as well as the temperature program are listed in Table 1. The parameters are partly based on procedures optimized in a previous work [34].

The method development for ETV measurements is an iterative procedure, since sample mass, heating rate, and selected spectral line in the ICP-OES must match. While the heating rate should be sufficient to achieve a transient signal intensity that is well above the limit of detection for the chosen spectral line, an excessive rate of vaporization at high heating rates may lead to suppression of signals due to effects associated with (over-)loading of the plasma [35]. Additionally, the rate of aerosol formation can influence the transport efficiency from the ETV to the ICP-OES [36, 37]. To reduce and investigate the influence of the heating rate, multiple heating rates are investigated.

Since no overload of the analysed elements is detected under 800 °C, all samples are heated to 800 °C in 20 s. Above 800 °C different temperature profiles are chosen to get to the final temperature of 2400 °C that is held for 20 s. The temperature is linearly increased by \(10~\frac{^{\circ }C}{s}\). The twenty-three applied temperature profiles have temperature jumps, in which the temperature is rapidly increased to a target temperature between 850 and 2000 °C and held there for 60 s. This way, the release at the target temperature can be investigated. After the temperature jump, the temperature profile continues to heat to 2400 °C with a heating rate of \(10~\frac{^{\circ }C}{s}\). The peak vaporization temperature of 2400 °C is a trade off to minimize degradation of graphite components while ensuring complete vaporization of the sample. A purge step following vaporization and cooling prevents memory effects [34].

The results of all 23 temperature profiles are averaged. In doing so, the effects of heating rates can be minimised and the overall accuracy can be increased by increasing the amount of sample analysed.

The routines are calibrated with the certified reference materials (CRM) IPE-568 and IPE-638. The IPE-568 reference material is milled grain of summer wheat (Triticum aestivum) from the Netherlands. IPE-638 is milled maize (Zea mays L.) also originating from the Netherlands [38, 39]. Biomass CRMs are chosen to minimize the influence of matrix effects, both in the vaporization process and in the plasma.

The recorded transient signals are integrated over the entire measurement duration and the mass of the respective elements in the reference sample plotted against the resulting intensity. Fitting of data points according to the following linear or first order rational function yields the calibration parameters used to calculate elemental mass \(m\) from integrated intensity \(I\):

For IPE-568 standardization, 19 samples, including two blanks, are weighed into the sample boats, ranging from 0.4 to 9.59 mg. For IPE-638, 20 samples, including one blank, are measured, ranging from 0.25 to 10.81 mg. It is found that IPE-638 yields superior R2 values and calculated concentrations of biomass samples that are closer to wet chemical analysis values. Therefore, all ETV results presented here are based on IPE-638. A summary of standardization parameters is listed in Table 2.

XRF

As a second solid sampling method, X-ray fluorescence spectroscopy (XRF) is used. Due to the sensitivity of the XRF system, biomass ash is investigated instead of raw biomass. In this work, ash is prepared according to DIN EN ISO 18122 by heating the biomass samples to 550 °C in a muffle furnace [8]. For the creation of the sample pellets that are introduced into the XRF system, 100 mg of ash are homogenized with 20 mg of CEREOX® wax (FLUXANA ® GmbH & Co. KG, Germany) using a mortar and pistil. The resulting mixture is then pressed into a pellet in a benchtop hydraulic press. All samples are analysed in a Shimadzu EDX 800HS energy-dispersive XRF-Spectrometer (Shimadzu corporation, Japan). It is assumed that the analysed elements are present in the highest oxide form. To obtain mass-related concentrations (mg/kg) of the elements, the results of the XRF measurements are converted with the corresponding conversion factors [6, 40].

Compared to the wet chemical analysis methods, the sample preparation of the XRF measurements is easier and safer. The used method is developed for the ash analysis. Wide ranges of biomass types and concentration can be a challenge, since accurate XRF measurements require matrix-specific calibration. [41]. In addition to the elements analysed in all analytical methods, the conducted XRF analysis includes aluminium, silicon, titanium, manganese, iron, strontium and barium.

Results and Discussion

The results of the chemical fractionation analysis are shown in Fig. 3. On the horizontal axis the analysed elements are shown for the investigated biomass samples of beechwood (BW), miscanthus (MC), wheat straw (WS), spruce bark (SB), and torrefied wood (TW). The vertical axis holds the concentration in the sample. The concentrations leached in each steps are staged so the bar graph holds the total concentration. The leaching steps are indicated by different colours.

Independent of the biomass type, potassium, sulphur, and phosphorous are almost completely solved by the water fraction. Ammonium acetate is needed to solve calcium and magnesium out of the biomass samples. The hydrochloric acid fraction only contains relatively large concentrations of calcium in spruce bark and torrefied wood. This is to be expected, as bark is known to contain more calcium than core wood, some of which is in the form of oxalate, which is only soluble in acid [24]. For torrefied wood, it is a result of the torrefication process, which seems to transform some of the more soluble fractions into more inert species [42].

Figure 4 shows the potassium concentration found in beechwood by the different methods of analysis. The bar of the CFA Residues holds the potassium concentration of the solid residues after each leaching step. The residues are analysed using the ETV setup. Since most of the potassium in beechwood is water soluble, only small concentrations are detected after the water leaching step and hardly any potassium is left after the other two leaching steps of the chemical fractionation analysis. The concentrations of the other methods of analysis are in the same order of magnitude. The lower concentrations in the HBF4 leachate might be explained by relatively small samples sizes and the heterogeneity of the sample.

An overview of the elemental concentration in beechwood detected by the different methods is shown in Fig. 5. The results are sorted by the element. The column for potassium is identical to Fig. 4.

The detected concentrations are in the same order of magnitude for all methods of analysis. Except for the potassium concentration, XRF gives the lowest elemental concentrations in beechwood. This may be due to errors in the ashing process, or the generally difficult calibration of the XRF method. The liquid sampling methods and the ETV-setup detect comparable concentrations for all elements. The deviations are within a range that can be explained by the heterogeneity of the sample.

The elemental concentrations in beechwood range from less than 100 mg/kg to over 3000 mg/kg. In other biomass samples examined, such as straw, the range of concentrations is even greater. This is a challenge, especially for the ETV setup, as sample amount, heating rate and the chosen spectral lines have to match the expected concentration to get accurate results. Since the results of the EVT-Setup are in agreement with the results of the liquid sampling methods, the ETV-Setup has proven to be sufficient for the analysis of the investigated elements in beechwood.

Figures 6-12 compare the elemental concentrations in the investigated biomass samples and the applied methods of analysis. The different methods are shown on the horizontal axis. The CFA residues are not included in these diagrams, as they give different results by definition. The coloured lines connect the measured concentration of each biomass.

In theory, the connection of the data points should result in straight horizontal lines. As the investigated samples are highly heterogeneous and the methods of analysis vary, the resulting lines are not perfectly horizontal. In this way, it is possible to asses the heterogeneity of the sample for each element. Furthermore, it is possible to get a general overview of the robustness of the methods with respect to the analysed element.

The potassium concentration is shown in Fig. 6. The stalk-like biomass miscanthus and straw have significantly higher potassium concentrations than the woody biomass samples of beech wood, torrefied wood and spruce bark, as expected for these plants [43]. The concentrations obtained with the different methods differ only slightly. Since potassium is of great interest in the fine particle and deposition formation, the ETV method was primarily tuned to provide accurate results for potassium. This might explain the higher consistency compared to other elements.

The sodium and zinc concentration, shown in Figs. 7 and 8, are low compared to the other investigated elements. Bark naturally shows relatively high concentrations in both elements and the relatively high concentrations in toreffied wood can be explained by the torrefication process [27]. The high deviation between the different measurements can be explained by the low concentrations. The signal to background ratio becomes less clear for low concentrations, so these elements are more susceptible to inaccuracies. Additionally, if the inorganic compounds originate from impurities from harvest and processing, statistic deviations are more significant in small samples sizes.

Figure 9 shows the calcium concentration. With the exception of the XRF results of straw, all concentrations agree well. Bark and torrefied wood have high calcium contents for the reasons mentioned above.

The magnesium content, shown in Fig. 10, ranges from about 400 to 1000 mg/kg for all biomass types. The XRF results are outliers compared to the other methods of analysis. In the case of straw, bark, and torrefied wood the XRF results are elevated, but in the case of beechwood, the XRF magnesium concentration is significantly lower compared to the other methods. One explanation could be, that the process of creating the ash is a source of error. Impurities from the muffle furnace, aging of the crucibles, and multiplied weighing errors could falsiefiy the results. As other elements can be reliably determined by XRF, it is more likely that the detection of magnesium itself might be problematic. In the applied XRF method, the calibration of magnesium is less accurate compared to other elements.

The sulphur content is shown in Fig. 11. Stalk-like biomass has three to four times higher sulphur concentrations compared to the samples of woody origin. While the liquid sampling methods and the ETV yield similar results, the XRF sulphur concentration is significantly lower for all biomass types. A significant amount of the sulphur in the biomass appears to evaporate from the biomass during the production of the ash sample.

Figure 12 shows the phosphorous concentration of the analysed biomass samples. The different methods of analysis show consistent results. The ETV result for straw is an outlier, since it returns by far the highest concentration. Compared to the other biomass samples, beechwood has a significantly lower phosphorous concentration. Stalk-like biomass and bark seem to have naturally higher phosphorus concentrations and the torrefication process seems to increase the concentration. Since the XRF analysis are consistent with the other methods of analysis, most of the phosphors stays in the ash. This should be considered when discussing phosphorous recycling.

The chemical fractionation analysis shows consistent results when compared to the other methods. Water leching shows that the majority of the investigated elements are bound as soluble salts. The ammonium acetat and the hydrochloric acid leaching step are only necessary for the analysis of calcium and magnesium. As the multiple leaching steps are time intensive and require a lot of work, chemical fractionation should only be applied when the chemical associated form is of interest.

The results of the ETV System agree well with the results of the liquid sampling methods. Moreover, with only few exceptions, the ETV value is in between the results of the three liquid sampling methods. The ETV is neither systematically above nor below the expected value. The comparison with the CFA shows that the ETV provides reliable results, regardless of the chemically associated form of the analysed element. While a wide range of concentrations is a challenge for ETV methods in general, the applied method proved to be reliable and robust for the given variety of elemental contents. This is not only shown by the range of concentrations in the analysed biomass samples, but also by the plausible investigation of the CFA residues with significantly lower concentrations. When taking the small sample size and the elaborate method creation process into account, the ETV setup can compete with commercial available liquid sampling methods for the analysis of biomass composition. Furthermore, in contrast to the liquid sampling methods, ETV may be suitable for the analysis of chlorine and silicon.

The microwave pressure digestion in HNO3 and in a solution of HNO3, HCl and HBF4 return reliable results, that agree well with each other and the results of the CFA and ETV system. The deviations are in the range of the expected heterogeneity of the biomass samples. As there is no systematic deviation between the digestion in HNO3 and in a solution of HNO3, HCl, and HBF4, the digestion in HNO3 seems to be sufficient. Compared to the CFA, the microwave pressure digestion ensures a complete dissolution. The ICP-OES liquid sampling method used for analysis in CFA and microwave pressure digestion is different from the method used for the ETV system, even if the same ICP-OES system is used. For calibration, a multi-element standard supplied by the manufacturer of the ICP-OES system can be used for liquid sampling. Compared to the solid sampling method, it is proven and commercially available. Therefore, microwave pressure digestion most likely provides the most reliable results.

The XRF measurements are most cost-effective measurements because the sample preparation and measurement procedure require little time and material. For some elements like potassium, phosphorus, sodium, zinc, and calcium, the XRF results are in an acceptable range when taking the other methods as a reference. For sulphur and magnesium however, the XRF results are not reliable. In the case of sulphur this can be traced back to the ashing process. Since the production of ash is an integral part of the measurement procedure in order to meet the sensitivity thresholds of the XRF system, volatile elements cannot be analysed with this method. Another challenge is the correct calibration for all elements at once. Since the ash elements are assumed to be present in their highest oxide form, deviations from that assumed compound could lead to conversion problems. For the analysis of magnesium the employed calibration is insufficient. The calibration could be optimised in order to determine magnesium contents more accurately. In addition to the seven elements presented here, seven other typical ash elements are analysed by the XRF. All in all, the XRF analysis gives a quick and comprehensive overview over the ash composition of the investigated biomass, but lacks accuracy for some elements. When using XRF analysis, the results should therefore be critically reviewed for each element.

Figure 13 shows the relative deviation of each method of analysis from the concentration determined by wet chemical analysis with HNO3. The HNO3 method is chosen as a reference, because it is well established and yields reliable results. The relative deviation is calculated according to Eq. 3 by averaging the deviation of all samples. The bars indicate the standard deviation within the different biomass samples. Since the phosphorous analysis of the NH4Ac fraction of the miscanthus sample was invalid, this measurement point was excluded from the data set. Other than that, Fig. 13 shows the results of all 5 methods of analysis for all 5 biomass samples.

Potassium yields the most homogeneous results for all methods. The average deviation from the HNO3 measurements are close to zero and the standard deviations are within the expected range for biomass analysis. The measured sodium concentration in miscanthus differed drastically in the CFA and the XRF analysis. The resulting standard deviation are therefore unusually high. The XRF measurement of sulphur are systematically lower than all other elements. For the other elements, most methods differ in an acceptable range from the HNO3 measurements.

Since biomass samples are usually highly heterogeneous, deviations between different measurements and methods are expected. Comparison with the HNO3 measurements and the other methods shows that ETV analysis is well within the accuracy range of wet chemical analysis. For all analysed elements, the ETV analysis has standard deviations comparable to other methods of analysis or even lower.

Conclusion

In this paper, the minor elements in five different biomass samples are analysed using five analytical methods. The range of biomass samples under examination spans from stalk-like biomass such as straw and miscanthus, to woody biomass including bark and beech wood, to pretreated fuel such as torrefied wood.

Five different methods of analysis are used to validate an electrothermal vaporization unit connected to an inductively coupled plasma optical emission spectrometer (ETV ICP-OES) for the analysis of solid biomass samples. A chemical fractionation analysis (CFA) is performed to investigate the influence of the chemically associated form on the release behavior and the detectability in the ETV setup. Microwave pressure digestion with two different acid solutions (HNO3 and HBF4) is performed. Since microwave pressure digestion is the standardised method for the analysis of minor elements in biomass, the results of the HNO3 are taken as a benchmark for all other measurements [6]. Moreover, X-ray fluorescence (XRF) is performed to determine the elemental concentration in ash samples of the biomass.

While microwave pressure digestion yields reliable and accurate results, it involves elaborate sample preparation and the handling of strong, potentially toxic acids. The three staged CFA process is time consuming and has the risk of multiplying errors. The applied XRF methods required ashing and therefore has problems to detect volatile elements. Once a robust and validated method for the ETV system is developed, the system has several advantages. Since little to no sample preparation is required, multiple samples can be analysed in a short time. This enables the analysis of more samples which can give a more accurate picture of a heterogeneous feed stock like biomass. In addition, ETV analysis can potentially provide temperature resolved release patterns of the analysed elements.

The spread between most of the results of the different measurement techniques is well within the expected range for heterogeneous biomass samples. However, the spread is wider for elements like sodium, zinc, and sulphur, while the results for potassium, calcium, magnesium, and phosphorous are more homogeneous.

Of the methods used, only the XRF method deviates significantly from the results of the other methods for magnesium and sulphur concentration. The deviation can be explained with the required ashing procedure and an insufficient calibration for the analysed magnesium concentration.

The results of the ETV are well within the range of the wet chemical analysis methods. The ETV results do not deviate significantly from the HNO3 chemical analysis. Moreover, the comparison of the CFA and the ETV results prove that the chemically associated form does not influence the ETV analysis. While a wide concentration range is a challenge for an ETV method in general, the consistent results of potassium concentration demonstrate the robustness of the developed method. The potassium concentrations range from 1000 mg/kg in beechwood to over 10,000 mg/kg in wheat straw and are determined by ETV with a similar accuracy as with the other methods. The robustness towards different orders of magnitude of concentrations is also emphasised by the analysis of the CFA residues in the ETV. It can be shown that the ETV setup is within the accuracy range of the liquid sampling methods used. While the analysis of potassium, magnesium, sulphur, calcium and phosphorous is very accurate, the ETV method can be improved for the analysis of sodium and zinc.

All in all the accuracy and complexity of five different methods of analysis compared in order to validate an ETV system for the analysis of minor and trace elements in biomass.

Outlook

The next step is the development of a liquid calibration method for the ETV system. This is necessary for the analysis of some trace elements. In addition, the ETV system’s ability to analyse biomass release patterns with temperature resolution is going to be implemented and validated.

Data Availability

Data sets generated during the current study are available from the corresponding author on reasonable request.

References

IEA, International Energy Agency: World energy outlook 2021

Kaltschmitt, M., Hartmann, H., Hofbauer, H. (eds.): Energie aus Biomasse: Grundlagen, Techniken und Verfahren, 3., aktual. aufl. 2016 edn. Springer Berlin Heidelberg, Berlin, Heidelberg (2016). http://nbn-resolving.org/urn:nbn:de:bsz:31-epflicht-1507321

Spliethoff, H.: Power Generation from Solid Fuels. Springer, Berlin (2010). https://doi.org/10.1007/978-3-642-02856-4

DIN EN ISO 17225-1:2021: Solid biofuels—Fuel specifications and classes—Part 1: General requirements

DIN EN ISO 16948:2015-09, Biogene Festbrennstoffe_- Bestimmung des Gesamtgehaltes an Kohlenstoff, Wasserstoff und Stickstoff_(ISO_16948:2015); Deutsche Fassung EN_ISO_16948:2015. Beuth Verlag GmbH, Berlin. https://doi.org/10.31030/2244183

DIN EN ISO 16967:2015-07, Biogene Festbrennstoffe_- Bestimmung von Hauptelementen_- Al, Ca, Fe, Mg, P, K, Si, Na und Ti (ISO_16967:2015); Deutsche Fassung EN_ISO_16967:2015. Beuth Verlag GmbH, Berlin. https://doi.org/10.31030/2266314

DIN EN ISO 16994:2016-12, Biogene Festbrennstoffe_- Bestimmung des Gesamtgehaltes an Schwefel und Chlor (ISO_16994:2016); Deutsche Fassung EN_ISO_16994:2016. Beuth Verlag GmbH, Berlin. https://doi.org/10.31030/2558210

DIN EN ISO 18122:2016-03, Biogene Festbrennstoffe_- Bestimmung des Aschegehaltes (ISO_18122:2015); Deutsche Fassung EN_ISO_18122:2015. Beuth Verlag GmbH, Berlin. https://doi.org/10.31030/2316155

DIN EN ISO 18123:2016-03, Biogene Festbrennstoffe_- Bestimmung des Gehaltes an flüchtigen Bestandteilen (ISO_18123:2015); Deutsche Fassung EN_ISO_18123:2015. Beuth Verlag GmbH, Berlin. https://doi.org/10.31030/2316183

DIN EN ISO 18134-1:2015-12, Biogene Festbrennstoffe_- Bestimmung des Wassergehaltes_- Ofentrocknung_- Teil_1: Gesamtgehalt an Wasser_- Referenzverfahren (ISO_18134-1:2015); Deutsche Fassung EN_ISO_18134-1:2015. Beuth Verlag GmbH, Berlin. https://doi.org/10.31030/2311530

ISO: 16996 Solid biofuels—determination of elemental composition by X-ray fluorescence

Thy, P., Esbensen, K.H., Jenkins, B.M.: On representative sampling and reliable chemical characterization in thermal biomass conversion studies. Biomass Bioenerg. 33(11), 1513–1519 (2009). https://doi.org/10.1016/j.biombioe.2009.07.015

Zimmermann, T., von der Au, M., Reese, A., Klein, O., Hildebrandt, L., Pröfrock, D.: Substituting HF by HBF4-an optimized digestion method for multi-elemental sediment analysis via ICP-MS/MS. Anal. Methods 12(30), 3778–3787 (2020). https://doi.org/10.1039/d0ay01049a

DIN Deutsches Institut für Normung e.V.: Wasserbeschaffenheit—Bestimmung von ausgewählten Elementen durch induktiv gekoppelte Plasma-Atom-Emissionsspektrometrie (ICP-OES) (ISO 11885:2007); Deutsche Fassung EN ISO 11885:2009

Carey, J.M., Caruso, J.A.: Electrothermal vaporization for sample introduction in plasma source spectrometry. Crit. Rev. Anal. Chem. 23(5), 397–439 (1992). https://doi.org/10.1080/10408349208051652

Nixon, D.E., Fassel, V.A., Kniseley, R.N.: Inductively coupled plasma-optical emission analytical spectroscopy. Tantalum filament vaporization of microliter samples (1974)

Hassler, J., Matschat, R., Richter, S., Barth, P., Detcheva, A.K., Waarlo, H.-J.: Determination of 22 trace elements in high-purity copper including SE and TE by ETV-ICP OES using sf 6, NF 3, CF 4 and H2 as chemical modifiers. J. Anal. At. Spectrom. 31(3), 642–657 (2016). https://doi.org/10.1039/C5JA00240K

Amberger, M.A., Broekaert, J.A.C.: Direct multielement determination of trace elements in boron carbide powders by slurry sampling ETV-ICP-OES. J. Anal. At. Spectrom. 25(8), 1308 (2010). https://doi.org/10.1039/c003290e

Nickel, H., Zadgorska, Z.: A strategy for calibrating direct ETV ICP OES analysis of industrial ceramics in powder form. Fresenius J. Anal. Chem. 351(2–3), 158–163 (1995). https://doi.org/10.1007/BF00321631

Resano, M., Vanhaecke, F., de Loos-Vollebregt, M.T.C.: Electrothermal vaporization for sample introduction in atomic absorption, atomic emission and plasma mass spectrometry–a critical review with focus on solid sampling and slurry analysis. J. Anal. At. Spectrom. 23(11), 1450 (2008). https://doi.org/10.1039/b807756h

Kaveh, F., Beauchemin, D.: Improvement of the capabilities of solid sampling ETV-ICP-OES by coupling ETV to a nebulisation/pre-evaporation system. J. Anal. At. Spectrom. 29(8), 1371 (2014). https://doi.org/10.1039/C4JA00041B

Detcheva, A., Barth, P., Hassler, J.: Calibration possibilities and modifier use in ETV ICP OES determination of trace and minor elements in plant materials. Anal. Bioanal. Chem. 394(5), 1485–1495 (2009). https://doi.org/10.1007/s00216-009-2835-4

Hommel, C., Laabs, M., Vogt, T., Vogt, C., Guhl, S., Meyer, B.: Continuous measurement of k and s release by means of ETV-ICP-OES for high-temperature coal conversion processes. Fuel 316, 123292 (2022). https://doi.org/10.1016/j.fuel.2022.123292

Zevenhoven, M., Yrjas, P., Skrifvars, B.-J., Hupa, M.: Characterization of ash-forming matter in various solid fuels by selective leaching and its implications for fluidized-bed combustion. Energy Fuels 26(10), 6366–6386 (2012). https://doi.org/10.1021/ef300621j

Lamble, K.J., Hill, S.J.: Microwave digestion procedures for environmental matrices. Analyst 123(7), 103–133 (1998). https://doi.org/10.1039/a800776d

Frandsen, F.: Ash formation, deposition and corrosion when utilizing straw for heat and power production (2011)

Sjöström, E.: Wood Chemistry: Fundamentals and Applications, 2nd edn. Academic Press Inc, London (1993)

Bundesministerium für Ernährung und Landwirtschaft: Holzmarktbericht 2021: Abschlussergebnisse Für die Forst- und Holzwirtschaft des Wirtschaftsjahres 2021, Berlin (2022). https://www.bmel.de/DE/themen/wald/holz/holzmarktberichte.html Accessed 13 July 2022

Input raw materials-torrefaction process-output product: Datasheet. https://www.torrcoal.com/download/input-raw-materials-torrefaction-process-output-product/

Werkelin, J., Skrifvars, B.-J., Zevenhoven, M., Holmbom, B., Hupa, M.: Chemical forms of ash-forming elements in woody biomass fuels. Fuel 89(2), 481–493 (2010). https://doi.org/10.1016/j.fuel.2009.09.005

Zilling, H.: Ash Forming Matter in Hydrothermally Carbonized Biomass. Technical University of Munich, München (2020)

Vehe, M.: Characterization of biomass fuels using chemical fractionation. Bachelor thesis, Technical University of Munich, München (2020)

Peter Perzl: Elektrothermischer Verdampfer ETV 4000 (2019)

Zilling, H.: Untersuchung des temperaturabhängigen freisetzungsverhal-ten von aschebildenden elementen in festen biomassen. Master thesis, Technical University of Munich, München (2021)

Aramendía, M., Resano, M., Vanhaecke, F.: Electrothermal vaporization-inductively coupled plasma-mass spectrometry: a versatile tool for tackling challenging samples - a critical review. Anal. Chim. Acta 648(1), 23–44 (2009). https://doi.org/10.1016/j.aca.2009.06.027

Ediger, R.D., Beres, S.A.: The role of chemical modifiers in analyte transport loss interferences with electrothermal vaporization ICP-mass spectrometry. Spectrochim. Acta Part B 47(7), 907–922 (1992). https://doi.org/10.1016/0584-8547(92)80085-U

Kántor, T.: Sample introduction with graphite furnace electrothermal vaporization into an inductively coupled plasma: effects of streaming conditions and gaseous phase additives. Spectrochim. Acta Part B 55(5), 431–448 (2000). https://doi.org/10.1016/S0584-8547(00)00193-2

International Plant-Analytical Exchange: Certificate of analysis IPE sample 568 (1997)

International Plant-Analytical Exchange: Certificate of analysis IPE-638 (1998)

Shimadzu Corporation (ed.): EDX Sereies Instruction Manual vol. 2008

ISO International Organization for Standardization: solid biofuels-determination of elemental composition by X-ray fluorescence (2015-12-00)

Khazraie Shoulaifar, T., DeMartini, N., Zevenhoven, M., Verhoeff, F., Kiel, J., Hupa, M.: Ash-forming matter in torrefied birch wood: changes in chemical association. Energy Fuels 27(10), 5684–5690 (2013). https://doi.org/10.1021/ef4005175

Vassilev, S.V., Baxter, D., Andersen, L.K., Vassileva, C.G.: An overview of the chemical composition of biomass. Fuel 89(5), 913–933 (2010). https://doi.org/10.1016/j.fuel.2009.10.022

Acknowledgements

This research is funded by the German Federal Ministry of Food and Agriculture and is part of the project “BioAdd” (Funding code 2219NR023). The financial support is gratefully acknowledged. The responsibility for for the content of this publication lies with the authors. The authors would like to thank Andrea Hartung and Anja Mair for their valuable input. For the supply of the miscanthus samples and the academic exchange, the authors would like to thank Dr. Nicolai Jablonowski.

Funding

This research is funded by the German Federal Ministry of Food and Agriculture and is part of the project “BioAdd” (Funding code 2219NR023). Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mörtenkötter, H., Grünwald, D., Fendt, S. et al. Validation of Electrothermal Vaporization for the Analysis of Biomass Samples and Comparison with Other Methods of Analysis. Waste Biomass Valor 14, 3489–3502 (2023). https://doi.org/10.1007/s12649-023-02129-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02129-0