Abstract

Virgin olive oil processing results in a large amount of biomass (leaves, pomace, stones and wastewater) during harvesting, pruning and production. In recent years, these by-products have been studied as possible sources of bioactive compounds, and several techniques have been developed, including microwave, ultrasound, subcritical extraction, high hydrostatic pressure, a pulsed electric field, and high-voltage electrical discharge. However, these techniques can be expensive, and may require specialized staff to implement them. Therefore, this study proposes a novel method. Hydrodistillation is a simple and fast technique that can recover valuable compounds from olive oil biomasses. As it uses water as a solvent, it is sustainable, does not harm the environment, and is compatible with industrial practice. This paper presents the results of a hydrodistillation experiment on olive leaves, olive pomace and olive stones. Two fractions were obtained: a “phytocomplex” fraction from inside the boiler, and a “hydrolate” fraction from inside the condenser column. HPLC–DAD–MS and GC–MS analyses characterized and differentiated these two fractions. In general, more bioactive compounds, notably phenolic, were recovered from the phytocomplex fraction than the hydrolate fraction. Total phenolic compounds (mgtyr/kgoil) in the phytocomplex fraction were 11903.51, 4007.33, and 2469.42 mgtyr/kgoil for olive leaves, olive pomace and olive stone, while in the hydrolate fraction they were 67.67, 1.98, and 29.05 mgtyr/kgoil, respectively. Furthermore, interesting phenolic compounds typical of Olea europaea L. were found for both matrices. The main families were phenolic alcohols, secoiridoids and flavonoids. In particular, oleuropein, hydroxytyrosol, and tyrosol were recovered from the phytocomplex fraction of leaves and pomace. Finally, the analysis revealed higher amounts of volatile compounds in the hydrolate fraction than the phytocomplex fraction for leaves, stone and pomace. The main class of compounds were esters, ketones, aldehydes, alcohols, terpenes, phenols and their derivatives.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

In the study, hydrodistillation extraction was used as a method to recover bioactive compounds from the different biomasses that result from virgin olive oil production. The first novelty regards the application of this technology (hydrodistillation) in the agri-food field. The second novelty is the ability to simultaneously obtain two, potentially different fractions by the proposal technology. In this sense, hydrodistillation extraction method would offer an eco-friendly, using water as a solvent, and sustainable solution for producers, both in terms of costs and accessibility. Furthermore, it could open the way to interesting new uses of virgin olive oil residues in different fields of application.

Introduction

Olive (Olea europaea L.) is widely cultivated around the world, mainly to make virgin olive oil. Harvesting, pruning and production result in a large amount of biomass [1], which mainly consists of leaves, pomace, stones, and mill wastewater [2]. Each year, trees are pruned to improve the following harvest, and it is estimated that about 25 kg of leaves are collected annually, for each tree. In addition, about 10% of the total weight of the harvest is made up of leaves and branches [3]. In general, leaves are separated from harvested olives as soon as they arrive at the mill, before extraction, by blowing air. Then, olive fruit undergoes a series of well-known processes, such as crushing, kneading, centrifugal extraction, and filtration, in order to obtain virgin olive oil.

A large quantity of biomass is produced during extraction. This includes around 800–850 kg t−1 olives of pomace, depending on whether a two- or three-phase extraction system is used. Pomace is a combination of liquid and solid waste, notably olive pulp, skin, stones, and water [4]. It can be further processed to separate the hard and softer parts, thus obtaining another important biomass, olive stone. Currently, there are few uses for these biomasses, and they are often only seen as waste to be disposed of. Moreover, they can be harmful to the environment, and must be handled correctly. In general, their management requires a significant amount of manpower and storage. However, in recent years, researchers have studied the chemical composition of these residues to try to identify some uses.

Olive leaves are generally used for direct combustion, animal feed, feedstock or pellet manufacturing. Olive stones are mainly used to produce energy, and olive pomace is processed to obtain combustible material to generate energy [5]. Although the use of olive biomasses to produce energy is widely-known and well-studied, it is potentially harmful for the environment, and it is necessary to focus on alternative uses. In this context, a research priority is to investigate olive biomasses as a source of bioactive compounds [6].

In recent years, virgin olive oil residues have been studied as a source of valuable compounds—especially phenols—thanks to their well-known antioxidant properties that are used in the pharmaceutical, cosmetic, and food industries [7, 8].

The agri-food industry has developed many approaches to recover bioactive compounds in biomass. Typically, phenolic compounds are extracted with conventional methods that use large quantities of organic solvents, usually methanol or ethanol. Other techniques have been developed to reduce the amount of organic solvent, and optimize extraction conditions. The most-studied methods are: microwave, ultrasound, or subcritical extraction; high hydrostatic pressure; a pulsed electric field; and high-voltage electrical discharge [9,10,11].

However, the management of these technologies can be difficult, and may require specialized staff. This can translate into high costs for companies and, in some cases, may be beyond their reach. It is therefore necessary to develop a more sustainable technology that does not require the use of organic solvent or expensive equipment, for both economic and environmental reasons. Water is the greenest solvent, as it does not harm either the environment or human health. Several researchers have already studied the use of water as an extraction solvent to recover valuable compounds from different matrices, with interesting results [12].

Building on this earlier work, the present study uses water as a green solvent. The proposed hydrodistillation process (HD) is an environmentally-friendly way to recover bioactive compounds from virgin olive oil biomasses. This relatively fast and easy-to-use system is a traditional method that is used to extract secondary metabolites from plants in processes where the matrix is in direct contact with a solvent in a boiler.

In the boiler, the processed matrix typically undergoes autohydrolysis at a mild temperature (about 100 °C) [13,14,15] allowing the extraction of valuable compounds. At the same time, steam from the heated water vaporizes the volatile compounds in the matrix, and this mixture collected and condensed. HD simultaneously obtains two fractions: the condensate fraction, recovered in the condenser column, and the water extract, a phytocomplex that is recovered inside the boiler [16].

The aim of this study was to use HD extraction with water as a solvent to recover bioactive compounds from the different biomasses that result from virgin olive oil production. To the best of our knowledge, the application of this technology is a novel development in the agri-food field. A second novelty is the ability to simultaneously obtain two, potentially-different fractions.

Therefore, the objective of the present study was to ascertain the effectiveness or suitability of HD as an extraction technology for virgin olive oil residues, and to characterize and differentiate the two fractions obtained by the process. The longer-term aim is to investigate other methodologies that can exploit the different biomasses generated during virgin olive oil production. If successful, the HD extraction method would offer an eco-friendlier, and more sustainable solution for producers, both in terms of costs and accessibility. Furthermore, it could open the way to interesting new uses of virgin olive oil residues in different fields of application.

Materials and Methods

Materials

Olive oil residues were provided by a local olive mill in Tuscany (Bucine, Arezzo, Italy) during the 2020 harvest. Three residues were considered, namely olive leaves (OL), olive pomace (OP), and olive stones (OS). In the following, these residues are called the “matrix”.

OL were separated from the mass of olives entering the mill with a defoliation apparatus (model DLE SUPER TD, MORI-TEM Srl, Italy), and then shredded using a mechanical shredder (MORI-TEM Srl, Italy), reducing them into small pieces of about 5 mm. OP was recovered from the two-phase decanter (MORI-TEM Srl, Italy). Finally, OS was obtained by a de-stoning machine (model DN/O, Clemente-industry, Italy). For each matrix, moisture was measured with a drying oven (Heraeus Function, Thermo Scientific Heraeus, USA) that ran for 24 h at 104 °C (18.8% OS, 47.5% OL, 62.1% OP). Dry matrices were extracted using a stainless-steel distiller (Spring 12 l, Albrigi Luigi Store, Italy), and an induction plate (Konig HA-INDUC-11) was used for warming. Deionized water was used inside the boiler, and tap water was used for the cooling circuit.

Methods

Extraction Conditions

Extraction conditions were chosen based on detailed preliminary tests [12, 16]. The solid/ liquid ratio was 1/5 (g/mL), with a 600 W induction plate. Each extraction ended when 50% of the water solvent in the boiler was recovered in the condenser column, after around 1 h. Before extraction, the moisture of each matrix was measured as described above. Three replicates were run for each matrix (OL, OP, OS) using the HD method, making a total of nine extractions. Two fractions were recovered for each extraction, and the 18 extracts were analyzed and characterized. The water extract fraction was recovered from inside the boiler, while the condensate fraction was recovered from the condenser column. All samples were filtered to separate solids from the liquid phase. Finally, each sample was stored at − 5 °C until chemical analyses were performed.

Chemical Analysis

High-Performance Liquid Chromatography with Diode-Array and Mass-Spectrometry Detector Analysis

The extraction of the phenolic compounds were performed following the official IOC method [17]. Samples of both fractions were centrifuged at 14,000 rpm for 5 min, and the obtained supernatant was diluted 1:10 with water before high-performance liquid chromatography with diode-array and mass-spectrometry detector (HPLC–DAD–MS) analysis.

Chromatographic separation was carried out using an Agilent HP 1260L system equipped with an autosampler, column heater module and quaternary pump, coupled to a DAD and a MSD with API/electrospray interface all from Agilent Technologies (Palo Alto, CA, USA). An Infinity Lab 150 mm × 3 mm i.d., 2.7 µm Poroshell 120, EC-C18 column (Agilent Technologies) was used, equipped with a pre-column of the same phase, and maintained at 28 °C. Injection volume was 3 µL for phytocomplexes and 20 µL for hydrolates. The elution method was performed at a flow rate of 0.4 mL/min using water at pH 3.2 by formic acid (solvent A) and acetonitrile (solvent B). All solvents were Chromasolv™ LC–MS grade (Sigma Aldrich S.R.L.). Broadly, in the present experiment, solution concentrations were as follows: Starting at 95% at 0 min; than changed at 60% at 40 min; remained at 60% at 45 min; decreased at 30% at 50 min; remained at 30% at 60 min; decreased at 0% at 65 min and remained at 0% until 68 min; then returned to 95% at 70 min. UV–vis spectra were recorded in the range 220–600 nm. Chromatograms were registered at 240, 280, and 330 nm. The total phenolic compound content (mgtyrosol/kgoil) was determined as the sum of the peak areas of phenols recorded at 280 nm.

Gas Chromatography–Mass Spectrometry Analysis

Headspace solid-phase microextraction coupled with gas chromatography-mass spectrometry (HS–SPME–GC–MS) was perfomed using the multiple internal standard method, described by Fortini et al. [18]. 4.3 g of an oil sample and 0.1 g of an internal standard (ISTD mix) into 20 mL screw cap vials fitted with a PTFE/silicone septa. After 5 min equilibration at 60 °C, SPME fiber (50/30 µm DVB/CAR/PDMS by Supelco) was exposed for 20 min in the vial headspace under orbital shaking (500 rpm). Then, the fiber was immediately desorbed for 2 min in a gas chromatograph injection port operating in splitless mode at 260 °C. After each desorption a 15 min fiber backout at 260 °C was carried out in a backout unit such to avoid carryover phenomena among subsequent specimens.

The GC–MS identification of VOCs was performed using a Trace CG-MS Thermo Fisher Scientific, equipped with a ZB-FFAP capillary column (Zebron) 30 m × 0.25 mm ID, 0.25 µm df. The temperature of the column was controlled as follows: 36 °C for 10 min, increase to 156 °C at 4 °C min−1, increase to 260 °C at 10 °C min−1, decrease to 250 °C at 10 °C min−1, with hold time of 2 min. Helium was used as the carrier gas at constant flow of 0.8 mL min−1. The temperature of both the ion source and transfer line was 250 °C. The mass detector was operated in scan mode within a 30–330 Th mass range at 1500 Th s−1, with an ionization energy of 70 eV.

Compounds were identified by comparison of their mass spectra and retention times with those of the ISTD mix, consisting of the following 11 compounds: 3,4-dimethylphenol, 4-methyl-2-pentanol, hexanoic acid-d11, 1-butanol-d10, ethyl acetate-d8, toluene-d8, ethyl hexanoate-d11, acetic acid 2,2,2-d3, 6-chloro-2-hexanone, 3-octanone, and trimethyl acetaldehyde. The stock external standard mix contained 71 analytes in refined oil, which was previously verified to be free of any interferent. The analytes and their concentration ranges were chosen based on previous works on Italian virgin olive oils. Deconvoluted peak spectra (obtained using the Agilent MassHunter software suite) were matched against the NIST 11 spectral library for initial identification. Kovats’ retention indices were calculated for further confirmation, and compared with those reported in the literature for the chromatographic column used.

Statistical analyses

A two-way ANOVA was conducted to assess the effect of the different fractions and matrices in the recovery of chemical compounds by HPLC–DAD–MS and GC–MS analysis. The significance of main effects was tested, without interactions. Both tested factors were considered significantly different at p < 0.01. Furthermore, a principal component analysis (PCA) was performed on the significant volatile compounds recovered by GC–MS analysis. All statistical analyses were run using R software (version 3.6.0 for Windows).

Results

HD extraction obtained two fractions from each of the three matrices (OL, OP and OS). The first was named “phytocomplex” (PT), and was recovered from inside the boiler; it was potentially rich in bioactive compounds. The second, named “hydrolate” (HY), was recovered from inside the condenser column; it was potentially rich in volatile compounds. All samples were analyzed to characterize and differentiate the two fractions obtained using HCLP–DAD–MS and GC–MS.

High-Performance Liquid Chromatography with Diode-Array and Mass-Spectrometry Detector Analysis

HPLC–DAD–MS was used to identify the main chemical compounds in the two fractions (PT and HY) for the three matrices (OL, OP and OS). All chromatograms at a wavelength of 280 nm (typical for phenolic compounds) are reported in Figs. 1 and 2.

In the following step, we examined the peaks in the PT fraction of the OL and OP matrices. By this way, we identified numerous peaks with good resolution, and high values of total phenolic compounds (Table 1). Only a few, small indistinct peaks were found in the PT of the OS matrix. On the opposite, as concerns the HY fraction, very small peaks were found for all three matrices and, consequently, very low levels of total phenolic compounds. Thus, these samples were not further investigated.

We therefore examined the PT fraction of the OL and OP matrices in more detail. A total of 13 phenolic compounds were tentatively identified for OL, and 10 for OP, while further four and three peaks were found for the two matrices, respectively, which however remained unidentified. The identified compounds are summarized in Figs. 3 and 4. Consistent with the current literature, the main families of phenolic compounds were phenolic alcohols, secoiridoids and flavonoids for both the matrices [19,20,21].

HPLC–DAD–MS chromatogram of the PT fraction for OL showing the main phenolic compounds (PT phytocomplex fraction, OL olive leaves). 1 unknow; 2 hydroxytyrosol glucoside; 3 hydroxytyrosol; 4 unknow; 5 hydroxytyrosol diglucoside; 6 unknow; 7 caffeic acid; 8 unknow; 9 rutin isomer; 10 cafselogoside; 11 hydroxy oleuropein digucloside, 12 hydroxy oleuropein derivate; 13 rutin; 14 luteolin-7-O-glucoside; 15 apigenin-7-O-rutinoside; 16 luteolin-4-Oʹ-glucoside; 17 oleuropein

HPLC–DAD–MS chromatogram of the PT fraction for OP showing the main phenolic compounds (PT phytocomplex fraction, OP olive pomace). 1 hydroxytyrosol glucoside; 2 hydroxytyrosol; 3 tyrosol glucoside; 4 tyrosol; 5 unknow; 6 unknow; 7 β-OH acteoside isomers 1; 8 β-OH acteoside isomers 2; 9 rutin; 10 unknow; 11 verbascoside; 12 nüzhenide; 13 comselogoside

Some of the OL peaks (1, 4, 6 and 8) could not be identified with the available spectral information. On the other hand, peaks 2, 3 and 5 were identified as simple phenols. Peak 2 was hydroxytyrosol glucoside based on the presence of the [M–H]− at m/z 315 and the aglycone ion at m/z 153; at the same time, peak 3 was hydroxytyrosol, as confirmed by the [M–H]− at m/z 153 and the product ion at m/z 123, in agreement with previous literature [22]. Peak 5 was tentatively identified as hydroxytyrosol diglucoside based on the [M–H]− at m/z 477 and the product ions at m/z 315 and 153 relative the loss of one and two glucose moieties, respectively. Peak 7 was tentatively identified as caffeic acid, based on its λmax in the UV spectrum, and on the [M–H]− at m/z 179 [23]. Peaks 13 and 9 were tentatively identified as rutin and an its isomer, respectively. These compounds share the same fragment ions [M–H]− at m/z 609 and the ion at m/z at 301 in concordance with the literature reports [22].

Peak 10 was tentatively identified as cafselogoside based on the presence of the [M–H]− at m/z 551. Turning to secoiridoids, peaks 11 and 12 were hydroxy oleuropein diglucoside and hydroxy oleuropein derivative, respectively, while peak 17 was identified as oleuropein. Peak 17 was tentatively identified as oleuropein based on the [M–H]− at m/z 539 and on the product ions at m/z at 223 and 377, in agreement with previous literature [24]. Finally, peaks 14, 15 and 16 were identified as luteolin-7-O-glucoside, apigenin-7-O-rutinoside isomer, and luteolin-4-Oʹ-glucoside, respectively. Peak 14 was luteolin-7-O-glucoside based on the presence of [M–H]− at m/z 447 and the ion at m/z at 285 [25]. Peak 15 was apigenin-7-O-rutinoside isomer as confirmed by the [M–H]− at m/z 577 [23]. Finally, peak 16 was tentative identified as luteolin-4-Oʹ-glucoside based on the presence of [M–H]− at m/z 447 and the ion at m/z at 895 in concordance with the literature reports [26].

Turning to OP, like OL, some peaks (5, 6 and 10) could not be identified. Among the simple phenols, peaks 1 and 2 were tentative identified as hydroxytyrosol glucoside and hydroxytyrosol, respectively. Peak 1 was hydroxytyrosol glucoside based on the presence of the [M–H]− at m/z 315 and the aglycone ion at m/z 153; while peak 2 was hydroxytyrosol, as confirmed by the [M–H]− at m/z 153 and the product ion at m/z 123, in agreement with previous literature [27, 28]. Peak 3 was tentative identified as tyrosol glucoside, and peak 4 as tyrosol. Peak 3 was identified as tyrosol glucoside based on the presence of the [M–H]− at m/z 299 and the aglycone ion at m/z 137, while peak 4 was tyrosol as confirmed by the [M–H]− at m/z 137 [28].

Peaks 7 and 8 were identified as β-OH acteoside isomers 1 and 2, respectively. These compounds share the same fragmentation pattern, with [M–H]− at m/z 639 and the product ions with m/z at 161 and 179 [29]. Peak 9 was identified as rutin confirmed by the presence of [M–H]− at m/z 609 and and the ion at m/z at 301; peak 11 was tentatively identified as verbascoside based on the [M–H]− at m/z 623 and the product ion at m/z 161 and 461 [30]. Peak 12 was tentative identified as nüzhenide, as confirmed by the [M–H]− at m/z 685 and 523, 223 [23]. Finally, peak 13 was tentative identified as comselogoside confirmed by the presence of [M–H]− at m/z 535 and 491 in concordance with the literature reports [23]. Data were reported in Table 1.

In the following step, the concentration of total phenolic compounds (mgtyr/kgoil) was calculated, and quantitative results are summarized in Table 2. Data are reported as mg per kg of dry weight of matrix under extraction. Significant differences (p < 0.05) were found for total phenolic compounds.

ANOVA results showed significant differences for the two main effects (matrix and fraction). Specifically, phenolic compound extraction was higher in PT fractions than HY fractions for all three matrices studied. Total phenolic compounds in the PT fraction were 11903.51, 4007.33, and 2469.42 mgtyr/kgoil for OL, OP and OS, respectively, while in the HY fraction they were 67.67, 1.98, and 29.05 mgtyr/kgoil, respectively. Moreover, a comparison of the matrices found highest quantities of OL in both fractions (11903.51 and 67.67 mgtyr/kgoil), followed by OP and OS for the PT fraction (4007.33 and 2469.42 mgtyr/kgoil). For the HY fraction, phenolic compound recovery was higher for OS compared to OP matrices (29.05 and 1.98 mgtyr/kgoil).

Gas-Chromatography-Mass Spectrometry Analysis

The GC–MS analysis examined the volatile profiles of the two fractions (PT and HY) and the three matrices (OL, OP and OS), with the aim of identifying the main peaks. For some compounds, the commercial standard was used to confirm the identification, while for others, mass spectra of the peaks were compared with mass spectra in the NIST standard library database. Gas chromatograms of the two fractions of each matrix are reported in Figs. 5 and 6.

Table 3 summarizes the identified compounds. A higher number of volatile compounds were detected for the HY fraction than for the PT fraction. Specifically, 48 compounds were found in the HY fraction of OL, compared to only 18 for the PT fraction. The same results were obtained for OP, with 38 and 18 compounds reported for HY and PT fractions, respectively. Finally, for OS, 41 compounds were found for the HY fraction compared to 20 for the PT fraction. Overall, the same trend can be observed for all matrices, and it appears that the aromatic profile of HY fractions is more complex than PT fractions.

For each matrix, large quantities of compounds associated with both the typical positive flavors, and the off-flavors found in virgin olive oil were recovered. These include: hexanal; (E)-2-hexenal; 1-hexanol; (Z)-3-hexen-1-ol; and (E)-2-hexen-1-ol for positive attributes, and 3-octanone; heptanal; octanal; (E)-2-heptenal; 1-octen-3-ol; 2,4-heptadienal, and nonanal for negative attributes [31,32,33].

In the following step, the total peak area was calculated for the identified compounds, and quantitative results are summarized in Table 4. The analysis found significant differences (p < 0.05).

The ANOVA found significant main effects for both the fraction and matrix. Higher values were reported for the HY fraction than the PT fraction for all three matrices. For the HY fraction, total peak area was highest for OL (155044,598.79 ± 80752072.57), followed by OS (41628463.10 ± 5297044.94) and OP (17743439.82 ± 3731139.99). For the PT fraction, values were lower (6747350.53 ± 232326.96, 1868154.16 ± 1415872.82, 545249.07 ± 281341.00) for OL, OP and OS, respectively. Among the matrices, values were highest for OL for both fractions (155044598.79 ± 80752072.57 and 6747350.53 ± 232326.96), followed by OP (17743439.82 ± 3731139.99, 1868154.16 ± 1415872.82), and OS (41628463.10 ± 5297044.94, 545249.07 ± 281341.00).

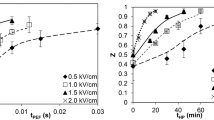

Results of the PCA analysis are summarized in Fig. 7. The first two components (Dim1, Dim2) explained nearly 73.49% of total variance (44.39 and 29.1%, respectively). The biplot shows the projection of all of the samples on Dim1 and Dim2 axes. The PCA clearly separated the two fractions obtained by our HD method. A visual inspection can distinguish samples from the HY fraction (right quadrant), and the PT fraction (bottom left).

Discussion

HD extraction method recovered two fractions (PT and HY) with potentially different by-products. HPLC–DAD–MS and GC–MS analyses were conducted to characterize and differentiate the chemical profiles of the three matrices (OL, OP and OS). In general, HPLC–DAD–MS results showed higher recovery of total phenolic compounds for the PT fraction compared to the HY fraction for all three matrices studied. Beginning with the PT fraction: 11903.51 ± 3375.64 mg/kg of phenols were recovered for OL; 4007.33 ± 875.00 mg/kg of phenols for OP; and 2469.42 ± 317.92 mg/kg for OS. As for the HY fraction: 67.67 ± 117.20 mg/kg of phenols were recovered for OL; followed by 1.98 ± 3.42 mg/kg and 29.05 ± 50.32 mg/kg for OS and OP, respectively. In the latter case, more total phenolic compounds were recovered for OS than OP. However, overall values for HY fractions were low compared to PT fractions, which was an interesting outcome of the study.

At the light of these results, the total phenolic compounds recovered with the proposal method agree with the current literature. Talhaoui et al. [34, 35] report a total phenolic compounds in a range from 60.6 to 52.1 mg/g and from 83.3 to 46.0 mg/g for olive leaves in different cultivar using organic solvent. Bilgin and Şahin [36] report a range from 7.35 to 38.66 mg/g of total phenolic compounds using ultrasound-assisted extraction and from 10.11 to 61.66 mg/g using homogeniser-assisted extraction for olive leaves. Values between 13.00 and 28.83 mg/g are reported by Chanioti and Tzia [37] using natural deep eutectic solvents, with the maximum yield at a temperature of 60°. In the same study, when water is used as a solvent of about 10 mg/g are obtained of total phenolics compounds and the result agree with the values recovery with the HD method.

On the other hand, Cea Pavez et al. [38] report lower values between 241.1 and 1141.3 mg/kg for olive pomace by pressurized liquid extraction. Cioffi et al. [39] report 210 and 381.4 mg/kg for olive pomace and leaves, respectively. Therefore, at the light of the result obtained with HD method, the use of water demonstrated to be a good solvent for the extraction of phenols from olive oil by-products as reported by Ismail et al. [40]. Subsequent investigations focused on the identification of peaks for PT fractions, as their complex chemical profiles, and numerous peaks made them an interesting subject (unlike profiles of HY fractions, where peaks were small and indistinct). The analysis of the PT fraction of OL and OP identified a considerable number of valuable compounds. Several phenol compounds of olive oil and its by-products, typically reported in the literature were recovered and identified [19, 20, 41]. Hydroxytyrosol, verbascoside, and tyrosol were the main compounds recovered in OP, while oleuropein, hydroxytyrosol, luteolin-4-Oʹ-glucoside, and luteolin-7-O-glucoside predominated in OL. In both cases, these results agree with the current literature [6, 42,43,44].

GC–MS analysis provided further insight into the volatile profile of all the samples. In general, a higher number of compounds was recovered in the HY fraction compared to the PT fraction. All three matrices of the HY fraction contained compounds associated with the flavors and off-flavors found in olive oil, consistent with the current literature [31, 32, 42]. Most compounds were detected in OL, followed by OS and OP. The analysis of the total peaks area of the identified volatile compounds found highest values for HY fractions for OL (155044598.79 ± 80752072.57), followed by OP (41628463.10 ± 5297044.94) and OS (17743439.82 ± 3731139.99). These values can be compared to values for PT fractions (6747350.53 ± 232326.96, 1868154.16 ± 1415872.82, 545249.07 ± 281341.00) for OL, OP, and OS respectively. Our findings highlight that HY fractions resulted in a richer mix of volatile compounds with respect to PT fractions. Finally, the PCA clearly separated the two fractions, providing further confirmation of the differences between the aromatic profiles of the two fractions reported above.

Our study confirms that the proposed method could recover two fractions with different, and interesting characteristics from virgin olive oil by-products. The PT fraction of OL, OP and OS was richer in phenolic compounds than the HY fraction, and could be used in antioxidant applications. On the other hand, the HY fraction of OL, OP and OS had a more complex, and richer aromatic profile than the PT fraction. This could translate into two, potentially different uses of these fractions.

Conclusion

In conclusion, the proposed method allowed to recover valuable compounds from the by-products of virgin olive oil processing. The present study demonstrates that HD processing of agri-food by-products has the potential to be an easy, fast and sustainable method that produces two fractions with potentially different uses. The use of water as a solvent allowed to extract a considerable number of valuable compounds. Further studies are needed to optimize the whole process. In particular, the main parameters will be studied and deepened to increase extraction efficiency and to obtain a high-quality product in both qualitative and quantitative terms.

Data Availability

The datasets generated during and/or analysed during the current study are included in this manuscript.

Abbreviations

- HD:

-

Hydrodistillation

- OL:

-

Olive leaves

- OP:

-

Olive pomace

- OS:

-

Olive stone

- PT:

-

Phytocomplex fraction

- HY:

-

Hydrolate fraction

- PCA:

-

Principal component analysis

- ANOVA:

-

Analysis of variance

References

Lama-Muñoz, A., Contreras del, M.M., Espínola, F., Moya, M., Romero, I., Castro, E.: Content of phenolic compounds and mannitol in olive leaves extracts from six Spanish cultivars: extraction with the Soxhlet method and pressurized liquids. Food Chem. (2019). https://doi.org/10.1016/j.foodchem.2020.126626

Xie, P., et al.: Phenolic compounds and triterpenes in different olive tissues and olive oil by-products, and cytotoxicity on human colorectal cancer cells: the case of Frantoio Moraiolo and Leccino cultivars (Olea europaea L.). Food 10(11), 2823 (2021)

Abaza, L., Taamalli, A., Nsir, H., Zarrouk, M.: Olive tree (Olea europeae L.) leaves: Importance and advances in the analysis of phenolic compounds. Antioxidants 4(4), 682–698 (2015). https://doi.org/10.3390/antiox4040682

Bellumori, M., et al.: A by-product from virgin olive oil production (pâté) encapsulated by fluid bed coating: evaluation of the phenolic profile after shelf-life test and in vitro gastrointestinal digestion. Int. J. Food Sci. Technol. 56(8), 3773–3783 (2021). https://doi.org/10.1111/ijfs.15068

Berbel, J., Posadillo, A.: Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 10(1), 1–9 (2018). https://doi.org/10.3390/su10010237

Dermeche, S., Nadour, M., Larroche, C., Moulti-Mati, F., Michaud, P.: Olive mill wastes: biochemical characterizations and valorization strategies. Process Biochem. 48(10), 1532–1552 (2013). https://doi.org/10.1016/j.procbio.2013.07.010

Rodrigues, F.: Composition of the leaf, flower and fruit volatile oils of pittosporum tobira (thunb.) WT aiton grown in three locations in portugal. Flavour Fragr. J. (2007). https://doi.org/10.1002/ffj

Rodrigues, F., Pimentel, F.B., Oliveira, M.B.P.P.: Olive by-products: challenge application in cosmetic industry. Ind. Crops Prod. 70, 116–124 (2015). https://doi.org/10.1016/j.indcrop.2015.03.027

Martiny, T.R., Raghavan, V., De Moraes, C.C., Da Rosa, G.S., Dotto, G.L.: Optimization of green extraction for the recovery of bioactive compounds from Brazilian olive crops and evaluation of its potential as a natural preservative. J. Environ. Chem. Eng. 9(2), 105130 (2021). https://doi.org/10.1016/j.jece.2021.105130

Lama-Muñoz, A., Del Mar Contreras, M., Espínola, F., Moya, M., Romero, I., Castro, E.: Optimization of oleuropein and luteolin-7-o-glucoside extraction from olive leaves by ultrasound-assisted technology. Energies (2019). https://doi.org/10.3390/en12132486

Caballero, A.S., Romero-García, J.M., Castro, E., Cardona, C.A.: Supercritical fluid extraction for enhancing polyphenolic compounds production from olive waste extracts. J. Chem. Technol. Biotechnol. 95(2), 356–362 (2020). https://doi.org/10.1002/jctb.5907

Angeloni, G., Masella, P., Guerrini, L., Innocenti, M., Bellumori, M., Parenti, A.: Application of a screening design to recover phytochemicals from spent coffee grounds. Food Bioprod. Process. 118, 50–57 (2019). https://doi.org/10.1016/j.fbp.2019.08.017

Garrote, G., Domínguez, H., Parajó, J.C.: Mild autohydrolysis: an environmentally friendly technology for xylooligosaccharide production from wood. J. Chem. Technol. Biotechnol. 74(11), 1101–1109 (1999)

Angeloni, G., Masella, P., Guerrini, L., Innocenti, M., Bellumori, M., Parenti, A.: Application of a screening design to recover phytochemicals from spent coffee grounds. Food Bioprod. Process (2019). https://doi.org/10.1016/j.fbp.2019.08.017

Conde, T., Mussatto, S.I.: Isolation of polyphenols from spent coffee grounds and silverskin by mild hydrothermal pretreatment. Prep. Biochem. Biotechnol. 46(4), 406–409 (2016). https://doi.org/10.1080/10826068.2015.1084514

Spadi, A., et al.: Hydrodistillation of coffee by-products to recover of bioactive compounds: the spent coffee ground and coffee silvers skin case-study. Chem. Eng. Trans. 87(April), 313–318 (2021). https://doi.org/10.3303/CET2187053

International Olive Council. Determination of Biophenols in Olive Oils by HPLC. Int. Olive Counc. Madrid, Spain (2017)

Fortini, M., Migliorini, M., Cherubini, C., Cecchi, L., Calamai, L.: Multiple internal standard normalization for improving HS-SPME-GC-MS quantitation in virgin olive oil volatile organic compounds (VOO-VOCs) profile. Talanta 165, 641–652 (2017). https://doi.org/10.1016/J.TALANTA.2016.12.082

Herrero, M., Temirzoda, T.N., Segura-Carretero, A., Quirantes, R., Plaza, M., Ibañez, E.: New possibilities for the valorization of olive oil by-products. J. Chromatogr. A 1218(42), 7511–7520 (2011). https://doi.org/10.1016/j.chroma.2011.04.053

De Leonardis, A., Aretini, A., Alfano, G., MacCiola, V., Ranalli, G.: Isolation of a hydroxytyrosol-rich extract from olive leaves (Olea europaea L.) and evaluation of its antioxidant properties and bioactivity. Eur. Food Res. Technol. 226(4), 653–659 (2008). https://doi.org/10.1007/s00217-007-0574-3

Talhaoui, N., Taamalli, A., Gómez-Caravaca, A.M., Fernández-Gutiérrez, A., Segura-Carretero, A.: Phenolic compounds in olive leaves: analytical determination, biotic and abiotic influence, and health benefits. Food Res. Int. 77, 92–108 (2015). https://doi.org/10.1016/j.foodres.2015.09.011

Savarese, M., De Marco, E., Sacchi, R.: Characterization of phenolic extracts from olives (Olea europaea cv. Pisciottana) by electrospray ionization mass spectrometry. Food Chem. 105(2), 761–770 (2007). https://doi.org/10.1016/j.foodchem.2007.01.037

Obied, H.K., Bedgood, D.R., Prenzler, P.D., Robards, K.: Chemical screening of olive biophenol extracts by hyphenated liquid chromatography. Anal. Chim. Acta 603(2), 176–189 (2007). https://doi.org/10.1016/j.aca.2007.09.044

De Nino, A., Lombardo, N., Perri, E., Procopio, A., Raffaelli, A., Sindona, G.: Direct identification of phenolic glucosides from olive leaf extracts by atmospheric pressure ionization tandem mass spectrometry. J. Mass Spectrom. 32(5), 533–541 (1997). https://doi.org/10.1002/(SICI)1096-9888(199705)32:5%3c533::AID-JMS506%3e3.0.CO;2-9

Laguerre, M., et al.: Characterization of olive-leaf phenolics by esi-ms and evaluation of their antioxidant capacities by the CAT assay. J Am Oil Chem Soc (2009). https://doi.org/10.1007/s11746-009-1452-x

Quirantes-Piné, R., Lozano-Sánchez, J., Herrero, M., Ibáñez, E., Segura-Carretero, A., Fernández-Gutiérrez, A.: HPLC-ESI-QTOF-ms as a powerful analytical tool for characterising phenolic compounds in olive-leaf extracts. Phytochem. Anal. (2012). https://doi.org/10.1002/pca.2401

Peralbo-Molina, Á., Priego-Capote, F., Luque De Castro, M.D.: Tentative identification of phenolic compounds in olive pomace extracts using liquid chromatography-tandem mass spectrometry with a quadrupole- quadrupole-time-of-flight mass detector. J. Agric. Food Chem. 60(46), 11542–11550 (2012). https://doi.org/10.1021/jf302896m

Lozano-Sánchez, J., et al.: Wastes generated during the storage of extra virgin olive oil as a natural source of phenolic compounds. J. Agric. Food Chem. 59(21), 11491–11500 (2011). https://doi.org/10.1021/jf202596q

Cecchi, L., et al.: Phenolic profiles, oil amount and sugar content during olive ripening of three typical tuscan cultivars to detect the best harvesting time for oil production. Food Res. Int. 54(2), 1876–1884 (2013). https://doi.org/10.1016/j.foodres.2013.04.033

Cardoso, S.M., Guyot, S., Marnet, N., Lopes-da-Silva, J.A., Renard, C.M.G.C., Coimbra, M.A.: Characterisation of phenolic extracts from olive pulp and olive pomace by electrospray mass spectrometry. J. Sci. Food Agric. 85(1), 21–32 (2005). https://doi.org/10.1002/jsfa.1925

Romero, I., García-González, D.L., Aparicio-Ruiz, R., Morales, M.T.: Validation of SPME-GCMS method for the analysis of virgin olive oil volatiles responsible for sensory defects. Talanta 134, 394–401 (2015). https://doi.org/10.1016/j.talanta.2014.11.032

Cecchi, L., Migliorini, M., Giambanelli, E., Cane, A., Mulinacci, N., Zanoni, B.: Volatile profile of two-phase olive pomace (alperujo) by HS-SPME-GC-MS as a key to defining volatile markers of sensory defects caused by biological phenomena in virgin olive oil. J. Agric. Food Chem. 69(17), 5155–5166 (2021). https://doi.org/10.1021/acs.jafc.1c01157

Giuffrè, A.M., Capocasale, M., Macrì, R., Caracciolo, M., Zappia, C., Poiana, M.: Volatile profiles of extra virgin olive oil, olive pomace oil, soybean oil and palm oil in different heating conditions. LWT (2019). https://doi.org/10.1016/j.lwt.2019.108631

Talhaoui, N., Vezza, T., Gómez-Caravaca, A.M., Fernández-Gutiérrez, A., Gálvez, J., Segura-Carretero, A.: Phenolic compounds and in vitro immunomodulatory properties of three andalusian olive leaf extracts. J. Funct. Foods 22, 270–277 (2016). https://doi.org/10.1016/J.JFF.2016.01.037

Talhaoui, N., Gómez-Caravaca, A.M., León, L., De la Rosa, R., Segura-Carretero, A., Fernández-Gutiérrez, A.: Determination of phenolic compounds of ‘Sikitita’ olive leaves by HPLC-DAD-TOF-MS. comparison with its parents ‘arbequina’ and ‘picual’ olive leaves. LWT Food Sci. Technol. 58(1), 28–34 (2014). https://doi.org/10.1016/J.LWT.2014.03.014

Bilgin, M., Şahin, S.: Effects of geographical origin and extraction methods on total phenolic yield of olive tree (Olea europaea) leaves. J. Taiwan Inst. Chem. Eng. 44(1), 8–12 (2013). https://doi.org/10.1016/J.JTICE.2012.08.008

Chanioti, S., Tzia, C.: Extraction of phenolic compounds from olive pomace by using natural deep eutectic solvents and innovative extraction techniques. Innov. Food Sci. Emerg. Technol. 48(June), 228–239 (2018). https://doi.org/10.1016/j.ifset.2018.07.001

Cea Pavez, I., et al.: Molecules obtaining an extract rich in phenolic compounds from olive pomace by pressurized liquid extraction. Molecules (2019). https://doi.org/10.3390/molecules24173108

Cioffi, G., Pesca, M.S., De Caprariis, P., Braca, A., Severino, L., De Tommasi, N.: Phenolic compounds in olive oil and olive pomace from cilento (Campania, Italy) and their antioxidant activity. Food Chem. 121(1), 105–111 (2010). https://doi.org/10.1016/j.foodchem.2009.12.013

Ismail, B.B., Pu, Y., Guo, M., Ma, X., Liu, D.: LC-MS/QTOF identification of phytochemicals and the effects of solvents on phenolic constituents and antioxidant activity of baobab (Adansonia digitata) fruit pulp. Food Chem. 277, 279–288 (2019). https://doi.org/10.1016/J.FOODCHEM.2018.10.056

Pereira, A.P., et al.: Phenolic compounds and antimicrobial activity of olive (Olea europaea L. cv. cobrançosa) leaves. Molecules 12, 1153–1162 (2007)

Difonzo, G., Troilo, M., Squeo, G., Pasqualone, A., Caponio, F.: Functional compounds from olive pomace to obtain high-added value foods—a review. J. Sci. Food Agric. 101(1), 15–26 (2021). https://doi.org/10.1002/jsfa.10478

Rubio-Senent, F., Rodríguez-Gutiérrez, G., Lama-Muñoz, A., Fernández-Bolaños, J.: Phenolic extract obtained from steam-treated olive oil waste: characterization and antioxidant activity. LWT Food Sci. Technol. 54(1), 114–124 (2013). https://doi.org/10.1016/j.lwt.2013.04.011

Erbay, Z., Icier, F.: The importance and potential uses of olive leaves. Food Rev. Int. 26(4), 319–334 (2010). https://doi.org/10.1080/87559129.2010.496021

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Spadi, A., Angeloni, G., Cecchi, L. et al. Exploiting Virgin Olive Oil By-products Using Hydrodistillation. Waste Biomass Valor 14, 1931–1944 (2023). https://doi.org/10.1007/s12649-022-01973-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01973-w