Abstract

Different strategies for sewage sludge management have been implemented to minimize the environmental impacts and benefit from the resources embedded in this waste stream. In that regard, Hydrothermal treatments (HTTs) of biomass can contribute generating high-value products (hydrochar) and enhancing biogas generation. In this work, different strategies were analysed for implementing HTTs at WWTPs considering the effect of 2 different process temperatures (160 and 250 °C) on different sewage sludge samples (primary, secondary and digestate sludge). Determination of carbon, nitrogen and phosphorus fate and mass and energy balances in hydrochar and process waters were carried out. HTT promoted solubilization of nitrogen, phosphorus and organic carbon up to 89%, 13% and 124% respectively. Moreover, biomethane yield increased up to 168% reaching methane concentrations up to 79% in the biogas. High heating values of hydrochars ranged from 12.0 to 18.2 MJ kg−1. The integration of HTT as an intermediate step between two-step anaerobic digestion process showed an increase in the net energy balance of up to 124% in comparison with the conventional anaerobic digestion process.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

The current waste water treatment systems only rely in the production of biogas as the only source of energy resulting in the energy production that can cover up to 30% of the whole system. After the anaerobic digestion of the sewage sludge, the sludge is disposed either in land or is composted. However, still a lot of potential energy is content in the remaining treated sludge that is not used. This research evaluated sewage sludge from different points of a wastewater treatment plant were at lab scale. As a result, this paper provides strategies to harness better the properties of the sewage sludge by evaluating the integration of hydrothermal treatments in different key points of a conventional wastewater treatment plants.

Introduction

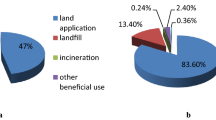

Biomass is considered an important renewable resource for energy production and has gained interest in recent years. In the European Union area, in 2015, the energy produced from biomass conversion to biogas reached 61 TWh of electricity and 127 TJ of heat, which 9% of the total energy belonged to the biogas produced from sewage sludge [1]. Sewage sludge is one of the main biomass waste streams with more impact to the environment if not properly handled due to the high amount of organic matter and contaminants. This means that sewage sludge represents an important biomass stream for energy production. As a consequence, different strategies for sewage sludge management have been applied to minimize the environmental impact and harness its properties [2,3,4]. The most common strategy for sewage sludge management at wastewater treatment plants (WWTPs) includes anaerobic digestion (AD) [1, 3, 5,6,7]. AD brings benefits such as the reduction of the final volume of waste to be disposed of, odour control, the reduction of some pathogens and the production of biogas [1, 8, 9]. Furthermore, biogas production has the potential to cover between 40 and 80% of the overall energy requirement of a typical WWTP [7, 10]. In Europe, in 2015, from the total amount of biogas produced, 9% came from sewage sludge [1]. This means that sewage sludge represents an important biomass stream for energy production. However, conventional AD of sewage sludge is limited by the solubilisation step of the organic compounds during the hydrolysis, withdrawing only half of its potential for energy production [5, 11, 12].

In recent years, hydrothermal processing has gained attention as an alternative co-treatment of AD to increase the energy production from sewage sludge and reduce the energy demand from WWTPs [3, 13,14,15,16]. Hydrothermal treatments (HTTs) are based on the application of high pressures and temperatures conditions to the biomass in a closed system producing (depending on the process conditions) solid, liquid and gas by-products [3, 17, 18]. HTTs brings benefits such as final volume waste reduction, complete pathogen inactivation, enhance of hydrolysis [6, 19] (solubilization of organics), and production of bio-oils, hydrochars and syngas [18]. HHTs promote also the reduction of the viscosity of the sewage sludge and lead to the production of hydrophobic solids (hydrochar) helping to reduce the high energy demand of the dewatering step [9, 20, 21]. Moreover, one of the HTTs main products, the process water, has been demonstrated to be suitable for methane production, representing an extra energy production for the system [9, 14, 18, 22].

HHT applied to sewage sludge and its feasibility of integration before the AD process has been well studied, and large scale technology has successfully been developed such as CAMBI® and BIOTHELYS® processes [4, 12, 21, 23, 24]. This configuration was found to improve energy production by up to 43% [5]. Nonetheless, the concept of integrating HTT after the AD process has gained more interest in the past years because potentially can increase the energy production up to 179%, the possibility to use it as a strategy to recover nitrogen and phosphorus and the contribution to better digestate management considering future restriction on current land disposal route [3, 9, 13,14,15, 18, 25,26,27]. Another recent approach is the valorisation of biomass through integrating double HTT or double AD step to obtain more complex by-products like hydrogen, proteins, sugars or organic acids [28,29,30,31,32,33]. However, those studies focused on feedstocks such as lignocellulosic biomass, algae or animal manures. As a consequence of the potential benefits that bring this recent approach, companies and the research community are aiming to design portable and flexibles HTT units to ease the integration into WWTPs [18]. Companies such as CarboRem and Terranova Energy have developed technology that follows this new trend but these commercial applications are still under development [18].

Indeed, the inclusion of HTTs into a WWTP boost the energy production and valorisation from sewage sludge leading to economic and environmental benefits [3, 9, 13]. Nevertheless, there are few studies related to the strategies that should be taken to couple AD with an HTT to maximize the energy production from sewage sludge within a WWTP [3, 9, 13, 34]. The main challenge is to bring a seamless integration for coupling HTTs to the current infrastructure at the WWTPs for better sewage sludge management to comply with the environmental and operational requirements related to waste reduction, resource recovery, and the reduction of the treatment costs. The principal objective of this particular research work was to analyse the strategies for the integration of HTTs into a conventional WWTP with sewage sludge management. Also, it was investigated the fate of key constituents in sewage sludge as a result of anaerobic digestion treatment and hydrothermal process conditions. Research findings of this work can be applied to develop novel process configurations for WWTPs by incorporating HTTs as part of an integral strategy for sewage sludge management.

Methods

The methodology followed for this research is as shown in Fig. 1.

Sewage Sludge and Inoculum Samples

The primary sludge (PS) and secondary sludge (SS) were collected from Esholt WWTP (Yorkshire Water) located in Bradford, UK. A third sample was prepared with the blend of primary and secondary sludge (total solids ratio 1:1) and named MIX. After collection and prior characterisation the samples were conserved and stored at 4 °C.

The inoculum used for BMP tests and digestate samples preparation was obtained from the anaerobic reactor at Esholt’s WWTP. To keep the anaerobic microorganisms of the inoculum active until its use, the digestate was conserved in sealed bottles at 37 °C and fed every week with untreated sewage sludge until its use.

Digestate Samples and BMP Test

Digestate samples preparation was carried out as described in Aragón-Briceño, et al. [3]. The resulted treated samples were labelled as follows: AD primary sludge (ADPS); AD secondary sludge (ADSS); and AD mix (ADMIX).

BMP tests for the samples followed the methodology as reported in Aragón-Briceño, et al. [15].

Hydrothermal Experiments

Hydrothermal experiments are described in Aragón-Briceño, et al. [3]. Samples were treated in a 500 mL stainless steel batch Parr reactor (non-stirred) with a working volume of 220 mL. Sewage sludge samples were adjusted to the concentration of 2.5% of dry solids before treatments. The supercritical process conditions selected for this study were 160 °C—30 min and 250 °C—30 min and heating rates of ≅ 5.3 and 4.2 °C/min respectively. The process temperature and time conditions were selected based on previous studies [5, 15].

Solid Samples Analyses

The solid samples characterization followed the methodology from previous studies [15]. The treated and non-treated samples were dried in an oven at 40 °C until constant weight (7 days). To perform the ultimate and proximate analyses of the dry samples, an Elemental analyser (CE Instruments Flash EA 1112 Series) and a Thermogravimetric analyser (Shimadzu, TGA-50) were used.

Liquid Products Characterization

The characterisation of process waters (PW) were based on the standard methods for the characterization of wastewater [35]. Total Solids (TS), Suspended Solids (SS), Total Kjeldahl Nitrogen (TKN), Ammonium, Total Phosphorus, Reactive Phosphorus, Chemical Oxygen Demand (COD), Volatile Fatty Acids (VFAs) and pH were determined for all liquid samples. To perform the ultimate analyses of PW’s, liquid samples were evaporated and dried for 7 days at 40 °C prior analysis in the CHNS analyser. A TOC analyser (HACH Lange IL550 TOC/TIC Analyser) was used to determine the Total organic carbon (TOC).

Data Processing and Analysis

The following equations reported by Aragón-Briceño, et al. [5] were used for the data processing of hydrochar and PWs analyses:

Hydrochar Yield

Hydrochar yield (Y), energy densification (Ed) and energy yield (Ey) were determined as follows:

where HHV is High Heating Value.

High Heating Value (HHV)

The Dulong equation reported by Aragón-Briceño, et al. [5] was used to determine the theoretical HHV.

Biochemical Methane Production (BMP)

The following BMP formula as reported by Aragón-Briceño, et al. [5], was used to evaluate the performance of methane production per gram of chemical oxygen demand (COD) added:

where BMP = Biochemical Methane Potential (mL of CH4/ g of COD added); VCH4 = Volume of methane produced in the bottle (mL); VCH4, blank = Volume of methane produced in the blanks (mL); Mass of COD = Mass of COD of the substrate (g of COD substrate).

Theoretical BMP (BMP th )

BMP theoretical values were calculated using Boyle’s formula as reported in Aragón-Briceño, et al. [15].

Boyle’s equation:

where n, a, b and c represent the molar fraction of C, H, O and N, respectively.

Anaerobic Biodegradability (BD)

The experimental (BMP exp) and the theoretical (BMPthBO) BMPs were used to calculate the anaerobic biodegradability following the formula:

Kinetics: Modified Gompertz Equation

The modified Gompertz model is commonly used to report the kinetics of methane production in relation to bacterial growth during the anaerobic process [29, 36, 37]. The obtained parameters from the equation ease the comparison between samples regarding anaerobic digestion performance [29, 36, 38].

where VCH4 is the cumulative methane production at fermentation time (day) expressed in mL /g of COD, Pmax is the maximum cumulative methane production (mL /g of COD), Rmax is the maximum methane production rate (mL / g COD / DAY) and the λ is the lag phase (day). To fit the parameters of the modified Gompertz equation, the solver tool from Microsoft excel was used.

Results and Discussions

Fate of Solids from Raw and Digested Sewage Sludge After HTT

Figure 2a presents the mass distribution before and after different HTT conditions from the raw and processed sludge/digestate samples. To observe the maximum solubilization rate of organics and nutrients into the liquid fraction during the HTTs, 2.5% of solid concentration was selected for loading the reactor [15]. The solid fraction in the original samples, after thermal treatment, was reduced up to 70% either solubilized or converted into a gas (See Fig. 2b. The hydrolysis reactions that organic and inorganic compounds suffer during thermal treatment lead to an increase in the concentration of the water-soluble products or volatilization and at the same time a reduction of the solid fraction [5, 39,40,41,42]. Between 8 to 50% of the solid fraction suffered volatilization and from 13 to 34% suffered solubilization. According to Zabaleta, et al. [39], most of the produced gas fraction are principally composed of CO2. The severity of the reaction showed that higher temperatures favoured the volatilization-solubilization of the solid fraction. Process temperature at 250 °C showed higher volatilization of the liquid and solid fractions than treatments at 160 °C (See Fig. 1a, b). This is the case of PS and ADPS samples that presented a solid fraction transformation of 31% after the 160 °C treatment and 61% after the 250 °C treatment. SS sludge after 160 and 250 °C thermal treatments showed the highest solid transformation with 62 and 70% respectively. MIX and Digestates also presented the same trend favouring the volatilization-solubilization of the solid fraction during 250 °C treatment.

Liquid Products Characteristics

pH

The changes in the pH of process waters from thermal treatment are related to the feedstock composition and the formation-hydrolysis reactions during the thermal treatment. The formation of ammonium (through decomposition of proteins) and alkaline compounds can contribute to an increase in the pH, while organic acids resulting from thermal hydrolysis can contribute to pH reduction [5, 18, 26]. Although, the buffering capacity of the sample is another factor that might limit the effects of the initial hydrolysis reactions [43]. The pH of the process waters from all sewage sludge samples can be observed in Fig. 3a. Results showed that prior thermal treatment, the samples that come from biological treatments (SS and digestates), promoted the production of alkaline compounds propitiating in an increase of the pH (7.49–8.74). On the other hand, the PS and MIX samples suffered a slight reduction in the pH after thermal treatment (5.28–6.81), which suggests the net accumulation of acid compounds. It has been reported a wide range of pH values in PWs from thermally treated sewage sludge, which supports the argument that the pH is feedstock dependent. For instance, our previous studies reported pH values from 7.04 to 9.15 for PWs from AD treated sewage sludge at different treatment temperatures (160–250 °C) [5] while other works reported pH values from 3.8 to 7.8 for hydrothermally treated synthetic faecal sludge (140–200 °C) [44].

Total Solids and Total Volatile Solids

The change in the concentration of TS and TVS between raw liquors and PWs from sewage sludge samples before and after thermal treatments are shown in Fig. 3b. It is clear that the thermal treatments favoured the solubilisation of the solid fraction (organics and inorganics) into the liquid fraction due to the hydrolysis reactions [5, 15, 19, 25, 44, 45]. Therefore, an increase in the concentration of the TS and TVS is observed in all the samples after HTT.

The highest concentration was obtained with the PS samples with an increase of TS after HTT at 160 °C and 250 °C of 307 and 321% respectively. This could be attributed to the presence of organics and inorganics compounds highly hydrolysable presented in PS unlike the biological treated sludge samples (SS and Digestates) where those compounds have been already hydrolysed. The increase in the TVS concentration can be also related to the solubilization of the organic compounds. The amount of TVS in process waters showed a two to six-fold increase when compared with the raw liquor after thermal treatment. In the raw liquors, TVS accounted for 20–49% of the TS but in process waters, they contributed to up to 95% of TS. That means that TVS constitutes the larger fraction of solids in process waters. Process waters from SS samples achieved the highest increment of TVS at 160 °C, which might be due to the higher content of biological biomass present in the sludge purged from the activated sludge process.

Sludge samples from anaerobic pre-treatment produced process waters with lower content of TS and TVS. This might be during the AD process most of the high hydrolysable organics are consumed and transformed mainly into biogas. Nonetheless, a considerable amount of organic matter still remains in AD sludges that could be harnessed even further following thermal treatments.

Chemical Oxygen Demand and Total Organic Carbon

Figures 3c and d show changes in TOC and COD concentrations in liquid fractions of sewage sludge samples before and after thermal treatment. In agreement with previous studies, the TOC and COD concentrations increased as the process temperature increased [15, 26, 29, 45]. This is due to the severity of the reaction that favours the hydrolysis of polysaccharides and proteins that lead to the solubilisation of organic and inorganic compounds and hence, it is reflected in the increase of the COD and TOC concentrations in the PWs [5, 26, 40, 41].

The COD concentration in PWs from PS, SS and MIX samples increased up to 3, 16 and fivefold, respectively in comparison with raw liquors. Process waters of ADPS, ADSS and ADMIX samples reported an even higher relative increment of COD concentrations of 5.0, 7.0- and 7.3-fold, respectively. Previous studies reported a seven-fold increase of COD concentration in process waters from sewage digestate after thermal treatments at 160 and 250 °C [5].

Process waters from SS samples achieved the highest soluble COD conversion rates with 357 and 522 mg of COD per gram of feedstock at 160 and 250 °C thermal treatments respectively. These COD conversion rate values are followed by PS samples with 288 and 501 mg of COD per gram of feedstock, and MIX sludge samples with 277 and 464 mg of COD per gram of feedstock. On the other hand, sludge samples undertaking anaerobic pre-treatment reported much lower net solubilisation of organic compounds in the PWs showing COD solubilisation rates between 158 and 316 mg of COD per gram of feedstock. This might be attributed to the higher concentration of hydrolysable organic compounds contented in non-anaerobically treated sludge samples.

TOC concentrations followed a similar pattern as described for COD concentrations in PWs (see Fig. 3c), in which there was an increase of the TOC concentration due to the solubilisation of organic compounds in the liquid fraction. All sample’s concentrations in the liquid fraction showed an increase of 3.0 to 14.5 after thermal treatment. Some studies have reported similar trends on the increase of the TOC concentration after thermal treatment of biomass ranging from 43.9 up to 68% [5, 15, 46]. TOC conversion rates from PS, SS and MIX samples ranged from 167 and 240 mg of TOC per gram of feedstock, while corresponding figures from ADPS, ADSS and ADMIX samples ranged from 92 to 151 mg of TOC per gram of feedstock.

The proximate analyses in the PWs support that there was a carbon solubilisation during the thermal treatments (See Table 1). SS showed higher carbon solubilisation with the thermal treatment increasing from 11.8% of carbon in the liquid fraction of original feedstock to 35.9 and 39.8% after 160 and 250 °C treatments respectively. The majority of the carbon material of the SS comes from the activated sludge bacteria which is released as organic and inorganic compounds into the liquid fraction during thermal treatment. In the case of PS, the carbon material in the liquid fraction was already high in comparison with the other sludge samples and the carbon solubilized came mainly from the settled solids presented as suspended solids. For that reason, PS showed a lower increase in the carbon percentage after thermal treatment from 27.6 up to 33.3%. The elemental carbon in the MIX sample increased from 19 to 38% after thermal treatment. The effect of the thermal treatment on the sludge digestates showed a significant increase of the elemental carbon in the liquid fraction (1.4 to 2 times) reflecting that still some organic matter can be hydrolysed to be used for further biogas production. The results for elemental carbon reported in this study for PWs derived from digestates were similar to the values reported by Aragón-Briceño, et al. [5] who reported 46–68% elemental carbon in PWs from sewage sludge. Nonetheless, despite the digestates presented a significative carbon solubilisation during the thermal treatment; the majority of that carbon compounds are less suitable for biogas production.

Volatile Fatty Acids (VFAs)

The total VFAs concentration of the liquid fraction of the sewage sludge samples before to and after HTT are presented in Fig. 3e. Based on the reported by Aragón-Briceño, et al. [5], the severity of the reaction increases the production and solubilization of VFAs. The research works from Nyktari, et al. [44] and Aragón-Briceño, et al. [5] found that the acetic acid is the major product of the VFAs during the HTTs.

The VFAs concentration of the treated PS were similar regardless reaction temperature (4083 and 4155 mg of COD/L for 160 and 250 °C respectively). This means that 160 °C and 30 min treatment was enough to hydrolyse the long-chain fatty acids to volatile fatty acids. A similar trend was observed for the MIX sample in which the 160 and 250 °C treatments did not have significant influence on the VFAs solubilization. The concentrations obtained were 2875 and 2672 mg of COD/L for 160 and 250 °C treatments respectively. Although the low concentration VFAs presented in the SS and digestate samples, the severity of the reaction temperature had a clear influence on the VFAs solubilisation.

Phosphorus (P)

Generally, during the hydrothermal process, it can be solubilized up to 20% of the P contained within the solid fraction of the feedstock [27]. Phosphorus fate during hydrothermal treatment is strongly related to the source of biomass, phosphorus speciation, heavy metals present, reaction temperature, time solid loading and pH [18, 27, 40, 47]. During thermal treatment, most of the P species are transformed mainly into orthophosphates [48]. The solubilisation is carried on due to the hydrolysis of species such as phosphate diesters, phytic acids, pyrophosphates, polyphosphates during the thermal [40, 47,48,49]. On the other hand, the precipitation of phosphorus (phosphate salts) during thermal treatments is closely related to the species and levels of metals present in the feedstock [5, 18, 40, 47, 48].

Figure 4a shows the liquid fraction phosphorus concentration of the different samples before and after thermal treatment. The reaction temperature exhibited a clear influence on P solubilisation in most of the samples with exception of the SS and MIX samples. Higher temperatures promoted higher P solubilisation, especially for the digestate samples. Nonetheless, the raw liquors still presented low P concentrations hence, it can be concluded that majority of the phosphorus remains in the solid fraction. There was a P transfer up to 10 to12% from the solid to the liquid fraction during the thermal treatments (See Fig. 3d). For SS samples, the P concentration and solubilization in process waters suggested that 160 °C treatment favoured P solubilisation and 250 °C treatment promoted the phosphorus fixation within the hydrochar.

These results are in agreement with previous studies reported by Aragón-Briceño, et al. [5] in which it was found that the extraction of organic P species in sewage digestate is higher at low process temperatures. However, this study does not present a clear trend about the production of inorganic and organic P species production during the HTT.

Nitrogen (N)

During HTT the N can take different transformation pathways. Organic N species (proteins and pyridine N compounds) and inorganic N species (i.e. NO3−, NH4+, NO2− and CN−) suffer hydrolysis to mainly form NO3−–N and NH4+–N compounds [18, 50, 51]. Previous studies reported that majority of the N transferred into the liquid fraction is in ammonia form, especially from sewage sludge samples [5, 15, 40, 51,52,53,54,55]. According to Marin-Batista, et al. [27], during the thermal treatment, up to 60% of the nitrogen can be transferred from the solid into the liquid fraction.

Figure 4b presents the concentrations of the organic and inorganic N (as ammonia) from the different sewage sludge samples before and after HTTs. Results show a clear influence between the severity of the reaction temperature and the solubilisation of N, in which the N concentration increase as the treatment temperature increase. The N concentration in the liquid fraction increased up to 340% in the non-AD treated sludge samples at 160 °C and up to 540% at 250 °C. For the digestate samples, there was an increment of up to 36% at 160 °C and up to 70% at 250 °C. The same trend (increase) was found for the inorganic N concentration (ammonia) in the liquid fraction from different sewage sludge samples. The inorganic N solubilisation reached up to 204 and 431% for the non-AD treated sludge samples and up to 109 and 136% for digestate samples at 160 and 250 °C respectively. However, it seems that the thermal treatment favoured the solubilisation of organic nitrogen, especially in those sludge samples that had been biologically treated (secondary and digestates sludge) prior to thermal treatment. These findings match with the previous study reported by Aragón-Briceño, et al. [5] whereas the N concentration in the PWs from HTT sewage sludge digestate increased up to 45% and 50% at 160 °C and 250 °C treatments.

Biomethane Potential of PWs (BMP)

Figure 5 presents the BMP values of the untreated sewage sludge samples and their PWs derived from the HTTs. It can be observed that all the sample’s BMP values increased after HTT. The process temperature influenced the BMP of the samples resulting in higher BMP values for the PWs coming from 250 °C treatment in comparison to 160 °C treatment, with exception of the PW from the ADSS where there was no significant difference on the BMP values regardless of the treatment temperature.

The non-AD treated sludge samples showed higher BMP than digestates samples. The PWs coming from SS presented higher BMP values (276 mL of CH4 per g of COD) in comparison to the PWs coming from PS sample (208 mL of CH4 per g of COD). At 250 °C treatment, PWs coming from PS and SS did not show significant differences where the BMP values were 325 and 312 mL of CH4 per g of COD respectively. In general, the HTT favoured the increase of the BMP in PWs from SS and PS up to 168% and 151% respectively in comparison to their untreated samples. The HTTs also enhanced the BMP values of the liquid fraction of the MIX sample after 160 and 250 °C treatments, reaching values of 252 and 351 mL of CH4 per g of COD respectively, representing an increase between 11 and 55% in comparison to the untreated sample.

BMP values of the digestate samples were considered zero due to previous anaerobic treatment received before HTTs. The thermal treatment had a positive impact on the digestate samples propitiating an increase in the BMP. However, the BMP values from PWs coming from ADSS and ADMIX were similar showing that the treatment temperature has not significant effect on the BMP value of those digestate samples. Only the BMP values of process waters from ADPS presented a trend in which the process temperature had a clear influence whereas the BMP value increases as the treatment temperature increases. Previous studies have reported BMP values PW coming from PS treated at 200 °C of 335 mL of CH4 per g of COD [56], 256.6 mL of CH4 per g of COD PW from municipal sewage sludge treated at 170 °C [42] and 178–277 mL of CH4 per g of COD for PW from sewage sludge digestate (160–250 °C) [5, 57].

COD degradation in the process waters ranged from 37 to 97% and 59–75% for 160 °C and 250 °C treatments respectively (see Table 2). During the HTT, the hydrolysis led to a reduction in the concentration of complex organic compounds that consequently enhance the COD degradation during the anaerobic digestion [58]. Process waters treated at 160 °C showed higher COD degradation during the anaerobic digestion process than process waters treated at 250 °C. Diminution of the COD removal can be attributed to the recalcitrant products such as furans, pyrazines, and phenols, formed during higher temperatures that directly affect the performance of anaerobic bacteria [9, 59]. The present findings are similar to the values reported for COD degradation during the anaerobic digestion for PWs from sewage sludge (56–88%) [5, 9, 44, 57].

The biodegradability factor (BD) is a variable that provides an idea about the amount of organic matter susceptible to biodegradation by comparing the theoretical BMP values against the experimental results [5]. The biodegradability of sewage sludge samples increases according to the increase in the treatment temperature (see Table 2). The biodegradability values ranged from 28 to 57% and from 58 to 115% for PWs from 160 to 250 °C treatments respectively. However, the limitation of Boyle’s formula, as the majority of the other prediction formulas (and models), only assumes that the kinetics are first order and also do not account for the interaction of the microbial communities with other chemical compounds [60]. As a consequence, process waters from MIX and PS samples treated at 250 °C presented biodegradability values above 100% (115% and 110% respectively).

Table 2 shows the biogas composition from the anaerobic digestion tests of the different samples. Raw PS, SS and MIX samples showed a methane concentration of 72, 66 and 72% respectively. Although the 160 °C treatment increased the BMP values in process waters, the methane concentration in the biogas was reduced (66–70%) with exception of the ADMIX sample (79%) in comparison to the untreated samples. On the other hand, 250 °C treatment promoted the production of biogas with a higher concentration of methane (70–77%) with exception of the PS sample (60%). In general, all samples presented methane concentration values above 60% representing good quality biogas. Wirth and Mumme [61] and Aragón-Briceño, et al. [15] obtained similar results for HTC PWs from corn silage (70% of methane) and sewage digestate (63–80% of methane).

Kinetic Analysis

The modified Gompertz model was applied to the experimental results to simulate the methane production of anaerobic digestion of the PWs. The parameters of the model can be observed in Table 3. The correlation factors (R2) showed a good fitting of the modified Gompertz model ranging from 0.944 to 0.997. The maximum accumulative values (Pmax) obtained from the model were more accurate in comparison to the calculated theoretical values. That means that the Gompertz model could adequately simulate the maximum cumulative methane yield. The experimental results with the model fitting curve plots of all the samples can be seen in Fig. 6.

Experimental BMP production of batch assays and adjusted modified Gompertz model for untreated samples [PS (a), SS (b), MIX (c)], 160 °C process waters [160 PS (d), 160 SS (e), 160 MIX (f), 160 ADPS (g), 160 ADSS (g) and 160 ADMIX (i)], and 250 °C process waters [250 PS (j), 250 SS (k), 250 MIX (l), 250 ADPS (m), 250 ADSS (n) and 250 ADMIX (o)]

The lag phase (λ) time of the AD of the process waters varied from 1.4 to 9.6 days. The lowest value corresponded to the 160 °C PS process water. In contrast, according to the applied model, the PS sample treated at 250 °C takes a longer time for starting the AD in comparison with the other samples. Despite that, the value is lower in comparison with the untreated sample. The maximum methane production for the thermally treated samples (Rmax) reached 35.9 mL of CH4 *g of COD−1 * day−1 and was accounted for the MIX process water coming from the 250 °C treatment. These results are similar to those reported by Villamil, et al. [14] for the modified Gompertz model applied to HTC process waters co-digested with PS samples where the R2 reported ranged between 0.835 and 0.968, the λ ranged 2.9–8.9 days, Pmax 111–204 mL of CH4 / g of COD and Rmax from 50 to 71 mL of CH4 *g of COD−1 * day−1.

Hydrochar Characteristics

Physical Characteristics

Hydrochar’s proximate analysis and yields are shown in Table 4. According to Ekpo, et al. [40] and Danso-Boateng, et al. [19], the reaction temperature and the severity of the process affects the hydrochar yields. Results showed that hydrochar yield decreases as the reaction temperature increased. Hydrochar yields varied from 38 to 69% and 30–40% for sludge samples treated at 160 °C and 250 °C respectively. These values are lower in comparison with other studies that have reported yields between 40.3 and 81.1% for hydrochar coming from sewage sludge [5, 13, 15, 19, 40].

Ash content has a strong relationship with the energy that we can harness from the hydrochar. The energy densification is lower if the ash content of a hydrochar is high. Results obtained for ash content showed a direct relationship between the process temperature and the concentration of ash in the hydrochar. The ash content increases in conjunction with the process temperature. The ash content of PS, SS and MIX samples ranged from 25.7 to 36.4%. After 160 °C treatment, the ash content increased between 3 and 7.7% and between 14.9 and 20.31% after the 250 °C treatment. Similar values for ash content in the hydrochars from digestate have been reported by Aragón-Briceño, et al. [5] (36.9%) and Berge, et al. [43] (55.8%).

It was observed, after thermal treatment, the volatile matter content of the different sludge samples decreased as the severity of the reaction increased. In addition, the thermally treated digestate samples presented a higher decrease in the volatile matter than the non-AD treated sludge. That means that the 250 °C treatment presented lower volatile matter percentage than the 160 °C treatment. The percentage of the volatile matter varied from 0.5 to 4% when the sludge samples were treated at 160 °C and from 8 to 14% after the 250 °C treatment.

Elemental Composition

The Table 5 shows the ultimate analyses of the different solid samples analysed in this work (sewage sludge and hydrochars). The carbon content of the non-treated samples are strongly linked to the source of sewage sludge and ranged from 31.1 to 40.3%. After the 250 °C treatment the PS sludge suffered a reduction of to 37.4% but after the 160 °C treatment did not show any significant change (40.3%). A different trend was found for the SS sample (33.5%) which the carbon content after 160 °C treatment showed a similar concentration (33.1%) in comparison to the untreated sample, but after the 250 °C treatment the carbon content increased (36.1%) showing carbon densification during the thermal process. MIX sludge carbon content (35.5%) was the only sample that suffered carbon densification at both thermal treatments with 37.5 and 35.8% at 160 and 250 °C respectively. Digestate samples (ADPS, ADSS and ADMIX) presented lower carbon content than the non-AD treated samples due to the prior biological treatment received. Moreover, all digestate samples presented a similar tendency in which the concentration of carbon in the solid fraction decreased regardless of the process temperature of the thermal treatment. ADPS, ADSS and ADMIX carbon content (31.1, 32.2 and 30.9% respectively) were reduced to 28.9,29.4 and 29.9 after 160 °C treatment and to 27.3, 27.5 and 26.6% after 250 °C treatment respectively. In general, for these sewage sludge samples, the severity of the reaction promoted solubilization of the carbon compounds from the solid to the liquid fraction rather than the carbon densification. A reduction up to 8% of carbon content in the solid fraction after thermal treatment of sewage sludge has been reported by Ekpo, et al. [40] or Marin-Batista, et al. [27]. On the other hand, the values obtained in this study are similar to those reported by Berge, et al. [43] (32.6%), Danso-Boateng, et al. [19] (36.6–39.2%) and Aragón-Briceño, et al. [5] (33–38%).

It was observed a reduction in the nitrogen in the solid fraction after hydrothermal treatment. During the thermal treatment the nitrogen released into the process waters which is reflected in the increase of the nitrogen concentration in the process waters and the reduction in the solid fraction [5]. Furthermore, during the hydrothermal process, decarboxylation reactions are carried out propitiatin the oxygen reduction resulting in lower oxygen content in hydrochars compared to the original feedstock [19].

Energy Characteristics

In this study, the combustion analyses through calorimeter bomb for the solid samples was not performed. For that reason, to obtain an estimation of the high heating value (HHV) of the hydrochars, the Dulong equation as reported by Aragón-Briceño, et al. [15] was used. Results showed that higher HHV for the hydrochars coming from SS and MIX sludge than their untreated samples reaching values up to 16.5 and 17.5 MJ kg−1 respectively (See Table 5). In contrast, the different digestates and the PS showed a HHV reduction after the thermal treatment. This is linked to the fact that there was no carbon densification and thus, it was reflected in lower HHV. Therefore, the energy from the original feedstock is accumulated in the PW rather than the solid fraction. HHVs determined in this study are close to reported by Aragón-Briceño, et al. [5] (14.3–17.8 MJ Kg−1), Aragón-Briceño, et al. [15] (15.4–16.5 MJ Kg−1), Danso-Boateng, et al. [19] (17.2–18.4 MJ Kg−1), Berge, et al. [43] (13.7 MJ Kg−1), and Marin-Batista, et al. [27] (14.9–15.1 MJ Kg−1) for thermally treated sewage sludge.

Hydrothermal Treatment Integration Strategies

It has been proved that the thermal treatments coupled before or after the AD can bring benefits to the entire wastewater treatment system such as the improvement of the sludge dewaterability properties and on the overall energy production as long as the solid fraction is considered as a fuel source [3, 5, 13, 15, 27, 62].

Table 6 shows the energy balance of different scenarios constructed based on the experimental results of the different sewage sludge samples. To harness better the energy properties of the system as suggested by Aragón-Briceño, et al. [15], a 15% solids loading was considered for all scenarios. The scenarios considered only energy production from the potential combustion of the solid fraction (HHV) and the anaerobic digestion of the sewage sludge samples (BMP) expressed as energy produced/consumed per kg of feedstock treated. Table 6 also presents the overall net energy balance (hydrochar and biogas production considered as energy sources) and the energy balance when biogas is the only energy source (hydrochar is not considered). Furthermore, proposed scenarios were based on when only conventional AD is included, when the thermal process is applied as pre-treatment and when the thermal process is integrated as an intermediate step in a 2-step AD process. The energy required for the hydrothermal treatment was calculated based on the principle to heat water in a closed system which is lower in comparison to the energy required to evaporate water in an open system [5, 63].

In agreement to previous studies, when the hydrochar and biogas are considered as fuel sources, the present results showed a positive overall net energy production (See Table 5) [3, 5, 13, 15, 27, 62]. However, considering the current technology that do not reach the 100% energy conversion efficiency, not all the energy contained in the hydrochar and biogas can be used. Liao, et al. [64] reported for a combined heat power unit (CHP) of the coal fired cogeneration process of 28% electrical and 43% of thermal efficiencies while Mayer, et al. [65] reported up to 38% and 60% for electrical and thermal efficiencies for an incineration unit of co-combustion of hydrochar with wood-waste. For the CHP units for biogas combustion, it has been reported electrical efficiencies of 33.3–37% and thermal efficiencies of 47.6–53% [15, 65]. For this study, only the high heating value of the hydrochar and biogas was considered and the performance of the equipment was neglected since the aim is to provide information of the maximum energy that can be obtained from hydrochar and process water for further process modelling and system’s optimization.

For the proposed scenarios (see Table 6), the overall net energy balance was calculated as the energy consumed by the HTC unit and the potential energy that can be produced by the produced biogas and hydrochar. The energy consumed by the AD unit is not considered because it is assumed that already exist in the WWTP and its energy consumption is already accounted in the energy balance of the whole WWTP. According to the concentration of carbon and available hydrolysable organic matter, as expected, PS scenarios showed the highest net energy balance, followed by MIX scenarios and SS scenarios respectively. On the other hand, when only biogas is considered as the only potential fuel source, the net energy balance decreases significantly to the point that extra energy supply is needed to cover thermal treatment energy requirements. That means that the inclusion of hydrochar as a fuel source plays a fundamental role in the integration of thermal treatments into WWTPs.

In the proposed scenarios can be observed that the net energy production increased when thermal treatment is placed as pre-treatment. However, two things should be pointed out, firstly is the potential energy obtained from biogas is drastically reduced (up to 85%) in comparison with the conventional AD scenarios, and secondly is that hydrochars turned in the main potential energy source to cover the energy needs of the system. The scenarios proposed for 160 °C treatment showed an increase in the net energy production of 19% for PS, 107% for SS and 44% for MIX. Scenarios that considered 250 °C as pre-treatment, presented similar net energy production as the 160 °C pre-treatment scenarios with an increase of 141% for SS and 48% for MIX and a decrease of 4% for PS. As a result, HTT as pre-treatment does not seem to be a good option since the overall net energy balance is reduced up to 53% in comparison to the conventional AD. Only the scenario of SS with 160 °C as pre-treatment presented an increment of 27% in the net energy balance.

The scenarios that considered the integration of thermal treatments as an intermediate step in a 2-step AD process presented the highest net energy production and overall net energy balance. Some studies have found the feasibility of applying this configuration resulting in an increase in the biomethane production and hence the net energy balance [3, 5, 13, 15, 38]. It can be observed that for PS, SS and MIX scenarios, when 160 °C thermal treatment was considered, the net energy production increased up to 59, 205 and 118% respectively, and up to 51, 168 and 96% for 250 °C treatment. As a result, the overall net energy balance in the different scenarios showed an increase ranging from 2.5 to 124%. Another important point is that this configuration showed that it not only relies on the hydrochars as the main energy source, resulting in a better-balanced energy distribution between the liquid and solid fractions. The energy distribution in the PS scenarios showed higher potential energy production in the liquid fraction (66–75%) than in the solid fraction (25–34%). SS and MIX scenarios showed an energy distribution of 42–56% and 53–66% in the liquid fractions and in the solid fractions of 44–58% and 34–47% respectively. Hence, the energy production from biogas is sufficient to satisfy the energy demand of the thermal treatment from PS and MIX scenarios with this proposed configuration. Figure 7 shows a conclusive process diagram of the 2-step AD process with intermediate 160 °C HTT of the MIX sludge. Nevertheless, the main disadvantage of this configuration is the potential high cost of the installation and maintenance of the thermal treatment and the second AD unit that can arise up to 42% extra on the operation costs and up to 37% in the capital investment in comparison to the conventional AD system [13]. Recirculation and co-digestion of the PW with the raw sewage sludge in the AD unit can be a suitable option. It was found that the co-digestion of HTC process water with sewage sludge can reach 1.15 time higher methane yield [9]. Furthermore, in the diagram can be seen that the nitrogen can be recovered either in the solid and liquid fraction, while phosphorus tends to remain in the solid fraction. That means, HTT shows to be a very promising process to enhance the water treatment facilities because of the potential to recover nutrients either from the hydrochar and/or the process water.

Conclusions

This study showed the promising potential of the HTT integration into a wastewater treatment facility as a strategy to enhance the sewage sludge treatment and at the same time recovering valuable products. The conclusions are listed below:

-

HTT promoted the solubilization of organic carbon increasing the TOC concentration up to 14.5 times in the liquid fraction.

-

HTT promoted the solubilization of nitrogen and phosphorus reaching values of 89% for N and 13% for P solubilization.

-

The BMP of the sewage sludge samples improved up to 168% after thermal treatment with an increase on the methane concentration in the biogas from 66 to 72% (untreated samples) up to 79%.

-

HTT enhanced the COD removal achieving a maximum value of 97%.

-

The scenario built in this study showed that the integration of HTT for the treatment of mix primary and secondary sewage sludge as an intermediate step between a two-stage AD process was found to be the most suitable option due to an increase in the net energy balance up to 124% in comparison with the conventional AD and the potential enhancement of nitrogen recovery in the liquid fraction.

Still further research is required to understand and determine other key factors that can lead to an improvement on the HTT process as a strategy for sewage sludge management in a WWTP.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Scarlat, N., Dallemand, J.-F., Fahl, F.: Biogas: developments and perspectives in Europe. Renew. Energy 129, 457–472 (2018)

Cieślik, B.M., Namieśnik, J., Konieczka, P.: Review of sewage sludge management: standards, regulations and analytical methods. J. Clean. Prod. 90, 1–15 (2015)

Aragón-Briceño, C.I., Ross, A.B., Camargo-Valero, M.A.: Mass and energy integration study of hydrothermal carbonization with anaerobic digestion of sewage sludge. Renew. Energy 167, 473–483 (2021)

Carrere, H., et al.: Review of feedstock pretreatment strategies for improved anaerobic digestion: from lab-scale research to full-scale application. Bioresour. Technol. 199, 386–397 (2016)

Aragón-Briceño, C., Ross, A.B., Camargo-Valero, M.A.: Evaluation and comparison of product yields and bio-methane potential in sewage digestate following hydrothermal treatment. Appl. Energy 208, 1357–1369 (2017)

Kim, D., Lee, K., Park, K.Y.: Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel 130, 120–125 (2014)

Berglund, M., Börjesson, P.: Assessment of energy performance in the life-cycle of biogas production. Biomass Bioenerg. 30(3), 254–266 (2006)

Abad, V., Avila, R., Vicent, T., Font, X.: Promoting circular economy in the surroundings of an organic fraction of municipal solid waste anaerobic digestion treatment plant: biogas production impact and economic factors. Bioresour. Technol. 283, 10–17 (2019)

Villamil, J.A., Mohedano, A.F., San Martín, J., Rodriguez, J.J., de la Rubia, M.A.: Anaerobic co-digestion of the process water from waste activated sludge hydrothermally treated with primary sewage sludge. A new approach for sewage sludge management. Renew. Energy 146, 435–443 (2020)

Shen, Y., Linville, J.L., Urgun-Demirtas, M., Mintz, M.M., Snyder, S.W.: An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States: challenges and opportunities towards energy-neutral WWTPs. Renew. Sustain. Energy Rev. 50, 346–362 (2015)

Hindle, M.: Anaerobic digestion in the United Kingdom, (in English). Biocycle 54(5), 41–43 (2013)

Abelleira-Pereira, J.M., Pérez-Elvira, S.I., Sánchez-Oneto, J., de la Cruz, R., Portela, J.R., Nebot, E.: Enhancement of methane production in mesophilic anaerobic digestion of secondary sewage sludge by advanced thermal hydrolysis pretreatment. Water Res. 71, 330–340 (2015)

Medina-Martos, E., Istrate, I.-R., Villamil, J.A., Gálvez-Martos, J.-L., Dufour, J., Mohedano, Á.F.: Techno-economic and life cycle assessment of an integrated hydrothermal carbonization system for sewage sludge. J. Clean. Prod. 277, 122930 (2020)

Villamil, J.A., Mohedano, A.F., Rodriguez, J.J., De la Rubia, M.A.: Anaerobic co-digestion of the aqueous phase from hydrothermally treated waste activated sludge with primary sewage sludge. A kinetic study. J. Environ. Manag. 231, 726–733 (2019)

Aragón-Briceño, C.I., Grasham, O., Ross, A.B., Dupont, V., Camargo-Valero, M.A.: Hydrothermal carbonization of sewage digestate at wastewater treatment works: influence of solid loading on characteristics of hydrochar, process water and plant energetics. Renew Energy 157, 959–973 (2020)

Lucian, M., et al.: Hydrothermal carbonization coupled with anaerobic digestion for the valorization of the organic fraction of municipal solid waste. Bioresour. Technol. 314, 123734 (2020)

Biller, P., Ross, A.B.: Hydrothermal processing of algal biomass for the production of biofuels and chemicals. Biofuels 3(5), 603–623 (2012)

Aragón-Briceño, C.I., Pozarlik, A.K., Bramer, E.A., Niedzwiecki, L., Pawlak-Kruczek, H., Brem, G.: Hydrothermal carbonization of wet biomass from nitrogen and phosphorus approach: a review. Renew. Energy 171, 401–415 (2021)

Danso-Boateng, E., Shama, G., Wheatley, A.D., Martin, S.J., Holdich, R.G.: Hydrothermal carbonisation of sewage sludge: effect of process conditions on product characteristics and methane production. Bioresour. Technol. 177, 318–327 (2015)

Xu, Z., Zhou, J., Liu, Y., Gu, L., Wu, X., Zhang, X.: Effect of hydrothermal carbonization on dewatering performance of dyeing sludge. RSC Adv. 8(67), 38574–38581 (2018)

Li, C., Wang, X., Zhang, G., Yu, G., Lin, J., Wang, Y.: Hydrothermal and alkaline hydrothermal pretreatments plus anaerobic digestion of sewage sludge for dewatering and biogas production: bench-scale research and pilot-scale verification. Water Res. 117, 49–57 (2017)

Villamil, J.A., Mohedano, A.F., Rodriguez, J.J., Rubia, M.: Valorisation of the liquid fraction from hydrothermal carbonisation of sewage sludge by anaerobic digestion. J. Chem. Technol. Biotechnol. 93(2), 450–456 (2018)

Pilli, S., Yan, S., Tyagi, R.D., Surampalli, R.Y.: Thermal pretreatment of sewage sludge to enhance anaerobic digestion: a review. Crit. Rev. Environ. Sci. Technol. 45(6), 669–702 (2015)

Cano, R., Nielfa, A., Fdz-Polanco, M.: Thermal hydrolysis integration in the anaerobic digestion process of different solid wastes: energy and economic feasibility study. Bioresour. Technol. 168, 14–22 (2014)

Gaur, R.Z., et al.: Hydrothermal carbonization of sewage sludge coupled with anaerobic digestion: integrated approach for sludge management and energy recycling. Energy Convers. Manag. 224, 113353 (2020)

Xu, Z.-X., et al.: Hydrothermal carbonization of sewage sludge: effect of aqueous phase recycling. Chem. Eng. J. 387, 123410 (2020)

Marin-Batista, J.D., Mohedano, A.F., Rodríguez, J.J., de la Rubia, M.A.: Energy and phosphorous recovery through hydrothermal carbonization of digested sewage sludge. Waste Manag. 105, 566–574 (2020)

Liao, Q., et al.: How can hydrothermal treatment impact the performance of continuous two-stage fermentation for hydrogen and methane co-generation? Int. J. Hydrogen Energy 46(27), 14045–14062 (2021)

Cao, Z., Hülsemann, B., Wüst, D., Illi, L., Oechsner, H., Kruse, A.: Valorization of maize silage digestate from two-stage anaerobic digestion by hydrothermal carbonization. Energy Convers. Manag. 222, 113218 (2020)

Si, B., Watson, J., Aierzhati, A., Yang, L., Liu, Z., Zhang, Y.: Biohythane production of post-hydrothermal liquefaction wastewater: a comparison of two-stage fermentation and catalytic hydrothermal gasification. Bioresour. Technol. 274, 335–342 (2019)

Li, Y., et al.: Hydrochars from bamboo sawdust through acid assisted and two-stage hydrothermal carbonization for removal of two organics from aqueous solution. Bioresour. Technol. 261, 257–264 (2018)

Jazrawi, C., et al.: Two-stage hydrothermal liquefaction of a high-protein microalga. Algal Res. 8, 15–22 (2015)

Rose, D.J., Inglett, G.E.: Two-stage hydrothermal processing of wheat (Triticum aestivum) bran for the production of feruloylated arabinoxylooligosaccharides. J. Agric. Food Chem. 58(10), 6427–6432 (2010)

Lucian, M., Fiori, L.: Hydrothermal carbonization of waste biomass: process design, modeling, energy efficiency and cost analysis. Energies 10(211), 18 (2017)

Eaton, A.D., American Public Health Association, American Water Works Association, Water Environment Federation: Standard Methods for the Examination of Water and Wastewater. APHA-AWWA-WEF, Washington, D.C. (2005)

Shen, J., Zhao, C., Liu, Y., Zhang, R., Liu, G., Chen, C.: Biogas production from anaerobic co-digestion of durian shell with chicken, dairy, and pig manures. Energy Convers. Manage. 198, 110535 (2019)

Parra-Orobio, B.A., Donoso-Bravo, A., Torres-Lozada, P.: Anaerobic digestion of food waste. Predicting of methane production by comparing kinetic models. Ingeniería y competitividad 19(1), 219–227 (2017)

Ortega-Martinez, E., Sapkaite, I., Fdz-Polanco, F., Donoso-Bravo, A.: From pre-treatment toward inter-treatment. Getting some clues from sewage sludge biomethanation. Bioresour. Technol. 212, 227–235 (2016)

Zabaleta, I., Marchetti, P., Lohri, C.R., Zurbrügg, C.: Influence of solid content and maximum temperature on the performance of a hydrothermal carbonization reactor. Environ. Technol. 38(22), 1–10 (2017)

Ekpo, U., Ross, A.B., Camargo-Valero, M.: A comparison of product yields and inorganic content in process streams following thermal hydrolysis and hydrothermal processing of microalgae, manure and digestate. Bioresour. Technol. 200, 951–960 (2015)

Keymer, P., Ruffell, I., Pratt, S., Lant, P.: High pressure thermal hydrolysis as pre-treatment to increase the methane yield during anaerobic digestion of microalgae. Bioresour. Technol. 131, 128–133 (2013)

Qiao, W., Yan, X., Ye, J., Sun, Y., Wang, W., Zhang, Z.: Evaluation of biogas production from different biomass wastes with/without hydrothermal pretreatment. Renew Energy 36(12), 3313–3318 (2011)

Berge, N.D., Ro, K.S., Mao, J., Flora, J.R.V., Chappell, M.A., Bae, S.: Hydrothermal carbonization of municipal waste streams. Environ. Sci. Technol. 45(13), 5696–5703 (2011)

E. Nyktari, A. Wheatley, E. Danso-Boateng, and R. Holdich, "Anaerobic Digestion of Liquid Products following Hydrothermal Carbonisation of Sewage Sludge with different reaction conditions," presented at the 13th IWA Specialized Conference on Small Water and Wastewater Systems & 5th IWA Specialized Conference on Resources-Oriented Sanitation, Athens, Greece., 14–16 September, 2016, 2017.

Shrestha, A., Acharya, B., Farooque, A.A.: Study of hydrochar and process water from hydrothermal carbonization of sea lettuce. Renew. Energy 163, 589–598 (2021)

Stemann, J., Putschew, A., Ziegler, F.: Hydrothermal carbonization: process water characterization and effects of water recirculation. Bioresour. Technol. 143, 139–146 (2013)

Huang, R., Fang, C., Lu, X., Jiang, R., Tang, Y.: Transformation of phosphorus during (Hydro)thermal treatments of solid biowastes: reaction mechanisms and implications for P reclamation and recycling. Environ. Sci. Technol. 51(18), 10284–10298 (2017)

Huang, R., Tang, Y.: Speciation dynamics of phosphorus during (Hydro) thermal treatments of sewage sludge. Environ. Sci. Technol. 49(24), 14466–14474 (2015)

Dai, L., et al.: Immobilization of phosphorus in cow manure during hydrothermal carbonization. J. Environ. Manag. 157, 49–53 (2015)

Wang, T., et al.: Influence of temperature on nitrogen fate during hydrothermal carbonization of food waste. Bioresour. Technol. 247, 182–189 (2018)

He, C., Wang, K., Yang, Y., Amaniampong, P.N., Wang, J.-Y.: Effective nitrogen removal and recovery from dewatered sewage sludge using a novel integrated system of accelerated hydrothermal deamination and air stripping. Environ. Sci. Technol. 49(11), 6872–6880 (2015)

Ekpo, U., Ross, A.B., Camargo-Valero, M.A., Fletcher, L.A.: Influence of pH on hydrothermal treatment of swine manure: impact on extraction of nitrogen and phosphorus in process water. Bioresour. Technol. 214, 637–644 (2016)

Zhuang, X., Huang, Y., Song, Y., Zhan, H., Yin, X., Wu, C.: The transformation pathways of nitrogen in sewage sludge during hydrothermal treatment. Bioresour. Technol. 245, 463–470 (2017)

Huang, W., et al.: Coupling hydrothermal treatment with stripping technology for fast ammonia release and effective nitrogen recovery from chicken manure. ACS Sustain. Chem. Eng. 4(7), 3704–3711 (2016)

Reza, M.T., Freitas, A., Yang, X., Hiibel, S., Lin, H., Coronella, C.J.: Hydrothermal carbonization (HTC) of cow manure: carbon and nitrogen distributions in HTC products. Environ. Prog. Sustain. Energy 35(4), 1002–1011 (2016)

Nilsson E, "Anaerobic digestion trials with HTC process water," Master Program in Environmental and Water Engineering Dissertation, Department of Energy and Technology, Swedish University of Agricultural Sciences: Division of Bioenergy, Uppsala, 17008, 2017.

Wirth, B., Reza, T., Mumme, J.: Influence of digestion temperature and organic loading rate on the continuous anaerobic treatment of process liquor from hydrothermal carbonization of sewage sludge. Bioresour. Technol. 198, 215–222 (2015)

Becker, R., Dorgerloh, U., Helmis, M., Mumme, J., Diakité, M., Nehls, I.: Hydrothermally carbonized plant materials: patterns of volatile organic compounds detected by gas chromatography. Bioresour. Technol. 130, 621–628 (2013)

Hübner, T., Mumme, J.: Integration of pyrolysis and anaerobic digestion—use of aqueous liquor from digestate pyrolysis for biogas production. Bioresour. Technol. 183, 86–92 (2015)

Achinas, S., Euverink, G.J.W.: Theoretical analysis of biogas potential prediction from agricultural waste. Resour. Effic. Technol 2(3), 143–147 (2016)

Wirth, B., Mumme, J.: Anaerobic digestion of waste water from hydrothermal carbonization of corn silage. Appl. Bioenergy 1, 1–10 (2013)

Merzari, F., Langone, M., Andreottola, G., Fiori, L.: Methane production from process water of sewage sludge hydrothermal carbonization. A review. Valorising sludge through hydrothermal carbonization. Crit. Rev. Environ. Sci. Technol. 49(11), 947–988 (2019)

Berge, N.D., Ro, K.S., Mao, J., Flora, J.R.V., Chappell, M.A., Bae, S.: Hydrothermal carbonization of municipal waste streams: supporting information. Environ. Sci. Technol. 45(13), 5696–5703 (2011)

Liao, C., Ertesvåg, I.S., Zhao, J.: Energetic and exergetic efficiencies of coal-fired CHP (combined heat and power) plants used in district heating systems of China. Energy 57, 671–681 (2013)

Mayer, F., Bhandari, R., Gäth, S.A.: Life cycle assessment on the treatment of organic waste streams by anaerobic digestion, hydrothermal carbonization and incineration. Waste Manag. 130, 93–106 (2021)

Passos, F., Ferrer, I.: Microalgae conversion to biogas: thermal pretreatment contribution on net energy production. Environ. Sci. Technol. 48(12), 7171–7178 (2014)

Acknowledgements

The authors would like to thank the Consejo Nacional de Ciencia y Tecnología of Mexico (CONACYT) for the financial support provided to Dr Christian Aragón-Briceño as part of his PhD Scholarship (248333/383197) at the University of Leeds.

Funding

This work was supported by Consejo Nacional de Ciencia y Tecnología of Mexico (CONACYT) for the financial support provided to Dr Christian Aragón-Briceño as part of his PhD Scholarship (248333/383197) at the University of Leeds.

Author information

Authors and Affiliations

Contributions

CAB: Conceptualization, Methodology, Validation, Formal analysis, Investigation, writing original draft, data curation and editing and visualization. MACV: Resources, Supervision, Writing-Review and editing, Project administration and Funding acquisition. AR: Resources, Supervision, Writing-Review and editing, Project administration and Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Aragon-Briceño, C.I., Ross, A.B. & Camargo-Valero, M.A. Strategies for the Revalorization of Sewage Sludge in a Waste Water Treatment Plant Through the Integration of Hydrothermal Processing. Waste Biomass Valor 14, 105–126 (2023). https://doi.org/10.1007/s12649-022-01856-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01856-0