Abstract

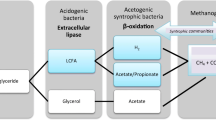

Disposing of residual cooking oil is a major environmental concern, so its conversion into commercial products is a desirable goal. To design the chemical modification of a domestic waste oil into valuable biochemicals other than biodiesel, we analyzed a series of its samples, collected over a period of three years, using quantitative 1H-NMR. This analysis, allowing a quick determination of its main chemical characteristics, has rendered the image of a vegetable oil with an almost constant composition over time and with a relative low content of saturated fatty acids. To make this collection protocol more economical, we projected its chemical transformation into esters and epoxidized esters of long chain and branched alcohols, which could find employment as biolubricants and/or bioplasticizers. The one-pot transesterification of the waste cooking oil into esters of commercially available and biodegradable Guerbet alcohols was obtained under environmentally friendly conditions by employing commercial CaO as a catalyst. Additionally, microwave irradiation of this reaction allowed to optimize the energy expenditure by significantly reducing the reaction time as compared with reactions run under conventional heating. To improve their oxidation stabilities, the resulting esters were epoxidized under conditions useful to minimize side-reactions. An investigation of their main rheological properties shows that some of the resulting products display characteristics that make their use as biolubricants or bioplasticizers predictable. The entire process represents a virtuous example of circular economy.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

Thanks to an original harvesting protocol, we have recovered as a secondary raw material a pre-purified waste cooking oil with a chemical composition almost constant over time, containing a high percentage of mono and polyunsaturated fatty acids.

To aid in designing its transformation into biochemicals other than biodiesel, several pre-purified samples were analyzed using a non-destructive control method that significantly reduces the analysis time and the amount of sample required.

Accordingly, its chemical modification under low impact conditions afforded valuable biochemicals, as supported by the determination of the physico-chemical properties of some of the resulting products.

Introduction

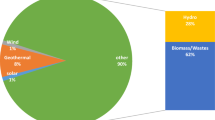

The valorisation of wastes [1, 2] is a key concept in reducing the environmental impact and costs of chemical productions. Waste cooking oil (WCO) is a widely available and inexpensive renewable resource whose uncontrolled disposal is responsible for severe environmental pollution, with ample potential to be transformed into a variety of useful biochemicals [3,4,5,6,7,8]. In 2018, around 1,400,000 tons of vegetable oils and fats were consumed for food purposes in Italy. A significant share of these oils, around 20%, was disposed of after the cooking process, which means a supply potential of 260,000 tons of WCO. In the same year, the WCO recovery was 76,000 tons, three to four times lower than the supply potential; 90% of the treated and cleaned WCO was sold to a biodiesel producer and the remaining 10% was used in the production of biolubricants, soaps, waxes, inks, or cosmetics [9].

In Sardinia, one of the two main islands of Italy, consuming approx. 7500 ton/year of vegetable oils and not furnished with plants for the production of biodiesel, WCO is successfully collected by a local company, Il Gabbiano Industria Ecologica s.r.l. (Porto Torres, Italy), that developed an original harvesting system differentiating WCO produced by commercial activities from WCO produced by domestic use. Whilst WCO from commercial activities is conferred to the production of biodiesel, WCO from domestic use is purified and locally marketed as an oil for chainsaw chains (120 tons/year) and other biochemicals (100 tons/year), such as lubricants and release agents for concrete.

In this article we report our efforts to make this harvesting protocol even more cost effective by designing the chemical modification of the chainsaw chain oil into valuable biochemicals other than biodiesel [8]. To this end, we further characterized this purified oil by means of quantitative 1H-NMR (q 1H-NMR). As an advantage over the most common protocols, this spectroscopic technique affords an almost complete characterization of vegetable oils within short times, consuming extremely small quantities of samples and of a single solvent [10,11,12]. According to thus obtained analytical results, we designed the chemical modification of this renewable resource into valuable biochemicals, namely esters and epoxidized esters of 2-ethyl-1-hexanol (2-EtC6H12OH) and 2-butyl-1-octanol (2-BuC8H16OH), two commercially available Guerbet alcohols [13, 14] which are considered biodegradable [15].

Indeed, 2-EtC6H12OH is one of the most important synthetic alcohols [16], and its esters with saturated and mono-unsaturated fatty acids found employment as non-toxic and biodegradable low viscosity solvents, in the production of biolubricants, as well as in the cosmetic and pharmaceutical industries [17,18,19,20,21]. On the other side, 2-BuC8H16OH, which comes naturally in safflower oil [22], is used as a solvent and an emollient in the cosmetic industry [23, 24].

Among epoxidized esters of vegetable oils, epoxidized isooctyl soyate (E-2-EtC6H12Soyate, Vikoflex® 4050) is employed as a low temperature plasticizer providing heat and light stability in vinyl formulations [25], as a scavenger for the hydrochloric acid released from PVC at high temperatures [26], or as a component of a biocide to protect PVC from attack by microorganisms [27]. Additionally, epoxidized esters of WCOs with 2-EtC6H12OH proved to be effective alternatives to dioctyl phthalate as plasticizers for PVC [28], as well as valuable biolubricants with good oxidation stability and low-temperature properties [29].

As an additional advantage, according to the European Chemicals Agency (ECHA) non-epoxidized [30] and epoxidized [31] esters of 2-EtC6H12OH with unsaturated fatty acids are readily biodegradable.

Esterification of vegetable oils with 2-EtC6H12OH, is usually run in two steps. A first methodology involves the hydrolysis of vegetable oils followed by esterification of the resulting fatty acids catalyzed either by enzymes [21], or by acidic homogeneous [32] or heterogeneous [33] catalysts (Scheme 1).

As an alternative, 2-EtC6H12OH esters are obtained by a transesterification of the vegetable oils with methanol (or ethanol), followed by transesterification of thus obtained biodiesel with 2-EtC6H12OH in the presence of a basic catalyst (e.g., CH3ONa [18] or K2CO3 [20], Scheme 2). A comparable procedure was successfully applied to the synthesis of the epoxidized 2-EtC6H12OH ester of a WCO catalyzed by CaO, a particularly cheap and easily available base [29].

Interestingly, a single example involves the one-pot transesterification of soybean oil with 2-EtC6H12OH [34]. As a distinct advantage, operating such a transformation in a single step maximizes atom economy, increases energy efficiency, and minimizes both reaction waste and the employment and wear of the necessary equipment’s. On the other side, such a reaction was catalysed with CH3ONa, a strong base usually generated under harsh reaction conditions, e.g., by reacting dry CH3OH with Na metal.

To set-up an environmentally friendlier synthetic approach, we investigated the one-pot transesterification of our WCO’s with Guerbet alcohols catalyzed by commercially available CaO (Scheme 3). To optimize the energy expenditure, the results obtained under conventional heating were compared with results obtained under microwave irradiation.

Besides transesterification, epoxidation is one of the most widely applied chemical modifications of vegetable oils. Despite the availability of several efficient methodologies to synthesize epoxidized vegetable oils, the Prilezhaev reaction is probably the most widely employed methodology, mostly at the industrial level [35,36,37]. The overall reaction is a two-step process occurring in a biphasic system, as diagrammatically shown in Scheme 4.

In the first, rate determining step [39], the peracid is generated by the reaction of a carboxylic acid, usually CH3COOH or HCOOH, with a concentrated aqueous solution of H2O2 (30–60% w/w). Formation of peracetic acid usually requires the presence of catalytic amounts of a strong Brønsted acid which, on the other side, is unnecessary to generate performic acid [39]. In the second step, formation of the oxirane ring occurs after migration of the peracid to the organic phase, where it reacts with the carbon–carbon double bonds leading to a highly exothermic (-55 kcal/mol for each double bond) reaction [40].

Numerous research works are dedicated to the optimization of the selectivity of this reaction, with particular attention to the set-up of useful conditions to avoid runaway reactions [40,41,42], to substitute homogeneous with heterogeneous acidic catalysts [38, 43, 44], to evaluate the activity of these last catalysts under conventional or microwave heating [45], and to avoid the formation of by-products due to the acid-catalyzed ring opening of the oxiranes [12, 38, 39, 43, 46,47,48].

At this level of our research, with the aim of using a relatively simple procedure able to avoid the formation of by-products, we decided to perform the epoxidation of both the WCO and the Guerbet esters with HCOOH and H2O2 in the presence of an organic co-solvent, thus avoiding the addition of other acids [39].

Finally, we will report on some of the physicochemical properties (cloud point, kinematic viscosity, viscosity index and oxidation stability) of the starting material and some of the corresponding esters and epoxidized esters to envisage their possible applications.

Experimental

Materials Information

Four different samples of WCO (termed as WCO1 to WCO4) were provided by Il Gabbiano Industria Ecologica srl (Porto Torres, Italy) within a three-year span of time. Al2O3 (neutral, Brockmann® I), Celite, CaO (99.9%), dry Na2SO4 and CDCl3 (99.8% atom D), were purchased from Sigma-Aldrich. AcOEt (> 98%), 2-ethyl-1-hexanol (> 99.5%), 2-butyl-1-octanol (> 98%) and HCOOH (> 99.5%) were purchased form TCI. 30% H2O2 was purchased from VWR BDH Chemicals.

Preliminary Purification of WCOs

WCO, which is conferred in capped plastic bottles, is drained from the bottles and coarsely filtered through a 2 mm stainless steel strainer filter to remove the macroscopic solid residues, washed with water in a counter-current washing tower (400 mm diameter, 5000 mm high) and decanted by means of a series of 3 successive stainless-steel tanks (10 m3 each). The oil separated from the washing water is thereafter filtered twice, first through a 10-micron bag filter and, after vacuum dehydration (600 mmHg, 70 °C), through a 5-micron paper filter with a 1 atm maximum differential pressure. The resulting product is collected in 5 L sealed plastic tanks and labelled as biodegradable chainsaw chain oil. During this work, four different WCO samples (purified as described above and referred to as WCO1-WCO4) were collected and used as starting materials over a three-year span of time.

Titration and Deacidification of WCO

The free fatty acid content (%FFA) of WCOs was determined according to IUPAC's recommendation [49]. Deacidification was run in a 3 L Erlenmeyer flask by dissolving 1 L of WCO into 760 mL of AcOEt followed by the addition of 100 – 200 g of neutral Al2O3. The resulting mixture was slowly stirred (to avoid excessive fragmentation of Al2O3 particles) at rt overnight, then filtered over Celite, dried (Na2SO4) and the filtrate evaporated to afford the deacidified WCO.

NMR Experiments

1H-NMR (400 MHz) and 13C-NMR (100 MHz spectra were recorded with a Bruker Ascend 400 spectrometer in CDCl3 (99.8% D content) solution with the residual peak of CHCl3 as reference for the chemical shift values. Quantitative 1H-NMR analyses of WCOs were run in agreement with literature data (Fig. S1, Supporting information) [10,11,12].

CaO Catalysed Transesterifications Under Conventional Heating

CaO from a freshly opened container (Sigma-Aldrich, 99.9%) was stored in an oven at 120 °C during 48 h and chilled to rt in a desiccator immediately before use. Transesterification of WCO3 with 2-EtC6H12OH is illustrative of a general procedure.

The reaction was run under dry Ar in a 500 mL two-necked round-bottom flask equipped with magnetic stirrer, dropping funnel and reflux condenser connected with an Ar inlet. The reactor was immersed in a thermostatic bath oil. Dry CaO (15 or 25 mol % of WCO) was added to a mixture of 100 g (0.11 mol) of deacidified WCO3 and 2-EtC6H12OH (1.1 to 2.0 equivalents) and the resulting mixture was vigorously stirred at the temperature and during the time reported in Table V. The resulting mixture was filtered over Celite, separated from glycerol, washed several times with brine until neutrality, dried with Na2SO4 and evaporated to recover excess of 2-EtC6H12OH. The reaction product was characterized by 1H- and 13C-NMR.

Microwave-Assisted CaO Catalysed Transesterifications

Microwave-assisted reactions were run in a CEM Discover microwave apparatus, consisting of a continuous microwave power delivery system with operator selectable power output from 0—300 watts., a self-adjusting single mode microwave cavity and an infrared temperature control system, located below the microwave cavity floor, that monitors reaction temperature and pressure and maintains the desired temperature (between 0 and 300 °C) by computer control. The transesterification of WCO3 with 2-EtC6H12OH is illustrative of a general procedure.

In a 10 mL vial were charged under dry Ar 0.9 g (1.5 mmol) of deacidified WCO3, 1.1 to 2.7 equivalents of 2-EtC6H12OH and dry CaO (15 to 25 mol %). The vial was inserted into the microwave apparatus and irradiated at 200 W for the time and at the temperature reported in Table VI. The resulting mixture was filtered over Celite, separated from glycerol, washed several times with brine until neutrality, dried with Na2SO4 and evaporated to recover excess of 2-EtC6H12OH. The reaction product was characterized by 1H- and 13C-NMR.

Characterization of CaO

Characterization of dry CaO by Infrared spectroscopy was performed with a Jasco FT-IR 4600 spectrophotometer operating in ATR mode.

Epoxidation

Epoxidation of WCO3 is illustrative of a general procedure. The reaction was run in a 250 mL three-necked spherical glass reactor (internal maximum diameter 95 mm) immersed in a thermostatic bath oil and equipped with an egg-shaped magnetic stir bar (length 25 mm, diameter 12 mm), dropping funnel, internal thermometer and reflux condenser. 50 g of the substrate (WCO3, 5.6 × 10–2 mol, 3.81 C = C/mol) was dissolved in 100 mL of toluene and chilled at 0 °C. To this mixture were successively dropwise added 7.9 mL of HCOOH (9.6 g, 2.1 × 10–1 mol); the mixture was then conditioned at 0 °C for 5 min. Next, under stirring, 64.3 ml of hydrogen peroxide (30% w/w, 6.3 × 10–1 mol) were added dropwise during 30 min. Once the addition was finished, the mixture was stirred at 1400 rpm (onset of the vortex at 550 rpm) and heated at 60 °C (ΔT = ± 8 °C) for 6 h, then chilled at rt and the biphasic solution separated. The organic phase was washed with saturated NaHCO3 (100 ml), saturated NaCl (100 ml) and H2O (100 ml). The resulting organic phase was then dried with anhydrous MgSO4 and, after filtration, distilled under vacuum to remove the toluene. The reaction product was characterized by 1H- and 13C-NMR.

Oxidation Stability

Pressurized differential scanning calorimetry (PDSC) experiments were accomplished using a Sensys calorimeter by Setaram (Lione, France) equipped with stainless steel hermetic high-pressure cells. Typically, a sample mass between 35 and 60 mg was placed in the crucible of the high-pressure cells, that was closed under air. As a reference, a high-pressure empty cell was used. The cells were pressurized at 9 bars of pure dry oxygen (99.999%; provided by SOL S.p.A, Monza, Italy). A 10 °C min–1 heating rate from 25 °C to 250 °C was used during each experiment. The oxidation onset (OT, °C) and signal maximum temperatures (SMT, °C) were obtained from the calorimetric profile for each experiment. Each sample was run in triplicate and the average values rounded to the nearest whole degree are reported together with their standard deviation values.

The oxidation onset temperature is a relative measure of the degree of oxidative stability in a material evaluated for a given heating rate and oxidation environment. The signal maximum temperature is the temperature at which maximum heat output is observed in the sample during oxidative degradation. The calorimeter was calibrated with pure indium before the temperature evaluations.

Results and Discussion

Collecting and Purification of WCOs

WCO was collected in capped plastic bottles delivered either through a door-to-door collection system or by depositing the capped bottles in special street containers. The purpose of this collection method is to avoid mixing the oil from domestic users with that from commercial activities. Indeed, the latter usually contains a high percentage of palm oil whose relatively high content of saturated fatty acids determines its relatively high melting point. As described below, this selection allows to recover a WCO containing a relatively low percentage of saturated fatty acids (< 17%). After filtering, washing and drying, recovered WCOs were submitted to titration to determine their %FFA. Indeed, it is well known that WCOs usually contain a relatively high %FFA and these impurities negatively affect the efficiency of base-catalysed transesterifications [50].

Therefore, we determined the %FFA of all WCOs under investigation according to IUPAC's recommendation [50]. The results, as reported in Table 1 (column 3), show a relatively high content of FFA, thus suggesting the need to submit the different samples to an efficient deacidification procedure.

By modifying a patented procedure [51], the oil was dissolved in AcOEt (WCO/AcOEt = 1.3:1.0 v/v) and deacidified with neutral alumina (WCO/Al2O3 = 10:1 w/w), followed by filtration and evaporation of the solvent. The results, as reported in Table 1 (column 4), show the efficiency of this protocol leading to recover WCOs with %FFA < 0.2 in all cases but one (Table 1, entry 2). Partially deacidified WCO2 was therefore submitted to a second deacidification procedure, either with a WCO2:Al2O3 = 10:1 or 5:1 (w/w), leading to satisfactory results (Table 1, entries 3 and 4).

According to the original procedure [51], spent Al2O3 can be reactivated by washing with 1 M aqueous NaOH and water, followed by drying to remove moisture.

Characterization of WCOs

Quantitative 1H-NMR (q1H-NMR) was employed to determine significant chemical properties of the different batches of the deacidified WCOs: molecular weight (MW), iodine value (IV), average Carbon–Carbon double bond/mole (C = C/mol), % molar composition of saturated fatty acids (%SFA), mono-unsaturated fatty acids (%MUFA) and poly-unsaturated fatty acids (%PUFA), and the molar ratio between unsaturated fatty acids and saturated fatty acids (%UFA/%SFA, with %UFA = %MUFA + %PUFA) [10,11,12].

The results, as reported in Table 2, show that the main physico-chemical characteristics of the recovered WCOs do not vary to a great extent within the analysed batches, thus affording a picture of a secondary raw material [52] with an almost constant chemical composition, and demonstrating the effectiveness of the harvesting method.

To validate the above reported results, the fatty acid compositions of WCO2 and WCO3 were determined by GC analysis of the transesterification products of the oils with methanol (CH3WCO2 and CH3WCO3, respectively) according to IUPAC’s recommendation [53] (Table 3).

Starting from the fatty acid profiles, we calculated the corresponding MW, IV, C = C/mol, %SFA, %MUFA, %PUFA and %UFA/%SFA data, which were compared with the results obtained by q1H-NMR analysis of the same samples.

The results, as reported in Table 4, show a pretty good agreement between data determined either by GC or by q1H-NMR analyses of the different methyl esters.

Interestingly, the presence of relatively low percentages of saturated fatty acids lowers the pour point temperature of the products that can be obtained from the chemical modification of these vegetable oils, an important feature for products that are used as lubricants and/or plasticizers. On the other side, the presence of high percentages of mono- and poly-unsaturated fatty acids requires their conversion into the corresponding epoxides to improve their oxidation stabilities [29, 43, 54, 55].

Transesterification Reactions

All reactions were run under Ar atmosphere with an excess of the appropriate alcohol and in the presence of variable amounts of the catalyst. The transesterification of deacidified oil WCO3 (%FFA = 0.062) with an excess of 2-EtC6H12OH in the presence of a catalytic amount of dry CaO was first investigated.

The extent of the transesterification reaction was monitored by 1H-NMR spectroscopy of crude reaction mixtures, by comparing the integration of the newly formed multiplet centred at 3.96 ppm, corresponding to the CH2O of the esterified 2-EtC6H12O chain, with the integration of the (overlapped) triplet(s) at 2.33–2.27 ppm, corresponding to the CH2 in the α-position with respect to the carbonyl group(s). Complete disappearance of the hydrogen resonances of the trialkyl glyceride backbone (one multiplet at 5.43–5.34 and two doublets of doublets at 4.33 and 4.10 ppm) was also indicative of a good conversion of the starting materials.

Selected results, as reported in Table 5, show that under conventional heating conditions the transesterification reaction is quite slow. Additionally, although complete conversion of the starting material was observed under conditions reported in Table 5, entries 3 and 4, an accurate analysis of 1H-NMR spectra of crude reaction mixtures have shown that the 2-EtC6H12OH ester of WCO3 (2-EtC6H12WCO3) was contaminated by non-negligible quantities of the intermediate products of mono- and di-transesterification. Indeed, products of incomplete transesterification, i.e., diglycerides (DG) and monoglycerides (MG), give rise to several multiplets within the 4.35–3.55 ppm region.

Although purification of 2-EtC6H12WCO3 from relatively small amounts of mono- and di-glycerides can be achieved by storing the impure compounds in the fridge (6 °C) for 2–3 days, followed by filtration of the resulting heterogeneous mixtures, we decided to investigate the possibility to overcome such a problem and to reduce the reaction time by running the transesterification reaction under microwave (MW) irradiation. Indeed, it is well known that MW irradiation has been used extensively to accelerate a variety of chemical reactions, significantly reducing reaction times [56].

Accordingly, a new set of reaction was run under MW irradiation. Selected results, as reported in Table 6, show that all the investigated reaction parameters (oil to 2-EtC6H12OH molar ratio, relative amount of the catalyst, reaction temperature and time) affect the overall conversion of the starting material to the desired 2-EtC6H12OH ester. With an oil to 2-EtC6H12OH molar ratio = 1:6 and in the presence of a 25 mol % of the catalyst, high conversion and selectivity of the starting material were obtained after 3 h at 190 °C (Table 6, entry 7), thus demonstrating the good performance of the MW-assisted process.

Recovered 2-EtC6H12WCO3 was characterized by 1H-NMR spectroscopy as reported in Fig. 1, where a comparison between the 1H-NMR spectra of WCO3 and the corresponding 2-EtC6H12OH ester is reported.

13C-NMR spectroscopy was employed to further characterize 2-EtC6H12WCO3. Besides the disappearance of the resonances corresponding to the trialkyl glyceride carbons (69.0 and 62.2 ppm) and the the simplification of resonances relating to ester carbonyls (174.0–174.1 ppm), the main differences concern the appearance of resonances corresponding to the CH2O (66.7 ppm), to the CH (38.9 ppm) and to the side chain CH3 of the isooctylate (11.1 ppm) (Figure S2, Supporting Information).

Under comparable reaction conditions, we realized the transesterification of WCO3 with 2-BuC8H16OH (Scheme 3), and the resulting product (2-BuC8H16WCO) was characterized by means of 1H- and 13C-NMR spectroscopies; as discussed above, the corresponding spectra are mainly characterized by the resonances of the CH2O of the esterified alcohol chain and by the disappearance of the resonances of, respectively, the hydrogen and the carbon atoms of the trialkyl glyceride skeleton (Figures S3 and S4, Supporting Information).

It is finally worth noting that processing of all transesterification mixtures led, by evaporation at reduced pressure, to recover the excess of the different alcohols. Recovered alcohols (usually 80–85% mass recovery of the starting materials) were analytically pure by 1H- and 13C-NMR analyses and identical to commercial samples, thus allowing their successful recycling to successive runs without detrimental effects.

Characterization of Dry CaO

Dry CaO was characterized by means of FT-IR spectroscopy. CaO displays a strong band around at 550 cm−1 [57] and the reported IR spectrum (Fig. 2) allows to identify the presence of small amounts of impurities characteristic of an oxide marketed in packages unsealed under an inert atmosphere. The two weak bands at 1484 and 1412 cm−1 can be ascribed to asymmetric stretching bands of carbonate due to absorption of CO2 on the surface of CaO as a monodentate ligand [58]. The sharp band at 3641 cm−1 can be attributed to free (non-hydrogen bonded) O–H stretching typical of calcium hydroxide [59]. The absence of broad absorption(s) in this region strongly suggests the absence of water molecules adsorbed to the oxide.

Epoxidation of WCO3, 2-EtC6H12WCO3 and 2-BuC8H16WCO3

Epoxidized WCO3 (E-WCO3), epoxidized 2-EtC6H12WCO3 (E-2-EtC6H12WCO3) and 2-BuC8H16WCO3 (E-2-BuC8H16WCO3) esters were prepared by reacting the different starting materials with 30% H2O2 and HCOOH with a C = C/H2O2/HCOOH ratio = 1:3:1 at 60 °C during 6 h, using toluene as a diluent of the organic phase (1:1 v/v) to reduce viscosity, minimize side reactions [39, 43] and obtain efficient dispersion of the reaction heat [60].

Under these conditions, > 95% conversion of each starting material was obtained within 6 h, as determined by 1H-NMR analysis of crude reaction mixtures. Indeed, epoxidation of C = C double bonds led to the disappearance of resonances due to the vinylic (multiplet at ca. 5.42–5.28 ppm), bis-allylic (triplet at ca. 2.76 ppm) and allylic protons (multiplet at ca. 2.10–1.96 ppm). On the other side, the epoxidized compounds show new resonances due to the protons of the oxirane rings (multiplets at ca. 3.15–2.85 ppm) and to protons at the α-position of the oxirane rings (multiplet at ca. 1.55–1.40 ppm). Accordingly, 13C-NMR spectra of epoxidized compounds are characterized by the disappearance of the resonances between 130.3 – 128.0 ppm due to the vinylic carbons and by the appearance of a series of new resonances at 57.3 – 54.2 ppm due to the carbons of the oxirane rings (Figures S5-S10, Supporting Information).

Pour Point, kinematic viscosity, viscosity index and oxirane oxygen content. Pour point, kinematic viscosity and viscosity index are key parameters to evaluate the efficiency of a vegetable oil derivative as a plasticizer or as a lubricant [54, 61, 62]. Pour points were determined according to ASTM D5950-14. Kinematic viscosities at 40 and 100 °C were determined for WCO2 and WCO3, E-WCO3, 2-EtC6H12WCO3, E-2-EtC6H12WCO3, 2-BuC8H16WCO3 and E-2-BuC8H16WCO3 according to ASTM D445-19a; the corresponding viscosity indexes were determined according to ASTM D2270.

The results are reported in Table 7, where literature data for two commercially available plasticizers derived from soybean oil, i.e., epoxidized soybean oil (E-SoyOil, Vikoflex® 7170) [54, 63] and E-2-EtC6H12Soyate (Vikoflex® 4050) [25, 54] and for a proposed biolubricant for drilling fluids, i.e., 2-ethylhexyl palmitate (2-EtC6H12PO) [15], are also reported for comparison purposes. Due to the well-known increase of viscosity with epoxidation [64], the oxirane oxygen contents of epoxidized compounds are also reported.

As a first remark, it is worth noting that all investigated properties of the WCO batches under consideration are very similar (Table 7, entries 1 and 2), thus providing further evidence of the relative stability of their fatty acid composition over time.

As expected, the molecular weight differences between WCOs and E-WCO3 on the one hand (Table 7, entries 1–3) and the corresponding Guerbet esters (Table 7, entries 4 and 6) and epoxidized Guerbet esters on the other (Table 7, entries 5 and 7), lead to a large decrease in both pour points and viscosity data for the lower molecular weight compounds. Additionally, epoxidation led to an increase of pour points and kinematic viscosities, as well as to a decrease of the viscosity indexes (Table 7, entry 2 versus entry 3; entry 4 versus entry 5; entry 6 versus entry 7).

Among the synthesized derivatives of our WCO, 2-BuC8H16WCO3 and E-2-BuC8H16WCO3 show pour point temperatures significantly lower and relatively higher kinematic viscosities than those of the corresponding 2-EtC6H12OH derivatives, most probably due to the superior steric hindrance of their alkoxy moiety [29], as well as to their relatively higher molecular weight.

As a comparison with commercially available plasticizers, it can be observed that epoxidized derivates of WCO synthesized in the present work (Table 7, entries 3, 5 and 7) compare well with epoxidized soybean oil derivates (Table 7, entries 8 and 9). Indeed, despite differences in kinematic viscosities between E-WCO3 and E-SoyOil, viscosity indices of epoxidized WCO derivatives are comparable with those of the corresponding soybean oil derivative; additionally, there is a significant decrease of pour points when switching from soybean oil derivatives to those of the WCO, once again accounting for the relative differences in oxirane oxygen content [64] (Table 7, entries 3, 5, 8 and 10).

Finally, pour points, kinematic viscosities and viscosity indexes determined for 2-EtC6H12WCO3 and 2-BuC8H16WCO3 compare well with the corresponding properties of the 2-EtC6H12OH ester of palm oil (2-EtC6H12OPO), which was proposed as a biolubricant for drilling fluids [18] (Table 7, entry 10).

Oxidative Stability

Pressure differential scanning calorimetry (PDSC) was used to evaluate the oxidative stability of two WCOs and all WCO derivatives, an important parameter to evaluate their possible employment as biolubricants or plasticizers. The results are reported in Table 8, where the literature data for E-SoyOil and E-2-EtC6H12Soyate are also reported for comparison purposes [54].

As expected from their almost constant fatty acid composition, OT ed SMT recorded values are quite similar for our triglycerides WCO2 and WCO3 (Table 8, entries 1 and 2). From this point of view, it is interesting to notice that while no appreciable variations in the oxidative stability values are observed in passing from WCO3 to 2-EtC6H12WCO3, we observed a decidedly higher stability for the corresponding 2-BuC8H16OH epoxidized ester (Table 8, entries 2, 4 and 6).

On the other hand, epoxidation of carbon–carbon double bonds of WCO3, 2-EtC6H12WCO3 and 2-BuC8H16WCO3, was accompanied by a significant increase of the OT and SMT values of the corresponding reaction products, i.e., E-WCO3, E-2-EtC6H12WCO3 and E-2-BuC8H16WCO3, respectively (Table 8, entry 2 versus entry 3; entry 4 versus entry 5; and entry 6 versus entry 7). It is worth noting that the highest OT and SMT values were obtained in the case of the 2-BuC8H16OH ester. These results strongly suggest a positive influence on the oxidation stability of an increase in the chain length of the carbon atoms and/or of the steric hindrance of the alkoxy portion of the monoester derivatives.

Finally, it is interesting to note that while the OT and SMT values obtained for E-WCO3 and E-2-EtC6H12WCO3 describe products with slightly lower oxidation stabilities than that reported for the corresponding commercially available soybean oil derivatives (Table 8, entries 8 and 9), the values obtained in the case of E-2-BuC8H16WCO3 (Figure S11, Supplementary Information) describe a product with oxidation stability characteristics that compare well with those of Vikoflex 4050.

Conclusion

Our report illustrates an original collection method of a WCO that allows the recovery of a secondary raw material with an almost constant composition over time, as well as its chemical modification into useful biochemicals.

The design of these useful chemical modifications was based on the rapid determination of the chemical characteristics of the oil, made possible by using quantitative 1H-NMR as an analytical tool.

The key transesterification step of the triglyceride with long chain and branched primary alcohols was obtained for the first time by employing commercially available CaO as a basic catalyst. Additionally, MW irradiation allowed the optimization of energy expenditure.

The success of our protocol is evidenced by the determination of the main physico-chemical properties of the resulting products. Indeed, our Guerbet esters compare well in terms of pour points and kinematic viscosities with the 2-EtC6H12OH ester of palm oil (2-EtC6H12PO), recently proposed as a biolubricant for drilling fluids, whilst the epoxidized Guerbet esters synthesized in the present work compare well with a commercially available plasticizers also in terms of oxidative stability.

References

Brandão, A.S., Gonçalves, A., Santos, J.M.R.C.: A: Circular Bioeconomy Strategies: From Scientific Research to Commercially Viable Products. J. Clean. Prod. 295, 126407 (2021). https://doi.org/10.1016/j.jclepro.2021.126407

Plazzotta, S., Manzocco, L., Food Waste Valorization. In: Galanakis C. M. (ed.) Saving Food – Production, Supply Chain, Food Waste and Food Consumption, pp. 279–313. Academic Press, Elsevier, Amsterdam (2002). https://doi.org/10.1016/B978-0-12-815357-4.00010-9

Cárdenas, J., Orjuela, A., Sánchez, D.L., Narváezm, P.C., Katryniok, B., Clark, J.: Pre-treatment of used cooking oils for the production of green chemicals: A review. J. Clean. Prod. 289, 125129 (2021). https://doi.org/10.1016/j.jclepro.2020.125129

Paul, A.K., Borigadda, V.B., Goud, V.B.: In-situ epoxidation of waste cooking oil and its methyl esters for lubricant application characterization and rheology. Lubricants 9, 27 (2021). https://doi.org/10.3390/lubricants9030027

Mannu, A., Garroni, S., Porras, I.P., Mele, A.: Available Technologies and Materials for Waste Cooking Oil Recycling. Processes 8, 366 (2020). https://doi.org/10.3390/pr8030366

Tsai, W.-T.: Mandatory recycling of waste cooking oil from residential and commercial sectors in Taiwan. Resources 8, 38 (2019). https://doi.org/10.3390/resources8010038

Mannu, A., Ferro, M., Colombo Dugoni, G., Panzeri, W., Petretto, G.L., Urgeghe, P., Mele, A.: Improving the recycling technology of waste cooking oils: chemical fingerprint as tool for non-biodiesel application. Waste Manage. 96, 1–8 (2019). https://doi.org/10.1016/j.wasman.2019.07.014

Mannu, A., Ferro, M., Di Pietro, M.E.: Mele, A: Innovative applications of waste cooking oils as raw material. Sci. Prog. 102, 153–160 (2019). https://doi.org/10.1177/0036850419854252

Consorzio nazionale di raccolta e trattamento degli oli e dei grassi vegetali ed animali esausti: Consuntivo dell’attività di raccolta e trattamento degli oli e dei grassi vegetali ed animali esausti da parte del CONOE. http://www.conoe.it/wp-content/uploads/2018/11/ANNUAL-REPORT-2018.pdf. Accessed 17 April 2022

Miyake, Y., Yokomizo, K., Matsuzaki, N.: Rapid determination of iodine value by 1H nuclear magnetic resonance spectroscopy. J. Am. Oil Chem. Soc. 75, 15–19 (1998). https://doi.org/10.1007/s11746-998-0003-1

Miyake, Y., Yokomizo, K., Matsuzaki, N.: Determination of unsaturated fatty acid composition by high-resolution nuclear magnetic resonance spectroscopy. J. Am. Oil Chem. Soc. 75, 1091–1094 (1998). https://doi.org/10.1007/s11746-998-0295-1

Polese, R., E. Pintus, E., Nuvoli, L., Tiana, M., Pintus, S., Satta, G., Beccu, A., Gaspa, S., Carraro, M., De Luca, L., Azzena, U., Pisano: L. Aquivion perfluorosulfonic superacid as an effective catalyst for selective epoxidation of vegetable oil. R. Soc. Open Sci. 9, 211554 (2022). https://doi.org/10.1098/rsos.211554

O’Lenick, A.J.: Guerbet Chemistry. J. Surfactants Deterg. 4, 311–315 (2001). https://doi.org/10.1007/s11743-001-0185-1

https://lipidlibrary.aocs.org/chemistry/physics/lipid-chemistry/guerbet-compounds. Accessed 17 April 2022

https://echa.europa.eu/registration-dossier/-/registered-dossier/11955/5/3/1. Accessed 17 April 2022

Bahrmann, H., Hahn, H.-D., Mayer, D., Frey, G. D.: 2‐Ethylhexanol. In: Ullmann’s Encyclopedia of Industrial Chemistry, Wiley, Weinheim, Germany, 2005. https://doi.org/10.1002/14356007.a10_137.pub3

Nieendick, C., Schmid, K., Müller, H., Herold, C.-P.: Process for Cold Cleaning Oil-Contaminated Metal Surfaces with 2-Ethylhexyl Esters of Fatty Acids. US 005421907 A (1995)

Habib, N. S. H. A., R. Yunus, R., Rashid, U., Taufiq-Yap, Y. H., Abidin, Z. Z., Syam, A. M.: Synthesis of palm-based ethylhexyl ester as a synthetic base oil for drilling fluids using chemical transesterification. Grasas y Aceites, 65, e005 (2014). https://doi.org/10.3989/gya.074513

Chapman, J., Ward, I.: Lubricant for drilling mud. EP Patent 0 770 661 (1997)

Zheng, T., Wu, Z., Xie, Q., Lu, M., Xia, F., Wang, G., Nie, Y., Ji, J.: Biolubricant Production of 2-Ethylhexyl Palmitate by Transesterification Over Unsupported Potassium Carbonate. J. Am. Oil Chem. Soc. 95, 79–88 (2018). https://doi.org/10.1002/aocs.12023

da Silva, M.V.C., Rangel, A.B.S., Aguiar, L.G., de Castro, H.F., de Freitas, L.: Continuous Enzymatic Synthesis of 2-Ethylhexyl Oleate in a Fluidized Bed Reactor: Operating Conditions, Hydrodynamics, and Mathematical Modeling. Ind. Eng. Chem. Res. 59, 19522–19530 (2020). https://doi.org/10.1021/acs.iecr.0c03504

Krist, S.: Lexikon der pflanzlichen Fette und Öle, pp. 205–213. Springer-Verlag, Wien (2013). https://doi.org/10.1007/978-3-7091-1005-8_31

Jarchem Innovative Ingredients: JarcolTM I-12. https://www.jarchem.com/portfolio/jarcol-i-12/. Accessed 17 April 2022

A. Ansmann, M. Dierker, C. Weichold, Cosmetic compositions containing ester obtained from 2-butyl-1-octanol, 2007, EP Patent 2 051 781 B1

Accessed 13 July 2021 SpecialChem: Vikoflex® 4050 epoxidized vegetable oil - technical data sheet. https://adhesives.specialchem.com/product/a-arkema-vikoflex-4050-epoxidized-vegetable-oil. Accessed 17 April 2022

McNeill, I.C., Memetea, L., Cole, W.J.: A study of the products of PVC thermal degradation. Polym. Degrad. Stab. 49, 181–191 (1995). https://doi.org/10.1016/0141-3910(95)00064-S

Frenkel, P.: Bio-Based Biocide Compositions and Methods of Preserving therewith. US 9,580,574 B2 (2017)

Zheng, T., Wu, Z., Xie, Q., Fang, J., Hu, Y., Lu, M., Xia, F., Nie, Y., Ji, J.: Structural modification of waste cooking oil methyl esters as cleaner plasticizer to substitute toxic dioctyl phthalate. J. Clean. Prod. 186, 1021–1103 (2018). https://doi.org/10.1016/j.jclepro.2018.03.175

Li, W., Wang, X.: Bio-lubricants Derived from Waste Cooking Oil with Improved Oxidation Stability and Low-temperature Properties. J. Oleo Sci. 64, 367–374 (2015). https://doi.org/10.5650/jos.ess14235

European Chemicals Agency: 2-ethylhexyl oleate. https://echa.europa.eu/it/registration-dossier/-/registered-dossier/15935/1. Accessed 18 April 2022

European Chemicals Agency: Fatty acids, C16–18 and C18-unsatd., isooctyl esters, epoxidized. https://echa.europa.eu/it/registration-dossier/-/registered-dossier/10690. Accessed 18 April 2022

Lacaze-Dufaure, C., Mouloungui, Z.: Catalysed or uncatalysed esterification reaction of oleic acid with 2-ethyl hexanol. Appl. Cat. A 204, 223–227 (2000). https://doi.org/10.1016/S0926-860X(00)00533-0

Kim, Y.-H., Han, J., Jung, B.Y., Yamada, Y.M.A., Uozumi, Y., Lee, Y.-S.: Production of valuable esters from oleic acid with a porous polymeric acid catalyst without water removal. Synlett 27, 29–32 (2016). https://doi.org/10.1055/s-0035-1560584

Hwang, H.-S., Adhvaryu, A., Erhan, S.Z.: Preparation and properties of lubricant basestocks from epoxidized soybean oil and 2-ethylhexanol. J. Am. Oil Chem. Soc. 80, 811–815 (2003). https://doi.org/10.1007/s11746-003-0777-y

Meng, Y., Taddeo, F., Aguilera, A.F., Cai, X., Russo, V., Tolvanen, P.: Leveneur: The Lord of the Chemical Rings: Catalytic Synthesis of Important Industrial Epoxide Compounds. Catalysts 11, 765 (2021). https://doi.org/10.3390/catal11070765

Wai, P.T., Jiang, P., Shen, Y., Zhang, P., Leng, Y.: Catalytic developments in the epoxidation of vegetable oils and the analysis methods of epoxidized products. RSC Adv. 2019(9), 38119–38136 (2019). https://doi.org/10.1039/C9RA05943A

Danov, S.M., Kazantsev, O.A., Esipovich, A.L., Belousov, A.S., Rogozhin, A.E., Kanakov, E.A.: Recent advances in the field of selective epoxidation of vegetable oils and their derivatives: a review and perspective. Catal. Sci. Technol. 7, 3659–3675 (2017). https://doi.org/10.1039/C7CY00988G

A. Campanella, A., Baltanás, M. A.: Degradation of the oxirane ring of epoxidized vegetable oils in liquid–liquid heterogeneous reaction systems. Chem. Eng. J. 118, 141–152 (2006). https://doi.org/10.1016/j.cep.2006.06.001

Gan, L.H., Goh, S.H., Ooi, K.S.: Kinetic studies of epoxidation and oxirane cleavage of palm olein methyl esters. J. Am Oil Chem. Soc. 69, 347–351 (1992). https://doi.org/10.1007/BF02636065

Santacesaria, E., Tesser, R., Di Serio, M., Turco, R., Russo, V., Verde, D.: A biphasic model describing soybean oil epoxidation with H2O2 in a fed-batch reactor. Chem. Eng. J. 173, 198–209 (2011). https://doi.org/10.1016/j.cej:2011.05.018

Leveneur, S.: Thermal safety assessment through the concept of structure-reactivity: application to vegetable oils valorization. Org. Process Res. Dev. 21, 543–550 (2017). https://doi.org/10.1021/acs.oprd.6b00405

Leveneur, S., Pinchard, M., Rimbault, A., Safdari Shadloo, M., Meyer, T.: Parameters affecting thermal risk through a kinetic model under adiabatic condition: Application to liquid-liquid reaction system. Thermochim. Acta 10–17 (2018). https://doi.org/10.1016/j.tca.2018.05.024

Campanella, A., Baltanás, M.A.: Degradation of the oxirane ring of epoxidized vegetable oils with solvated acetic acid using cation-exchange resins. Eur. J. Lipid. Sci. Tech. 106, 524–530 (2004). https://doi.org/10.1002/ejlt.200400965

Freites Aguilera, A., Tolvanen, P., Wärnå, J., Leveneur, S., Salmi, T.: Kinetics and reactor modelling of fatty acid epoxidation in the presence of heterogeneous catalyst. Chem. Eng. J. 375, 121936 (2019). https://doi.org/10.1016/j.cej.2019.121936

Freites Aguilera, A., Tolvanen, P., Oger, A., Eränen, K., Leveneur, S., Mikkola, J.-P., Salmi, T.: Screening of ion exchange resin catalysts for epoxidation of oleic acid under the influence of conventional and microwave heating. J. Chem. Technol. Biotechnol. 94, 3020–3031 (2019). https://doi.org/10.1002/jctb.6112

Cai, X., Zheng, J.-L., Freites Aguilera, A., Vernières-Hassimi, L., Tolvanen, P., Salmi, T., Leveneur, S.: Influence of ring opening reactions on the kinetics of bio-based cottonseed oil epoxidation. Int. J. Chem. Kinet. 50, 726–741 (2018). https://doi.org/10.1002/kin.21208

Rios, L.A., Echeverri, D.A., Franco, A.: Epoxidation of jatropha oil using heterogeneous catalysts suitable for the Prileschajew reaction: Acidic resins and immobilized lipase. Appl. Catal. A Gen. 394, 132–137 (2011). https://doi.org/10.1016/j.apcata.2010.12.033

Azzena, U., Carraro, M., Pisano, L., Pintus, E., Pintus, S., Polese, R., Satta, P., Gaspa, S., De Luca, L., Taras, A., Garroni, S.: Size Selectivity in the Hydroxylation of Esters of Unsaturated Fatty Acids. Eur. J. Lipid. Sci. Tech. 124 (2022) in press. https://doi.org/10.1002/ejlt.202100234

Paquot, C.: Standard methods for the analysis of oils, fats and derivatives, pp. 52–55. Pergamon Press, Oxford (1979). https://doi.org/10.1016/C2013-0-10129-8

Canakci, M., Van Gerpen, J.: Biodiesel production from oils and fats with high FFAs. T. ASAE 44, 1429–1436 (2001). https://doi.org/10.13031/2013.7010

Ayorinde, F.O., Hassan, M.: Deacidification of Vegetable Oils. US 005414100 A (1995)

European Parliament: Strategy for secondary raw materials. https://www.europarl.europa.eu/legislative-train/theme-new-boost-for-jobs-growth-and-investment/file-strategy-for-secondary-raw-materials. Accessed 18 April 2022

Ref. 49, p.103–108.

Sharma, B.K., Doll, K.M., Erhan, S.Z.: Oxidation, friction reducing, and low temperature properties of epoxy fatty acid methyl esters. Green Chem. 9, 469–474 (2007). https://doi.org/10.1039/B614100E

Adhvaryu, A., Erhan, S.Z.: Epoxidized soybean oil as a potential source of high temperature lubricants. Ind. Crops Prod. 15, 247–254 (2002). https://doi.org/10.1016/S0926-6690(01)00120-0

de la Hoz, A., Díaz-Ortiz, A., Prieto, P.: Microwave-Assisted Green Organic Synthesis. In: G. Stefanidis, Stankiewicz, A. (eds.) Alternative Energy Sources for Green Chemistry, pp. 1–33. RSC, London (2016). https://doi.org/10.1039/9781782623632-00001

Mirghiasi, Z., Bakhtiari, F., Darezereshki, E., Esmaeilzadeh, E.: Preparation and characterization of CaO nanoparticles from Ca(OH)2 by direct thermal decomposition method. J. Ind. Eng. Chem. 20, 113–117 (2014). https://doi.org/10.1016/j.jiec.2013.04.018

Fukuda, Y., Tanabe, K.: Infrared Study of Carbon Dioxide Adsorbed on Magnesium and Calcium Oxides. Bull. Chem. Soc. Jpn. 46, 1616–1619 (1973). https://doi.org/10.1246/bcsj.46.1616

Poggi, G., Toccafondi, N., Chelazzi, D., Canton, P., Giorgi, R., Baglioni, P.: Calcium hydroxide nanoparticles from solvothermal reaction for the deacidification of degraded waterlogged wood. J. Colloid Interface Sci. 473, 1–8 (2016). https://doi.org/10.1016/j.jcis.2016.03.038

Vianello, C., Salzano, E., Maschio, G.: Thermal behaviour of peracetic acid for the epoxydation of vegetable oils in the presence of catalyst. Process Saf. Environ. 116, 718–726 (2018). https://doi.org/10.1016/j.psep.2018.03.030

Appiah, G., Tulashie, S.K., Akpari, E.E.A., Rene, E.R., Dodoo, D.: Biolubricant production via esterification and transesterification processes: Current updates and perspectives. Int. J. Energy Res. 46, 3860–3890 (2021). https://doi.org/10.1002/er.7453

Tulashie, S.K., Kotoka, F.: The potential of castor, palm kernel, and coconut oils as biolubricant base oil via chemical modification and formulation. Therm. Sci. Eng. Prog. 16, 100480 (2020). https://doi.org/10.1016/j.tsep.2020.100480

SpecialChem: Vikoflex® 7170 epoxidized vegetable oil - technical data sheet. https://adhesives.specialchem.com/product/a-arkema-vikoflex-7170-epoxidized-vegetable-oil. Accessed 18 April 2022.

Yan, M., Frank, E.M., Cochran, E.W.: Effects of Vegetable Oil Composition on Epoxidation Kinetics Physical Properties. J. Am. Oil Chem. Soc. 85, 209–216 (2018). https://doi.org/10.1002/aocs.12014

Acknowledgements

U.A., M.C., and L.P. thanks UNISS for the financial support received within the program “Fondo di Ateneo per la Ricerca 2019 and 2020”.

Funding

Open access funding provided by Università degli Studi di Sassari within the CRUI-CARE Agreement. This work was supported by the Università di Sassari (Fondo di Ateneo per la Ricerca 2019 and 2020—Ugo Azzena, Massimo Carraro and Luisa Pisano).

Author information

Authors and Affiliations

Contributions

Ugo Azzena, Chiara Milanese and Angelo Montenero contributed to the conceptualization; Ugo Azzena, Chiara Milanese, Angelo Montenero, and Luisa Pisano contributed to methodology, data analysis and curation; Massimo Carraro, Rosella Crisafulli, Luca Nuvoli, Luisa Pisano, Elisa Pintus, Salvatore Pintus, Riccardo Polese, Silvia Gaspa and Alessandro Girella contributed to the execution of experiments and data collection; Ugo Azzena, Angelo Montenero, Chiara Milanese and Luisa Pisano contributed to writing the original draft; Elisa Pintus and Salvatore Pintus contributed to the graphical abstract; Luisa Pisano, Silvia Gaspa and Lidia De Luca contributed to review and editing the manuscript; Ugo Azzena, Massimo Carraro and Luisa Pisano contributed to funding acquisition.

Ethics declarations

Conflict of interest

Angelo Montenero is Manager of Il Gabbiano Industria Ecologica s.r.l.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Azzena, U., Montenero, A., Carraro, M. et al. Recovery, Purification, Analysis and Chemical Modification of a Waste Cooking Oil. Waste Biomass Valor 14, 145–157 (2023). https://doi.org/10.1007/s12649-022-01845-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01845-3