Abstract

Nowadays, Tunisia faces challenging environmental and energy issues which relate mainly to the implementation of an appropriate solid waste management system capable of dealing with the high production of biowaste on the one hand, and the increased need for water and energy resources on the other. Therefore, the current study is intended to develop a closed cycle technical concept treating mainly food waste (FW) through combined biological processes. In this approach, FW anaerobic digestion (AD) was destined to provide a valuable input material for FW in vessel-composting by exploiting the produced digestates. To this end, the gathered AD-effluents of three systems (D1, D2, D3) were entirely analyzed to select, as a further step, the most suitable one to be subject of the suggested post-treatment. Hence, several physiochemical parameters were examined as key performance indicators. It mainly consisted of moisture content, pH, C:N ratio and heavy metals contents. The current findings depicted that the generated digestates were characterized by a high moisture content which inspired its utilization as an unconventional moisturizing agent (MA) aiming to reduce the fresh water consumption during the composting process. Thus, two experimental setups were carried out to evaluate the effect of the selected digestate on FW-in-vessel composting process performance, as a non-standard MA inserted to A2, comparing to the unamended one (A1) which was moistened by fresh water. In fact, basing on the above-mentioned criteria, the relatively high C:N ratio (of around 15), as well as the relatively significant rate of the required macro- and micro-nutrients promoted the exploitation of biochar-rich digestate (D3) as not only an efficient unconventional MA, but also as a composting process booster. Furthermore, the results revealed that the addition of D3 improved significantly the composting process performance in terms of steering parameters including the attained temperature, MC and pH. When it comes to the maturity and stability assessment, the decreased profiles of C:N ratio, the nitrification index (NI), as well as the respiration activity (AT4) ascertained the fulfilment of the required conditions for both A1 and A2 to produce stable and mature end-products. However, regarding the compost quality, the examined concentrations of heavy metals met the requirement set by German standards and attested that both A1 and A2 generated highly-qualified products, rated as class B and A, respectively. Furthermore, it is noteworthy to mention that even the AD-effluents which were classified as an “inappropriate substrate” to be inserted to the composters, met the required criteria to be applied directly to land as a highly-qualified liquid biofertilizer. This latter ascertained, additionally, the efficiency and feasibility of the suggested closed cycle for a sustainable FW management.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

The outcomes of the current research work intended to help decision makers to convey sufficient technical details to draw the design of biological facilities in order to implement sustainable organic waste management system in the framework of “Renew_Value” project. Therefore, various residues generated from different sectors of activity in Tunisia were object of biological treatments. Organics collected from catering and hospitality area (i.e. food waste), from agricultural sector (i.e. wheat straw and cattle manure) and industrial area (i.e. unmarkable biochar) were initially anaerobically co-digested to collect later AD-effluents. As Tunisia suffers not only from organic waste mismanagement but also from water shortage, the combination of aerobic-anaerobic processes served firstly to upcycle efficiently the generated AD-effluent and then to boost composting process by providing the matrix with acclimatized inoculum and reducing fresh water consumption simultaneously.

Introduction

The inappropriate collection and disposal of organic wastes creates serious concerns in terms of environmental degradation, health risks and socioeconomic problems which conducted to an unavoidable instability, particularly in developing countries [1]. Therefore, increasing public pressure, as well as the consequent environmental legislation, has driven stakeholders, decision makers and experts to introduce stronger waste management strategies [2]. These strategies are intended not only to deal with the environmental and socioeconomic conditions of the affected countries, but also to ensure the efficient recovery of significant volumes of biowaste [3], [4]. In recent years, biological treatments have come to be considered to be one of the most suitable options for handling organic residues. However, such treatments were sometimes deemed to be of limited use, due to either some process weaknesses, or to feedstock characteristics [5]. Several researchers reported that both anaerobic and aerobic processes were, to some extent, technologically challenging when it came to developing simple, sustainable and cost-effective options due to process maintenance problems [6], [7], [8]. However, some scientific works have revealed that anaerobic or aerobic co-digestion might, to a certain extent, overcome the outlined issues in term of biological treatment performance, and simultaneously enhance the effectiveness of worldwide organic waste management [9], [10].

Starting with anaerobic co-digestion, the mixture of nitrogen-rich substrates such as food waste (FW) or manure and carbonaceous substrates nowadays attracts a great deal of attention, as it ensures an initial balanced C:N ratio, an improved buffer capacity, and highly-qualified AD-effluents in the form of Biogas and digestates [11], [12]. However, to unlock the sustainability of AD, it is crucial to exploit appropriately the generated AD effluents, particularly the digestate [13]. However, a significant selection of a suitable post-exploitation of the obtained digestate still remains limited due to environmental, economic and regulatory features [14], [15]. Indeed, AD-slurry was often utilized as a biofertilizer to be directly spread out to the land [13], as a source of noteworthy nutrients to be extracted in a costly manner [16] or as a principal substrate to be thermally treated and transferred into biochar [17]. However, as previously mentioned, several challenges associated with the appropriate management of digestate have arisen. On the one hand, legislative and environmental issues essentially due to strict EU regulations concerning ammonia emission, high moisture content and heavy metal content, poses problems for the selection of a suitable digestate post-treatment [18]. On the other hand, there are economic issues related to intensive energy consumption during digestate post-treatment [16], [19]. Consequently, AD-slurry post-utilization seems to be one of the fundamental aspects to be taken into consideration as to whether or not anaerobic digestion is to be used.

When it comes to aerobic processes, blending different kinds of organics is beneficial to ensure well-balanced feedstock nutrients, adequate porosity, and more importantly, sufficient moisture content (MC) [20]. Given that the latter governs microorganism development by ensuring the transfer of the soluble nutrients needed for microbial metabolic activity, MC is considered as a key factor which influences the performance of the entire process [21], [22]. Previous studies have reported that a notable drop in water content is a substantial indicator of efficient biodegradability [7], [23]. However, a strong dehydration of the compost matrix may inhibit the aerobic process, and hinder microbial activity [24], [25]. To this end, such an operational parameter should be carefully controlled and regulated, not only through the selection of rich-moisture feedstocks as well as the selected type of the composting process, but also by a continuous wetting. In fact, even if composting process is considered as a suitable option for organic waste recovery, particularly for developing countries due to the simplicity of the process, the significant water consumption during the composting might restrict its applicability, particularly in countries suffering from water shortage [26], [27].

As one such developing country, Tunisia suffers from both organic waste mismanagement and water scarcity. Indeed, in term of water shortage, Tunisia is classified as a water-stressed area, characterized by 486 m3 per capita of renewable water availability, which is below the average of 1200 m3 per capita for the Middle East and North Africa (MENA) regions [28], [29]. Regarding organic waste recovery, only 5% of the total solid waste generated is dedicated to composting, while around 95% is landfilled, an aspect which requires particular consideration [30]. To this end, there is an urgent need to move towards a simple and sustainable organic waste management system which can cope with the current environmental and socioeconomic situation of the study area.

To sum-up, the present research work aims (1) to couple, as a dual technical process, anaerobic and aerobic digestion intending a sustainable and efficient exploitation of the generated digestates; In this approach, the collected digestates were entirely characterized (2) to select the most appropriate AD-slurry to be tapped as a potential unconventional MA reducing fresh water consumption and boost mainly aerobic treatments of FW in terms of composting performance; (3) to seek a sustainable alternative to treat simply and biologically, the organic residues generated abundantly by different sectors of activity in Tunisia.

Materials and Methods

Raw Materials

Over the course of the experimental work, the exploited organic residues were subjected to several processes such as conditioning, mixing, sampling and analysis. Starting with FW which was used as the main substrate for the in-vessel composting process, the residue was gathered from the canteen of the University of Rostock, Germany. However, as the experimental work was undertaken in Germany as part of the framework of «Renew_Value project» destined to be applicable in Tunisia, the selection of FW was rigorous in terms of being as similar as possible in terms of its composition to FW generated in the study area. FW mostly consisted of pasta, salad, a small amount of meat, and cooked potatoes and entirely characterized (Table 5). Once collected, it was conserved in small containers and stored at − 20 °C to avoid any microbiological reaction. As a potential co-substrate, Wheat Straw (WS) was gathered from a farm in the vicinity of Rostock, after which it was chopped (< 10 mm) and stored in plastic airtight buckets kept at an ambient temperature. WS was added at a rate of 25% of the total fresh mass to enhance the initial C:N ratio of the compost matrix [31]. Furthermore, in accordance with previous research works, Mature Compost (Mc) that was obtained from a local composting plant for treating garden waste was used as a bulking agent (BA) to ensure the necessary porosity and to sustain air spaces for oxygen transfer [23], [32].

Experimental Setup

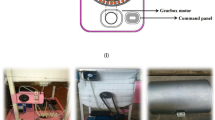

The current research aimed to boost the recovery of FW combined with further kinds of organic residue generated from different activity sectors. During the experimental work, FW was subjected to consecutive biological treatments: aerobic and anaerobic digestion (Fig. 1). However, the work was fundamentally divided into two phases and the current research work focused mainly on the second phase which concerned composting treatment. To this end, a 200 L laboratory-scale composter was used during the experimental work (Fig. 2). The composter is a stainless-steel vessel of a nominal inside diameter of around 700 mm and covered by a heat insulation layer to minimize heat losses. The airflow distribution is ensured by a metal grid with small holes fixed at the bottom of the vessel. The airflow was manually regulated during composting using a gas flow meter. Regarding the leachate collection, it was achieved by a fixed valve at the conical bottom of the composter. For the temperature monitoring, temperature sensors (TIR1) and (TIR2) were attached at different depths to monitor the fluctuation of the compost temperature. Both the compost temperature and the ambient temperature variations were automatically logged every 10 min using ALMEMO® data logger system (Ahlborn, German).

In addition to the oxygen supply, a performant aerobic treatment was ensured by an adequate proportion of MC, an adjusted C:N ratio, and an initial source of acclimated microorganisms. The amendment of composters with an acclimatized digestate (D) aimed to replace the amount of fresh water to be added during the biodegradation of the organic materials, and to allow the researchers to evaluate the effect of this on the process performance and on the end product quality [33]. In this approach, three digestates were generated from anaerobic reactors treating mixed substrates (Fig. 1, were entirely characterized to select later the most appropriate one to be subsequently exploited as an unconventional moisturizing agent added to FW-composters.

Two experimental trials were carried out to evaluate the impact of digestate addition on in-vessel FW composting. The composter was filled with around 56 kg of fresh matter. FW and Wheat Straw (WS) co-composting without any amendment (A1) was firstly conducted in duplicate, while the amended ones (A2) were then carried out to evaluate the digestate addition effects. Before feeding the composter, organic materials, including the BA, were manually mixed, while the MA, either fresh water or AD-effluent, was added later in order to regulate the moisture content of the initial starting material to be in the required range of 55%–65%. As the maintenance of MC at a certain range during the composting process was crucial, the amount of MA to be added (in litters) was determined to compare the consumption of digestate and water. In fact, MC fluctuations were assigned as an indicator pointing out the need to add further amount of MA. Otherwise, an estimated volume of both fresh water and digestate was determined from the beginning of the process referring to the initial feedstock mixture moisture content and the required MC range [20], [34]. Table 1 displays the trial ingredients and the composting time.

Sampling and Analysis

During the nine weeks of the experimental work, sampling was achieved at regular intervals to evaluate the evolution of the composting process. Weekly, three representative samples were taken and were either analysed directly or stored (4 °C and − 20 °C) for future analyses. Different parameters were determined in triplicate; and moisture content (MC) (%), total carbon (TC), total nitrogen (TN), pH, electrical conductivity (EC), total solid (TS) (%) and mineral nitrogen content, such as ammonium (NH4+) and nitrate (NO3−), were monitored. However, to determine the stability and maturity of the compost, the respiration activity (AT4) was identified at the end of the process. In addition, to assess the quality of the end product, the Heavy Metals content (HMs) was measured to be compared with the quality requirements for the compost of several countries with regard to Pb, Cu, Ni, Zn, Cd, Cr, Hg and As concentrations. All the experimental protocols which were carried out were described in detail in a previous work [22][34] (Table 2).

Statistical Analysis

Statistical analysis was conducted using XLSTAT 2021 with one-way analysis of variance (ANOVA) and the Tukey method with a probability level of 0.05 to evaluate the effects of digestate addition on MC, pH and C:N ratio tendencies.

Results and Discussion

Physio-Chemical Properties of the Raw Materials

Criteria for Digestate Selection

Once the anaerobic treatment had been accomplished, the generated digestates were collected to be fully characterized. However, a comparison between the digestate properties was undertaken during the experimental work to evaluate whether the gathered AD-residues could be directly spread of land or needed further post-treatments. In fact, the feasibility of anaerobic treatments depends significantly on the effectiveness of end-products uses. Therefore, to unlock the sustainability of anaerobic process, digestate-uses gain progressively attention [35]. To this end, the current research work investigated whether the generated AD-effluent met the required criteria to be efficiently exploited for agricultural purposes. Accordingly, some physio-chemical properties were examined. This latter consisted predominantly of the capacity of the digestate to replace fresh water as an unconventional MA, thus the first parameter to be evaluated was MC. Secondly, it is equally important to identify further critical factors influencing the composting progress such as pH and more particularly C:N ratio. Therefore, several parameters were considered as efficient indicators, to check, on one hand, whether the collected AD-effluents could influence the effectiveness of the compost applied to agricultural land, and on the other hand, to assess the feasibility of digestate post-treatment via composting. Table 3 summarized the physio-chemical characteristics of D1, D2 and D3 produced from R1 (FW + WS + CM), R2 (100% FW) and R3 (FW + UBc), respectively.

As one of the most important steering factors, MC was firstly identified, and a relatively high-water content of around 97% marked all the produced digestates. Therefore, as the generated AD-residues were characterized by almost the same water amount, further factors including pH and C:N ratio were additionally examined for digestate selection. Focusing on pH tendencies, pH values ranged around a neutral range for D1 and D2, which was beneficial for a direct digestate application to land, while an alkaline pH of around 8.53 marked D3 and made it less promoting to be instantaneously used. In fact, such a relatively high pH might intensify the ammonium emissions which limited the digestate-use and in turn, imposed a post-treatment [25]. However, it should be mentioned that the high pH value of D3 was expected due to the alkaline nature of the biochar added initially to the anaerobic reactors [36]. In the same context, Shen et al. (2016) depicted the significant impact of the woody derived biochar on AD by-products characteristics, including pH value [37]. When it comes to C:N ratio, D3 was qualified by a high C:N ratio, while lower values marked D1 and D2 to be around 8.53 and 9.51, respectively. Indeed, the types of the mixed substrates feeding the anaerobic digesters influenced significantly the biodegradation rate of carbon and nitrogen during AD-process and impacted, in turn, the end-products characteristics [38]. For instance, both FW and CM are considered as nitrogen-rich materials implying the generation of digestates of a low C:N ratio [31], while the addition of a carbonaceous substrate such as biochar affected substantially the carbon rate of the AD-residue to be around 47.60% of fresh matter [39]. As high heavy metal contents (HMs) are considered harmful to the environment and guidelines are usually established to illustrate the tolerated concentrations, much attention was paid to AD-effluents analysis in terms of HMs concentrations. As shown in Table 3, the examined heavy metal contents outlined that all the generated digestates met the requirement of the Standards of digestate (EU recommendations for 2025) and in turn, can be safely spread directly to land or used for agricultural purposes.

To sum-up, the criteria used to select the appropriate digestate for further biological treatment were recapitulated in Table 4. Thus, all the key performance indicators outlined that D3 was the most suitable effluent, as it was characterized, on one hand, by a high pH preventing its direct application to land in order to avoid GHGs emissions and on the other hand, by a high MC and more particularly a high C:N ratio promoting its exploitation during the composting process.

Properties of the Exploited Organic Wastes

The characteristics of the exploited organic materials are illustrated in Table 5. The moisture content was 77.4%, 6.5%, 53.3%, and 96.7% for FW, WS, Mc and D3, respectively. To meet the required range of MC, which is 55%-65%, MA was added to each mixture to regulate the MC of A1 to A2 to 65.8% and 68.7%, respectively. The initial C:N ratio was examined for each substrate to ensure the required carbon to nitrogen ratio demanded by microorganisms for an efficient biological degradation of the organics. Several studies reported that the appropriate initial C:N ratio of the feedstock ranged between 20 and 40 [20][40][41]. This was achieved by both A1 and A2 at around 32.21 and 29.74, respectively. Additionally, the heavy metals and trace elements content were identified. Moreover, several physio-chemical characteristics such as pH, conductivity (EC), potassium (K), phosphorus (P) as well as heavy metals, were investigated in order to guarantee an efficient development of the process. Similar physio-chemical characteristics of FW were achieved in previous work, characterizing initially FW collected from the refectory of different Tunisian universities and evaluating, as a further step, FW windrow piles composting [22].

Monitoring of Steering Parameters

Temperature Profile During the Composting Process

Temperature is one of the critical parameters allowing to evaluate the composting process progress. Therefore, temperature fluctuations were continuously controlled. As reported by Torres-Climent et al. (2015), different phases of the composting process should be successfully fulfilled to ascertain the biodegradability of the inserted raw materials [42]. According to Fig. 3, the composting process seemed to be appropriately conducted. Starting with the thermophilic stage, the amended bioreactor (A2) showed a prompt rise of temperature by the third day, while the unamended test achieved it after five days of the experimental setup to reach 57 °C. Indeed, focusing on the temperature profile of A1, lower temperatures were recorded during the entire bio-oxidative stage comparing to A2. For instance, the first temperature peak was attained at day 9 to be around 63 °C, while 67 °C was reached by A2 under almost the same experimental conditions. As the temperature variation is significantly dependent on the development of the microbiological population as well as the rate of biodegradability [43], the temperature profile of A2 ascertained the significant effects of the digestate addition on the composting performance. Furthermore, on one hand, sustaining thermophilic temperatures is crucial for a complete decomposition of the composted materials, but on the other hand, it is essential to guarantee the disinfection of the end-products. For this purpose, MacLean (1990) found that maintaining the compost temperature between 55 °C and 65 °C for five days is sufficient for the elimination of pathogens [44]. Whereas, in the same context, BioAbfV (1998) criteria pointed out that for total inactivation of pathogens, the temperature has to be sustained at 55 °C for two successive weeks [22]. Hence, the sanitation of the produced composts collected from A2 and more particularly from A1 has to be under consideration to be deemed as hygienically acceptable end-product. Fulfilling the thermophilic stage, a drop of temperature marked both A1 and A2. As shown in Fig. 3, the temperatures of the different trials decreased significantly to approximate to ambient temperature announcing the start of the maturation phase. Thereafter, a stable temperature pattern was recorded attesting the complete organic waste degradation in accordance with the findings of Li et al., (2017) [45].

Moisture Monitoring Profile During the Composting Process

Moisture content (MC) is also considered as an important parameter governing the effectiveness of the composting process, a feature which has been regularly determined over the experimental period [20]. As a high MC of about 97% marked the digestate, it promoted its exploitation as an unconventional MA [46]. When it comes to the unamended test, the adjustment of the initial MC, within the required range of about 55% -65%, was ensured by fresh-water addition which was not really practicable in Tunisia given that it is a semi-arid country suffering from water scarcity. Figure 4 showed that the initial MC of A1 and A2 was titrated at around 65% and 68%, respectively. During the first two weeks, a significant decrease in MC occurred in both A1 and A2, reaching 51% and 55%, respectively, by the end of the thermophilic phase. In fact, MC profiles were expected, as the first two weeks are usually dominated by acclimatized microbial community, and therefore a significant drop in MC was projected [47]. However, an enhanced water holding capacity marked A2 from the third week of the experimental work (p-value < 0.05). While, a considerable decrease in MC in the case of the unamended test was recorded and affirmed that a large amount of water was consumed [21]. Indeed, in terms of MA supplement, the volume of the digestate was 0.8 times lower than the volume of the potable water used, ascertaining the effectiveness of unconventional MA exploitation. However, the compost matrix wetting, either by fresh water or digestate addition, was ensured only from the beginning of the experimental work. In fact, there was no need to add MA whether the MC values were kept within the suitable range which was the case of both A1 and A2 (Fig. 4). But it is noteworthy to mention, that the produced leachate was collected and recycled which might be useful to sustain the MC in the required range. Furthermore, it was notable that, once lifting the lid of the bio-composter, some drops of water covered it which might be also considered to some extent as a kind of MA recycling. Hence, the technique of composting process, whether it is carried out as open windrows composting or in-vessel ones, impacted additionally the evolution of MC of the matrix, as it influences the evaporation rate of the MA [48]. Once the cooling phase occurred, an almost steady moisture tendencies were registered until the end of the composting trials; A1 and A2 were qualified by a MC of 47.8% and 51.6%, respectively.

pH Profile During the Composting Process

The degradability of organic matter depends greatly on the tendencies of the various steering parameters—temperature, moisture and pH—which are to some extent intertwined. Therefore, pH variations were regularly monitored. At the beginning of the process, the recorded pH values for both the amended and the unamended reactors were almost alkaline. Once the thermophilic phase began, Fig. 5 depicted that the pH profiles of A1 and A2 were almost the same, while the pH value deviations were to some extent different (p-value < 0.05). Indeed, an acidic tendency was recorded for A1 which was due to the biodegradation of carbonaceous substances, while the emission of CO2 led to an acidic pH [49]. Meanwhile, the amended digester A2 showed a minor variance of pH decreasing from 8.02 to 7.82 during the first two weeks of the composting process. This was due to the significant buffering capacity of the AD-effluent as an unconventional MA comparing to the added fresh water (A1) [48]. In addition, pH trends which were recorded during A2-running might be a supplemental effects of the added biochar to AD-digesters to alleviate acid gas emissions [31], [39]. However, the unamended trial was characterized by a quasi-acidic pH of around 6.82, once the thermophilic phase was accomplished. Thereafter, a substantial rise of pH marked A1 to fluctuate within neutral ranges until the end of the process. In fact, the pH tendencies might be explained by the significant content of nitrogen supplied by the used feedstock (FW) which led to an intensive volatilization of the nitrogenous elements (NH3) [25]. The current results were in conformity with the results of several studies investigating the effect of digestate addition, or rather the biochar supplement on pH fluctuations [41] [13]. With the drop in temperature, the pH values of both A1 and A2 stabilized between 7 and 8, which satisfied the required conditions in terms of pH values [48].

Monitoring of Stability and Maturity Indicators

C:N Ratio Profile During the Composting Process

The C:N ratio is known to be one of the relevant key parameters that determines the status of the maturity and stability of the generated compost [45]. It was therefore monitored frequently to determine the progress of the microbial community of the different trials. The initial C:N ratio characterizing the unamended and amended mixtures were 32.21 and 29.74, respectively. In fact, this latter was not expected, as it was awaited that the addition of digestate will enhance to some extent the initial C:N ratio of A2. However, the relatively high C:N ratio which marked initially A1 comparing to A2 might be due to several reasons including, on one hand, the effect of the relatively higher amount of a carbon-rich substrate such as WS to the amended bioreactor and, on the other hand, it might be a result of the notable amounts of FW and Mc which were initially characterized by quite low C:N ratios and added to the unamended one (Table 1). Focusing on C:N ratio tendencies, once the temperature rose, it varied similarly for both A1 and A2. While, a significant drop marked the unamended test by the end of the thermophilic stage. Indeed, it might be due to the intensive degradation of the rapidly consumable materials such as FW achieved by the coexistent microorganisms and entailing high losses in terms of nitrogen and carbon. When it comes to A2, the amended vessels presented lower C:N ratio fluctuations (p-value > 0.05), followed by a quasi-stable C:N values to be around 25, as shown in Table 6. Thus, the revealed steadiness reflected a balanced degradation of carbonaceous as well as proteinaceous substances, which was due to the abundance of the microbial community provided by the digestate [50].

With the accomplishment of the thermophilic phase (day 16), the identified C:N ratio of A2 seemed to be significantly higher than that of A1 to become quite close at day 21 of around 19.13 and 21.89 for A1 and A2, respectively. With reference to Casini et al., (2019), the recorded C:N ratio trends might be attributed to the high rate of carbonaceous component consumption during the first five weeks, as well as the lower nitrification rate which was in accordance with the current findings [39]. In the same context, Chaher et al., (2020) reported that a balanced utilization of nitrogenous and carbonaceous elements serves as an efficient indicator to point out the maturity of the end-product which was in line with the identified C:N ratios (at day 37) of both A1 and A2 attaining 12.78 and 14.51, respectively [34].

Nitrification Index (NI) Fluctuations During the Composting Process

Similarly to the C:N ratio, the nitrification index (NI) which is the ratio between NH4+ and NO3−, is a well thought out indicator of compost stability [50]. Therefore, it was noted during the aerobic process to track the nitrogen transformation progress. Nevertheless, the type of exploited residue has a direct impact on the amount of nitrogen consumed by the microorganism’s present. It initially influences the nitrogen-ammonification and subsequently the rate of nitrification [51]. Figure 6 illustrated that, for thermophilic temperatures (> 45 °C), the NI of the unamended test (A1) was significantly higher than that of the second trial (A2), rising from 7.12 to 12.66 for A1 and 5.89 to 10.44 for A2. This can be explained by the initial alkaline pH of the biochar-rich digestate used, as well as its potential for enhancing the nitrogen conversion [11]. Indeed, the AD-residue promoted the formation of NH4+ and raised the NO3− leaching in the A2 trial which led to a balanced NI compared to the A1 trial [52]. In addition, the considerable drop in NI which marked the amended trial might be due to the intensified number of bacteria and archaea present in the digestate [53]. Several researchers have reported that lower nitrogen losses occur whenever the digestate is composted because of the abundancy of microorganisms consuming the available organic matter, which was in line with the current findings [54], [55]. On attainment of the cooling phase, the amended and unamended bioreactors illustrated a progressive decline in NI to be close of 3 at the end of the process. This latter indicated the maturity of the compost produced from both A1 and A2 with reference to Örtl (2018) [15].

Respiration Activity (AT4)

The respiration activity (AT4) was also examined to evaluate the stability of the end-product generated by each bioreactor. Low values of AT4 were found for both A1 and A2 in the form of 4.06 and 3.43 (mg O2 /g TS), respectively, and confirmed that no more biodegradation would occur [56]. To this end, referring to German Standards, the stability of all the analyzed compost samples indicated that they should be categorized as class V compost.

Monitoring of End-Product Quality Indicator: Heavy Metals Contents vs Compost Standards

The heavy metals (HMs) measurement of the end products was based on the quality limits for agricultural use of several countries in Europe, Germany, the UK, France as well as Canada and Tunisia. Table 7 summarizes the specifications with regard to seven HMs (Pb, Ni, Cu, Zn, Hg, Cr and Cd) for both A1 and A2. It was notable that the rate of HMs for A2 was higher than that for A1, especially in the case of Zn which attained 80.20 for the unamended trial and 120.41 mg/kg TS for the amended one. Indeed, the significant amounts of metal components which marked A2 were predicted by the initial rate of HMs provided by the digestate as described in Table 5. However, despite the remarkable content in terms of HMs, A2 met all the laws applicable in several countries, and the product was classified as a Class A biofertilizer based on German Standards [57]. Additionally, Table 8 shows that the compost gathered from A1 was categorized as Class B based on the German standards, and illustrated that both amended and unamended reactors generated high quality end products. Admittedly, the main organic residues exploited were characterized by low rates of HMs which affirmed the outlined quality of the biofertilizer produced by the unamended composter, but initially a slight uncertainty arose due to the addition of the AD-liquid effluent. Indeed, several works have focused on the feasibility of digestate recovery for agricultural benefits, and have highlighted that the inputs of AD-effluents in terms of HMs restrict its effectiveness [14] (Table 9).

Evaluation of Amended Digestate Effect on FW Composting

The above results show that both A1 and A2 produced stable, mature and high-quality composts in terms of several indicators. However, a Class B compost was generated from the amended FW in-vessel composter. Indeed, the addition of the biochar-rich digestate influenced not only the biofertilizer characteristic, but also the efficiency of the aerobic process. Table 8 summarizes all the obtained results and compares the situation of A1 and A2.

Conclusion

The current findings revealed that FW in-vessel composting process exploiting digestate gathered from biochar enriched anaerobic reactors presented boosted the composting process in terms of stability, maturity and end-products quality. Indeed, the tendencies of various steering parameters such as temperature, moisture and pH as well as the stability and maturity indicators, pH, C:N ratio and NI ascertained the efficiency of the AD-effluent addition in terms of FW aerobic treatment performance. Furthermore, the identification of the respiration activity (AT4) ascertained that low biological activity took place by the end of the process and confirmed that the generated composts meet the imposed German Standards in terms of stability. As the outcomes of the current research work will be exploited later as a guidance serving decision makers to convey sufficient technical detail to design biological facilities, results affirmed that AD-effluent was efficiently converted from an output hardly managed, to an input comfortably recovered by reducing the consumption of fresh water and enhancing simultaneously the composting process performance.

Data Availabililty

All data generated or analysed during this study are included in this published article.

Abbreviations

- AD:

-

Anaerobic digestion

- UBc:

-

Unmarkable biochar

- MC:

-

Moisture content

- FW:

-

Food waste

- WS:

-

Wheat straw

- CM:

-

Cattle manure

- Di :

-

Digestate

- MA:

-

Moisturizing agent

- FM:

-

Fresh matter

- TS:

-

Total solids

- TEs:

-

Trace elements

- Mc:

-

Mature compost

- BA:

-

Bulking agent

- HMs:

-

Heavy Metals contents

- TC:

-

Total Carbon

- TN:

-

Total Nitrogen

- EC:

-

Electrical Conductivity

- NI:

-

Nitrification Index

- AT4:

-

Respiration Activity

References

Ferronato, N., Torretta, V.: Waste mismanagement in developing countries: A review of global issues. Int. J. Environ. Res. Public Health. 16, 1060 (2019). https://doi.org/10.3390/ijerph16061060

Mahjoub, O., Jemai, A., Haddaoui, I.: Waste management in Tunisia—what could the past bring to the future? In: Negm, A.M., Shareef, N. (eds.) Waste Management in MENA Regions, pp. 35–69. Springer, Cham (2020)

Abu Hajar, H.A., Tweissi, A., Abu Hajar, Y.A., Al-Weshah, R., Shatanawi, K.M., Imam, R., Murad, Y.Z., Abu Hajer, M.A.: Assessment of the municipal solid waste management sector development in Jordan towards green growth by sustainability window analysis. J. Clean. Prod. 258, 120539 (2020). https://doi.org/10.1016/j.jclepro.2020.120539

Negm, A.M., Shareef, N.: Introduction to the “Waste Management in MENA Regions.” In: Negm, A.M., Shareef, N. (eds.) Waste Management in MENA Regions, pp. 1–11. Springer, Cham (2020)

Chaturvedi, H., Kaushal, P.: Comparative study of different biological processes for non-segregated Municipal Solid Waste (MSW) leachate treatment. Environ. Technol. Innov. 9, 134–139 (2018). https://doi.org/10.1016/j.eti.2017.11.008

Fagbohungbe, M.O., Herbert, B.M.J., Hurst, L., Ibeto, C.N., Li, H., Usmani, S.Q., Semple, K.T.: The challenges of anaerobic digestion and the role of biochar in optimizing anaerobic digestion. Waste Manage. 61, 236–249 (2017). https://doi.org/10.1016/j.wasman.2016.11.028

Lin, L., Xu, F., Ge, X., Li, Y.: Chapter Four—Biological treatment of organic materials for energy and nutrients production—Anaerobic digestion and composting. In: Li, Y., Ge, X. (eds.) Advances in Bioenergy, pp. 121–181. Elsevier, Amsterdam (2019)

Demichelis, F., Piovano, F., Fiore, S.: Biowaste management in italy: challenges and perspectives. Sustainability. 11, 4213 (2019). https://doi.org/10.3390/su11154213

Haider, Muhammad Rizwan, Zeshan, Sohail Yousaf, Malik, Riffat Naseem, Visvanathan, Chettiyappan: Effect of mixing ratio of food waste and rice husk co-digestion and substrate to inoculum ratio on biogas production. Bioresour. Technol. 190, 451–457 (2015). https://doi.org/10.1016/j.biortech.2015.02.105

Tang, J., Zhang, L., Zhang, J., Ren, L., Zhou, Y., Zheng, Y., Luo, L., Yang, Y., Huang, H., Chen, A.: Physicochemical features, metal availability and enzyme activity in heavy metal-polluted soil remediated by biochar and compost. Sci. Total Environ. 701, 134751 (2020). https://doi.org/10.1016/j.scitotenv.2019.134751

Agyarko-Mintah, E., Cowie, A., Van Zwieten, L., Singh, B.P., Smillie, R., Harden, S., Fornasier, F.: Biochar lowers ammonia emission and improves nitrogen retention in poultry litter composting. Waste Manage. 61, 129–137 (2017). https://doi.org/10.1016/j.wasman.2016.12.009

Campuzano, R., González-Martínez, S.: Influence of process parameters on the extraction of soluble substances from OFMSW and methane production. Waste Manage. 62, 61–68 (2017). https://doi.org/10.1016/j.wasman.2017.02.015

Al Seadi, T., Drosg, B., Fuchs, W., Rutz, D., Janssen, R.: 12—Biogas digestate quality and utilization. In: Wellinger, A., Murphy, J., Baxter, D. (eds.) The Biogas Handbook, pp. 267–301. Woodhead Publishing, Cambridge (2013)

Stoknes, K., Scholwin, F., Krzesiński, W., Wojciechowska, E., Jasińska, A.: Efficiency of a novel “Food to waste to food” system including anaerobic digestion of food waste and cultivation of vegetables on digestate in a bubble-insulated greenhouse. Waste Manage. 56, 466–476 (2016). https://doi.org/10.1016/j.wasman.2016.06.027

Örtl, E.: Quality assurance of compost and digestate. Umweltbundesamt (2018)

Bolzonella, D., Fatone, F., Gottardo, M., Frison, N.: Nutrients recovery from anaerobic digestate of agro-waste: Techno-economic assessment of full scale applications. J. Environ. Manage. 216, 111–119 (2018). https://doi.org/10.1016/j.jenvman.2017.08.026

Jiang, B., Lin, Y., Mbog, J.C.: Biochar derived from swine manure digestate and applied on the removals of heavy metals and antibiotics. Biores. Technol. 270, 603–611 (2018). https://doi.org/10.1016/j.biortech.2018.08.022

Amery, F., Schoumans, O.F.: Agricultural phosphorus legislation in Europe. Institute for Agricultural and Fisheries Research (ILVO), Merelbeke (2014)

Amri, F.: Carbon dioxide emissions, total factor productivity, ICT, trade, financial development, and energy consumption: testing environmental Kuznets curve hypothesis for Tunisia. Environ Sci Pollut Res. 25, 33691–33701 (2018). https://doi.org/10.1007/s11356-018-3331-1

Xu, Z., Li, G., Huda, N., Zhang, B., Wang, M., Luo, W.: Effects of moisture and carbon/nitrogen ratio on gaseous emissions and maturity during direct composting of cornstalks used for filtration of anaerobically digested manure centrate. Biores. Technol. 298, 122503 (2020). https://doi.org/10.1016/j.biortech.2019.122503

Makan, A., Assobhei, O., Mountadar, M.: Effect of initial moisture content on the in-vessel composting under air pressure of organic fraction of municipal solid waste in Morocco. Iranian J Environ Health Sci Eng. 10, 3 (2013). https://doi.org/10.1186/1735-2746-10-3

Chaher, N.E.H., Chakchouk, M., Nassour, A., Nelles, M., Hamdi, M.: Potential of windrow food and green waste composting in Tunisia. Environ Sci Pollut Res. (2020). https://doi.org/10.1007/s11356-020-10264-7

Chaher, N.E.H., Chakchouk, M., Redjem, H., Nassour, A., Nelles, M., Hamdi, M.: Comparative Study of Cooked and Uncooked Food Waste Co-composting with Green Waste and Sewage Sludge: A Case Study of Tunisia. In: Ksibi, M., Ghorbal, A., Chakraborty, S., Chaminé, H.I., Barbieri, M., Guerriero, G., Hentati, O., Negm, A., Lehmann, A., Römbke, J., Costa Duarte, A., Xoplaki, E., Khélifi, N., Colinet, G., Miguel Dias, J., Gargouri, I., Van Hullebusch, E.D., Sánchez Cabrero, B., Ferlisi, S., Tizaoui, C., Kallel, A., Rtimi, S., Panda, S., Michaud, P., Sahu, J.N., Seffen, M., Naddeo, V. (eds.) Recent Advances in Environmental Science from the Euro-Mediterranean and Surrounding Regions, 2nd edn., pp. 777–781. Springer, Cham (2021)

Kim, J., Kim, J., Lee, C.: Anaerobic co-digestion of food waste, human feces, and toilet paper: Methane potential and synergistic effect. Fuel 248, 189–195 (2019). https://doi.org/10.1016/j.fuel.2019.03.081

Zakarya, I.A., Khalib, S.N.B., Mohd Ramzi, N.: Effect of pH temperature and moisture content during composting of rice straw burning at different temperature with food waste and effective microorganisms. E3S Web Conf. 34, 02019 (2018). https://doi.org/10.1051/e3sconf/20183402019

Aboelnga, H.T., El-Naser, H., Ribbe, L., Frechen, F.-B.: Assessing water security in water-scarce cities: applying the Integrated Urban Water Security Index (IUWSI) in Madaba. Jordan. Water. 12, 1299 (2020). https://doi.org/10.3390/w12051299

Scardigno, A.: New solutions to reduce water and energy consumption in crop production: A water–energy–food nexus perspective. Curr. Opin. Environ. Sci. Health. 13, 11–15 (2020). https://doi.org/10.1016/j.coesh.2019.09.007

Ardhaoui, K., Bellali, F., Moussa, M.: Composting and lixiviation, case study in Médenine-Tunisia. 7 (2019)

Chaher, N.E.H., Hemidat, S., Thabit, Q., Chakchouk, M., Nassour, A., Hamdi, M., Nelles, M.: Potential of Sustainable concept for handling organic waste in Tunisia. Sustainability. 12, 8167 (2020). https://doi.org/10.3390/su12198167

ANGED: Agence Nationale de Gestion des Déchets, http://www.anged.nat.tn/cadre-reglementaire-et-institutionnel.html

Chaher, N.E.H., Chakchouk, M., Engler, N., Nassour, A., Nelles, M., Hamdi, M.: Optimization of food waste and biochar in-vessel co-composting. Sustainability. 12, 1356 (2020). https://doi.org/10.3390/su12041356

Kato, K., Miura, N.: Effect of matured compost as a bulking and inoculating agent on the microbial community and maturity of cattle manure compost. Biores. Technol. 99, 3372–3380 (2008). https://doi.org/10.1016/j.biortech.2007.08.019

Franke-Whittle, I.H., Confalonieri, A., Insam, H., Schlegelmilch, M., Körner, I.: Changes in the microbial communities during co-composting of digestates. Waste Manag. 34, 632–641 (2014). https://doi.org/10.1016/j.wasman.2013.12.009

Chaher, N.E.H., Hemidat, S., Chakchouk, M., Nassour, A., Hamdi, M., Nelles, M.: From anaerobic to aerobic treatment: upcycling of digestate as a moisturizing agent for in-vessel composting process. Bioresour. Bioprocess. (2020). https://doi.org/10.1186/s40643-020-00348-0

Chaher, N.E.H., Engler, N., Nassour, A., Nelles, M.: Effects of co-substrates’ mixing ratios and loading rate variations on food and agricultural wastes’ anaerobic co-digestion performance. Biomass Conv. Bioref. (2021). https://doi.org/10.1007/s13399-021-01655-y

Sharma, B., Suthar, S.: Enriched biogas and biofertilizer production from Eichhornia weed biomass in cow dung biochar-amended anaerobic digestion system. Environ. Technol. Innov. (2020). https://doi.org/10.1016/j.eti.2020.101201

Shen, Y., Linville, J.L., Ignacio-de Leon, P.A.A., Schoene, R.P., Urgun-Demirtas, M.: Towards a sustainable paradigm of waste-to-energy process: Enhanced anaerobic digestion of sludge with woody biochar. J. Clean. Prod. 135, 1054–1064 (2016). https://doi.org/10.1016/j.jclepro.2016.06.144

Zahan, Z., Georgiou, S., Muster, T.H., Othman, M.Z.: Semi-continuous anaerobic co-digestion of chicken litter with agricultural and food wastes: A case study on the effect of carbon/nitrogen ratio, substrates mixing ratio and organic loading. Biores. Technol. 270, 245–254 (2018). https://doi.org/10.1016/j.biortech.2018.09.010

Casini, D., Barsali, T., Rizzo, A.M., Chiaramonti, D.: Production and characterization of co-composted biochar and digestate from biomass anaerobic digestion. Biomass Conv. Bioref. (2019). https://doi.org/10.1007/s13399-019-00482-6

Kumar, M., Ou, Y.-L., Lin, J.-G.: Co-composting of green waste and food waste at low C/N ratio. Waste Manage. 30, 602–609 (2010). https://doi.org/10.1016/j.wasman.2009.11.023

Tibu, C., Annang, T.Y., Solomon, N., Yirenya-Tawiah, D.: Effect of the composting process on physicochemical properties and concentration of heavy metals in market waste with additive materials in the Ga West Municipality, Ghana. Int J Recycl Org Waste Agricult. 8, 393–403 (2019). https://doi.org/10.1007/s40093-019-0266-6

Torres-Climent, A., Martin-Mata, J., Marhuenda-Egea, F., Moral, R., Barber, X., Perez-Murcia, M.D., Paredes, C.: Composting of the solid phase of digestate from biogas production: optimization of the moisture, C/N ratio, and pH conditions. Commun. Soil Sci. Plant Anal. 46, 197–207 (2015). https://doi.org/10.1080/00103624.2014.988591

Rastogi, M., Nandal, M., Khosla, B.: Microbes as vital additives for solid waste composting. Heliyon. 6, e03343 (2020). https://doi.org/10.1016/j.heliyon.2020.e03343

MacLean, J.T.: Composts and Composting of Organic Wastes: January 1985–July 1990. National Agricultural Library (1990)

Li, S., Li, D., Li, J., Li, G., Zhang, B.: Evaluation of humic substances during co-composting of sewage sludge and corn stalk under different aeration rates. Biores. Technol. 245, 1299–1302 (2017). https://doi.org/10.1016/j.biortech.2017.08.177

Kim, E., Lee, D.-H., Won, S., Ahn, H.: Evaluation of optimum moisture content for composting of beef manure and bedding material mixtures using oxygen uptake measurement. Asian-Australas J Anim Sci. 29, 753–758 (2016). https://doi.org/10.5713/ajas.15.0875

Franke-Whittle, I.H., Confalonieri, A., Insam, H., Schlegelmilch, M., Körner, I.: Changes in the microbial communities during co-composting of digestates. Waste Manage. 34, 632–641 (2014). https://doi.org/10.1016/j.wasman.2013.12.009

Arab, G., McCartney, D.: Benefits to decomposition rates when using digestate as compost co-feedstock: Part I—Focus on physicochemical parameters. Waste Manage. 68, 74–84 (2017). https://doi.org/10.1016/j.wasman.2017.07.018

Chen, M., Huang, Y., Liu, H., Xie, S., Abbas, F.: Impact of different nitrogen source on the compost quality and greenhouse gas emissions during composting of garden waste. Process Saf. Environ. Prot. 124, 326–335 (2019). https://doi.org/10.1016/j.psep.2019.03.006

Cáceres, R., Malińska, K., Marfà, O.: Nitrification within composting: A review. Waste Manage. 72, 119–137 (2018). https://doi.org/10.1016/j.wasman.2017.10.049

Cáceres, R., Coromina, N., Malińska, K., Martínez-Farré, F.X., López, M., Soliva, M., Marfà, O.: Nitrification during extended co-composting of extreme mixtures of green waste and solid fraction of cattle slurry to obtain growing media. Waste Manage. 58, 118–125 (2016). https://doi.org/10.1016/j.wasman.2016.08.014

Markfoged, R., Nielsen, L.P., Nyord, T., Ottosen, L.D.M., Revsbech, N.P.: Transient N2O accumulation and emission caused by O2 depletion in soil after liquid manure injection. Eur. J. Soil Sci. 62, 541–550 (2011). https://doi.org/10.1111/j.1365-2389.2010.01345.x

Sánchez-Rodríguez, A.R., Carswell, A.M., Shaw, R., Hunt, J., Saunders, K., Cotton, J., Chadwick, D.R., Jones, D.L., Misselbrook, T.H.: Advanced processing of food waste based digestate for mitigating nitrogen losses in a winter wheat crop. Front. Sustain. Food Syst. (2018). https://doi.org/10.3389/fsufs.2018.00035

Alburquerque, J.A., Gonzálvez, J., García, D., Cegarra, J.: Measuring detoxification and maturity in compost made from “alperujo”, the solid by-product of extracting olive oil by the two-phase centrifugation system. Chemosphere 64, 470–477 (2006). https://doi.org/10.1016/j.chemosphere.2005.10.055

Sangamithirai, K.M., Jayapriya, J., Hema, J., Manoj, R.: Evaluation of in-vessel co-composting of yard waste and development of kinetic models for co-composting. Int J Recycl Org Waste Agricult. 4, 157–165 (2015). https://doi.org/10.1007/s40093-015-0095-1

Bazrafshan, E., Zarei, A., Kord Mostafapour, F., Poormollae, N., Mahmoodi, S., Zazouli, M.A.: Maturity and Stability Evaluation of Composted Municipal Solid Wastes, http://jhealthscope.com/en/articles/20165.html

Fricke, K., Heußner, C., Hüttner, A., Turk, T.: Recycling of Biowaste: Experience with Collection, Digestion, and Quality in Germany. In: Maletz, R., Dornack, C., Ziyang, L. (eds.) Source separation and recycling: implementation and benefits for a circular economy, pp. 175–175. Springer, Cham (2018)

Wang, H., Wang, D., Zhou, X.: Analysis on the trend of water quality in Haihe River Basin from 2005 to 2017. GEP. 06, 1–7 (2018). https://doi.org/10.4236/gep.2018.611001

Acknowledgements

The authors express their sincere appreciation to Technical Lab for Waste Management and Bioenergy, University of Rostock, Germany, for co-funding this study and more particularly to Dr.Nils Engler for his support during the experimental work.

Funding

Open Access funding enabled and organized by Projekt DEAL. This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization, NEHC; methodology, NEHC; formal analysis, NEHC; investigation, NEHC, data curation, NEHC; writing—original draft preparation, NEHC; writing—review and editing, NEHC; supervision, A.N, MH and MN.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chaher, N.E.H., Nassour, A., Hamdi, M. et al. Digestate Post-treatment and Upcycling: Unconventional Moisturizing Agent for Food Waste In-Vessel Composting. Waste Biomass Valor 13, 1459–1473 (2022). https://doi.org/10.1007/s12649-021-01565-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01565-0