Abstract

This study investigated heterotrophic bioleaching of rare earth elements (REEs) and base metals from spent nickel-metal-hydride (NiMH) batteries. Furthermore, the impacts of phosphorous source [Ca3(PO4)2, KH2PO4 and K2HPO4] and its concentration on organic acid production by Gluconobacter oxydans and Streptomyces pilosus were evaluated. Phosphorous source affected microbial acid production and metal leaching. Among the studied phosphorous sources, use of K2HPO4 resulted in highest organic acid production by both bacteria. Increasing K2HPO4 concentration from 2.7 to 27 mM enhanced pyruvic acid production by S. pilosus from 2.2 to 10.7 mM. However, no metal was leached from the spent NiMH batteries with S. pilosus using either one-step, two-step or spent-medium bioleaching. With G. oxydans, highest gluconic acid concentration of 45.0 mM was produced at the lowest K2HPO4 concentration of 2.7 mM. When using two-step bioleaching with G. oxydans, higher leaching efficiencies were obtained for base metals (88.0% vs. 68.0% Fe, 41.5% vs. 35.5% Co, 18.5% vs 16.5% Ni), while more REEs were leached using spent-medium bioleaching (9.0% vs. 6.0% total REEs). With both bioleaching methods, base metals leaching was faster than that of REEs. Surplus of phosphorous should be avoided in bioleaching cultures as precipitation especially with REEs is possible.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

Bioleaching is considered as an alternative green technology to the common physico-chemical routs for metal recycling from waste materials. While several studies have investigated hydrometallurgical treatment of spent NiMH batteries, no report exists on heterotrophic bioleaching of REEs and major base metals from spent NiMH batteries. Developing efficient bioleaching processes requires optimized medium composition for enhanced production of microbial leaching agents. Here, role of factors such as phosphorus source also has not been delineated. This study investigates phosphorous source effects on microbial acid production and metal leaching using heterotrophic microorganisms Gluconobacter oxydans and Streptomyces pilosus. The results demonstrate potential for developing efficient heterotrophic bioleaching processes using G. oxydans to recycle elements with high supply risk from spent NiMH batteries.

Introduction

Nickel-metal-hydride (NiMH) batteries are used widely as power source in many electronic devices such as computers, cell phones and hybrid electric vehicles [1, 2]. It is expected that the rising production of hybrid electric vehicles will lead to considerable increases in the use of NiMH batteries and thus in battery waste production [3]. Essentially, NiMH batteries consist of two main parts: the cathode and the anode. While the cathode is made of nickel coated with nickel hydroxide, the anode consists of a mixture of rare earth elements (REEs) and base metals including Ni, Co, Mn and Al [1, 4]. Development of NiMH battery recycling procedures is of great importance from economic and environmental management point of views [1, 5]. Typically, NiMH batteries are recycled by using them as a cheap nickel source in stainless steel production, but this approach results in loss of the valuable shares of cobalt and REEs to the smelter slags [6, 7]. The existing physicochemical recycling routes for recovery of base metals and REEs from spent NiMH batteries have mainly been studied in laboratory and pilot scale while their scale up and commercialization has been hindered by the complexity and high costs of the processes as well as generation of remarkable amounts of hazardous waste [3, 8, 9].

An alternative process option for metal recovery from NiMH battery waste could be bioleaching, which takes advantage of microbial activity and metabolites produced by microorganisms to solubilize metals from solid materials. Due to mild operation conditions and relative simplicity of the process, bioleaching could be more cost-efficient and environmentally friendly process compared to the currently applied physicochemical methods [10,11,12]. Acidophilic bioleaching, which is commercially utilized to leach metals from sulfidic minerals [13], would require addition of sulfur source and pH adjustment to a pH of 2.0 or below [14], while spent NiMH batteries as a non-sulfidic secondary metal source with alkaline nature could be more amenable to heterotrophic bioleaching [15, 16]. Heterotrophic microorganisms such as G. oxydans and S. pilosus can utilize organic carbon sources such as glucose to produce organic acids such as gluconic acid and pyruvic acid, respectively [17, 18]. G. oxydans produces gluconic acid through oxidization of glucose by membrane-bound glucose dehydrogenase [19], while Streptomycetes mostly use Embden–Meyerhof–Parnas (glycolysis) pathway for glucose usage [20]. Organic acids can mediate metal mobilization from solid materials via complexation and/or proton promoted dissolution [5, 16]. Detailed information on complexation and protonation promoted REE bioleaching mechanisms can be found in the review by Rasoulnia et al. [5].

In order to enable as high metal dissolution as possible, microbial production of the leaching agents as well as the leaching conditions have to be optimized. Since the optimal conditions for microbial leaching agent production might be different from those required for efficient metal leaching [5], each step needs to be studied separately to maximize the overall process efficiency. Factors to consider for optimum leaching agent production include medium composition and growth conditions such as pH, temperature, cultivation duration, stirring and aeration [5, 21]. Both microorganisms used in this study are reported to grow at pH of 5–7 and temperature of 25–30 °C [5, 17, 22]. Previous studies have focused on medium composition optimization via evaluating the effects of e.g. nitrogen and organic carbon sources [5, 12, 21], while the role of other factors, such as the phosphorus source, has not been delineated. Furthermore, while several studies have investigated hydrometallurgical treatment of spent NiMH batteries [1,2,3,4], no report exists on simultaneous mobilization of REEs and major base metals from spent NiMH batteries by means of heterotrophic bioleaching. Therefore, the present study aimed at:

-

(1)

Investigating the impacts of phosphorus source (type and concentration) on organic acid production by the two heterotrophic bioleaching microorganisms Gluconobacter oxydans and Streptomyces pilosus; and

-

(2)

Evaluating and comparing the efficiency of one-step, two-step and spent-medium bioleaching methods in mobilizing REEs and base metals from spent NiMH batteries.

Materials and Methods

Spent NiMH Battery Powder Composition

A sample of spent NiMH battery powder was obtained from AkkuSer Oy, Finland. The NiMH battery powder was homogenized and screened through 630 µm sieve prior to the bioleaching experiments. To analyze the metal content of the spent NiMH battery, 50 mg of the sample was chemically digested using 5 ml of aqua regia solution comprised of concentrated HCl (35%) and HNO3 (65%) at a 4:1 volume ratio (~ 3:1 molar ratio). The spent NiMH battery contained a wide variety of REEs and base metals in different quantities (Table 1). The detected base metals included high levels of Ni and Co along with lower amounts of Cu, Zn, Fe and Mn. The major REEs present in the spent NiMH battery were La, Ce, Nd, Pr, Sm, Y, Yb, Gd and Er in a descending order. The sample also contained 29.3 ± 3.29 wt% C, 4.99 ± 0.65 wt% N and 0.65 ± 0.20 wt% H.

Microorganisms and Growth Media Used for Inoculum Preparation

Gluconobacter oxydans (DSM 3503) and Streptomyces pilosus (DSM 40097) were purchased from German Collection of Microorganisms and Cell Cultures (DSMZ). G. oxydans stock culture was maintained on glucose-yeast extract (GY) medium containing 100 g/l glucose (= 555 mM glucose), 10 g/l yeast extract, 20 g/l CaCO3 and 15 g/l agar. S. pilosus stock culture was maintained on glucose-yeast and malt extract (GYM) medium with the following composition: 4 g/l glucose (= 22.2 mM glucose), 10 g/l malt extract, 4 g/l yeast extract, 2 g/l CaCO3 and 12 g/l agar. The incubation temperature was 27 ± 1 °C and the cultures were transferred to fresh agar plates once a month.

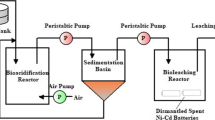

In order to study acid production and bioleaching of spent NiMH battery powder, S. pilosus inoculum was prepared as follows: the surface of GYM agar culture incubated for 4 days was washed using 10 ml of sterilized ultrapure water and subsequently 1 ml of the well mixed suspension (freeze dried weight: 4 mg/ml) was inoculated into the media using cut tip micropipettes. In case of G. oxydans, 1 ml of bacterial culture (107 cells, OD600: 1.22, pH: 2.55) incubated for 7 days in GY broth (excluding agar and CaCO3 used in the agar medium) was used to inoculate the flasks. The same inoculation procedure was followed in all the acid production and bioleaching experiments. In the first set of experiments, the cultivation media were optimized for organic acid production by the bacteria through evaluating initial medium pH and phosphorous source effect, and then the efficiency of one-step, two-step and spent-medium bioleaching in mobilization of valuable elements from the spent NiMH battery was evaluated using the optimized media (Fig. 1).

Overall experimental design used in the study to optimize organic acid production with Gluconobacter oxydans and Streptomyces pilosus, and to investigate spent NiMH battery bioleaching with the two microorganisms (PVK: Pikovskaya medium, \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\): PVK medium with 2.7 mM K2HPO4, \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-10×P: PVK medium with 27 mM K2HPO4)

Medium Optimization Experiments

Based on previous studies G. oxydans and Streptomyces sp. have shown good growth in Pikovskaya (PVK) and GYM medium, respectively [17, 18, 23]. Thus, prior to medium optimization via analyzing the effects of initial medium pH and phosphorus source, the growth of both bacteria was compared in GYM and PVK broth media through measurement of optical density (OD) at 600 nm, pH and production of organic acids (Online Resource 1). The composition of PVK medium was as follows: 10 g/l glucose (= 55.5 mM glucose), 5 g/l Ca3(PO4)2 (= 32.2 mM PO43−), 0.5 g/l (NH4)2SO4, 0.2 g/l NaCl, 0.2 g/l KCl, 0.1 g/l MgSO4, and 0.5 g/l yeast extract.

Since both bacteria produced higher quantities of organic acids in PVK medium (Online Resource 1), it was used as the basis for medium optimization with the aim to further increase organic acid production. In PVK medium, Ca3(PO4)2 acts as a buffer, preventing medium pH from reaching low values. Since acidolysis plays an important role in metal bioleaching alongside complexolysis [24], PVK medium was modified via replacing the insoluble buffering compound Ca3(PO4)2 with 2.7 mM of soluble phosphorous sources of either K2HPO4 or KH2PO4 in combination with 0.3 mM CaCl2·2H2O [18]. The phosphorous source affects medium pH and thus bacterial activity and organic acid production. More specifically, KH2PO4 and K2HPO4 have pKa values of ~ 7.0 and 12.0 [25, 26], providing different pH ranges for bacterial cultivation. Choosing the right phosphorous source can help to provide the required optimum pH range for bacterial growth without the need for further pH adjustment, thus lowering the operational costs in potential commercial applications. The effect of initial medium pH on bacterial growth and organic acid excretion was also evaluated by manual adjustment of initial pH of KH2PO4 and K2HPO4 containing media using H2SO4 and NaOH (Table 2). Moreover, to ensure that phosphorous concentration was not a limiting factor in organic acid production, five times (5×P) and ten times (10×P) higher K2HPO4 concentrations of 13.5 and 27 mM were studied.

Bioleaching of Metals from Spent NiMH Battery Powder

Bioleaching of the spent NiMH battery powder was carried out in 250 ml Erlenmeyer flasks with 100 ml initial working volume using \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\) and \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-10×P media for G. oxydans and S. pilosus, respectively. These media were chosen based on the results of growth studies described in “Optimization of PVK Medium to Enhance Organic Acid Production” section. The flasks were inoculated with 1% (v/v) bacterial inoculum and incubated at 27 ± 1 °C, mixing at 150 rpm for 14 days. To avoid bacterial contamination, the NiMH battery sample was autoclaved for 1 h at 121 °C in a nitrogen atmosphere to avoid oxidation reactions. Metal leaching efficiencies of three different bioleaching methods were investigated with both bacteria using a pulp density of 1% (w/v) of the spent NiMH battery. In one-step bioleaching, the spent NiMH battery sample was added simultaneously with the bacterial inoculum to the medium. In two-step bioleaching, the spent NiMH battery sample was added at the beginning of the logarithmic growth phase of the bacteria (1 day for G. oxydans and 2 days for S. pilosus). Spent-medium bioleaching experiments were carried out using cell-free microbial culture supernatant. To obtain the cell-free medium, the cells were removed after 6 days of growth by centrifugation at 10,000 rpm for 10 min (SIGMA, 4-16KS, Germany). Duration of the leaching phase with all the studied methods was 14 days. Control flasks containing respective sterile media without bacteria were incubated both in the presence and absence of the spent NiMH battery powder. In addition, pure cultures of the bacteria (without battery sample) were also included as controls. All bioleaching experiments were performed as triplicates.

Analytical Methods

During the experiments, pH variations were monitored using a pH meter (pH 3110, WTW 82362 Wellhelm, Germany) with Hamilton Slimtrode electrode. Ultrospec 500 pro spectrophotometer (Amersham Biosciences, England) was used to measure optical density at 600 nm (OD600) of G. oxydans cultures. Ultrapure water was used as the blank for the OD measurements. The concentrations of microbially produced organic acids were analyzed using high performance liquid chromatography (HPLC, Agilent 1100 series, Germany) equipped with Aminex HPX-87H column (300 × 7.8 mm) and a diode array detector at 210 nm. Sample injection volume was 20 µl and mobile phase flow rate was 0.6 ml/min. The mobile phase was 20 mM sulfuric acid and the column temperature 70 °C. d-Gluconic acid (Sigma Aldrich) and pyruvic acid (Acros Organics) sodium salts were used as the organic acid standards. A Shimadzu HPLC (SIL-20 series) equipped with a Rezex™ RHM-Monosaccharide H+ (300 × 7.8 mm) column and a refractive index (RI) detector was utilized for glucose determination under the following conditions: column temperature of 70 °C, injection volume of 2 µl and mobile phase of 5 mM sulfuric acid at flow rate of 0.8 ml/min. The concentration of phosphate in spent-medium leaching samples was monitored using ion-chromatography equipped with Dionex IonPac AS22 anion exchange column (Thermo Scientific). The eluent was a mixture of 4.5 mM Na2CO3 and 1.4 mM NaHCO3 at a flow rate of 1.2 ml/min. The sample injection volume was 10 µl, the column temperature was 30 °C and K2HPO4 was used as the standard. Metal concentrations were measured using inductively coupled plasma mass spectrometry (iCAP RQ ICP-MS, Thermo Scientific, USA) in kinetic energy discrimination mode to reduce interferences. Rhodium and germanium were used as internal standards and the samples were 100-fold diluted using 2% ultrapure nitric acid. All samples were filtered through 0.2 µm disposable syringe filters (CHROMAFIL® Xtra PET-20/25, Germany) prior to use in HPLC and ICP-MS analyses. The carbon, hydrogen and nitrogen content of the spent NiMH battery powder was determined using a Flash Smart elemental analyzer (Flash 2000, Thermo Scientific, USA) using cystine as a standard. The bioleached battery residues were collected at the end of spent-medium experiments and dried at room temperature prior to scanning electron microscope (SEM) analysis. Jeol JSM-IT500 SEM equipped with energy-dispersive X-ray spectrometer (EDS) was used for the characterization of the samples before and after bioleaching. Both the morphology and the cross-sections of the samples were studied. In the preparation of the cross-section specimen, the sample powder was mixed with a small amount of epoxy resin and cured in a mold in a vacuum. Then the mold was filled with epoxy. The samples were metallurgically ground with sandpaper and polished with a diamond paste. Before the analyses, all samples were carbon coated using a carbon evaporator.

Results and Discussion

Optimization of PVK Medium to Enhance Organic Acid Production

High acid production enables increased metal leaching yields due to a decrease of pH and thus increase of proton promoted leaching. In theory, high organic acid concentration also leads to increased availability of the complexation agent. However, any occurring complexation mediated contribution to the overall leaching process will be diminished with decreasing pH and might not be compensated by the increased concentration of the complexing agent [5, 27]. In order to compare the effect of different phosphorus sources on organic acid production, the PVK medium was modified by substitution of calcium phosphate (= 32.2 mM PO43−) with either KH2PO4 or K2HPO4 (= 2.7 mM PO43−). As a result, the initial pH of the PVK medium changed from 6.5 to 5.3 when KH2PO4 was used (\({\text{PVK}}_{{{\text{KH}}_{{2}} {\text{PO}}_{{4}} }}\)) and to 6.9 when K2HPO4 was used (\({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)) as the phosphorus source. Therefore, to delineate how both the phosphorus source and the change in initial pH of the medium affect the bacterial growth and organic acid production, \({\text{PVK}}_{{{\text{KH}}_{{2}} {\text{PO}}_{{4}} }}\) and \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\) media with initial pH adjusted (\({\text{PVK}}_{{{\text{KH}}_{{2}} {\text{PO}}_{{4}} }}\)-pH adj and \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-pH adj) to 6.5 (same initial pH as in the original PVK medium) were also investigated (Table 2).

In PVK medium containing Ca3(PO4)2, 28.0 mM of gluconic acid was produced by G. oxydans within 2 days of incubation (Online Resource 1). During the following days, the concentration of gluconic acid in PVK medium decreased possibly due to conversion of gluconic acid to 2-keto-gluconic and 5-keto-gluconic acid [28, 29]. Substitution of Ca3(PO4)2 by KH2PO4 and K2HPO4 improved G. oxydans growth and enhanced production of gluconic acid from 28.0 to 33 mM and 41 mM, respectively (Fig. 2a, b). No decrease in gluconic acid concentration was observed after it had reached the highest value, indicating that conversion of gluconic acid to 2-keto-gluconic acid and 5-keto-gluconic acid was negligible when Ca3(PO4)2 was eliminated from the medium [29]. Also previous studies have shown that presence of buffering agents such as CaCO3 can increase the conversion degree of gluconic acid to 2-keto-gluconic acid and 5-keto-gluconic acid by G. oxydans [28].

The highest gluconic acid concentrations obtained with G. oxydans in \({\text{PVK}}_{{{\text{KH}}_{{2}} {\text{PO}}_{{4}} }}\) and \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\) media were obtained by day 4 and 2, respectively. The lower and slower gluconic acid production in \({\text{PVK}}_{{{\text{KH}}_{{2}} {\text{PO}}_{{4}} }}\) compared to \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\) could have been a result of the lower initial pH (5.3 vs. 6.9). This was confirmed by adjusting the initial pH of \({\text{PVK}}_{{{\text{KH}}_{{2}} {\text{PO}}_{{4}} }}\) to 6.5 which resulted in increase of gluconic acid production to 42 mM. Adjusting the initial pH of \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\) to 6.5 led to only slightly higher production of gluconic acid than without pH adjustment (45 mM vs. 41 mM). As the use of \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\) enabled production of more than 40 mM gluconic acid without the need to adjust the initial medium pH, this medium was selected to study the effect of K2HPO4 concentration on acid production.

Increasing the amount of K2HPO4 from 2.7 to 13.5 mM (\({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-5×P) slowed down bacterial growth and reduced gluconic acid production to 26.0 mM. In presence of 27.0 mM K2HPO4 (\({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-10×P), a negligible amount of gluconic acid was produced (Fig. 2a). Increasing the K2HPO4 concentration five- and ten-times, increased the initial medium pH to 8.2 and 8.4 respectively. Under these alkaline conditions, Maillard type reactions are enhanced during autoclaving, resulting in sugar and amino acid degradation and formation of toxic substances that can inhibit bacterial growth [30, 31]. This could explain the reduced gluconic acid production at the higher K2HPO4 concentrations. Thus, \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\) medium containing 2.7 mM of K2HPO4 was selected for conducting the bioleaching experiments with G. oxydans.

Similar medium modifications were also applied to S. pilosus (Fig. 2c, d). In PVK medium with Ca3(PO4)2, 5.5 mM of puryvic acid was produced by S. pilosus within 4 days (Online Resource 1). In \({\text{PVK}}_{{{\text{KH}}_{{2}} {\text{PO}}_{{4}} }}\) with initial pH of 5.3, negligible amount of pyruvic acid was produced. However, medium pH decreased to 3.3 likely as a result of production of other, unidentified metabolites. By adjusting initial medium pH to 6.5, production of approximately 2 mM of pyruvic acid was observed. Utilization of \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\) medium which had a higher initial pH of 6.9, enabled production of 2.2 mM pyruvic acid without requiring pH adjustment. Increasing the concentration of K2HPO4 to 13.5 mM in \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-5×P and to 27.0 mM in \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-10×P, with both media having an initial pH of 7.0, further improved pyruvic acid production to 5.5 and 10.7 mM, respectively. The higher pyruvic acid production in \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-10×P medium was most likely due to the higher buffering capacity of the medium allowing for increased acid production, while still maintaining favorable pH conditions for growth. The results showed that pyruvic acid production by S. pilosus is highly affected by the initial medium pH which it is also dependent on the type and concentration of the utilized phosphorous source.

Despite the possible occurrence of Maillard type reactions during autoclaving and detection of only 11.1 mM glucose on the initial day of S. pilosus cultivation (instead of 55.5 mM initial glucose content of medium before autoclaving), 10.7 mM pyruvic acid was produced after 4 days. In the same time glucose concentration decreased by 7.2 mM. This indicates a 74% conversion efficiency of measured glucose into pyruvic acid. Considering the same conversion efficiency, theoretically 82.1 mM pyruvic acid could be produced from 55.5 mM glucose in absence of Maillard type reactions and presence of favorable microbial growth conditions. S. pilosus growth in \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-10×P decreased medium pH from 7 to 4.4 within 4 days. From day 4 onwards, medium pH and pyruvic acid concentration remained constant. When lower phosphate concentrations were used, buffering capacity of the medium was reduced. Thus, the lower pyruvic acid production may have been caused by the faster pH decrease, and therefore, \({\text{PVK}}_{{{\text{K}}_{{2}} {\text{HPO}}_{{4}} }}\)-10×P medium was chosen for studying bioleaching with S. pilosus.

Bioleaching of Spent NiMH Battery

Organic Acid Production and pH Variations in the Bioleaching Experiments

Acid production was negligible in one-step bioleaching by both bacteria presumably due to toxicity of the spent NiMH battery powder and metals present in the powder. The constant medium pH during the process confirmed the lack of excretion of microbial metabolites and thus the interaction with the metals in the NiMH battery waste (Fig. 3a–d). Reduced bacterial growth due to presence of hazardous components has been reported for other solid waste materials such as waste electrical and electronic equipment shredding dusts [32], printed circuit boards [33] and spent lithium-ion batteries [34].

Organic aid production and pH variation with different bioleaching methods: G. oxydans (time of NiMH battery addition was day 0 in one-step and spent-medium, and day 1 in two-step bioleaching) (a, b); and S. pilosus (time of NiMH battery addition was day 0 in one-step and spent medium, and day 2 in two-step bioleaching) (c, d). Error bars indicate standard deviations of triplicate experiments (error bars not visible fall within the symbols)

The two-step bioleaching method enabled bacteria to grow and enter logarithmic growth phase prior to the addition of the spent NiMH battery sample. In G. oxydans cultures, medium pH decreased from 7.0 to 2.7 within 1 day due to production of 35 mM gluconic acid (Fig. 3a, b). After addition of the spent NiMH battery powder, medium pH instantly increased to 3.2. Gluconic acid production continued to increase to 40 mM by day 2 and then gluconic acid concentration remained stable until the end of the experiment (day 14). The medium pH continued to increase reaching 6.5 within 14 days, respectively. The increase of medium pH during the bioleaching process, despite acid production by G. oxydans, was likely due to the fast proton consumption and release of alkaline compounds by the spent NiMH battery [35]. In case of two-step bioleaching with S. pilosus, acid production decreased medium pH from 7.0 to 6.7 within 2 days (Fig. 3c, d). The addition of the spent NiMH battery led to an increase of pH from 6.7 to 7.0. The pH gradually continued to increase to 7.5 within 14 days. No production of pyruvic acid was observed from day 2 onwards, which may indicate inhibition of S. pilosus growth by addition of the battery waste.

Spent-medium bioleaching experiments were conducted using cell-free culture supernatants. In G. oxydans cultures, the medium pH decreased from 7.0 to 2.6 by production of 42 mM gluconic acid during the 6-day incubation without the battery sample (Fig. 3a, b). The addition of the spent NiMH battery to cell-free supernatant of G. oxydans caused an increase in the medium pH from 2.6 to 3.1, similarly as in the two-step bioleaching. The increase in pH was due to the alkaline nature of the spent NiMH battery material. Concentration of gluconic acid in the cell-free supernatant remained almost stable (39–42 mM) during the 14-day leaching period. In S. pilosus cultures, production of 10 mM pyruvic acid within the growth period decreased medium pH from 7.0 to 4.6, while the addition of the spent NiMH battery sample to the filtered supernatant caused an increase in pH from 4.6 to 5.9. The pH later increased gradually to 6.9 during the 14-day leaching experiment, while at the same time pyruvic acid concentration in the medium decreased from 10.0 to 5.3 mM (Fig. 3c, d). The gradual pH increase during spent-medium leaching is an indication of slow, chemical reactions that take place between the microbial metabolites and the spent NiMH battery sample. The constant pH of the sterile control media (Fig. 3b, d) verified that the interactions of the biogenic metabolites with the NiMH battery powder were responsible for the pH variations.

Bioleaching of REEs and Base Metals

With G. oxydans, no metals were leached when one-step bioleaching method was utilized as no bacterial activity was detected likely due to the toxicity of the spent NiMH battery sample. Application of two-step bioleaching method with G. oxydans enabled extraction of 34% Mn, 88% Fe, 41.5% Co, 18.5% Ni, 21% Cu, 12% Zn and 6.5% of total REEs. In spent-medium bioleaching experiments using filtered culture supernatant of G. oxydans, 35% Mn, 68% Fe, 35.5% Co, 16.5% Ni, 20% Cu, 9% Zn and 9% of total REEs were solubilized. Surprisingly, despite the production of similar level of gluconic acid with both methods, two-step bioleaching resulted in higher leaching efficiencies of base metals (especially Fe, Co, Ni and Zn), while spent-medium bioleaching method was more efficient at extracting REEs (9% vs. 6.5% leaching of total REEs) from the spent NiMH battery powder (Fig. 4a, b). The lower REE leaching efficiency in the two-step bioleaching could be at least partly due to adsorption of REEs on the microbial cells, while this was not the case in spent-medium bioleaching as the cells had been removed from the leaching solution. Preferential biosorption of REEs over base metals onto the cell surfaces has been reported for other microorganisms such as Penidiella sp. [36]. The total REE recovery yield of 9% obtained in this study is comparable with bioleaching efficiencies reported for other high-grade secondary REE sources such as fluorescent phosphors (Table 3). However, the obtained leaching yields are low in comparison to low-grade REE-containing waste materials such as fluid catalytic cracking (FCC) catalysts and combustion ashes (Table 3). Although the efficiency of a bioleaching process is highly dependent on REE bonding within the solid material as well as the applied microorganisms and growth conditions [5], it seems that there is an inverse relationship between REE extraction yields and original REE concentration within the material [37]. This could be due to the fact that under batch leaching conditions, solubility limits can constrain the attainable total REE recovery.

Comparison of base metal (a) and REE (b) leaching efficiency in two-step and spent-medium bioleaching by G. oxydans after 14 days of leaching; and base metal and REE bioleaching kinetics in two-step bioleaching (c, e) and spent-medium bioleaching (d, f) by G. oxydans. Error bars indicate standard deviations of triplicate experiments (error bars not visible fall within the symbols)

When S. pilosus was employed, no metals were leached from the spent NiMH battery powder using any of the studied bioleaching methods. Even with the spent-medium bioleaching, during which S. pilosus was allowed to grow and produce 10 mM pyruvic acid, no considerable leaching was observed for any of the target elements. This could be due to four different reasons: (1) concentrations higher than 10 mM pyruvic acid are needed; (2) K2HPO4 buffering impedes achieving low pH necessary for proton promoted leaching, (3) absence of metal complexation promoted leaching under these conditions, and/or (4) precipitation of leached metals with phosphorous in the medium [41].

Leaching Kinetics

During the 14-day two-step and spent-medium bioleaching by G. oxydans the leaching kinetics were also monitored (Fig. 4c–f). With both methods, the leaching rates of base metals were higher than the leaching rates of REEs. Both base metal and REE leaching kinetics followed a biphasic pattern. The majority of the base metals were leached out within the first 4 days of the leaching and although mobilization of the base metals continued up to day 14, the leaching rates became substantially slower. For example, in the spent-medium experiments the leaching rates of Ni, Co and Mn decreased from 151, 71 and 16 mg/l day until day 4 to 12, 3 and 1 mg/l day for the following 10 days. Similarly, in the two-step experiments, leaching rates of Ni, Co and Mn decreased from 176, 88 and 16 mg/l day during the first 4 days to 10, 2 and 1 mg/l day from day 4 to 14.

During the spent-medium bioleaching experiments, the leaching rates of La, Ce and Nd (the three most abundant REEs in the spent NiMH battery powder) decreased from 9, 5 and 4 mg/l day during the first 4 days to 2, 2 and 1 mg/l day from day 4 to 14. A similar trend was observed in the two-step bioleaching experiments: the REE leaching rates were higher within the four initial days of the leaching compared to the following days. However, the decrease in the REE leaching rates was lower compared to those of the base metals from day 4 onwards. Although the obtained REE leaching rates are comparable to previously reported leaching rates (Table 3), further improvement of leaching kinetics to shorten leaching duration is desirable for industrial-scale recycling of spent NiMH batteries.

The faster leaching rate of the base metals compared to the REEs in this study is in contradiction with the results reported for spent NiMH battery leaching using HCl and H2SO4 [42]. Both, the use of different leaching agents as well as the differences in pH could explain this contradiction. The pH during HCl and H2SO4 leaching of spent NiMH battery was 3, while in this study the pH during bioleaching was varying from 3.1 to 6.4. Thus, comprehensive investigations of the leaching kinetics using various leaching agents are required to clarify the leaching behavior of different elements from spent NiMH batteries.

SEM–EDS Analysis of the Spent NiMH Battery

The scanning electron microscope characterization of the spent NiMH battery was conducted using the bioleached residue from the spent-medium bioleaching experiments, as the obtained REE leaching efficiencies were the highest using this method. Secondary electron (SE) imaging of the spent NiMH battery was conducted to visualize changes in the particle morphology during the bioleaching process. Figure 5a, b show that during spent-medium bioleaching, the rough surface of the spent NiMH battery particles transformed into a smoother, but slightly cracked surface after bioleaching due to exposure to the microbially produced leaching agents.

Secondary electron images of surface morphology of the spent NiMH battery before (a) and after bioleaching (b); cross-sectional backscattered secondary electron images of the spent NiMH battery before (c), and after bioleaching (d); and EDS analysis maps of the spent NiMH battery before bioleaching (e)

The analysis of the cross-sectional samples was done using backscattered secondary electron (BSE) imaging that highlights the elemental contrast (Fig. 5c, d). The cross-sectional BSE images revealed a core–shell structure for the predominant particles of the spent NiMH battery before bioleaching similar to the structures observed by Zielinski et al. [42]. The EDS point analyses indicated that while both shell and core of the particles contained a mixture of the REEs and base metals, their oxygen content differed greatly. The shell contained 10–30 wt% oxygen, while the core had only traces of oxygen indicating an oxidation of the particle surface. The EDS analysis maps in Fig. 5e illustrate the oxidation of the surfaces of the particles and reveal the distribution of metals including Ni, Co, La and Ce throughout the particles. A slightly different distribution pattern was observed for Y, detecting more of it on the exterior of the particles. Comparison of the cross-sectional BSE images of the spent NiMH battery before and after bioleaching (Fig. 5c, d) shows formation of cracks in the shell of the particle. This indicates that metals were predominantly leached from the shell rather than the core. However, once the cracks formed, they might allow for access of the leaching agent and metal release from the core of the particle as well.

Impacts of Phosphorous Source and Possible Approaches for Process Improvement

In this study, after addition of the spent NiMH battery powder to the cell-free culture supernatants of G. oxydans and S. pilosus, the soluble phosphate level decreased by up to 200 mg/l and 400 mg/l, respectively, after 2 days of leaching. The reductions in phosphate level indicate occurrence of a chemical reaction between the elements present within the spent battery material and the unutilized phosphorous. REEs have the potential to precipitate with phosphate ions at pH range of 4–6 [41] which resembles the pH range (3.1–6.4) observed during the bioleaching processes in this study. Nevertheless, because of complexity of the bioleaching medium (presence of numerous bacterial metabolites) and hydrolysis and complexation reactions of the solubilized metals, it is hard to make exact predictions about the reaction behavior of the elements in solution [41]. The results of this study indicate that phosphate content of the culture medium plays an important role in both microbial acid production and metal leaching. Although increases in phosphate concentration might lead to higher acid production, it does not necessarily lead to improved bioleaching efficiencies. Thus, a careful optimization of the medium phosphate concentration to ensure both optimal microbial growth and no interference in the leaching process is critical. However, providing no additional phosphorous source can also lead to a reduction of leaching efficiency as observed during fluorescent phosphor leaching [39]. Alternatively, the use of organic phosphorous sources [43, 44] could be investigated as such compounds might not precipitate with REEs in solution as easily as readily soluble phosphate. Further studies are required to investigate the effects of surpluses of phosphate on metal leaching.

Another option to increase bioleaching efficiency of G. oxydans could be utilization of higher glucose concentrations than the 55.5 mM used in this study. Previous studies have used up to 555 mM glucose or 292 mM sucrose in REE bioleaching with bacteria and fungi [12, 15, 16]. However, considering economics of the process, the influencing factor is the conversion efficiency of the carbon source into the leaching agent and not the absolute amount of organic carbon source used [12].

In addition, removing easily soluble, acid consuming compounds from the spent NiMH batteries via a washing step could improve the leaching yields by increasing the rate of reactions between the target elements and the microbial metabolites [4, 45]. Furthermore, use of higher temperatures could accelerate leaching rates of REEs in spent-medium bioleaching. The increased temperature of the leaching step can enhance mineral dissolution, making up for the decreased solubility of REE salts at elevated temperatures as reviewed by Rasoulnia et al. [5]. Several methods such as solvent extraction, ion exchange, precipitation, liquid membrane processes, nanofiltration, and biosorption/adsorption can be applied to recover REEs from the leach solutions [46,47,48,49].

Conclusions

This study demonstrated that phosphorous source type and concentration are important factors affecting medium pH, bacterial activity, organic acid production and metal leaching. Use of K2HPO4 enabled achievement of favorable pH conditions for microbial growth and organic acid production without requiring additional pH adjustment. While increasing phosphate concentration hindered gluconic acid production by G. oxydans, it improved pyruvic acid production by S. pilosus. Potential for leaching of different metals from the spent NiMH battery powder was demonstrated with G. oxydans but not with S. pilosus. With G. oxydans, solubilization of base metals was more efficient when two-step bioleaching was used, while spent-medium leaching resulted in higher REE leaching yields. The SEM–EDS analysis demonstrated that the metals were predominantly leached from the shell rather than the core of the particles. The findings of this study provide a basic understanding for developing an efficient heterotrophic bioleaching process using G. oxydans to recycle elements with high risk of supply disruption and high economic importance from spent NiMH batteries and thus mitigating the impacts on the environment.

References

Rodrigues, L.E.O.C., Mansur, M.B.: Hydrometallurgical separation of rare earth elements, cobalt and nickel from spent nickel-metal-hydride batteries. J. Power Sources 195, 3735–3741 (2010). https://doi.org/10.1016/j.jpowsour.2009.12.071

Agarwal, V., Khalid, M.K., Porvali, A., Wilson, B.P., Lundström, M.: Recycling of spent NiMH batteries: integration of battery leach solution into primary Ni production using solvent extraction. Sustain. Mater. Technol. 22, e00121 (2019). https://doi.org/10.1016/j.susmat.2019.e00121

Innocenzi, V., Ippolito, N.M., De Michelis, I., Prisciandaro, M., Medici, F., Vegliò, F.: A review of the processes and lab-scale techniques for the treatment of spent rechargeable NiMH batteries. J. Power Sources 362, 202–218 (2017). https://doi.org/10.1016/j.jpowsour.2017.07.034

Innocenzi, V., Vegliò, F.: Recovery of rare earths and base metals from spent nickel-metal hydride batteries by sequential sulphuric acid leaching and selective precipitations. J. Power Sources 211, 184–191 (2012). https://doi.org/10.1016/j.jpowsour.2012.03.064

Rasoulnia, P., Barthen, R., Lakaniemi, A.: A critical review of bioleaching of rare earth elements: the mechanisms and effect of process parameters. Crit. Rev. Environ. Sci. Technol. (2020). https://doi.org/10.1080/10643389.2020.1727718

Müller, T., Friedrich, B.: Development of a recycling process for nickel-metal hydride batteries. J. Power Sources 158, 1498–1509 (2006). https://doi.org/10.1016/j.jpowsour.2005.10.046

Binnemans, K., Jones, P.T., Blanpain, B., Van Gerven, T., Yang, Y., Walton, A., Buchert, M.: Recycling of rare earths: a critical review. J. Clean. Prod. 51, 1–22 (2013). https://doi.org/10.1016/j.jclepro.2012.12.037

Benzal, E., Solé, M., Lao, C., Gamisans, X., Dorado, A.D.: Elemental copper recovery from e-wastes mediated with a two-step bioleaching process. Waste Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-020-01040-2

Čížková, M., Mezricky, P., Mezricky, D., Rucki, M., Zachleder, V., Vítová, M.: Bioaccumulation of rare earth elements from waste luminophores in the red algae, Galdieria phlegrea. Waste Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-020-01182-3

Naseri, T., Bahaloo-horeh, N., Mousavi, S.M.: Bacterial leaching as a green approach for typical metals recovery from end-of-life coin cells batteries. J. Clean. Prod. 220, 483–492 (2020). https://doi.org/10.1016/j.jclepro.2019.02.177

Fathollahzadeh, H., Hackett, M.J., Khaleque, H.N., Eksteen, J.J., Kaksonen, A.H., Watkin, E.L.: Better together: potential of co-culture microorganisms to enhance bioleaching of rare earth elements from monazite. Bioresour. Technol. Rep. 3, 109–118 (2018). https://doi.org/10.1016/j.biteb.2018.07.003

Thompson, V.S., Gupta, M., Jin, H., Vahidi, E., Yim, M., Jindra, M.A., Nguyen, V., Fujita, Y., Sutherland, J.W., Jiao, Y., Reed, D.W.: Techno-economic and life cycle analysis for bioleaching rare-earth elements from waste materials. ACS Sustain. Chem. Eng. 6, 1602–1609 (2018). https://doi.org/10.1021/acssuschemeng.7b02771

Kaksonen, A.H., Lakaniemi, A., Tuovinen, O.H.: Acid and ferric sulfate bioleaching of uranium ores: a review. J. Clean. Prod. (2020). https://doi.org/10.1016/j.jclepro.2020.121586

Pollmann, K., Kutschke, S., Matys, S., Raff, J., Hlawacek, G., Lederer, F.L.: Bio-recycling of metals: recycling of technical products using biological applications. Biotechnol. Adv. 36, 1048–1062 (2018). https://doi.org/10.1016/j.biotechadv.2018.03.006

Qu, Y., Lian, B.: Bioleaching of rare earth and radioactive elements from red mud using Penicillium tricolor RM-10. Bioresour. Technol. 136, 16–23 (2013). https://doi.org/10.1016/j.biortech.2013.03.070

Hopfe, S., Flemming, K., Lehmann, F., Möckel, R., Kutschke, S., Pollmann, K.: Leaching of rare earth elements from fluorescent powder using the tea fungus Kombucha. Waste Manag. 62, 211–221 (2017). https://doi.org/10.1016/j.wasman.2017.02.005

Zhang, L., Dong, H., Liu, Y., Bian, L., Wang, X., Zhou, Z., Huang, Y.: Bioleaching of rare earth elements from bastnaesite-bearing rock by actinobacteria. Chem. Geol. 483, 544–557 (2018). https://doi.org/10.1016/j.chemgeo.2018.03.023

Reed, D.W., Fujita, Y., Daubaras, D.L., Jiao, Y., Thompson, V.S.: Bioleaching of rare earth elements from waste phosphors and cracking catalysts. Hydrometallurgy 166, 34–40 (2016). https://doi.org/10.1016/j.hydromet.2016.08.006

Schleyer, U., Merfort, M., Bringer-meyer, S., Sahm, H.: Glucose oxidation and PQQ-dependent dehydrogenases in Gluconobacter oxydans. J. Mol. Microbiol. Biotechnol. (2009). https://doi.org/10.1159/000142890

Minas, W.: Regulation of morphological and physiological differentiation in actinomycetes, Habilitation Thesis, ETH-Zürich (2002).

Brisson, V.L., Zhuang, W.-Q., Alvarez-Cohen, L.: Bioleaching of rare earth elements from monazite sand. Biotechnol. Bioeng. 113, 339–348 (2016). https://doi.org/10.1002/bit.25823

Olijve, W., Kok, J.J.: An Analysis of the Growth of Gluconobacter oxydans in Chemostat Cultures. Arch. Microbiol. 121, 291–297 (1979).

Pikovskaya, R.I.: Mobilization of phosphorus in soil in connection with the vital activity of some microbial species. Mikrobiologiya 17, 362–370 (1948).

Shin, D., Kim, J., Kim, B., Jeong, J., Lee, J.: Use of phosphate solubilizing bacteria to leach rare earth elements from monazite-bearing ore. Minerals. 5, 189–202 (2015). https://doi.org/10.3390/min5020189

Grima, S., Bellon-Maurel, V., Silvestre, F., Feuilloley, P.: A new test method for determining biodegradation of plastic material under controlled aerobic conditions in a soil-simulation solid environment. J. Polym. Environ. 9, 39–48 (2001). https://doi.org/10.1023/A:1016044504688

Qafisheh, N., Mukhopadhyay, S., Joshi, A.V., Sasson, Y., Chuah, G.K., Jaenicke, S.: Potassium phosphate as a high-performance solid base in phase-transfer-catalyzed alkylation reactions. Ind. Eng. Chem. Res. 46, 3016–3023 (2007). https://doi.org/10.1021/ie060899e

Kutus, B., Varga, N., Peintler, G., Lupan, A., Attia, A.A.A., Pálinkó, I., Sipos, P.: Formation of mono- and binuclear neodymium(III)-gluconate complexes in aqueous solutions in the pH range of 2–8. Dalt. Trans. 46, 6049–6058 (2017). https://doi.org/10.1039/c7dt00909g

Beschkov, V., Velizarov, S., Peeva, L.: Some kinetic aspects and modelling of biotransformation of d-glucose to keto-d-gluconates. Bioprocess Eng. 13, 301–305 (1995). https://doi.org/10.1007/BF00369561

Gupta, A., Singh, V.K., Qazi, G.N., Kumar, A.: Gluconobacter oxydans: its biotechnological applications. J. Mol. Microbiol. Biotechnol. 3, 445–456 (2001)

Adrian, J.: Nutritional and physiological consequences of the Maillard reaction. World Rev. Nutr. Diet 19, 71–122 (1974). https://doi.org/10.1159/000394766

Bhattacharjee, M.K., Sugawara, K., Ayandeji, O.T.: Microwave sterilization of growth medium alleviates inhibition of Aggregatibacter actinomycetemcomitans by Maillard reaction products. J. Microbiol. Methods 78, 227–230 (2009). https://doi.org/10.1016/j.mimet.2009.06.004

Marra, A., Cesaro, A., Rene, E.R., Belgiorno, V., Lens, P.N.L.: Bioleaching of metals from WEEE shredding dust. J. Environ. Manage. 210, 180–190 (2018). https://doi.org/10.1016/j.jenvman.2017.12.066

Işıldar, A., van de Vossenberg, J., Rene, E.R., van Hullebusch, E.D., Lens, P.N.L.: Two-step bioleaching of copper and gold from discarded printed circuit boards (PCB). Waste Manag. 57, 149–157 (2016). https://doi.org/10.1016/j.wasman.2015.11.033

Heydarian, A., Mousavi, S.M., Vakilchap, F., Baniasadi, M.: Application of a mixed culture of adapted acidophilic bacteria in two-step bioleaching of spent lithium-ion laptop batteries. J. Power Sources 378, 19–30 (2018). https://doi.org/10.1016/j.jpowsour.2017.12.009

Porvali, A., Ojanen, S., Wilson, B.P., Serna-Guerrero, R., Lundström, M.: Nickel metal hydride battery waste: mechano-hydrometallurgical experimental study on recycling aspects. J. Sustain. Metall. 6, 78–90 (2020). https://doi.org/10.1007/s40831-019-00258-2

Ilyas, S., Kim, M.-S., Lee, J.-C., Jabeen, A., Bhatti, H.: Bio-reclamation of strategic and energy critical metals from secondary resources. Metals 7, 207 (2017). https://doi.org/10.3390/met7060207

Amin, M.M., El-Aassy, I.E., El-Feky, M.G., Sallam, A.M., El-Sayed, E.M., Nada, A.A., Harpy, N.M.: Fungal leaching of rare earth elements from lower carboniferous shales, southwestern Sinai, Egypt. Rom. J Biophys. 24, 25–41 (2014)

Tsaplina, I.A., Panyushkina, A.E., Grigor’eva, N.V., Bulaev, A.G., Kondrat’eva, T.F.: Growth of acidophilic chemolithotrophic microbial communities and sulfur oxidation in the presence of coal ashes. Microbiology 84, 177–189 (2015). https://doi.org/10.1134/s0026261715020174

Hopfe, S., Konsulke, S., Barthen, R., Lehmann, F., Kutschke, S., Pollmann, K.: Screening and selection of technologically applicable microorganisms for recovery of rare earth elements from fluorescent powder. Waste Manag. 79, 554–563 (2018). https://doi.org/10.1016/j.wasman.2018.08.030

Funari, V., Mäkinen, J., Salminen, J., Braga, R., Dinelli, E., Revitzer, H.: Metal removal from municipal solid waste incineration fly ash: a comparison between chemical leaching and bioleaching. Waste Manag. 60, 397–406 (2017). https://doi.org/10.1016/j.wasman.2016.07.025

Han, K.N.: Characteristics of precipitation of rare earth elements with various precipitants. Minerals (2020). https://doi.org/10.3390/min10020178

Zielinski, M., Cassayre, L., Destrac, P., Coppey, N., Garin, G., Biscans, B.: Leaching mechanisms of industrial powders of spent nickel metal hydride batteries in a pilot-scale reactor. Chemsuschem 13, 616–628 (2020). https://doi.org/10.1002/cssc.201902640

Cook, A.M., Daughton, C.G., Alexander, M.: Phosphonate utilization by bacteria. J. Bacteriol. 133, 85–90 (1978)

Siuda, W., Chrost, R.: Utilization of selected dissolved organic phosphorus compounds by bacteria in lake water under non-limiting orthophosphate conditions. Polish J. Environ. Stud. 10, 475–483 (2001)

Sethurajan, M., van Hullebusch, E.D., Fontana, D., Akcil, A., Deveci, H., Batinic, B., Leal, J.P., Gasche, T.A., Kucuker, M.A., Kuchta, K., Neto, I.F.F., Soares, H.M.V.M., Chmielarz, A.: Recent advances on hydrometallurgical recovery of critical and precious elements from end of life electronic wastes: a review. Crit. Rev. Environ. Sci. Technol. 49, 212–275 (2019). https://doi.org/10.1080/10643389.2018.1540760

Balaram, V.: Rare earth elements: a review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci. Front. 10, 1285–1303 (2019). https://doi.org/10.1016/j.gsf.2018.12.005

Smith, R.C., Taggart, R.K., Hower, J.C., Wiesner, M.R., Hsu-Kim, H.: Selective recovery of rare earth elements from coal fly ash leachates using liquid membrane processes. Environ. Sci. Technol. 53, 4490–4499 (2019). https://doi.org/10.1021/acs.est.9b00539

Kose Mutlu, B., Cantoni, B., Turolla, A., Antonelli, M., Hsu-Kim, H., Wiesner, M.R.: Application of nanofiltration for rare earth elements recovery from coal fly ash leachate: performance and cost evaluation. Chem. Eng. J. 349, 309–317 (2018). https://doi.org/10.1016/j.cej.2018.05.080

Park, D.M., Brewer, A., Reed, D.W., Lammers, L.N., Jiao, Y.: Recovery of rare earth elements from low-grade feedstock leachates using engineered bacteria. Environ. Sci. Technol. 51, 13471–13480 (2017). https://doi.org/10.1021/acs.est.7b02414

Acknowledgments

The authors acknowledge AkkuSer Oy for providing the spent NiMH battery powder sample. Payam Rasoulnia acknowledges Tampere University Doctoral School for funding this research. This work also made use of Tampere Microscopy Center facilities at Tampere University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rasoulnia, P., Barthen, R., Valtonen, K. et al. Impacts of Phosphorous Source on Organic Acid Production and Heterotrophic Bioleaching of Rare Earth Elements and Base Metals from Spent Nickel-Metal-Hydride Batteries. Waste Biomass Valor 12, 5545–5559 (2021). https://doi.org/10.1007/s12649-021-01398-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01398-x