Abstract

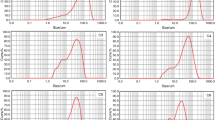

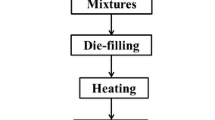

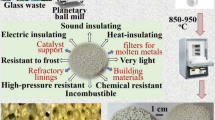

Glass foams were successfully produced from discarded glass bottles (GB) and pine scales (PS) as pore former agent in contents between 1 and 50 vol%. Samples containing glass and pine scale wastes in powder form were homogenized and uniaxially pressed (20 MPa). The obtained powder compacts were dried (room temperature/24 h and 110 ºC/24 h), fired at 850 ºC/30 min/10 ºC/min and characterized according to their chemical, structural, mechanical, and thermal properties. The results (porosities between 78 and 86% with thermal conductivities between 0.072 and 0.093 W/mK and compressive mechanical strength between 0.2 and 3.4 MPa) indicated that the obtained foams produced from low-cost starting materials have potential for being used in applications where thermal insulation and non-flammability are the main technical requirements.

Graphic Abstract

Similar content being viewed by others

References

Scheffler, M., Colombo, P.: Cellular Ceramics: Structure. Properties and Applications., Wiley-VCH, Wiley-VCHVerlag GmbH & Co. KGaA, Weinheim, Germany, Manufacturing (2005)

Caniato, M., Kyaw, G., D’Amore, J., Kaspar, A.G.: Sound absorption performance of sustainable foam materials: Application of analytical and numerical tools for the optimization of forecasting models. Appl Acoust (2020). https://doi.org/10.1016/j.apacoust.2019.107166

Chen, Q.Z., Thompson, I.D., Boccaccini, A.R.: 45S5 Bioglass®-derived glass–ceramic scaffolds for bone tissue engineering. Biomaterials 27, 2414–2425 (2006). https://doi.org/10.1016/j.biomaterials.2005.11.025

Midha, S., Kim, T.B., van den Bergh, W., Lee, P.D., Jones, J.R., Mitchell, C.A.: Preconditioned 70S30C bioactive glass foams promote osteogenesis in vivo. Acta Biomater. 9, 9169–9182 (2013). https://doi.org/10.1016/j.actbio.2013.07.014

Kyaw D’Amore, G., Caniato, M., Travan, A., Turco, G., Marsich, L., Ferluga, A., Schmid, C.: Innovative thermal and acoustic insulation foam from recycled waste glass powder. J. Clean. Prod. (2017). https://doi.org/10.1016/j.jclepro

M.F. Ashby, Chapter 3 - The material life cycle, in: M.F.B.T.-M. and the E. (Second E. Ashby (Ed.), Butterworth-Heinemann, Boston, 2013.

M.F. Ashby, Chapter 4 - End of first life: A problem or a resource?, in: M.F.B.T.-M. and the E. (Second E. Ashby (Ed.), Butterworth-Heinemann, Boston, 2013: pp. 79–97. https://doi.org/10.1016/B978-0-12-385971-6.00004-X.

Gaines, L.L., Mintz, M.M.: Energy implications of glass-container recycling, Golden. CO (United States) (1994). https://doi.org/10.2172/10161731

Bernardo, E., Scarinci, G., Bertuzzi, P., Ercole, P., Ramon, L.: Recycling of waste glasses into partially crystallized glass foams. J. Porous Mater. 17, 359–365 (2010). https://doi.org/10.1007/s10934-009-9286-3

de Moraes, E.G., Bigi, M., Stochero, N.P., Arcaro, S., Siligardi, C., Novaes de Oliveira, A.P.: Vitrocrystalline foams produced with EPS as pore former: Processing and characterization. Process Saf. Environ. Prot. 121, 12–19 (2019). https://doi.org/10.1016/j.psep.2018.10.007

Souza, M.T., Maia, B.G.O., Teixeira, L.B., de Oliveira, K.G., Teixeira, A.H.B., Novaes de Oliveira, A.P.: Glass foams produced from glass bottles and eggshell wastes. Process Saf. Environ. Prot. 111, 60–64 (2017). https://doi.org/10.1016/j.psep.2017.06.011

Paiva, A.L., de Moraes, E.G., Stochero, N.P., de Oliveira, A.P.N.: Characterization of Vitrocrystalline Foams Produced from Discarded Glasses and Recycled Polystyrene Spheres. Mater. Res. 20, 472–478 (2017). https://doi.org/10.1590/1980-5373-mr-2016-1089

Tulyaganov, D.U., Fernandes, H.R., Agathopoulos, S., Ferreira, J.M.F.: Preparation and characterization of high compressive strength foams from sheet glass. J. Porous Mater. 13, 133–139 (2006). https://doi.org/10.1007/s10934-006-7014-9

Fernandes, H.R., Tulyaganov, D.U., Ferreira, J.M.F.: Preparation and characterization of foams from sheet glass and fly ash using carbonates as foaming agents. Ceram. Int. 35, 229–235 (2009). https://doi.org/10.1016/j.ceramint.2007.10.019

Lebullenger, R., Chenu, S., Rocherullé, J., Merdrignac-Conanec, O., Cheviré, F., Tessier, F., Bouzaza, A., Brosillon, S.: Glass foams for environmental applications. J. Non. Cryst. Solids. 356, 2562–2568 (2010). https://doi.org/10.1016/j.jnoncrysol.2010.04.050

Bernardo, E., Albertini, F.: Glass foams from dismantled cathode ray tubes. Ceram. Int. 32, 603–608 (2006). https://doi.org/10.1016/j.ceramint.2005.04.019

Mear, F., Yot, P., Cambon, M., Caplain, R., Ribes, M.: Characterisation of porous glasses prepared from Cathode Ray Tube (CRT). Powder Technol. 162, 59–63 (2006). https://doi.org/10.1016/j.powtec.2005.12.003

Rincón, A., Giacomello, G., Pasetto, M., Bernardo, E.: Novel ‘inorganic gel casting’ process for the manufacturing of glass foams. J. Eur. Ceram. Soc. 37, 2227–2234 (2017). https://doi.org/10.1016/j.jeurceramsoc.2017.01.012

Studart, A.R., Gonzenbach, U.T., Tervoort, E., Gauckler, L.J.: Processing Routes to Macroporous Ceramics: A Review. J. Am. Ceram. Soc. 89, 1771–1789 (2006). https://doi.org/10.1111/j.1551-2916.2006.01044.x

Romano, R.C.O., Pandolfelli, V.C.: Obtenção e propriedades de cerâmicas porosas pela técnica de incorporação de espuma. Cerâmica. 52, 213–219 (2006). https://doi.org/10.1590/S0366-69132006000200015

Bernardo, E., Cedro, R., Florean, M., Hreglich, S.: Reutilization and stabilization of wastes by the production of glass foams. Ceram. Int. 33, 963–968 (2007). https://doi.org/10.1016/j.ceramint.2006.02.010

M.. Tasserie, Y.. Bideau, P.. LAurent, A. Verdier, A new expanded material: optimization of the fabrication process., J. High Temp. Chem. Process. 1 (1992) 241–250.

Tasserie, M., Bideau, D., Rocherulle, J., Verdier, P.: Laurent, New expanded material based on industrial glass. I Effect of the quality of powders and their mixing on properties of the material. Verre. 6, 9–15 (1992)

Bernardo, E.: Micro- and macro-cellular sintered glass-ceramics from wastes. J. Eur. Ceram. Soc. 27, 2415–2422 (2007). https://doi.org/10.1016/j.jeurceramsoc.2006.10.003

Llaudis, A.S., Tari, M.J.O., Ten, F.J.G., Bernardo, E., Colombo, P.: Foaming of flat glass cullet using Si3N4 and MnO2 powders. Ceram. Int. 35, 1953–1959 (2009). https://doi.org/10.1016/j.ceramint.2008.10.022

Tasserie, M., Bideau, D., Verdier, P.: Y. Laurent, New expanded material based on industrial glass II. Role and effect of the amount of an expansive additive on the characteristics of the material, Verre 6, 103–107 (1992)

Mugoni, C., Montorsi, M., Siligardi, C., Andreola, F., Lancellotti, I., Bernardo, E., Barbieri, L.: Design of glass foams with low environmental impact. Ceram. Int. 41, 3400–3408 (2015). https://doi.org/10.1016/j.ceramint.2014.10.127

Arcaro, S., deOMaia, B.G., Souza, M.T.M.T., Cesconeto, F.R.F.R., Granados, L., deOliveira, A.P.N., DeOliveiraMaia, B.G., Souza, M.T.M.T., Cesconeto, F.R.F.R., Granados, L., DeOliveira, A.P.N.: Thermal Insulating Foams Produced From Glass Waste and Banana Leaves. Mater. Res. 19, 1064–1069 (2016). https://doi.org/10.1590/1980-5373-MR-2015-0539

de Moraes, E.G., Sangiacomo, L., Stochero, N.P., Arcaro, S., Barbosa, L.R., Lenzi, A., Siligardi, C., Novaes de Oliveira, A.P.: Innovative thermal and acoustic insulation foam by using recycled ceramic shell and expandable styrofoam (EPS) wastes. Waste Manag. 89, 336–344 (2019). https://doi.org/10.1016/j.wasman.2019.04.019

Teixeira, L.B., deOMaia, B.G., Arcaro, S., Sellin, N., de Oliveira, A.P.N.: Produção e caracterização de espumas vitrocristalinas a partir de resíduos sólidos. Matéria (Rio Janeiro) (2017). https://doi.org/10.1590/s1517-707620170004.0218

Teixeira, L.B., Fernandes, V.K., Maia, B.G.O., Arcaro, S., de Oliveira, A.P.N.: Vitrocrystalline foams produced from glass and oyster shell wastes. Ceram. Int. 43, 6730–6737 (2017). https://doi.org/10.1016/j.ceramint.2017.02.078

da Silva, L.L., Ribeiro, L.C.N., Santacruz, G., Arcaro, S., Alves, A.K., Bergmann, C.P.: Glass foams produced from glass and yerba mate (Ilex paraguarinensis) waste. FME Trans. 46, 70–79 (2018). https://doi.org/10.5937/fmet1801070L

Carvalho, P.E.R.: Espécies florestais brasileiras: recomendações silviculturais, potencialidades e uso da madeira. Embrapa/SPI, Brasília, DF (1994)

F. a. Santos, Uso das escamas da pinha da Araucaria angustifolia para biosorção de metais pesados de efluente industrial de galvanoplastia, Universidade Católica do Rio Grande do Sul, Porto Alegre, Brazil, 2007.

Vogel, H.: Viscosity of liquids. Phys. Z. 22, 645–646 (1921)

ASTM E112:12. Standard Test Methods for Determining Average Grain Size, West Conshohocken, PA, 2012.

ASTM D3576:98. Standard Test Method for Cell Size of Rigid Cellular Plastics, West Conshohocken, PA, 2015.

Colombo, P.: Conventional and novel processing methods for cellular ceramics. Trans. R. Soc. A Math. Phys. Eng. Sci Philos (2006). https://doi.org/10.1098/rsta.2005.1683

Kim, H.S., Kim, S., Kim, H.J., Yang, H.S.: Thermal properties of bio-flour-filled polyolefin composites with different compatibilizing agent type and content. Thermochim. Acta. 451, 181–188 (2006)

F.A. dos Santos, Uso das escamas da pinha da araucaria angustifolia para biosorção de metais pesados de efluente industrial de galvanoplastia. Dissertação (Mestrado Engenharia e Tecnologia de Materiais), Universidade Católica do Rio Grande do Sul, Porto Alegre, 2007.

D.R. Mulinari, G. Luís, J.P. Silva, L. Caetano, P. Silva, D.D.E. Química, F. De Engenharia, Q. De Lorena, L. Sp, Adsorção de íons dicromato nos compósitos celulose/ZrO2 .nH2 o preparados pelos métodos da precipitação convencional e em solução homogênea, 29 (2006) 496–500.

L.B. Teixeira, B. Goulart, D.O. Maia, S. Arcaro, N. Sellin, A. Pedro, N. De Oliveira, Produção e caracterização de espumas vitrocristalinas a partir de resíduos sólidos Production and characterization of vitrocrystalline foams from solid wastes, (2017).

Petersen, R.R., König, J., Yue, Y.: The viscosity window of the silicate glass foam production. J. Non. Cryst. Solids. 456, 49–54 (2017). https://doi.org/10.1016/j.jnoncrysol.2016.10.041

Collishaw, P.G., Evans, J.R.G.: An assessment of expressions for the apparent thermal conductivity of cellular materials. J. Mater. Sci. 29, 486–498 (1994). https://doi.org/10.1007/BF01162512

Wang, Q., Li, Y., Li, S., Xiang, R., Xu, N., OuYang, S.: Effects of critical particle size on properties and microstructure of porous purging materials. Mater. Lett. 197, 48–51 (2017). https://doi.org/10.1016/j.matlet.2017.03.129

Vakifahmetoglu, C., Semerci, T., Soraru, G.D.: Closed porosity ceramics and glasses. J. Am. Ceram. Soc. 103, 2941–2969 (2020). https://doi.org/10.1111/jace.16934

König, J., Petersen, R.R., Yue, Y.: Influence of the glass particle size on the foaming process and physical characteristics of foam glasses. J. Non. Cryst. Solids. 447, 190–197 (2016). https://doi.org/10.1016/j.jnoncrysol.2016.05.021

König, J., Petersen, R.R., Yue, Y.: Influence of the glass–calcium carbonate mixture’s characteristics on the foaming process and the properties of the foam glass. J. Eur. Ceram. Soc. 34, 1591–1598 (2014). https://doi.org/10.1016/j.jeurceramsoc.2013.12.020

Ducman, V., Kovačević, M.: The Foaming of Waste Glass. Key Eng. Mater. 132–136, 2264–2267 (1997). https://doi.org/10.4028/www.scientific.net/KEM.132-136.2264

Méar, F., Yot, P., Cambon, M., Ribes, M.: The characterization of waste cathode-ray tube glass. Waste Manag. 26, 1468–1476 (2006). https://doi.org/10.1016/j.wasman.2005.11.017

P.A.M. dos Santos, A.V. Priebbnow, S. Arcaro, R.M. da Silva, D.A.R. Lopez, A.D.A.L. Rodriguez, Sustainable Glass Foams Produced from Glass Bottles and Tobacco Residue, Mater. Res. 22 (2018). doi:10.1590/1980–5373-mr-2018–0452.

Zhu, M., Ji, R., Li, Z., Wang, H., Liu, L.L., Zhang, Z.: Preparation of glass ceramic foams for thermal insulation applications from coal fly ash and waste glass. Constr. Build. Mater. 112, 398–405 (2016). https://doi.org/10.1016/j.conbuildmat.2016.02.183

Zilli, M., Arcaro, S., Cesconeto, F.R., De Oliveira Maia, B.G., Pereira, F.R., Novaes De Oliveira, A.P.: Production and characterisation of ceramic foams from industrial solid waste. Eng. Trans Chem (2015). https://doi.org/10.3303/CET1543298

Acknowledgements

The authors would like to thank the Coordination for the Improvement of Higher Education Personnel (CAPES) of Brazilian institutions, the National Council for Scientific and Technological Development (CNPq) for financing this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Stochero, N.P., de Souza Chami, J.O.R., Souza, M.T. et al. Green Glass Foams from Wastes Designed for Thermal Insulation. Waste Biomass Valor 12, 1609–1620 (2021). https://doi.org/10.1007/s12649-020-01120-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01120-3