Abstract

A pilot scale biorefinery platform for the treatment of agro-waste and the production of hydrogen, methane and volatile fatty acids was studied in real environment. The system adopted was a two stage anaerobic process where hydrogen and volatile fatty acids were produced in the first phase (fermentation) and methane in the second one (digestion). The study demonstrated the possibility to produce a biogas composed by hydrogen and methane (10% and 55%, respectively) while recovering volatile fatty acids. The yield for acids production was equivalent to 0.13 gVFA/gTVS (as COD) with acetate and butyrate as dominant observed species.

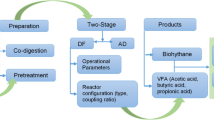

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

The bioeconomy approach requests for multi-feedstock and multi-purpose biorefinery platforms where agro-waste are valorised via the production of biobased products. In this paper we present the results deriving from a large pilot scale study where the conventional anaerobic digestion process was modified into a two-step process for the concurrent production of hydrogen volatile fatty acids and methane from cattle manure and grass silage.

Introduction

The agricultural wastes represent nowadays a consistent amount of the waste generated in EU achieving at least 50% of the fresh harvested crops [1]. In this scenario, the Circular Economy and the Bio-economy concepts intersect in their common aims to add value to biological waste and residues [2] through the smart management of agro-waste and their conversion into biobased products and biofuels avoiding harmful consequences on soils, water and air quality [3].

These agro-waste are mainly animal and vegetal residues which cannot be further processed into food or feed and need some kind of treatment to reduce their environmental burden.

These materials can however be considered as feedstocks for a bioeconomy approach and the production of biobased materials and biofuels rather than a mere waste [1, 4].

Today, at European level, these materials are treated mainly via anaerobic digestion: anaerobic digestion is in fact largely applied in the rural context because of its capability of stabilizing these organic residual matter while recovering biogas, thus renewable energy, and a renewable fertilizer, the digestate [5, 6]. Because of these specific features, more than 15,000 farmbased AD plants are in operation in Europe [7].

Considering this scenario, we applied a multi-feedstock and multi-purpose biorefinery derived from the typical anaerobic digestion process [8] in order to recover an interesting biofuel like bio-hythane, a mix of hydrogen and methane [9], and bio-based chemicals, like volatile fatty acids [10, 11] as precursors of polyhydrxyalkanoates [12, 13]. In fact, it is reported that producing biobased molecules from agro-waste instead of biofuels creates double economic added value [14].

This will be a fundamental step to drive society into a real and effective bioeconomy scenario; nowadays, in fact, only a small part of produced chemicals are of biobased origin: about 3% of chemicals [15], and about 2% of polymers [16] are originated from biological feedstock.

One important aspect to be considered is that agro-waste feedstock is seasonal and largely variable in composition and characteristics, therefore a robust biorefinery platform is needed to exploit such a feedstock [8].

Taking into account this scenario, in this paper we present the results of a pilot scale study where we considered a platform able to convert livestock effluents and grass silage into hydrogen, methane, and volatile fatty acids (VFA) within the same bioprocess: 2 years of studies demonstrated the reliability and robustness of the proposed approach.

Materials and Methods

The experimental activity took place in a pilot scale platform hosted at “La Torre” farm nearby a full-scale anaerobic digestion plant located in Isola della Scala, Verona, north-east Italy, which treats around 150 tons per day of agricultural waste in two anaerobic digesters with a size of 1 MW each one.

Figure 1 shows a graphical sketch of the general approach proposed: here livestock effluents and grass silage are transformed into biofuels and biobased products like VFAs or PHA.

Pilot Scale Plant Description

The biorefinery plant could be divided into three main areas:

-

Acidogenic fermentation for the Volatile fatty Acids production (VFAs);

-

Selection of the Storing PHA biomass and Accumulation of PHAs starting from the liquid phase of the fermentate;

Anaerobic Digestion, for the biogas and digestate production using the solid part of the fermentation effluent.

The external storage tank was equipped with a weighing system for the control of the amount of material fed to the system. A mixer (diameter 1.3 m; height 1.8 m; 40 RPM) was used to homogenize the substrates. If necessary, the rotation system of the mixer could be inverted to increase the homogenization performances. A special centrifuge pump (Vidotto Dissipatori, model TM451) was used to grind and pump the feedstock material. The grinder and the pump were connectedto the fermenter through a series of pipes (diameter 80 mm).The fermentation unit was a 4 m3 unit fed every day with 1 m3 of mixed feedstock from the external tank. The fermenter was temperature controlled by three electrical resistances (3 kW/each one) connected to a PT100 temperature probe with a tolerance of ± 0.1 °C with respect to the set temperature. The fermenter can operate both in mesophilic and thermophilic conditions. In this experimentation we operated at a temperature of 35 °C.

The operative conditions applied to the reactors are shown in Table 1. The fermentation process operated in mesophilic conditions with an average organic loading rate of 18 KgCOD/m3day and a hydraulic retention time of 4 days to improve the conversion of particulate COD into VFA (volatile fatty acids) for the subsequently production of PHA.

The anaerobic digester (1 m3 volume) was fed every day with 0.2 m3 of solid substrate coming from the separation of the fermentative product by means of a screw press unit (Type SEPBIOH11502, WAMGROUP) for the solid/liquid separation of anaerobic fermentate. The screw press treatment capacity is 5 m3/h. The anaerobic digester worked under mesophilic conditions with an organic loading rate of 3.6 kgCOD/m3day and hydraulic retention time of 25 days.

The liquid fraction obtained by screw-press separation (around 0.8 m3 per day) was sent through a screening unit (BAGONE-S) to remove the suspended solids and clarify the liquid which contains the VFAs.

The fermented liquid is then sent to two Sequencing Batch Reactors where a mixed microbial culture accumulates poly-hydroxy-alkanoates (PHA) (this part is not discussed in this paper) [17].

Analysis

The effluents of the reactors were monitored one or more times per week throughlaboratory analysis of the parameters total and volatile solids (TS and TVS), chemical oxygen demand (COD), Total Kjeldahl Nitrogen (TKN) and total phosphorus (TP) concentrations. The process stability parameters, namely pH, volatile Fatty Acid (VFA) content and speciation, total and partial alkalinity and ammonia (NH3–N) were checked daily. All the analyses, except for volatile fatty acids (VFAs), were carried out in accordance with the standard methods for water and wastewater analysis [18]. When needed, protocols were modified to deal with semi-solid samples.

Alkalinity was measured using a Crison pH probe by titration with hydrochloric acid 0.12 N. The partial alkalinity was calculated by titration till pH 5.75, and total alkalinity was measured at pH of 4.3 [19]. The PO4-P determination was carried out using an ion chromatography system (Dionex ICS-900 with AS14 column), with a previous centrifugation of samples and filtration through membrane filters (Whatman, 0.45 μm). For VFA determination an ion chromatography system (Dionex ICS 1100 with AS23 column) was employed [20]. Samples were previously filtered at 0.20 μm. Biogas flowrate was measured by acidic water displacement during batch trials, and with automatic gas counters during continuous trials while biogas composition in terms of CH4 and CO2 concentrations was measured using a portable gas monitor. The model adopted for the measure was the GAS Counter BIOGAS 5000. As pretreatment of the biogas to analyse, an hydraulic guard has been established to remove as H2S as possible.

Hydrogen content was determined by a gas-chromatograph (GC Agilent Technology 6890 N) equipped with the column HP-PLOT MOLESIEVE, 30 × 0.53 mm ID × 25 μm film, using a thermal conductivity detector and argon as gas carrier [9].

Results and Discussion

Feedstock and Effluents Characteristics

The feedstock fed to the biorefinery platform was a mix of cattle liquid manure and grass silage. Water was added to match up the desired final volume in order to keep the total solid content below 8% so to reduce viscosity and preventing pipes clogging. As an average, water was 30% of the total feeding mix, or 300 L per day.

The raw material, at a flowrate of 1 ton per day, was grinded through a special dedicated pump and fed to a 4 m3 mesophilic anaerobic fermenter, where hydrogen and volatile fatty acids (VFAs) were produced.

The characteristics of the fed streams are reported in Table 2, where the minimum and maximum observed values are reported. Characteristics of the two materials are in line with typical figures reported in literature [6].

The typical concentrations in terms of total and volatile solids along the process units are then reported in Table 3.

The characteristics of the fermenter effluent obtained applying the experimental conditions reported above (Table 1) are shown in Table 4.

During the anaerobic fermentation process 1.68 m3/day of biogas, mainly composed by CO2, were produced. Hydrogen content, despite the favorable conditions in terms of pH at 5.5, was low, typically < 10%, probably because of the high level of ammonia in the reactor [8]. Other studies where similar feedstocks were treated, reported hydrogen levels around 25–35% [21, 22] in the off gas of the fermentation unit.

The fermenter effluent showed an average solid concentration around 7%, 55% of which being volatile, and a high soluble COD concentration, up to 37 gCOD/L. Regarding the VFAs production, only 8–10 gCOD/L were observed. It could be observed that most of the soluble molecules were not fermented into short chain compounds as already observed by other authors [10, 23].

As for volatile fatty acids production, Fig. 2 shows the observed VFAs concentrations which passed from initial concentrations around 4 gCOD/L to concentrations in the range 8–10 gCOD/L. Clearly, during the start-up phase when livestock manure was the dominant substrate, the VFA yield was low (YVFA/COD 0.06 gCODVFA/gTVS) while in the following experimental periods, when grass silage, thus carbohydrates, was abundant, yields were in the range 0.11–0.13 gCODVFA/gTVS.

These values are in line with typical yields reported in literature for similar substrates: Cavinato et al. [10] where the substrate used was corn straw hydrolisated with a pH value of 5.5, HRT of 4 days and kept in mesophilic conditions (37 °C). The reported yields were in the range 0.06–0.18 gCODVFA/gTVS with typical values between 0.11 and 0.15 gCODVFA/gTVS. In literature yields as high as 0.2–0.3 gCODVFA/gTVS were also reported when cow manure and maize silage were fed to a system working at pH 5.5, with a HRT of 4 days in mesophilic conditions (37 °C). [24]. If compared with yields obtained through the fermentation of other residual organic substrates such as wastewater sludge (0.2–0.3 gCOD/gTVS) [25] and food waste (0.40–0.50 gCOD/gTVS), these values are in general low because of the high presence of lignin in the substrate that negatively affect the conversion of the feedstock into VFAs. In fact, reported VFAs productions for wastewater sludge are in the range 0.2–0.3 gCODVFA/gTVS while in the case of food waste yields can be as high as 0.40–0.50 gCODVFA/gTVS [26, 27]. In this case VFAs represent up to 60–70% of the soluble COD detected in the system [23, 26].

With specific reference to VFAs concentrations, Table 5 summarizes the typical concentrations observed for the different short chain VFAs, from C2 to C6, in steady state conditions.

Acetic acid was absolutely dominant, representing more than 80% of the VFAs mixture. This can be the case when short HRT are applied: in fact, other studies showed that both acetic and butiryc acid are dominant and typically show similar concentrations when HRT is increased from 2 to 6 days [10]. Moreover, it should be recalled that due to the process pH, around 5.5, acetic and butyric acids coexist, while butyric acid is dominant only for pH around 6 [28].

Anaerobic fermentate underwent to a solid/liquid separation process. The solid phase effluent from the screw-press, equivalent in volume to 0.2 m3, was fed to a mesophilic anaerobic digester.

The characteristics of this stream are shown in Table 3.

The biogas production was equivalent to 15 m3/day for a specific biogas production equivalent of 0.35 m3/kgVS, a typical value for these materials [29].

As for the characteristics of the gas effluents, Table 6 reports the values of the concentrations of H2, CH4 and CO2, observed in biogas from both the fermentation and anaerobic digester units. The first process, in particular, achieved high concentration of CO2 with little traces of CH4 and H2 while the AD reached typical value of around 54% of CH4 and 46% of CO2.

Digestate characteristics are reported in Table 7. These can be considered typical values for a digestate originated from agro-waste [30, 31]. In particular, the total solids concentrations were around 8%, total nitrogen and phosphorus concentrations were around 3 gN/L and 1.2 gP/L, respectively, while ammonium and phosphate were at concentrations around 1.5 gN/L and 0.6 g/L, respectively.

Mass Balance of the System

Figure 3 reports the mass balance of the biorefinery platform.

Around 1000 kg of agro-waste, resulting in 74 kg of dry matter, are mixed and grinded in order to better homogenize the feedstock and feed the anaerobic fermenter.

Then a solid/liquid separation unit is used to screen the liquid fraction in whicht the volatile fatty acids are solubilized. The obtained solid stream (0.2 m3/day) results in around 40 kg/day of the original dry matter, while the residual part (32 kg/day) remained in the liquid stream (0.8 m3/day).

The solid fraction is then used for feeding the anaerobic digester resulting in 15.

The separated solid part then underwent to anaerobic digestion and originated 15 m3/day of biogas.

Considering the liquid stream, 7 kg VFA were produced every day. As for nutrients, nitrogen was mainly present in the liquid phase (84% of the influent nitrogen), while phosphorus was equally distributed in the liquid and solid streams. These data are in line with previous studies on nutrients partitioning in digestate [32].

Conclusions

A biorefinery platform for the treatment of agro-waste was implemented at pilot scale in a real farm environment: biofuels (methane and hydrogen) and VFAs were the main products.

The highest overall yield reached was 0.13 gCODVFA/gTVS, which is similar to the value observed in previous studies for maize silage and manure (0.15 gCOD/gTVS).

The typical concentration for VFA were in the range 10 gCOD/L. VFA were 21–27% of the total soluble COD (sCOD) indicating that complex organic molecules were only partially hydrolysed to short chian fatty acids. The nutrients recovered with digestate can be used for agricultural purposes, while the overall production of hydrogen and methane was 10% and 12% in the fermentation unit and less than 1% and 54% in the anaerobic digester, respectively..

References

Gontard, N., Sonesson, U., Birkved, M., Majone, M., Bolzonella, D., Celli, A.: A research challenge vision regarding management of agricultural waste in a circular bio-based economy. Crit. Rev. Environ. Sci. Technol. 48(6), 614–654 (2018)

European Commission: A Sustainable Bioeconomy for Europe: Strengthening the Connection Between Economy, Society and the Environment. Research and Innovation, Brussels (2018)

Fischer, R., Van de Vliert, E.: Does climate undermine subjective well-being? A 58-nation study. Personal. Soc. Psychol. Bull. 37(8), 1031–1041 (2011)

Ragauskas, A. J., Williams, C. K., Davison, B. H., Britovsek, G., Cairney, J., Eckert, C. A.,…,& Mielenz, J. R.: The path forward for biofuels and biomaterials. Science, 311(5760), 484–489 (2006)

Ward, A.J., Hobbs, P.J., Holliman, P.J., Jones, D.L.: Optimisation of the anaerobic digestion of agricultural resources. Bioresour. Technol. 99(17), 7928–7940 (2008)

Garcia, N.H., Mattioli, A., Gil, A., Frison, N., Battista, F., Bolzonella, D.: Evaluation of the methane potential of different agricultural and food processing substrates for improved biogas production in rural areas”. Renew. Sustain. Energy Rev. 112, 1–10 (2019)

EBA European Biogas Association.: Biomethane & Biogas Report 2015. E.B.A. (2015)

Fava, F., Totaro, G., Diels, L., Reis, M., Duarte, J., Beserra Carioca, O., Sommer Ferreira, B.: Biowaste biorefinery in Europe: opportunities and research & development needs. New Biotechnol. 32(1), 100–108 (2015)

Bolzonella, D., Battista, F., Cavinato, C., Gottardo, M., Micolucci, F., Lyberatos, Gottardo M., Pavan, P.: Recent developments in biohythane production from household food wastes: a review. Bioresour. Technol. 257, 311–319 (2018)

Cavinato, C., Da Ros, C., Pavan, P., Bolzonella, D.: Influence of temperature and hydraulic retention on the production of volatile fatty acids during anaerobic fermentation of cow manure and maize silage. Biores. Technol. 223, 59–64 (2017)

Cavinato, C., Frison, N., Herrero, N., Gottardo, M., Da Ros, C., Strazzera, G.,…,& Bolzonella, D.: Volatile fatty acids production from organic waste for biorefinery platforms. In 5th International Conference on Sustainable Solid Waste Management (2017)

Domingos, J.M.B., Martinez, G.A., Scoma, A., Fraraccio, S., Kerckhof, F.M., Boon, N., Reis, M.A.M., Fava, F., Bertin, L.: Effect of operational parameters in the continuous anaerobic fermentation of cheese whey on titers, yields, productivities, and microbial community structures. ACS Sustain. Chem. Eng. 5(2), 1400–1407 (2017)

Domingos, J.M.B., Puccio, S., Martinez, G.A., Amaral, N., Reis, M.A.M., Bandini, S., Fava, F., Bertin, L.: Cheese whey integrated valorisation: production, concentration and exploitation of carboxylic acids for the production of polyhydroxyalkanoates by a fed-batch culture. Chem. Eng. J. 336, 47–53 (2018)

Kiran, E.U., Trzcinski, A.P., Liu, Y.: Platform chemical production from food wastes using a biorefinery concept. J. Chem. Technol. Biotechnol. 90(8), 1364–1379 (2015)

Fiorentino, G., Ripa, M., Ulgiati, S.: Chemicals from biomass: technological versus environmental feasibility: a review. Biofuels Bioprod. Biorefin. 11(1), 195–214 (2017)

Aeschelmann, F., Carus, M.: Biobased Building Blocks and Polymers: Global Capacities and Trends 2016–2021. Nova-Institüt, Hürth (2017)

Valentino, F., Karabegovic, L., Majone, M., Morgan-Sagastume, F., Werker, A.: Polyhydroxyalkanoate (PHA) storage within a mixed-culture biomass with simultaneous growth as a function of accumulation substrate nitrogen and phosphorus levels. Water Res. 77, 49–63 (2015)

APHA/AWWA/WEF: Standards Methods for the Examination of Water and Wastewater, 20th edn. United Book Press Inc., Baltimore (1998)

Ripley, L.E., Boyle, W.C., Converse, J.C.: Improved alkalimetric monitoring for anaerobic digestion of high-strength wastes. Water Pollut. Control Fed 58, 406–411 (1986)

Raposo, F., Borja, R., Cacho, J.A., Mumme, J., Mohedano, Á.F., Battimelli, A., Bolzonella, D., Schuit, A.D., Noguerol-Arias, J., Frigon, J., Peñuela, G.A., Muehlenberg, C., Sambusiti, C.: Harmonization of the quantitative determination of volatile fatty acids profile in aqueous matrix samples by direct injection using gas chromatography and high-performance liquid chromatography techniques: multi-laboratory validation study. J. Chromatogr. A 1413, 94–106 (2015)

Trad, Z., Akimbomi, J., Vial, C., Larroche, C., Taherzadeh, M.J., Fontaine, J.P.: Development of a submerged anaerobic membrane bioreactor for concurrent extraction of volatile fatty acids and biohydrogen production. Biores. Technol. 196, 290–300 (2015)

Xu, S., Zhu, J., Meng, Z., Li, W., Ren, S., Wang, T.: Hydrogen and methane production by co-digesting liquid swine manure and brewery wastewater in a two-phase system. Biores. Technol. 293, 122041 (2019)

Moretto, G., Valentino, F., Pavan, P., Majone, M., Bolzonella, D.: Optimization of urban waste fermentation for volatile fatty acids production. Waste Manag. 1(92), 21–29 (2019)

Li, Y., Xu, H., Hua, D., Zhao, B., Mu, H., Jin, F., Meng, G., Fang, X.: Two-phase anaerobic digestion of lignocellulosic hydrolysate: Focusing on the acidification with different inoculum to substrate ratios and inoculum sources. Sci Total Environ. 699, 134226 (2019)

Bolzonella, D., Fatone, F., Pavan, P., Cecchi, F.: Anaerobic fermentation of organic municipal solid wastes for the production of soluble organic compounds. Ind. Eng. Chem. Res. 44(10), 3412–3418 (2005)

Valentino, F., Gottardo, M., Micolucci, F., Pavan, P., Bolzonella, D., Rossetti, S., Majone, M.: Organic fraction of municipal solid waste recovery by conversion into added-value polyhydroxyalkanoates and biogas. ACS Sustain.Chem. Eng. 6(12), 16375–16385 (2018)

Yin, J., Wang, K., Yang, Y., Shen, D., Wang, M., Mo, H.: Improving production of volatile fatty acids from food waste fermentation by hydrothermal pretreatment. Biores. Technol. 171, 323–329 (2014)

Zhang, C., Yang, H., Yang, F., Ma, Y.: Current progress on butyric acid production by fermentation. Curr. Microbiol. 59(6), 656–663 (2009)

Giuliano, A., Bolzonella, D., Pavan, P., Cavinato, C., Cecchi, F.: Co-digestion of livestock effluents, energy crops and agro-waste: feeding and process optimization in mesophilic and thermophilic conditions. Biores. Technol. 128, 612–618 (2013)

Bolzonella, D., Fatone, F., Gottardo, M., Frison, N.: Nutrients recovery from anaerobic digestate of agro-waste: techno-economic assessment of full scale applications. J. Environ. Manage. 216, 111–119 (2018)

Battista, F., Bolzonella, D.: Exploitation of Solar Energy for Ammonium Sulfate Recovery from Anaerobic Digestate of Different Origin. Waste and Biomass Valorization (2019)

Frischmann, P.: Enhancement and treatment of digestates from anaerobic digestion. A review of enhancement techniques, processing options and novel digestate products Project code: OMK006-002 Research date: Feb. (2012)

Acknowledgements

The authors acknowledge financial support from Project NoAW: No Agro-Waste-Innovative approaches to turn agricultural waste into ecological and economic assets (http://noaw2020.eu/). This project has received funding from the European Union’s Horizon 2020 research and innovation programme under Grant Agreement No 688338. The authors acknowledge the Agricultural Society “La Torre” for the support given during the experimentation period.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Righetti, E., Nortilli, S., Fatone, F. et al. A Multiproduct Biorefinery Approach for the Production of Hydrogen, Methane and Volatile Fatty Acids from Agricultural Waste. Waste Biomass Valor 11, 5239–5246 (2020). https://doi.org/10.1007/s12649-020-01023-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01023-3