Abstract

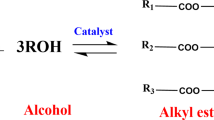

A new transesterification reactor, operating in continuous mode, has been designed, made and tested experimentally in order to produce a biodiesel from rapeseed oil. This reactor is an alternative solution to the batch system existing in the industry. It is composed of three-dimensional serpentine geometry (S-3D). The flow in this geometry is laminar, Reynolds number is less than 360. However the particle trajectories are completely erratic due to the geometry perturbations. This type of flow is called chaotic flow. The reactor ensures the mixing of reagents by the effects of inertia of the movement created in the flow by the chaotic advection. The experiments were conducted with a methanol / oil molar ratio of 6:1 and a KOH concentration of 1 wt%. Four oil mass flow rates were tested (1, 2, 3 and 4 g/s) in combination with four temperature levels (40, 50, 60 and 70 °C). The results show a very high conversion of oil to biodiesel. The physical and chemical properties of biodiesel such as viscosity, flash point, and cetane number comply with the international standards (ASTM D6751 and EN 14214). In addition, despite its compactness, the reactor is capable of continuously producing 13.5 kg/h of biodiesel thanks to the use of a chaotic mixer-reactor. The reaction time was reduced from 2 h in the batch system to 6 min.

Graphic Abstract

Similar content being viewed by others

References

Cárdenas, M.D., Armas, O., Mata, C., Soto, F.: Performance and pollutant emissions from transient operation of a common rail diesel engine fueled with different biodiesel fuels. Fuel 185, 743–776 (2016)

Yusuf, N.N., Kamarudin, S.K., Yaakub, Z.: Overview on the current trends in biodiesel production. Energy Convers. Manag. 52(7), 2741–2751 (2011)

Ma, F., Hanna, M.A.: Biodiesel production: a review. Bioresour. Technol. 70, 1–15 (1999)

Meher, L.C., Vidya Sagar, D., Naik, S.N.: Technical aspects of biodiesel production by transesterification—a review. Renew. Sustain. Energy Rev. 10, 248–268 (2006)

Rathore, V., Newalkar, B.L., Badoni, R.: Processing of vegetable oil for biofuel production through conventional and non-conventional routes. Energy Sustain. Dev. 31, 24–49 (2016)

Baskar, G., Aiswarya, R.: Trends in catalytic production of biodiesel from various feedstocks. Renew. Sustain. Energy Rev. 57, 496–504 (2016)

Kumar, A., Shukla, S. K., Tierkey, J. V.: A review of research and policy on using different biodiesel oils as fuel for C.I. engine. Energy Proc. 90, 292–304 (2016)

Delavari, A., Halek, F., Amini, M.: Continuous biodiesel production in a helicoidal reactor using ultrasound-assisted transesterification reaction of waste cooking oil. Clean Technol. Environ. Policy 17, 273–279 (2017)

Maulidiyah, N.M., Fatma, F., Natsir, M., Wibowo, D.: Characterization of methyl ester compound of biodiesel from industrial liquid waste of crude palm oil processing. Anal. Chem. Res. 12, 1–9 (2017)

Issariyakul, T., Dalai, A.K.: Biodiesel from vegetable oils. Renew. Sustain. Energy Rev. 31, 446–471 (2014)

Phan, A.N., Phan, T.M.: Biodiesel production from waste cooking oils. Fuel 87(17), 3490–3496 (2008)

Agarwal, A.K.: Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 33(3), 233–271 (2007)

Koc, A.B.: Ultrasonic monitoring of glycerol settling during transesterification of soybean oil. Bioresour. Technol. 100(1), 19–24 (2009)

Balat, M., Balat, H.: A critical review of bio-diesel as a vehicular fuel. Energy Convers. Manag. 49, 2727–2741 (2008)

Tarabet, L., Loubar, K., Lounici, M.S., Hanchi, S., Tazerout, M.: Eucalyptus biodiesel as an alternative to diesel fuel: preparation and tests on DI diesel engine. BioMed Res. Int. 2012, 1–8 (2012)

Graboski, M.S., McCormick, R.L.: Combustion of fat and vegetable oil derived fuels in diesel engines. Prog. Energy Combust. Sci. 24(2), 125–164 (1998)

Srivastava, P., Verma, M.: Methyl ester of karanja oil as an alternative renewable source energy. Fuel 87(8), 1673–1677 (2008)

Srivastava, A., Prasad, R.: Triglycerides-based diesel fuels. Renew. Sustain. Energy Rev. 4(2), 111–133 (2000)

Sharma, Y.C., Singh, B.: Development of biodiesel: current scenario. Renew. Sustain. Energy Rev. 13, 1646–1651 (2009)

Demirbas, A.: Progress and recent trends in biodiesel fuels. Energy Convers. Manag. 50, 14–34 (2009)

Leung, D.Y., Wu, X., Leung, M.K.: A review on biodiesel production using catalyzed transesterification. Appl. Energy 87, 1083–1095 (2010)

Verma, P., Sharma, M.P., Dwivedi, G.: Impact of alcohol on biodiesel production and properties. Renew. Sustain. Energy Rev. 56, 319–333 (2016)

Peterson, C.L., Cook, J.L., Thompson, J.C., Taberski, J.S.: Continuous flow biodiesel production. Appl. Eng. Agric. 18(1), 5–11 (2002)

Thompson, J.C., He, B.B.: Biodiesel production using static mixers. Trans. Am. Soc. Agric. Biol. Eng. 50, 161–165 (2007)

Boucher, M.B., Weed, C., Leadbeater, N.E., Wilhite, B.A., Stuart, J.D., Parnas, R.S.: Pilot scale two-phase continuous flow biodiesel production via novel laminar flow reactor-separator. Energy Fuels 23, 2750–2756 (2009)

Somnuk, K., Smithmaitrie, P., Prateepchaikul, G.: Two-stage continuous process of methyl ester from high free fatty acid mixed crude palm oil using static mixer coupled with high-intensity of ultrasound. Energy Convers. Manag. 75, 302–310 (2013)

Sungwornpatansakul, P., Hiroi, J., Nigahara, Y., Jayasinghe, T.K., Yoshikawa, K.: Enhancement of biodiesel production reaction employing the static mixing. Fuel Process. Technol. 116, 1–8 (2013)

Mostafaei, M., Ghobadian, B., Barzegar, M., Banakar, A.: Optimization of ultrasonic assisted continuous production of biodiesel using response surface methodology. Ultrason. Sonochem. 27, 54–61 (2015)

Likozar, B., Pohar, A., Levec, J.: Transesterification of oil to biodiesel in a continuous tubular reactor with static mixers: Modelling reaction kinetics, mass transfer, scale-up and optimization considering fatty acid composition. Fuel Process. Technol. 142, 326–336 (2016)

Somnuk, K., Prasit, T., Prateepchaikul, G.: Effects of mixing technologies on continuous methyl ester production: Comparison of using plug flow, static mixer, and ultrasound clamp. Energy Convers. Manag. 140, 91–97 (2017)

Breccia, A., Esposito, B., Fratadocchi, G.B., Fini, A.: Reaction between methanolband commercial seed oils under microwave irradiation. J. Microw. Power Electromagn. Energy 34, 3–8 (1999)

Barnard, T.M., Leadbeater, N.E., Boucher, M.B., Stencel, L.M., Wilhite, B.A.: Continuous-flow preparation of biodiesel using microwave heating. Energy Fuels 21, 1777–1781 (2007)

Encinar, J.M., González, J.F., Martínez, G., Sánchez, N., Pardal, A.: Soybean oil transesterification by the use of a microwave flow system. Fuel 95, 386–393 (2012)

Nomanbhay, S., Yin, O.M.: A review of microwave-assisted reactions for biodiesel production. Bioengineering 4(2), 57 (2017)

Motasemi, F., Ani, F.N.: A review on microwave-assisted production of biodiesel. Renew. Sustain. Energy Rev. 16, 4719–4733 (2012)

Choedkiatsakul, I., Ngaosuwan, K., Assabumrungrat, S., Mantegna, S., Cravotto, G.: Biodiesel production in a novel continuous flow microwave reactor. Renew. Energy 83, 25–29 (2015)

Kobayashi, J., Mori, Y., Kobayashi, S.: Multiphase organic synthesis in microchannel reactors. Chem. Asian J. 1, 22–35 (2006)

Canter, N.: Making biodiesel in a microreactor. Tribol. Lubr. Technol. 62, 15–17 (2006)

Sun, J., Ju, J., Ji, L., Zhang, l., Xu, Z.: Synthesis of biodiesel in capillary microreactors. Ind. Eng. Chem. Res. 47, 1398-1403 (2008)

Wen, Z., Yu, X., Tu, S.T., Yan, J., Dahlquist, E.: Intensification of biodiesel synthesis using zigzag micro-channel reactors. Bioresour. Technol. 100(12), 3054–3060 (2009)

Amaraporn, K., Siriluck, P., Attasak, J.: Transesterification of palm oil in a microtube reactor. Can. J. Chem. Eng. 94, 859 (2016)

Madhawan, A., Arora, A., Das, J., Kuila, A., Sharma, V.: Microreactor technology for biodiesel production: a review. Biomass Convers. Biorefinery 8, 485 (2018)

Tiwari, A., Rajesh, V.M., Yadav, S.: Biodiesel production in micro-reactors: a review. Energy Sustain. Dev. 43, 143–161 (2018)

Dai, J.-Y., Li, D.-Y., Zhao, Y.-C., Xiu, Z.L.: Statistical optimization for biodiesel production from soybean oil in a microchannel reactor. Ind. Eng. Chem. Res. 53(22), 9325–9330 (2014)

Kelkar, M. A., Gogate, P. R., Pandit, A. B.: Cavitation as a novel tool for process intensification of biodiesel synthesis. Proceedings of the 6th International Symposium on Catalysis in Multiphase Reactors. Pune, India (2007)

Ashish, V.M., Parag, R.G., Gabriel, V., Paulo, F., Reinaldo, G.: Intensification of biodiesel production using hydrodynamic cavitation based on high speed homogenizer. Chem. Eng. J. 316, 751–757 (2017)

Atadashi, I.M., Aroua, M.K., Abdul Aziz, A.R., Sulaiman, N.M.: High quality biodiesel obtained through membrane technology. J. Membr. Sci. 421–422, 154–164 (2012)

Peigang Cao, A.Y.: Kinetics of canola oil transesterification in a membrane reactor. Ind. Eng. Chem. Res. 48(5), 2533–2541 (2009)

Lijing, G., Wei, X., Guomin, X.: Modeling of biodiesel production in a membrane reactor using solid alkali catalyst. Chem. Eng. Process. 122, 122–127 (2017)

Yu, X.H., Wen, Z.Z., Lin, Y., Tu, S.T., Wang, Z.D., Yan, J.Y.: Intensification of biodiesel synthesis using metal foam reactors. Fuel 89, 3450–3456 (2010)

Kouzu, M., Fujimori, A., Fukakusa, R., Satomi, N., Yahagi, S.: Continuous production of biodiesel by the CaO-catalyzed transesterification operated with continuously stirred tank reactor. Fuel Process. Technol. 181, 311–317 (2018)

Aref, H.: Stirring by chaotic advection. J. Fluid Mech. 143, 1–21 (1984)

Lasbet, Y., Auvity, B., Castelain, C., Peerhossani, H.: A chaotic heat-exchanger for PEMFC cooling applications. J. Power Sour. 156, 114–118 (2006)

Saatdjiana, E., Rodrigob, A.J., Motab, J.P.: Stokes flow heat transfer in an annular, rotating heat exchanger. Appl. Therm. Eng. 31(8–9), 1499–1507 (2011)

Saatdjian, E., Rodrigo, A.J., Mota, J.P.: A study of mixing by chaotic advection in two three-dimensional open flows. Chem. Eng. Sci. 81, 179–190 (2012)

Hosseinalipour, S.M., Tohidi, A., Shokrpour, M.: Introduction of a chaotic dough mixer, part b: Chaotic behavior and mixing performance. Life Sci. J. 10, 414–422 (2013)

Habchi, C., Harison, J.L., Russeil, S., Bougeard, D.: Chaotic mixing by longitudinal vorticity. Chem. Eng. Sci. 104, 439–450 (2013)

Robin, H.L., Stremler, A.M., Sharp, K.V., Olsen, M.G., Santiago, J.G., Aref, H., Beebe, D.J.: Passive mixing in a three-dimensional serpentine microchannel. J. Micro Electro Mech. Syst. 9(2), 190–197 (2000)

Lasbet, Y., Auvity, B., Castelain, C., Peerhossani, H.: Thermal and hydrodynamic performances of chaotic mini-channel: application to the fuel cell cooling. Heat Transf. Eng. 28(8–9), 795–803 (2007)

Hwang, F.N., Cai, X.C., Cheng, Y.L.: A parallel fully coupled implicit domain decomposition method for numerical simulation of microfluidic mixing in 3D. Int. J. Comput. Math. 90(3), 615–629 (2013)

Boukhalkhal, A.L., Lasbet, Y., Makhlouf, M., Loubar, K.: Numerical study of the chaotic flow in three-dimensional open geometry and its effect on the both fluid mixing and heat performances. Int. J. Heat Technol. 35(1), 1–10 (2017)

Tohidi, A., Hosseinalipour, S. M., Monfared, Z. G., Mujumdar, A. S.: Laminar heat transfer enhancement utilizing nanofluids in a chaotic flow. ASME, J.Heat Transf. 136, 091704–1 (2014)

Naas, T.T., Lasbet, Y., Benzaoui, A., Loubar, K.: Characterization of pressure drops and heat transfer of non-newtonian power-law fluid flow flowing in chaotic geometry. Int. J. Heat Technol. 34(2), 251–260 (2016)

Khiari, K., Tarabet, L., Awad, S., Loubar, K., Mahmoud, R., Tazerout, M.: Optimization of Pistacia lentiscus oil transesterification process using central composite design. Waste Biomass Valor, 1–7, 2575 (2018)

Kadi, M.A., Akkouche, N., Awad, S., Loubar, K., Tazerout, M.: Heliyon Kinetic study of transesterification using particle swarm optimization method. Heliyon 5, e02146 (2019). https://doi.org/10.1016/j.heliyon.2019.e02146

6584–07, D. Determination of free and total glycerin in B-100 biodiesel methyl esters by gas chromatography. United States: ASTM standards, 2007.

Anh, N.P., Tan, M.P.: Biodiesel production from waste cooking oils. Fuel 87(17–18), 3490–3496 (2008)

Acknowledgements

The authors thank the team of technicians and engineers from the Department of Energy Systems and the Environment at IMT ATLANTIQUE—FRANCE for their valuable assistance in completing this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Boukhalkhal, A.L., Kadi, M.E.A., Lasbet, Y. et al. A Continuous Biodiesel Production Process Using a Chaotic Mixer-Reactor. Waste Biomass Valor 11, 6159–6168 (2020). https://doi.org/10.1007/s12649-019-00880-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00880-x