Abstract

Nutrient recovery from organic green biomass after processing in a green biorefinery concept for the production of protein feed, biogas and fertilizer for organic farming was investigated. Mass balances in terms of wet weight, TS, VS, C, N, P, K and S were evaluated for processing red clover and clover grass into protein concentrate, press cake and brown juice according to the green biorefinery concept. Depending on the biomass, between 60 and 79% of C and between 52 and 63% of N, P and S in the fresh biomass were found in the press cake, while only 6–10% of C, 8–15% of N, but up to 27% of P and up to 26% of S were found in the brown juice. In contrast, less than 45% of K was transferred to the press cake and 19–31% of K ended up in the brown juice. Moreover, nutrient recovery in the digestate after anaerobic co-digestion of press cake and brown juice produced from clover grass in a pilot-scale trial was assessed in a bench-scale biogas reactor. The analysis of the digestate from the AD process revealed that 56% of the influent total-C was converted into biogas and that the share of ammonia-N of total-N was increased from 9.4 to 43% during the biogas process. Therefore, the proportion of plant available N was improved in the digestate. The digestate to be applied as organic fertilizer presented a C:N ratio of 7 and a nutrients N:P:K ratio of 4:1:12.

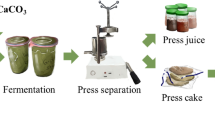

Graphic Abstract

Similar content being viewed by others

References

Santamaría-Fernández, M., Molinuevo-Salces, B., Kiel, P., Steenfeldt, S., Uellendahl, H., Lübeck, M.: Lactic acid fermentation for refining proteins from green crops and obtaining a high quality feed product for monogastric animals. J. Clean. Prod. 162, 875–881 (2017). https://doi.org/10.1016/j.jclepro.2017.06.115

Gutser, R., Ebertseder, T., Weber, A., Schraml, M., Schmidhalter, U.: Short-term and residual availability of nitrogen after long-term application of organic fertilizers on arable land. J. Plant Nutr. Soil Sci. 168, 439–446 (2005). https://doi.org/10.1002/jpln.200520510

Risberg, K., Cederlund, H., Pell, M., Arthurson, V., Schnürer, A.: Comparative characterization of digestate versus pig slurry and cow manure – Chemical composition and effects on soil microbial activity. Waste Manag. 61, 529–538 (2017). https://doi.org/10.1016/j.wasman.2016.12.016

Møller, H.B.: Nitrogen conversion in biogas plants. Bioenergy Res. 10–11 (2006)

Möller, K., Müller, T.: Effects of anaerobic digestion on digestate nutrient availability and crop growth: a review. Eng. Life Sci. 12, 242–257 (2012). https://doi.org/10.1002/elsc.201100085

Sankar Ganesh, K., Sundaramoorthy, P., Nagarajan, M., Lawrence Xavier, R.: Role of organic amendments in sustainable agriculture. In: Sustainable Agriculture towards Food Security. pp. 111–124. Springer, Singapore (2017)

Sogn, T.A., Dragicevic, I., Linjordet, R., Krogstad, T., Eijsink, V.G.H., Eich-Greatorex, S.: Recycling of biogas digestates in plant production: NPK fertilizer value and risk of leaching. Int. J. Recycl. Org. Waste. Agric. (2018). https://doi.org/10.1007/s40093-017-0188-0

Tambone, F., Scaglia, B., D’Imporzano, G., Schievano, A., Orzi, V., Salati, S., Adani, F.: Assessing amendment and fertilizing properties of digestates from anaerobic digestion through a comparative study with digested sludge and compost. Chemosphere 81, 577–583 (2010). https://doi.org/10.1016/j.chemosphere.2010.08.034

Arthurson, V.: Closing the global energy and nutrient cycles through application of biogas residue to agricultural land—potential benefits and drawbacks. Energies 2, 226–242 (2009). https://doi.org/10.3390/en20200226

Riva, C., Orzi, V., Carozzi, M., Acutis, M., Boccasile, G., Lonati, S., Tambone, F., D’Imporzano, G., Adani, F.: Short-term experiments in using digestate products as substitutes for mineral (N) fertilizer: agronomic performance, odours, and ammonia emission impacts. Sci. Total Environ. 547, 206–214 (2016). https://doi.org/10.1016/j.scitotenv.2015.12.156

Alburquerque, J.A., de la Fuente, C., Bernal, M.P.: Chemical properties of anaerobic digestates affecting C and N dynamics in amended soils. Agric. Ecosyst. Environ. 160, 15–22 (2012). https://doi.org/10.1016/j.agee.2011.03.007

De Notaris, C., Sørensen, P., Møller, H.B., Wahid, R., Eriksen, J.: Nitrogen fertilizer replacement value of digestates from three green manures. Nutr. Cycl. Agroecosyst. 112, 355–368 (2018). https://doi.org/10.1007/s10705-018-9951-5

Müller-Stöver, D.S., Sun, G., Kroff, P., Thomsen, S.T., Hauggaard-Nielsen, H.: Anaerobic co-digestion of perennials: Methane potential and digestate nitrogen fertilizer value. J. Plant Nutr. Soil Sci. 179, 696–704 (2016). https://doi.org/10.1002/jpln.201500599

Santamaría-Fernández, M., Molinuevo-Salces, B., Lübeck, M., Uellendahl, H.: Biogas potential of green biomass after protein extraction in an organic biorefinery concept for feed, fuel and fertilizer production. Renew. Energy. (2017). https://doi.org/10.1016/j.renene.2017.03.012

Kiel, P., Andersen, M., Lübeck, M.: A method for providing functional proteins from a plant material. PCT DK2015 050185. WO2015197078 (2015)

APHA: Standard Methods for the Examination of Water and Wastewater. American Public Health Association, American Water Works Association and Water Environment Federation, Washington DC (2005)

Symons, G.E., Buswell, A.M.: The methane fermentation of carbohydrates. J. Am. Chem. Soc. 55, 2028–2036 (1933)

Weiland, P.: Biogas production: current state and perspectives. Appl. Microbiol. Biotechnol. 85, 849–860 (2010). https://doi.org/10.1007/s00253-009-2246-7

Andersen, M., Kiel, P.: Integrated utilisation of green biomass in the green biorefinery. Ind. Crops Prod. 11, 129–137 (2000). https://doi.org/10.1016/S0926-6690(99)00055-2

Thomsen, M.H., Bech, D., Kiel, P.: Manufacturing of stabilised brown juice for l-lysine production—from university lab scale over pilot scale to industrial production. Chem. Biochem. Eng. Q. 18, 37–46 (2004)

Molinuevo-Salces, B., Ahring, B.K., Uellendahl, H.: Optimization of the co-digestion of catch crops with manure using a central composite design and reactor operation. Appl. Biochem. Biotechnol. 175, 1710–1723 (2014). https://doi.org/10.1007/s12010-014-1391-3

Möller, K., Schulz, R., Müller, T.: Substrate inputs, nutrient flows and nitrogen loss of two centralized biogas plants in southern Germany. Nutr. Cycl. Agroecosyst. 87, 307–325 (2010). https://doi.org/10.1007/s10705-009-9340-1

Cavalli, D., Cabassi, G., Borrelli, L., Geromel, G., Bechini, L., Degano, L., Marino Gallina, P.: Nitrogen fertilizer replacement value of undigested liquid cattle manure and digestates. Eur. J. Agron. 73, 34–41 (2016). https://doi.org/10.1016/j.eja.2015.10.007

McDonnell, R.P., Staines, M. VH., Bolland, M.D.A.: Determining the critical plant test potassium concentration for annual and Italian ryegrass on dairy pastures in south-western Australia. Grass Forage Sci. 73 112–122 (2018). https://doi.org/10.1111/gfs.12286

Acknowledgements

This work has been carried out in the frames of the Organic project: OrganoFinery—Organic growth with biorefined organic protein feed, fertilizer and energy. Authors are grateful to the “Green Development and Demonstration Program (GUDP) under the Danish Ministry of Food (34009-13-0961) and to the Organic RDD-2 program, coordinated by ICROFS, for financial support. Furthermore, the authors thank Morten Ambye-Jensen, Aarhus University, for collaboration with the pilot-scale process.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Santamaria-Fernandez, M., Ytting, N.K., Lübeck, M. et al. Potential Nutrient Recovery in a Green Biorefinery for Production of Feed, Fuel and Fertilizer for Organic Farming. Waste Biomass Valor 11, 5901–5911 (2020). https://doi.org/10.1007/s12649-019-00842-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00842-3