Abstract

This study presents in-situ upgrading of pyrolysis vapour derived from Napier grass over microporous and mesoporous ZSM-5 catalysts. It evaluates effect of process variables such catalyst–biomass ratio and catalyst type in a vertical fixed bed pyrolysis system at 600 °C, 50 °C/min under 5 L/min nitrogen flow. Increasing catalyst–biomass ratio during the catalytic process with microporous structure reduced production of organic phase bio-oil by approximately 7.0 wt%. Using mesoporous catalyst promoted nearly 4.0 wt% higher organic yield relative to microporous catalyst, which translate to only about 3.0 wt% reduction in organic phase compared to the yield of organic phase from non-catalytic process. GC–MS analysis of bio-oil organic phase revealed maximum degree of deoxygenation of about 36.9% with microporous catalyst compared to the mesoporous catalysts, which had between 39 and 43%. Mesoporous catalysts promoted production olefins and alkanes, normal phenol, monoaromatic hydrocarbons while microporous catalyst favoured the production of alkenes and polyaromatic hydrocarbons. There was no significant increase in the production of normal phenols over microporous catalyst due to its inability to transform the methoxyphenols and methoxy aromatics. This study demonstrated that upgrading of Napier grass pyrolysis vapour over mesoporous ZSM-5 produced bio-oil with improved physicochemical properties.

Similar content being viewed by others

References

Yakub, M.I., Mohamed, S., Danladi, S.U.: Technical and economic considerations of post-combustion carbon capture in a coal fired power plant. Int. J. Adv. Eng. Technol. 7(5), 1549–1581 (2014)

Yakub, M.I., Abdalla, A.Y., Feroz, K.K., Suzana, Y., Ibraheem, A., Chin, S.A.: Pyrolysis of oil palm residues in a fixed bed tubular reactor. J. Power Energy Eng. 3(04), 185 (2015)

Mohammed, I.Y., Abakr, Y.A., Kazi, F.K., Yusup, S., Alshareef, I., Chin, S.A.: Comprehensive characterization of Napier grass as a feedstock for thermochemical conversion. Energies 8(5), 3403–3417 (2015)

Mohammed, I.Y., Abakr, Y.A., Kazi, F.K., Yusup, S., Alshareef, I., Chin, S.A.: Pyrolysis of Napier grass in a fixed bed reactor: effect of operating conditions on product yields and characteristics. BioResources 10(4), 6457–6478 (2015)

Bridgwater, A.V.: Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 38, 68–94 (2012)

Hew, K.L., Tamidi, A.M., Yusup, S., Lee, K.T., Ahmad, M.M.: Catalytic cracking of bio-oil to organic liquid product (OLP). Bioresour. Technol. 101(22), 8855–8858 (2010)

Mohammed, I.Y., Kazi, F.K., Yusup, S., Alaba, P.A., Sani, Y.M., Abakr, Y.A.: Catalytic intermediate pyrolysis of Napier grass in a fixed bed reactor with ZSM-5, HZSM-5 and zinc-exchanged zeolite-A as the catalyst. Energies 9(4), 246 (2016)

Yildiz, G., Ronsse, F., Venderbosch, R., Van Duren, R., Kersten, S.R.A., Prins, W.: Effect of biomass ash in catalytic fast pyrolysis of pine wood. Appl. Catal. B. 168–169, 203–211 (2015)

Liu, G., Wright, M.M., Zhao, Q., Brown, R.C.: Catalytic fast pyrolysis of duckweed: effects of pyrolysis parameters and optimization of aromatic production. J. Anal. Appl. Pyrolysis 112, 29–36 (2015)

Park, Y.K., Yoo, M.L., Jin, S.H., Park, S.H.: Catalytic fast pyrolysis of waste pepper stems over HZSM-5. Renew. Energy 79, 20–27 (2015)

Gamliel, D.P., Du, S., Bollas, G.M., Valla, J.A.: Investigation of in situ and ex situ catalytic pyrolysis of miscanthus-giganteus using a PyGC–MS microsystem and comparison with a bench-scale spouted-bed reactor. Bioresour. Technol. 191, 187–196 (2015)

Ojha, D.K., Vinu, R.: Resource recovery via catalytic fast pyrolysis of polystyrene using zeolites. J. Anal. Appl. Pyrolysis. 113, 349–359 (2015)

Luo, G., Resende, F.L.: In-situ and ex-situ upgrading of pyrolysis vapours from beetle-killed trees. Fuel 166, 367–375 (2016)

Alaba, P.A., Sani, Y.M., Mohammed, I.Y., Daud, W.M.A.W.: Insight into catalyst deactivation mechanism and suppression techniques in thermocatalytic deoxygenation of bio-oil over zeolites. Rev. Chem. Eng. 32(1), 71–91 (2016)

Lee, H.W., Park, S.H., Jeon, J.K., Ryoo, R., Kim, W., Suh, D.J., Park, Y.K.: Upgrading of bio-oil derived from biomass constituents over hierarchical unilamellar mesoporous MFI nanosheets. Catal. Today 232, 119–126 (2014)

Gamliel, D.P., Cho, H.J., Fan, W., Valla, J.A.: On the effectiveness of tailored mesoporous MFI zeolites for biomass catalytic fast pyrolysis. Appl. Catal. A 522, 109–119 (2016)

Samson, R., Mani, S., Boddey, R.: The potential of C4 perennial grasses for developing a global bioheat industry. Crit. Rev. Plant Sci. 24, 461–495 (2005)

Flores, R.A., Urquiaga, S., Alves, B.J.R., Collier, L.S., Boddey, R.M.: Yield and quality of elephant grass biomass produced in the cerrados region for bioenergy. Engenharia Agrícola 32(5), 831–839 (2012)

Mohammed, I.Y., Abakr, Y.A., Yusup, S., Kazi, F.K.: Valorization of Napier grass via intermediate pyrolysis: optimization using response surface methodology and pyrolysis products characterization. J. Clean. Prod. 142, 1848–1866 (2017)

Richter, G.M., Riche, A.B., Dailey, A.G., Gezan, S.A., Powlson, D.S.: Is UK biofuel supply from Miscanthus water-limited? Soil Use Manag. 24, 235–245 (2008)

Cadoux, S., Riche, A.B., Yates, N.E., Machet, J.-M.: Nutrient requirements of Miscanthus × giganteus: conclusions from a review of published studies. Biomass Bioenergy 38, 14–22 (2012)

Imam, T., Capareda, S.: Characterization of bio-oil, syn-gas and bio-char from switchgrass pyrolysis at various temperatures. J. Anal. Appl. Pyrolysis 93, 170–177 (2012)

Serapiglia, M.J., Mullena, C.A., Boatenga, A.A., Cortese, L.M., Bonos, S.A., Hoffman, L.: Evaluation of the impact of compositional differences in switchgrass genotypes on pyrolysis product yield. Ind. Crops Prod. 74, 957–968 (2015)

Rena, S., Yea, X.P., Borole, A.P., Kimc, P., Labbé, N.: Analysis of switchgrass-derived bio-oil and associated aqueous phase generated in a semi-pilot scale auger pyrolyzer. J. Anal. Appl. Pyrolysis 119, 97–103 (2016)

Shemfe, M.B., Whittaker, C., Gu, S., Fidalgo, B.: Comparative evaluation of GHG emissions from the use of Miscanthus for bio-hydrocarbon production via fast pyrolysis and bio-oil upgrading. Appl. Energy 176, 22–33 (2016)

Tsai, W.T., Tsai, Y.L.: Thermochemical characterization of Napier grass as an energy source and its environmental and economic benefit analysis. Energy Sources Part B 11(2), 130–136 (2016)

Braga, R.M., Melo, D.M., Sobrinho, E.V., Barros, J.M., Melo, M.A., Carvalho, A.F., Maria do Socorro, B.F., Freitas, J.C.: Catalytic upgrading of elephant grass (Pennisetum purpureum Schum) pyrolysis vapor using WO3 supported on RHA and RHA-MCM-41. Catal. Today (2016). doi:10.1016/j.cattod.2016.06.003

Strezov, V., Evans, T.J., Hayman, C.: Thermal conversion of elephant grass (Pennisetum purpureum Schum) to bio-gas, bio-oil and charcoal. Bioresour. Technol. 99, 8394–8399 (2008)

Lee, M.-K., Tsai, W.-T., Tsaic, Y.-L., Lin, S.-H.: Pyrolysis of Napier grass in an induction-heating reactor. J. Anal. Appl. Pyrolysis 88, 110–116 (2010)

Braga, R.M., Melo, D.M.A., Aquino, F.M., Freitas, J.C.O., Melo, M.A.F., Barros, J.M.F., Fontes, M.S.B.: Characterization and comparative study of pyrolysis kinetics of the rice husk and the elephant grass. J. Therm. Anal. Calorim. 115(2), 1915–1920 (2014)

Sousa, J.F., Bezerra, M.B.D., Almeida, M.B.B., Moure, G.T., Mesa-Perez, J.M., Caramao, E.B.: Characteristics of bio-oil from the fast pyrolysis of elephant grass (Pennisetum purpureum Schumach) in a fluidized bed reactor. Am. Chem. Sci. J. 14(2), 1–10 (2016)

De Conto, D., Silvestre, W.P., Baldasso, C., Godinho, M.: Performance of rotary kiln reactor for the elephant grass pyrolysis. Bioresour. Technol. 218, 153–160 (2016)

Brosse, N., Dufour, A., Meng, X., Sun, Q., Ragauskas, A.: Miscanthus: a fast-growing crop for biofuels and chemicals production. Biofuels Bioprod. Biorefin. 6, 580–598 (2012)

Mohammed, I.Y., Lim, C.H., Kazi, F.K., Yusup, S., Lam, H.L., Abakr, Y.A.: Co-pyrolysis of rice husk with underutilized biomass species: a sustainable route for production of precursors for fuels and valuable chemicals. Waste Biomass Valorization (2016). doi:10.1007/s12649-016-9599-9

Zhang, B., Zhong, Z.P., Chen, P., Ruan, R.: Microwave-assisted catalytic fast pyrolysis of biomass for bio-oil production using chemical vapor deposition modified HZSM-5 catalyst. Bioresour. Technol. 197, 79–84 (2015)

Wei, Y., Lei, H., Zhu, L., Zhang, X., Liu, Y., Yadavalli, G., Zhu, X., Qian, M., Yan, D.: Hydrocarbon produced from upgrading rich phenolic compound bio-oil with low catalyst coking. Fuel 178, 77–84 (2016)

Ibáñez, M., Artetxe, M., Lopez, G., Elordi, G., Bilbao, J., Olazar, M., Castaño, P.: Identification of the coke deposited on an HZSM-5 zeolite catalyst during the sequenced pyrolysis-cracking of HDPE. Appl. Catal. B 148, 436–445 (2014)

Na, K., Choi, M., Ryoo, R.: Recent advances in the synthesis of hierarchically nanoporous zeolites. Microporous Mesoporous Mater. 166, 3–19 (2013)

Li, T., Duan, A., Zhao, Z., Liu, B., Jiang, G., Liu, J., Wei, Y., Pan, H.: Synthesis of ordered hierarchically porous L-SBA-15 material and its hydro-upgrading performance for FCC gasoline. Fuel 117, 974–980 (2014)

Saad, A., Ratanawilai, S., Tongurai, C.: Catalytic cracking of pyrolysis oil derived from rubberwood to produce green gasoline components. BioResources 10(2), 3224–3241 (2015)

Wang, L., Lei, H., Ren, S., Bu, Q., Liang, J., Wei, Y., Liu, Y., Lee, G.S.J., Chen, S., Tang, J., Zhang, Q.: Aromatics and phenols from catalytic pyrolysis of Douglas fir pellets in microwave with ZSM-5 as a catalyst. J. Anal. Appl. Pyrolysis 98, 194–200 (2012)

Du, S., Sun, Y., Gamliel, D.P., Valla, J.A., Bollas, G.M.: Catalytic pyrolysis of miscanthus × giganteus in a spouted bed reactor. Bioresour. Technol. 169, 188–197 (2014)

Jae, J., Coolman, R., Mountziaris, T.J., Huber, G.W.: Catalytic fast pyrolysis of lignocellulosic biomass in a process development unit with continual catalyst addition and removal. Chem. Eng. Sci. 108, 33–46 (2014)

Park, H.J., Park, K.-H., Jeon, J.-K., Kim, J., Ryoo, R., Jeong, K.-E., Park, S.H., Park, Y.-K.: Production of phenolics and aromatics by pyrolysis of Miscanthus. Fuel 97, 379–384 (2012)

Elordi, G., Olazar, M., Lopez, G., Castaño, P., Bilbao, J.: Role of pore structure in the deactivation of zeolites (HZSM-5, Hb and HY) by coke in the pyrolysis of polyethylene in a conical spouted bed reactor. Appl. Catal. B 102, 224–231 (2011)

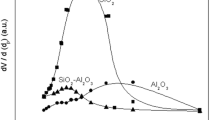

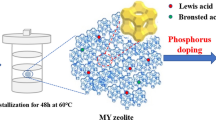

Li, J., Li, X., Zhou, G., Wang, W., Wang, C., Komarneni, S., Wang, Y.: Catalytic fast pyrolysis of biomass with mesoporous ZSM-5 zeolites prepared by desilication with NaOH solutions. Appl. Catal. A. 470, 115–122 (2014)

Zhang, H., Xiao, R., Jin, B., Xiao, G., Chen, R.: Biomass catalytic pyrolysis to produce olefins and aromatics with a physically mixed catalyst. Bioresour. Technol. 140, 256–262 (2013)

Scheer, A.M., Mukarakate, C., Robichaud, D.J., Nimlos, M.R., Ellison, G.B.: Thermal decomposition mechanisms of the methoxyphenols: formation of phenol, cyclopentadienone, vinylacetylene, and acetylene. J. Phys. Chem. A 115(46), 13381–13389 (2011)

Acknowledgements

The project was supported by the Crops for the Future (CFF) and University of Nottingham under the grant BioP1-005.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mohammed, I.Y., Abakr, Y.A. & Kazi, F.K. In-situ Upgrading of Napier Grass Pyrolysis Vapour Over Microporous and Hierarchical Mesoporous Zeolites. Waste Biomass Valor 9, 1415–1428 (2018). https://doi.org/10.1007/s12649-017-9925-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-9925-x