Abstract

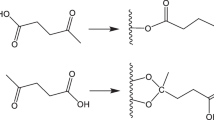

Green plasticizers were designed from liquefied wood flour, a non-edible biobased waste product. Wood flour was liquefied to low molecular weight polyols by acid catalyzed reaction. The resulting polyol mixture, including the remaining liquefaction solvents glycerol and diethylene glycol, was further utilized for the synthesis of low molecular weight ester plasticizers. Monomeric (MLWP) and oligomeric (OLWP) plasticizers were prepared by esterification of the polyols by hexanoic acid or a mixture of hexanoic and adipic acid, respectively. Liquefied wood polyol mixture and the synthesized plasticizers were characterized by size exclusion chromatography, electrospray ionization–mass spectrometry and fourier transform infrared spectroscopy. MLWP, OLWP and traditional dioctyl phthalate (DIOP) plasticizer were blended with poly(vinyl chloride) (PVC) and tensile testing was performed to evaluate the plasticizing efficiency of the new plasticizers. In addition PVC blends containing model disaccharide ester, sucrose octaacetate (SOA), were prepared and tested. Highest strain at break was obtained after addition of SOA ester, which clearly shows the potential of sugar esters as PVC plasticizers. Addition of MLWP also resulted in slightly higher strain at break as compared to films plasticized with same amount of phthalate plasticizer, DIOP. Differential scanning calorimetry showed one concentration dependent glass transition temperature for all the studied blends indicating good miscibility. Our novel plasticizers are attractive environmentally friendly alternatives for phthalate plasticizers and could be prepared from biomass waste from agriculture and forest industry.

Similar content being viewed by others

References

Alonso, D.M., Bond, J.Q., Dumesic, J.A.: Catalytic conversion of biomass to biofuels. Green Chem. 12(9), 1493–1513 (2010)

Kurimoto, Y., Koizumi, A., Doi, S., Tamura, Y., Ono, H.: Wood species effects on the characteristics of liquefied wood and the properties of polyurethane films prepared from the liquefied wood. Biomass Bioenergy 21, 381–390 (2001)

Jasiukaityte, E., Kunaver, M., Strlic, M.: Cellulose liquefaction in acidified ethylene glycol. Cellulose 16, 393–405 (2009)

Zhang, Y., Ikeda, A., Hori, N., Takemura, A., Ono, H., Yamada, T.: Characterization of liquefied product from cellulose with phenol in the presence of sulfuric acid. Bioresour. Technol. 97, 313–321 (2006)

Lee, S.H., Yoshioka, M., Shiraishi, N.: Liquefaction and product identification of corn bran (CB) in phenol. J. Appl. Polym. Sci. 78, 311–318 (2000)

Lee, S.H., Teramoto, Y., Shiraishi, N.: Acid-catalyzed liquefaction of waste paper in the presence of phenol and its application to novolak-type phenolic resin. J. Appl. Polym. Sci. 83, 1473–1481 (2002)

Mishra, D., Sinha, V.K.: Value-based polymer precursors from paper waste and its application in polyurethane foams. J. Cell. Plastics 46, 15–30 (2010)

Yamada, T., Ono, H.: Characterization of the products resulting from ethylene glycol liquefaction of cellulose. J. Wood Sci. 2001(47), 458–464 (2001)

Zou, X., Qin, T., Wang, Y., Huang, L.: Mechanisms and product specialties of the alcoholysis processes of poplar components. Energy Fuels 25, 3786–3792 (2011)

Krzan, A., Zagar, E.: Microwave driven wood liquefaction with glycols. Bioresour. Technol. 100, 3143–3146 (2009)

Lee, S.H., Teramoto, Y., Shiraishi, N.: Biodegradable polyurethane foam from liquefied waste paper and its thermal stability, biodegradability, and genotoxicity. J. Appl. Polym. Sci. 83, 1482–1489 (2002)

Lee, S.H., Ohkita, T., Teramoto, Y.: Polyol recovery from biomass-based polyurethane foam by glycolysis. J. Appl. Polym. Sci. 95, 975–980 (2005)

Lee, W.J., Chen, Y.C., Wu, C.C., Juan, Y.M.: Physicomechanical and thermal properties of moldings made from liquefied wood-based novolak PF resins under various hot-pressing conditions. J. Appl. Polym. Sci. 113, 1257–1263 (2009)

Kishi, H., Fujita, A., Miyazaki, H., Matsuda, S., Murakami, A.: Synthesis of wood-based epoxy resins and their mechanical and adhesive properties. J. Appl. Polym. Sci. 102, 2285–2291 (2006)

Kunaver, M., Jasiukaityte, E., Cuk, N., Guthrie, J.T.: Liquefaction of wood, synthesis and characterization of liquefied wood polyester derivatives. J. Appl. Polym. Sci. 115, 1265–1271 (2010)

Koleske, J.V., Lundberg, R.D.: Lactone polymers. I. Glass transition temperature of poly-ε-caprolactone by means of compatible polymer mixtures. J. Polym. Sci. Polym. Chem. 7, 795–807 (1969)

Hakkarainen, M.: New PVC materials for medical applications-the release profile of PVC/polycaprolactone-polycarbonate aged in aqueous environments. Polym. Degrad. Stab. 80, 451–458 (2003)

Lindström, A., Hakkarainen, M.: Designed chain architecture for enhanced migration resistance and property preservation in poly(vinyl chloride)/polyester blends. Biomacromolecules 8, 1187–1194 (2007)

Lindström, A., Hakkarainen, M.: Environmentally friendly plasticizers for poly(vinyl chloride)-improved mechanical properties and compatibility by using branched poly(butylene adipate) as a polymeric plasticizer. J. Appl. Polym. Sci. 100, 2180–2188 (2006)

Yin, B., Hakkarainen, M.: Core-shell nanoparticle-plasticizers for design of high performance polymeric materials with improved stiffness and toughness. J. Mater. Chem. 21, 8670–8677 (2011)

Lindström, A., Hakkarainen, M.: Migration resistant polymeric plasticizer for poly(vinyl chloride). J. Appl. Polym. Sci. 104, 2458–2467 (2007)

Choi, J., Kwak, S.Y.: Hyperbranched poly (ε-caprolactone) as a nonmigrating alternative plasticizer for phthalates in flexible PVC. Environ. Sci. Technol. 41, 3763–3768 (2007)

Yin, B., Hakkarainen, M.: Oligomeric isosorbide esters as alternative renewable resource plasticizers for PVC. J. Appl. Polym. Sci. 2011(119), 2400–2407 (2011)

Calo, E., Greco, A., Maffezzoli, A.: Effects of diffusion of a naturally-derived plasticizer from soft PVC. Polym. Degrad. Stab. 96, 784–789 (2011)

Da Silva, M.A., Vieira, M.G.A., Macumoto, A.C.G., Beppu, M.M.: Polyvinylchloride (PVC) and natural rubber films plasticized with a natural polymeric plasticizer obtained through polyesterification of rice fatty acid. Polym. Test. 30, 478–484 (2011)

Choi, S.Y., Rodríguez, H., Mirjafari, A., Gilpin, D.F., McGrath, S., Malcolm, K.R., Tunney, M.M., Rogers, R.D., McNally, T.: Dual functional ionic liquids as plasticisers and antimicrobial agents for medical polymers. Green Chem. 13, 1527–1535 (2011)

Yamada, T., Aratani, M., Kubo, S., Ono, H.: Chemical analysis of the product in acid-catalyzed solvolysis of cellulose using polyethylene glycol and ethylene carbonate. J. Wood Sci. 53, 487–493 (2007)

Acknowledgments

The authors gratefully acknowledge the financial support from the Swedish Research Council (VR) through the grant 2010-3877. Green plasticizers from non-edible liquefied biomass.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, B., Hakkarainen, M. Green Plasticizers from Liquefied Wood. Waste Biomass Valor 5, 651–659 (2014). https://doi.org/10.1007/s12649-013-9259-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-013-9259-2