Abstract

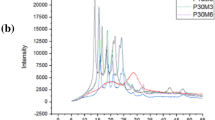

The use of recycled or waste materials is environmentally beneficial. This study focuses on recycled plastic and wood waste which are produced as wood–plastic composites (WPCs). The effect of loading, wood species, and maleic anhydride-grafted polypropylene (MAPP) on the physical and mechanical properties of WPCs is evaluated. Extrusion and compression were employed to produce the composite samples. Three types of wood waste are evaluated, namely rubberwood flour (RWF), coir fiber, and palm fiber at wood loadings of 30, 40, and 50 wt%. The results indicate that loading and wood species significantly affected the hardness, tensile strength, and flexural properties of the WPCs. Moreover, the addition of MAPP had a significant effect on the physical and mechanical properties of WPCs resulting in improved compatibility of wood and polymer matrix and crystallization properties. The highest impact strength (3.88 kJ/m2), tensile strength (25.73 MPa), flexural strength (37.55 MPa), and crystallinity (42.52%) were accomplished at 40 wt% RWF with MAPP. However, the water absorption, hardness, tensile modulus, and flexural modulus of the WPCs increased as the wood loading increased. Moreover, WPCs based on 30 wt% RWF with MAPP had the lowest water absorption (5.59%) after being immersed for 8 weeks. Therefore, this study provides a use for low-cost recycled plastic and wood waste as filler materials for WPCs that can be used in structures and building applications because of their high performance, benefitting both the economy and the environment.

Similar content being viewed by others

Data Availability

The data analyzed during this study are available from the corresponding author on reasonable request.

References

G.A. Ormondroyd, J. Kers, in Performance of Bio-based Building Materials. ed. by D. Jones, C. Brischke (Woodhead Publishing, 2017), p.61

T. Gurunathan, S. Mohanty, S.K. Nayak, Compos. Part A Appl. Sci. Manuf. 77, 1 (2015)

E. Stanaszek-Tomal, I.O.P. Conf, Ser. Mater. Sci. Eng. 603, 1 (2019)

H. Wang, X. Zhang, S. Guo, T. Liu, Polym. Compos. 42, 4174 (2021)

S.H. Kamarudin, M.S.M. Basri, M. Rayung, F. Abu, S. Ahmad, M.N. Norizan, S. Osman, N. Sarifuddin, M.S.Z.M. Desa, U.H. Abdullah, I.S.M.A. Tawakkal, L.C. Abdullah, Polym. 14, 3698 (2022)

T. Ratanawilai, K. Taneerat, Constr. Build. Mater. 172, 349 (2018)

A.C. Jadhav, N.C. Jadhav, Iran. Polym. J. 31, 821 (2022)

S. Khamtree, T. Ratanawilai, S. Ratanawilai, Mater. Today. Commun. 24, 1 (2020)

C. Srivabut, T. Ratanawilai, S. Hiziroglu, Constr. Build. Mater. 162, 450 (2018)

P.M. Pasang, Y. Yunianta, T. Estiasih, H. Harijaono, Russ. J. Agric. Soc.-Econ. Sci. 8, 452 (2018)

H. Essabir, R. Boujmal, M.O. Bensalah, R. Bouhfid, Mech. Mater. 98, 36 (2016)

M. Ramesh, L. Rajeshkumar, G. Sasikala, D. Balaji, A. Saravanakumar, V. Bhuvaneswari, R. Bhoopathi, Polym. 14, 589 (2022)

M.H. Akonda, H.M. El-Dessouky, J. Text. Sci. Technol. 5, 69 (2019)

A.K. Singh, R. Bedi, B.S. Kaith, Mater. Today. Proc. 26, 1293 (2020)

C.W. Huang, T.C. Yang, K.C. Hung, J.W. Xu, J.H. Wu, Polym. 10, 382 (2018)

G. Pokhrel, D.J. Gardner, Y. Han, Polym. 13, 2769 (2021)

H. Gupta, H. Kumar, A.K. Gehlaut, S.K. Singh, A. Gaur, S. Sachan, J.W. Park, J. Mater. Cycles. Waste. Manag. 24, 569 (2022)

S.K. Ramakrishnan, K. Vijayananth, G.P. Muthukutti, P. Spatenka, A. Arivendan, S.P. Ganesan, J. Mater. Cycles. Waste. Manag. 24, 667 (2022)

C. Homkhiew, C. Srivabut, T. Ratanawilai, S. Rawangwong, S. Chantaramanee, J. Mater. Cycles. Waste. Manag. 25, 1444 (2023)

S. Paul, M. Rahaman, S.K. Ghosh, A. Katheria, T.K. Das, S. Patel, N.C. Das, J. Mater. Cycles. Waste. Manag. 25, 1470 (2023)

S. Gairola, T.P. Naik, S. Sinha, I. Singh, J. Mater. Cycles. Waste. Manag. 25, 2063 (2023)

L.N. Megashah, H. Ariffin, M.R. Zakaria, M.A. Hassan, I.O.P. Conf, Ser. Mater. Sci. Eng. 368, 012049 (2018)

B. Abu-Jdayil, M.S. Barkhad, A.H. Mourad, M.Z. Iqbal, J. Build. Eng. 43, 103224 (2021)

J. Zhang, Y. Li, D. Xing, Q. Wang, H. Wang, A. Koubaa, Constr. Build. Mater. 228, 116718 (2019)

Z. Salleh, K.M. Hyie, M.N. Berhan, Y.M. Taib, N.R.N. Roselina, A.R.M. Razib, Appl. Mech. Mater. 465, 967 (2014)

M. Mohammed, A.J. Jawad, A.M. Mohammed, J.K. Oleiwi, T. Adam, A.F. Osman, O.S. Dahham, B.O. Betar, S.C. Gopinath, M. Jaafar, Polym. Test. 7, 108083 (2023)

S. Lv, X. Liu, J. Gu, Y. Jiang, H. Tan, Y. Zhang, Constr. Build. Mater. 144, 525 (2017)

D. Friedrich, A. Luible, Constr. Build. Mater. 124, 1142 (2016)

S. Durmaz, Wood. Res. 67, 302 (2022)

C. Homkhiew, C. Srivabut, S. Rawangwong, W. Boonchouytan, Fibers. Polym. 23, 2679 (2022)

T. Kongkaew, S. Kumneadklang, J. Panichpakdee, S. Larpkiattaworn, Int. J. Sci. Innov. Technol. 3, 53 (2020)

C. Homkhiew, T. Ratanawilai, W. Thongruang, Appl. Mech. Mater. 368, 785 (2013)

W. Lu, W. Yu, B. Zhang, X. Dou, X. Han, H. Cai, Compos. B Eng. 223, 109117 (2021)

B. Effah, A.V. Reenen, M. Meincken, Eur. J. Wood. Wood. Prod. 76, 57 (2018)

S. Khamtree, T. Ratanawilai, S. Ratanawilai, Prog. Ind. Ecol. 12, 297 (2018)

Z. Ranjbarha, P. Aberoomand-Azar, J. Mokhtari-Aliabad, S.A. Mirmohammadi, M. Saber-Tehrani, Polym. Polym. Compos. 29, S106 (2021)

S. Yang, B. Wei, Q. Wang, Compos. B Eng. 200, 108347 (2020)

A. Nuryawan, N.O. Hutauruk, E.Y.S. Purba, N. Masruchin, R. Batubara, I. Risnasari, F.K. Satrio, Rahmawaty, M. Basyuni, D. McKay, PLoS ONE 15, e0236406 (2020)

E.O. Olakanmi, E.A. Ogunesan, E. Vunain, R.A. Lafia-Araga, M. Doyoyo, R. Meijboom, Polym. Compos. 37, 2657 (2016)

Z.A. Nafis, M. Nuzaimah, S.A. Kudus, Y. Yusuf, R.A. Ilyas, V.F. Knight, M.N. Norrrahim, Materials 16, 479 (2023)

R. Huang, C. Mei, X. Xu, Materials 8, 8510 (2015)

S. Khamtree, T. Ratanawilai, S. Ratanawilai, J. Thermoplast. Compos. Mater. 33, 599 (2020)

T. Ratanawilai, V. Leelasilapasart, C. Srivabut, S. Ratanawilai, Fibers. Polym. 23, 1956 (2022)

Acknowledgements

This work was financially supported by Nakhon Si Thammarat Rajabhat University (grant numbers 017/2564). The authors would also like to thank the Faculty of Industrial Technology and Faculty of Science and Technology, Songkhla Rajabhat University, Thailand.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khamtree, S., Srivabut, C., Khamtree, S. et al. Effects of Natural Fiber Waste, Content, and Coupling Agent on the Physical and Mechanical Properties of Wood Species–Plastic Composites as Green Materials. Fibers Polym 25, 1391–1402 (2024). https://doi.org/10.1007/s12221-024-00493-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-024-00493-9