Abstract

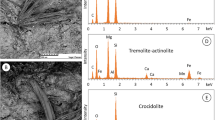

Asbestos Containing Wastes (ACW) were mixed with chemical additives and heated with microwaves. Eternit, Progypsol and Spray coated Amosite were thermo-chemically treated and the mineral residues recycled in mortar. Samples were analysed before and after thermal treatment by Scanning Electron Miscroscopy with Field Emission Gun (SEM FEG) and Energy Dispersive X-ray analysis (EDX) coupled to the SEM FEG. Mineralogy was examined by microprobe. X Ray diffraction (XRD) was used to identify the crystal lattice of products before and after melting. Additives such as borates, phosphates and sodium carbonate were introduced to lower the fusion temperatures and the treatment costs. Thermogravimetric analysis and differential scanning calorimetry were used to estimate melting effects due to the additives. EPR spectroscopy was used to study the environment of iron ions embedded on asbestos surfaces and demonstrate fiber transformation to a more isotropic phase. Magnesium silicates (serpentine group) were found in Eternit and Progypsol samples, and iron silicates (amphibole group) in Spray Coated Amosite samples. Observations by SEM illustrate differences in the structure between raw and treated materials but elemental analyses show the same chemical compositions. XRD patterns confirm the transformation of asbestos fibers into other crystalline materials. Borates are most effective for lowering the temperature of thermal transformation. The ground mixtures begin to melt at 900°C with borates compared to other melting products where the melting temperature is around 1,000–1,100°C. Heating with fusion additives allows irreversible transformation of the asbestos fibrous structure and recycling of the residues as filling materials in mortars. Thermal treatment seems to be the most effective process to transform and inactivate asbestos fibers from starting materials. Recycling treated ACW in mortar shows a decrease of mechanical properties when replacing cement or aggregate, but samples with 10 wt% ACW replacing aggregate show tensile strengths of 10 MPa, close to the value for the reference mortar with no ACW. Reuse of treated ACW would prevent stockpiling in hazardous waste landfills.

Similar content being viewed by others

References

Bentur, A., Mindess, S.: Fibre Reinforced Cementitious Composites. Elsevier Applied Science, London (1990)

Michaels, L., Chissick, S.S.: Asbestos, Properties, Applications, and Hazards, vol. 1–2. Wiley, New York (1979)

Hornbostel, C.: Construction Materials: Types. Uses and Applications. John Wiley & Sons, New York (1991)

Asbestos-Cement Products for War Buildings. In: Asbestos. pp. 2-4. (1942)

Rosato, D.V.: Asbestos: Its Industrial Applications vol. 1. Reinhold Publishing Corp, New York (1959)

Andrews, C., Barsch, C., Cooney, D.: Coping with Contamination: A Primer for Preservationists, vol. Information Bulletin No. 70. National Trust for Historic Preservation, Washington (1993)

Catherine, H., Skinner, W.: Mineralogy of Asbestos Minerals. Indoor and Built Environment 12(6), 385–389 (2003)

Donaldson, K., Tran, C.L.: An introduction to the short-term toxicology of respirable industrial fibres. Mutation Research - Fundamental and Molecular Mechanisms of Mutagenesis 553(1–2), 5–9 (2004)

Centre, L.H.: Asbestos Hazards Handbook - Chapter 10. London Hazards Centre Trust Ltd, Interchange Studios, London (1995)

Plescia, P., Gizzi, D., Benedetti, S., Camilucci, L., Fanizza, C., De Simone, P., Paglietti, F.: Mechanochemical treatment to recycling asbestos-containing waste. Waste Manage. 23(3), 209–218 (2003)

Turci, F., Colonna, M., Tomatis, M., Mantegna, S., Cravotto, G., Fubini, B.: New detoxification processes for asbestos fibers in the environment. Journal of Toxicology and Environmental Health - Part A: Current Issues 73(5–6), 368–377 (2010)

Werner, A.J., Hochella Jr, M.F., Guthrie Jr, G.D., Hardy, J.A., Aust, A.E., Rimstidt, J.D.: Asbestiform riebeckite (crocidolite) dissolution in the presence of Fe chelators: implications for mineral-induced disease. Am. Mineral. 80(11–12), 1093–1103 (1995)

Block, J., Petrakis, L., Dolhert, L.E., Myers, D.F., Hegedus, L.L., Webster, R.P., Kukacka, L.E.: A novel approach for the in situ chemical elimination of chrysotile from asbestos-containing fireproofing materials. Environ. Sci. Technol. 34(11), 2293–2298 (2000)

Leonelli, C., Veronesi, P., Boccaccini, D.N., Rivasi, M.R., Barbieri, L., Andreola, F., Lancellotti, I., Rabitti, D., Pellacani, G.C.: Microwave thermal inertisation of asbestos containing waste and its recycling in traditional ceramics. J. Hazard. Mater. 135(1–3), 149–155 (2006)

Gomez, E., Rani, D.A., Cheeseman, C.R., Deegan, D., Wise, M., Boccaccini, A.R.: Thermal plasma technology for the treatment of wastes: A critical review. J. Hazard. Mater. 161(2–3), 614–626 (2009)

Ek, R.B.: Mineralogical conversion of asbestos waste. United States Patent 5096692

Barnett, I.: Asbestos abatement. United States Patent 5439322

Mirick, W., Forrister, W.B.: Method for treating asbestos. United States Patent 5516973

Borderes, A.: Vitrification of the incineration residues. Revue Verre 6(4), 1–2 (2000)

Jianmiao, D., Shizong, L.: Effect of microwave processing on aluminate cement clinkering. Journal of Wuhan University of Technology–Materials Science Edition 20(2), 77–79 (2005)

Kenkre, V.M., Skala, L., Weiser, M.W., Katz, J.D.: Theory of microwave interactions in ceramic materials: the phenomenon of thermal runaway. J. Mater. Sci. 26(9), 2483–2489 (1991)

Clark, D.E., Sutton, W.H.: Microwave Processing of Materials. Annu. Rev. Mat. Sci. 26(1), 299–331 (1996). doi:10.1146/annurev.ms.26.080196.001503

Deer, W.A., Howie, R.A., Zussman, J.: An introduction to the rock-forming minerals, vol. 2. Prentice Hall, Harlow, England (1996)

Lemmon, R.K., Blackketter, D.M.: Stress analysis of an orthotropic material under diametral compression. Experimental Mechanics 36(3), 204–211 (1996)

Santana, H.H.S., Maier, G., Ródenas, J.: Diametral compression test: Analysing the H/D ratio influence on the mechanical resistance of UO2-green pellets. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment 619(1–3), 449–452 (2010)

Gualtieri, A.F., Cavenati, C., Zanatto, I., Meloni, M., Elmi, G., Gualtieri, M.L.: The transformation sequence of cement-asbestos slates up to 1200°C and safe recycling of the reaction product in stoneware tile mixtures. J. Hazard. Mater. 152(2), 563–570 (2008)

Dellisanti, F., Rossi, P.L., Valdrè, G.: Remediation of asbestos containing materials by Joule heating vitrification performed in a pre-pilot apparatus. Int. J. Miner. Process. 91(3–4), 61–67 (2009)

Gualtieri, A.F., Tartaglia, A.: Thermal decomposition of asbestos and recycling in traditional ceramics. J. Eur. Ceram. Soc. 20(9), 1409–1418 (2000)

Gualtieri, A.F., Gualtieri, M.L., Tonelli, M.: In situ ESEM study of the thermal decomposition of chrysotile asbestos in view of safe recycling of the transformation product. J. Hazard. Mater. 156(1–3), 260–266 (2008)

Ishida, T., Alexandrov, M., Nishimura, T., Minakawa, K., Hirota, R., Sekiguchi, K., Kohyama, N., Kuroda, A.: Selective detection of airborne asbestos fibers using protein-based fluorescent probes. Environ. Sci. Technol. 44(2), 755–759 (2010)

Oke, Y., Yamasaki, N., Yamamoto, G., Sasaki, K., Maeta, N., Fujimaki, H., Hashida, T.: Novel selective dyeing method for chrysotile asbestos detection in concrete materials. Environ. Sci. Technol. 42(5), 1638–1642 (2008)

Mackenzie, K.J.D., Meinhold, R.H.: Thermal reactions of chrysotile revisited: a 29Si and 25Mg MAS NMR study. Am. Mineral. 79(1–2), 43–50 (1994)

Candela, P.A., Crummett, C.D., Earnest, D.J., Frank, M.R., Wylie, A.G.: Low-pressure decomposition of chrysotile as a function of time and temperature. Am. Mineral. 92(10), 1704–1713 (2007)

Wesselsky, A., Jensen, O.M.: Synthesis of pure Portland cement phases. Cem. Concr. Res. 39(11), 973–980 (2009)

Tenorio, J.A.S., Pereira, S.S.R., Ferreira, A.V., Espinosa, D.C.R., Da Silva Araojo, F.G.: CCT diagrams of tricalcium silicate: Part I. Influence of the Fe2O3 content. Mater. Res. Bull. 40(3), 433–438 (2005)

Salesse, P.: Minerais et Fondants. Techniques de l’Ingénieur M 7 040, 24 p. (1989)

Nannini, M., Tralli, R.: Transformation method of products containing asbestos. IT Patent EP1382585A2

Block, J.: Composition and method to remove asbestos. US Patent

Joubert, D.: Method for modifying silicic crystalline materials

Fujishige, M., Sato, R., Kuribara, A., Karasawa, I., Kojima, A.: CaCl2 addition effect and melt formation in low-temperature decomposition of chrysotile with CaCO3. Nippon Seramikkusu Kyokai Gakujutsu Ronbunshi/Journal of the Ceramic Society of Japan 114(1334), 844–848 (2006)

Fujishige, M., Kuribara, A., Karasawa, I., Kojima, A.: Low-temperature pyrolysis of crocidolite and amosite using calcium salts as a flux. Nippon Seramikkusu Kyokai Gakujutsu Ronbunshi/Journal of the Ceramic Society of Japan 115(1343), 434–439 (2007)

Muzhen, S., Kurdowski, W., Sorrentino, F.: Development in non-portland cements. In: Proceedings of the 9th International Congress on the Chemistry of Cement, New Delhi 1992, pp. 317–354

Rager, H., Schneider, H.: EPR study of Fe3+ centers in cristobalite and tridymite. Am. Mineral. 71(1–2), 105–110 (1986)

Andersson, P.O., Kollberg, E.L., Jelenski, A.: Extra EPR spectra of iron-doped rutile. Physical Review B 8(11), 4956–4965 (1973)

Shinde, R.F., Balakrishnan, I.: EPR studies of iron substitution in the molecular sieve VPI-5. J. Phys. D Appl. Phys. 24(8), 1486–1488 (1991)

Delineau, T., Allard, T., Muller, J.P., Barres, O., Yvon, J., Cases, J.M.: FTIR reflectance vs. EPR studies of structural iron in kaolinites. Clays & Clay Minerals 42(3), 308–320 (1994)

Reis, S.T.D., Pontuschka, W.M., Yang, J.B., Faria, D.L.A.: Properties and structural features of iron doped BABAL glasses. Materials Research 6, 389–394 (2003)

Sharrock, P.: Chrysotile asbestos fibres from Quebec: electron magnetic resonance identification. Geochim. Cosmochim. Acta 46(7), 1311–1315 (1982)

Sengupta, A., Kadam, R.M., Rajeswari, B., Dhobale, A.R., Babu, Y., Godbole, S.V.: Characterization of Indian serpentine by X-ray diffraction, photoacoustic spectroscopy and electron paramagnetic resonance spectroscopy. Appl. Clay Sci. In Press, Corrected Proof

Burns, D.T., Flockhart, B.D.: Application of Quantitative EPR [and Discussion]. Philosophical Transactions: Physical Sciences and Engineering 333(1628), 37–48 (1990)

Bianchini, G., Marrocchino, E., Tassinari, R., Vaccaro, C.: Recycling of construction and demolition waste materials: a chemical-mineralogical appraisal. Waste Manage. 25(2), 149–159 (2005)

Marabini, A.M., Plescia, P., Maccari, D., Burragato, F., Pelino, M.: New materials from industrial and mining wastes: glass-ceramics and glass- and rock-wool fibre. Int. J. Miner. Process. 53(1–2), 121–134 (1998)

Redon, C., Chermant, J.-L.: Damage mechanics applied to concrete reinforced with amorphous cast iron fibers, concrete subjected to compression. Cem. Concr. Compos. 21(3), 197–204 (1999)

Gualtieri, A.F., Giacobbe, C., Sardisco, L., Saraceno, M., Lassinantti Gualtieri, M., Lusvardi, G., Cavenati, C., Zanatto, I.: Recycling of the product of thermal inertization of cement-asbestos for various industrial applications. Waste Management In Press, Corrected Proof (2010)

Corinaldesi, V.: Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates. Construct. Build. Mater. 24(9), 1616–1620 (2010)

Acknowledgments

This work was supported by the European project (n° 222142) AMIANTE (A Movable Innovative Asbestos Neutralisation Thermal treatment device). The Authors wish to thank Mr De Perseval and Mr Thibaut from Laboratoire des Mécanismes et Transferts en Géologie (Université Paul Sabatier—Toulouse III), and Mr Datas and Mr Le Blond Du Plouy from the team TEMSCAN (Université Paul Sabatier—Toulouse III) for technical support. We would like to thank also Mme Magnié, Mr Cojan and Mme Vialletelle from the society INERTEC (Paris) for delivering industrial ACW and for useful discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yvon, Y., Sharrock, P. Characterization of Thermochemical Inactivation of Asbestos Containing Wastes and Recycling the Mineral Residues in Cement Products. Waste Biomass Valor 2, 169–181 (2011). https://doi.org/10.1007/s12649-011-9063-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-011-9063-9