Abstract

In this investigation, highly adherent and unique advantageous properties of In2Se3 films were prepared for different studies and applications using a thermal evaporation technique under a high vacuum on different substrates (including glass, quartz, and a p-Si single crystal). X-ray diffraction results show that the prepared In2Se3 powder has a polycrystalline nature with α-phase. The average size of the crystallite, microstrain, and dislocation density was measured and found to be 273.6 nm, 4.9 × 10–3, and 1.34 × 10–5 nm−2, respectively. Due to the long-range array, the deposited In2Se3 films have an amorphous nature. SEM images of the film surface were measured to examine the RMS roughness features and grain-boundary effect. Spectrophotometer measurements of transmittance and reflectance were used to estimate the optical constants of In2Se3 films. The relationship between absorption coefficient and photon energy was tested, and the results revealed that the optical transition is directly allowed with an energy gap of 2.25 eV. The dispersion and oscillator energies were measured using the single oscillator model employing a relation of Wemple–DiDomenico and found to be 3.8 and 1.7 eV. The characteristics of the In2Se3-based junction showed promising candidates for photosensor applications under illumination.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Indium selenide (In2Se3) is a semiconductor chalcogenide material that belongs to the family A2IIIB3VI and crystallizes as Se–In–Se–In-Se atoms stacked in a double layer along the c-axis via the Se [1]. It's also been the most popular material due to its unique physical characteristics, two-dimensional (2D) material that leads to various potential electronic and optoelectronic devices, such as solar cells [2], detectors of light [3], phase-change memories [4], gas detector [5] and also ferroelectric field-effect transistors [6]. There is a direct bandgap material that demonstrates photovoltaic and optoelectronic, and enormous potential applications [7]. In2Se3 films have potential attention for solar cells and are researched as a precursor to CuInSe2 [8], a medium for optical recording [9], linear polarized radiation sensors [10], broadband optical radiation converters [11], Schottky diodes, nano-electronic apparatuses and also photoelectrochemical cells [12]. The films can also be used to process lithium, as current sources, and photodetectors that work in the visible electromagnetic spectrum [13]. The phase diagram for binary compounds containing III–VI is complicated, and the dimensions of their cell units are immense. As trivalent and divalent atoms interact in many energetic ways to satisfy bonding requirements, the phase diagram becomes ambiguous [14].

Due to the structures stacked with distinct motifs, In2Se3 is a polymorphic, complex crystalline chalcogenide, like many metal chalcogenides. To date, five stable ambient pressure phases have been discovered, including the α, β, δ, κ phases and defect wurtzite phases [15], so that it has a wide range of energy gap from 1.3 to 1.9 eV. Liu et al. [15] have suggested that β- and γ-phase should co-exist in the highly elevated 200–730 °C temperature range. Moreover, Li et al. [16] have demonstrated that the crystal structure of In2Se3 has a major impact on its electrical properties. Accordingly, β-In2Se3 with Se–In–Se–In–Se layer composition has a very small indirect bandgap of 0.46 eV, which is characterized as an interesting mid-infrared photodetector building block. The ordered-defect γ-In2Se3 compound, on the other hand, has a broader band gap directly 1.86 eV, increasing its visibility and allowing it to be used in electrical applications. [17]. As a result, many efforts must be made in addition to developing a successful monophasic In2Se3 synthetic process. Depending on the deposition method and growth parameters [18], In2Se3 films can form a variety of phases.

In2Se3 can crystallize in various systems as hexagonal, rhombohedral and wurtzite structures, denoted as β-phase, (γ, δ -phase) and anisotropic κ-phase [7]. As each step has unique physical and chemical properties, the nature of several phases in this compound affects its use in photovoltaic systems. [13, 18].

Various methods employed for preparing films of In2Se3, including thermal evaporation techniques, have been used for the preparation [19], co-evaporation [8], spray pyrolysis [12], techniques based on sol–gel [20], deposition in a chemical bath (CBD) [21], metal–organic chemical vapor deposition (MOCVD) [23], van der Waals epitaxy [22], molecular beam epitaxy (MBE) [23], chemical vapor transport (CVT) [7], potential pulse atomic layer deposition (PP-ALD) [24], evaporation in a flash [25], pulsed laser deposition (PLD) [23] and radio frequency (rf) magnetron sputtering [7] due to monophasic γ-In2Se3 thin films [26] and nanostructures [27], etc.

It has been found that the method of preparation can affect the type of phase. The substrate plays a particularly important part in the epitaxial growth process, for example, the orientation controller [28], doping source [29] and the phase. In2Se3 thin films are not yet fully studied in terms of structural and optical properties. As a result, the focus of this analysis is concerned with the crystalline and morphological structures of nanostructured In2Se3. The optical characterizations of nanocrystalline In2Se3 thin films, both linear and nonlinear, were also considered. To complete the study's goal, the In2Se3/p-Si junction hybrid system was constructed and examined under the action of light.

2 Experimental procedures

2.1 Preparation and characterization of In2Se3 thin film

In2Se3 with purity 99.999% (5 N) was purchased from Leybold Heraeus GmbH and used without additional purification. The conventional thermal evaporation procedure, type Edwards Co. model E 306A, England, has been used to produce In2Se3 thin films on various types of substrates depending on the aim of measurements. For structural characterization, fused amorphous glass substrates were used, whereas fused quartz substrates were selected for optical measurements, particularly in the UV–Vis-NIIR range, and finally, the p-Si single-crystalline substrate was used for photovoltaic characterization. The film thickness measurements were performed using a quartz crystal monitor and the "Tolansky's" interferometry method [30]. By regulating the rate of deposition, the varied thicknesses of In2Se3 thin films were also measured during film deposition using a quartz crystal monitor type FTM4 Edwards and the rate of evaporation remained constant at 4 Å/s through the evaporation process. To investigate the crystalline structural characteristics of the powder and thin films of In2Se3, Philips X, pert diffractometer with λCuKα = 1.540 Å worked at 30 mA and 40 kV and its range 2θ = 4–90° was used. By using a multi-purpose transmission electron microscope type JEM-2100 Plus, JOEL instrument with a 0.28sr of solid angle, the EDX analysis was done for checking the elemental stoichiometry of In2Se3.

2.2 Optical calculation of In2Se3 thin film

A spectrophotometer (JASCO model V-570 UV–VIS–NIR) was used to analyze the optical properties of the thin films under investigation. The optical transmittance T (\(\lambda\)) and reflectance R (\(\lambda\)), at normal incidence, were measured using a spectrophotometer with two beams in the spectral range of 200–2500 nm. To estimate the absorption coefficient, α and optical constants (refractive index n, and absorption index k) at different \(\lambda\), a computer program based on the absolute values of the measured T(\(\lambda\)) and R(\(\lambda\)) was calculated according to the equation [31, 32]:

where d is the thickness of the deposited film, T is the measured transmittance, and R is the measured reflectance.

The absolute values of R and T are given by [33]:

where Ift is the amount of light that passes through the film–quartz structure in terms of intensity, Iq is the quartz substrate reflectance intensity, Rq is the quartz reflectance intensity, and Im is the light intensities of the reference mirror, and the reflectance of the reference mirror is Rm. The experimental error in determining the film thickness was assumed as 3%, in T and R as 1%, and the measured values of n and k as 3%, with the computation procedure based on Murmann's precise equation. [34].

3 Results and discussion

3.1 Structural of In2Se3 properties

The microstructure and chemical content of the In2Se3 samples were determined using an EDX detector, or energy-dispersive X-ray unit, attached to a transmission electron microscope, (JEM-2100 Plus). The data were processed by the Zaf rectification tool to obtain full quantitative analysis results from the spectra. Table 1 shows the percentages of the constituent elements of In2Se3 that were obtained. The results indicate a good stoichiometry for the In2Se3 and also confirm the absence of probability of defect elements in the studied composition.

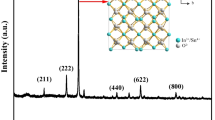

The X-ray powder diffraction, XRD pattern of In2Se3 in powder form, is presented in Fig. 1. The pattern contains several diffraction peaks with different intensities, showing that the In2Se3 powder is polycrystalline with α-phase, in agreement with the hexagonal phase of card no. 00-034-1279. The Fullprof Suite application was used to analyze the unit cell characteristics of In2Se3 (version 2020) that is based on the Rietveld method, considering a pseudo-Voigt function. The analysis confirms that the In2Se3 lattice has a hexagonal with space group p63/mmcc (194), with lattice parameters; a = b = 4.025 \(\mathop {\text{A}}\limits^{o}\), c = 19.235 \(\mathop {\text{A}}\limits^{o}\), V = 269.8699 \(\mathop {\text{A}}\limits^{o3}\), α = β = 90°, γ = 120°. The average crystallite size was determined by using the size–strain formula as follows [35]:

where dhkl, K, ε, θ and β are the interplanar spacing, Scherrer’s constant, Bragg’s angle, microstrain, full width at half maximum, respectively.

The size–strain plot, expressed by the plot of \((d_{hkl} \beta \cos \theta )^{2}\) versus \((d_{hkl}^{2} \cos \theta )\) for all In2Se3 preferred orientations with the hexagonal phase, is shown in Fig. 2. The average particle size, D, is calculated using Eq. (6) from the slope of the linearly fitted data, and the microstrain is calculated using the root of the y-intercept. The homogeneous distortion of the crystalline planes and their homogeneity is supported by the plot's linear fitting. The average crystallite size, D, and microstrain, ε, extracted from the plot are 273.6 nm and 4.9 × 10–3, respectively. Moreover, the length of dislocation lines per volume unit, or dislocation density, \(\delta\), is calculated using the relation [35].

The average dislocation density, δ, is found to be 1.34 × 10–5 nm−2. The estimated value of the structural parameters is tabulated in Table 2 in comparison with those published for similar structures. [36, 37]. The XRD pattern of In2Se3 thin film is shown in Fig. 3. The data were smoothed, and the Gaussian fitting is made on the figure. The XRD exhibits a broad feature that indicates an amorphous nature of In2Se3 thin film (i.e., there is no detected aa characteristic preferred orientations). This is supported by the absence of any discernible peaks in the diffractograms, leaving only a broad characteristic. The absence of polycrystalline nature in the In2Se3 films indicates that the sample was insufficient to allow for long atom arrangements in the deposited film.

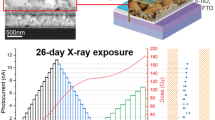

The surface morphology was investigated to examine the optical properties of In2Se3 and its applications because it has a significant impact on device performance [33]. The In2Se3 was treated using a restricted thermal evaporation technique to achieve specific nanostructure morphology for optoelectronic applications. SEM images were used to support the crystallinity and calculate the size of the obtained grains. The results of the SEM images and image applications were used to investigate the surface topography of the In2Se3 structure. The front view of SEM images illustrated in Fig. 4 shows a high density and aggregation of grains all over the surface and random distribution around the entire surface. Figure 5(a) shows the grain size distribution plot as well as the line profile distribution. The average grain size at the local and extended areas of the surface can be obtained based on the line profile distribution, and the grain size at local and extensive areas of the surface was found to be about 5 nm with non-uniform behavior, as shown in Fig. 5(b).

3.2 Optical properties

3.2.1 Transmittance and reflectance spectra

The analysis of thin films' optical properties provides precise information on their key and controlling physical properties, such as energy band gap, dispersion energy, oscillating energy, dielectric parameters, and linear and nonlinear parameters, all of which are essential for optoelectronic device applications.

The spectral behavior of the distribution of T (λ) and R (λ), measured at normal incidence in the investigated wavelength range of 200–2500 nm for different thicknesses of the In2Se3 thin film, is shown in Fig. 6(a) and (b). The change in film transmission and reflection as a function of incident wavelength is shown in Fig. 6. The transmission and reflection interference (i.e., wave-like pattern) increases as the film thickness increases. The reason for light interference can be predicted from the reflection between the air–film and film–quartz interfaces.

According to the relationship between the absorption coefficient, α, and photon energy, the optical band gap, Eg, of In2Se3 films was calculated using Tauc's relation in the high semiconductor absorption area [38]. The optical band gap, Eg, of In2Se3 films was considered using the Tauc's equation at the absorption edge as follows [38]:

To determine the value of Eg of In2Se3 films, plot (αE)2 against photon energy (E) is plotted to obtain the direct energy gap, as shown in Fig. 7. Extrapolating the linear part of this plot to intercept the axis E (E = 0) yields the optical direct bandgap. The estimated value of the direct energy gap is tabulated in Table 3 in comparison with those published for similar structures [37, 39,40,41,42,43]. The higher value of the energy gap of the studied In2Se3 films is due to the influence of nanostructure.

A comprehensive analysis of refractive index behavior at the spectrum of demand spectral wavelengths should be needed for the optimized design of optical devices. Figure 8 shows the spectra behavior of n as a function of the wavelength for In2Se3 films in the wavelength range 200–2500 nm. The dispersion exhibits two different spectral regions, as can be shown. The first region expositions anomalous dispersion behavior of n at λ < 700 nm. An extensive analysis of refractive index behavior at the range of demand spectral wavelengths should be needed for the improved strategy of optical devices. The dispersion exhibits two distinct spectral regions. At λ < 700 nm, the behavior exhibits anomalous dispersion of n. The anomalous dispersion of n may be due to resonant oscillations of polarized electrons. At λ > 700 nm, the second region shows normal dispersion behavior of n, in which the value of n decreases as the wavelength increases until it reaches a nearly constant value, and the single oscillator model can be used to study the normal dispersion and the dispersion parameters can be calculated [38].

3.2.2 Refractive index and dispersion analysis

The design of devices used in optical communications and other optoelectronics is highly influenced by dispersion parameters. The single oscillator model stated by Wemple and Di-Domenico formula [33] can be used to interpret the spectral behavior of refractive index, n, in wavelengths > 700 nm, where the refractive index is associated with incident photon energy, hv, as follows:

where the electronic transition's oscillator energy is Eo and the energy of dispersion is Ed. Plotting of (n2−1)−1 versus (hv)2, as shown in Fig. 9(a), provides experimental confirmation of Eq. (9). A straight line fit with the slope (E0Ed)−1 and the intercept with the ordinate axis equal to E0/Ed is obtained from this figure. Furthermore, the dielectric constant at high frequencies \(\varepsilon_{\infty }\) was calculated from the intersection of the y-axis at E = 0. Table 4 summarizes the estimated values of E0 and Ed. This may be explained by the nanocrystalline of the In2Se3 thin film, which has a small average crystallite size [34, 44].

The dielectric constant at high frequencies, ε∞, and the ratio of carrier concentration to effective mass, N/m*, can be calculated by using the following [16]:

Figure 9b shows the plot of n2 as a function of λ2. The intercept of the vertical axis at λ2 = 0 is related to εL. The slope of the straight line yields the N/m* carrier concentration to an effective mass ratio. Table 4 displays the extracted values of εL and N/m*.

3.2.3 Dielectric characterization

The complex dielectric function \(\varepsilon^{*}\) has expressions for light transmission, reflection, and loss through the medium. Moreover, \(\varepsilon^{*}\) is a significant amount for the manufacturer and a term used to describe a high-efficiency optical–electronic system. The complex dielectric function can be defined as \(\varepsilon^{*} (\omega ) = \varepsilon_{1} (\omega ) + i\varepsilon_{2} (\omega )\). N and k are connected to \({\upvarepsilon }_{{2}}\) and \({\upvarepsilon }_{{1}}\) by the following expression [39]:

Figure 10 depicts the modulation \(\varepsilon_{1}\) and \(\varepsilon_{2}\) versus photon energy, E, of the In2Se3 thin film. The appearance of peaks in the dielectric spectra indicates the base material and makes provision via interactions between outgoing photons and electrons on the material's electronic structure [45]. The surface energy loss function (SELF) and the volume energy loss function (VELF) are two measurements of how incident electromagnetic interacts with electrons in a material when it transports through its surface or penetrates its mass. The SELF and VELF are related to \(\varepsilon_{1}\) and \(\varepsilon_{2}\) as follows [46]:

Figure 11 illustrates the photon energy dependence of both VELF and SELF. Both the SELF and VELF spectra have the same behavior, of the high-intensity peak with maximum loss energy at 2.20 eV at distinct peaks that characterize the In2Se3 thin film. Another peak is recorded only for the VELF at 3.15 eV. On the other hand, the determined SELF has a lower value than VELF in the entire photon energy under consideration which means that the loosed energy from the surface is small as compared to when traveling through the bulk material.

The optical conductivity, which has a relationship with the material's dielectric constant and the density of the electronic state, can be expressed as follows [47, 48]:

The variance of both σ1 and σ2 as a function of photon energy for In2Se3 thin films is shown in Fig. 12 for both σ1 and σ2; the photon energy dependence exhibits a similar trend. The high optical conductivity suggests that the studied material has a remarkable photoresponse activity for optoelectronic system applications [48]. Furthermore, at photon energy > 3.2 eV, a strong notable rise in both σ1 and σ2 is observed.

3.2.4 The nonlinear optical characteristics of the In2Se3 film

The study of nonlinear optics (NLO) is important for all photosensitive signal processing units, optoelectronic and various switching devices [49]. For the optoelectronic application of In2Se3-based devices, knowledge of nonlinear optical characteristics is imperative [50]. Some earlier studies have been done on the nonlinear optical properties of In2Se3[51, 52]. The balance between second harmonic generation (SHG) intensity and laser-induced damage threshold (LIDT), as well as phase-matchable behavior, was investigated by Chi et al.[51]. They looked into the NLO property of defect wurtzite-type hexagonal-In2Se3 and discovered that it has a strong second harmonic generation, which they attribute to the contribution of the unique InSe5 unit in -In2Se3 based on birefringence calculations and analysis. Chen et al.[52] investigated the nonlinear optical characteristics and ultrafast carrier dynamics of indium selenide (InSe) nanosheets formed by liquid-phase exfoliation under pulsed stimulation of various durations. They discovered that InSe nanosheets have a better saturable absorption response under 6 ns pulse excitation at different pulse lengths, which is due to the thermal effect under ns pulse excitation.

The nonlinearity is manifested through the material's polarization, which is generally indicated through the electric field, E, linear optical susceptibility, \(\chi^{(1)}\), and second-order susceptibility, \(\chi^{(3)}\), by the following relation.

The single oscillator parameters, Eo (Energy of oscillation) and Ed (energy of dispersion), are correlated with \(\chi^{(1)}\) through:

At (\(h\upsilon \to 0\)), the value of n will have the same refractive index as the static refractive index, no, \(n_{o} = \sqrt {1 + \frac{{E_\text{d} }}{{E_{o} }}}\) So that

The variation in incident photon energy is estimated for visible and near-infrared wavelengths using a correlation of Miller's generalized rule and Wemple and Didomenico's single oscillator model. The photon energy is connected to \(\chi^{(3)}\) using the equation below.

where A ≈1.7 × 10–10 esu. Figure 13 shows the theoretical calculated \(\chi^{(1)}\) and \(\chi^{(3)}\) as a function of the photon energy of In2Se3 thin film, depending on the measured dispersion parameters. Similar behavior is observed with a characterized peak centered around 2.2 eV.

3.3 Photoresponse characteristics of In2Se3–based heterojunction

The schematic diagram of the heterojunction structure of analysis of Au/In2Se3/p-Si /Al heterojunction is illustrated in Fig. 14. The current density–voltage properties are crucial for optoelectronic applications, particularly in the dark and under the influence of illumination. In the dark and under illumination at 100 mW/cm2, Fig. 15 shows the property of the semi-logarithmic J–V curves of the Au /In2Se3/p-Si /Al heterojunction. In the dark, the device has a higher rectification ratio than those under illumination. Moreover, the reverse current increases faster under illumination than the dark forward current at the same voltage. The rise in the reverse current compared to the forwarding current under the presence of illumination can be associated with the formation of exciton due to light absorption. Under the influence of an external bias in the depletion field, the generated exciton is separated into the corresponding charge carriers and swept to the opposite electrodes to produce current [53]. The slope of the linear part of the I–V curve for the forward bias has been used to calculate the ideality factor n for the In2Se3/p-Si heterojunction, according to the formula given in the literature [54]. The values of n diverge from unity, as can be seen. This trend was followed in other materials, and it could be considered to be due to increasing the applied voltage, which would boost the diffusion current. In the depletion region, this trend could result in electron–hole recombination [55].

For studying the heterojunction performance, the predominant conduction mechanism is very optimistic. The double logarithmic plot of the J–V under forwarding bias at room temp is shown in Fig. 15.This graph represents a linear relationship with different distinct regions depending on the applied voltage and follows the relation, Jα Vs, where s is concerned with the distribution of trapping centers and differs with injection level. Figure 16 shows the least-square fit of the three distinct regions in SCLC J–V plots that have appeared for the dark condition. At lower voltages, the slope, s, of the lnJ–lnV plots indicates an exponential trap distribution followed by a strong dependence on the presence of traps in insulators, where a nearly vertical trap-filling-limited (TFL) sub-region is observed and come back to the exponential trap distribution at the third region. Under illumination, the lnJ–lnV plots indicate only two distinct regions, specified as quadratic for the first region and exponential trap distribution at the second region due to the influence of illumination on the rate of the depletion region. The phototransient characteristics of the prepared device for checking the applicability of the device in the optoelectronics are shown in Fig. 16

The performance of the photodiode is controlled by some important parameters like responsivity, R. The responsivity can be identified by the following relation [56]

where Jph is the photocurrent and P is the input power intensity. The change of the responsively of Au/In2Se3/p-Si /Al heterojunction versus the reverse bias is shown in Fig. 17(a). As observed from the figure that the responsivity increases with the reverse increase and reaches its maximum at 1.50 V and 1.85 V. The transit time of photocarriers in the depletion region, which is dependent on carrier drift velocity and depletion layer width, as well as the diffusion time of photocarriers beyond the depletion region, determines the response time of a photodetector with its output circuit.

The capability of several photodiodes to sense or detect a minor signal of light is characterized by specific detectivity and defined by the following [56]:

where Jd is the dark current density. The reverse bias of specific detectivity, D*, of Au / In2Se3/p-Si /Al heterojunction under 100 mW/cm2 is shown in Fig. 17(b). Like the reverse-biased responsivity plot, the specific detectivity increases with the reverse increase and gives the same behavior.

4 Conclusions

The use of the XRD technique to investigate the crystalline properties of In2Se3 thin films showed that the powder is polycrystalline, with a hexagonal system and α-phase. Based on the Williamson–Hall display, the average crystallite size, microstrain, and dislocation density were obtained and found to be 273.6 nm, 4.9 × 10–3, and 1.34 × 10–5 m−2, respectively. The absorption edge analysis showed that the transition type is directly allowed with an energy gap of 2.25 eV. The Wemple–DiDominco relationship was used to construct a single oscillator model, and the calculated dispersion parameters were found to be comparable. A high-intensity peak was detected \(\chi^{(1)}\) at 1.87 eV. The electrical properties of the In2Se3/p-Si heterojunction were investigated using the J–V method in both dark and light conditions. According to the electrical experiments, the heterojunction exhibits good rectifying properties and is sensitive to the impact of illumination. The In2Se3-based heterojunction method shows an exponential trap distribution followed by a substantial reliance on the existence of traps in insulators. The photocurrent transient properties verified a fast response to light and suitability for photodetector applications.

References

T Zhai et al. ACS Nano 4 949 (2010).

R B Jacobs-Gedrim et al. ACS Nano 8 514 (2014).

P Hou and Y Lv Nano Mater. 2 4443 (2019).

M S Choi, B K Cheong, C H Ra, S Lee, J H Bae, S Lee, G D Lee and C W Yang Mat. 29 1 (2017).

X Tang, J Shang and Y Gu J. Mater. Chem. A 8 7331 (2020).

M Si, A K Saha, S Gao, G Qiu, J Qin, Y Duan, J Jian, C Niu, H Wang and W Wu Electron. 2 580 (2019).

J Zhou, Q Zeng, D Lv, L Sun, L Niu, W Fu, F Liu, Z Shen, C Jin and Z Liu Nano Lett. 15 6400 (2015).

S H Know, B T Ahn, S K Kim, K H Yoon and J Song Thin Solid Films 323 265 (1998).

D Kang, T Rim and C K Baek Phys. Lett. 103 233504 (2013).

J Ye and T Yoshida Lett. 67 3066 (1995).

S R Tamalampudi, Y Y Lu, U R Kumar, R Sankar, C D Liao, B K Moorthy, C H Cheng, F C Chou and Y T Chen Nano Lett. 14 2800 (2014).

A A Yadav and S D Salunke J. Alloys Compd. 640 534 (2015).

R Sreekumar and R Jayakrishnan J. Appl. Phys. 100 033707 (2006).

R Niranjan and N Padha Mater. Chem. Phys. 1016 033707 (2020).

L Liu, J Dong, J Huang, A Nie, K Zhai, J Xiang, B Wang, F Wen, C Mu, Z Zhao and Y Gong Mat. 31 10143 (2019).

W Li, F P Sabino, F C de Lima and T Wang Rev. B 98 165134 (2018).

P Kumar and A G Vedeshwar J. Appl. Phys. 123 125107 (2018).

G Almeida, S Dogan, G Bertoni, C Giannini, R Gaspari, S Perissinotto and R Krahne J. Am. Chem. Soc. 139 3005 (2017).

I H Mutlu J. Sol. Gel Sci. Technol. 43 223 (2007).

P P Hankare and M R Asabe J. Mater. Sci. Mater. Electron. 19 1252 (2008).

M Lin, D Wu, Y Zhou, W Huang, W Jiang, W Zheng, S Zhao, C Jin and Y Guo J. Am. Chem. Soc. 135 13274 (2013).

Y Yan, S Li, Y Ou, Y Ji, Z Yu, L Liu and C Yan Lett. 10 1093 (2014).

C H Ho Actuator. B Chem. 209 811 (2015).

J M Czerniawski, J L Stickney and J Phys Chem. C 120 16162 (2016).

S Li, Y Yan, Y Zhang, Y Ou, Y Ji, L Liu, C Yan, Y Zhao and Z Yu Vacuum 99 228 (2014).

Y Yan, S Li, Y Ji, L Liu, C Yan and Y Zhang Lett. 109 291 (2013).

L Wang et al Nature 570 91 (2019).

S Dubey et al ACS Nano 11 11206 (2017).

S Tolansky J. Phys. Radium 11 373 (1950).

H T El-Shair, H Al-Abawi and M M El-Nahass J. Phys. 42 695 (1992).

T Altalhi Mat. 117 111152 (2021).

M M El-Nahass and A M Hassanien Commun. 325 116 (2014).

I Konstantinov Appl. Opt. 37 4260 (1998).

M Dongol, A El-Denglawey, A F Elhady and A A Abuelwafa Curr. Appl. Phys. 12 1334 (2012).

Lixuan Liu et al Chem. Mater. 31 10143 (2019).

S N Grigorov, V M Kosevich, S M Kosmachev, B A Savitsky and A V Taran Jpn. J. Appl. Phys. 39 179 (2000).

M M El-Nahass, A A M Farag, M El-Metwally, F S H Abu-Samaha and E Elesh Synth. Met. 195 110 (2014).

J Quereda, R Biele, G Rubio-Bollinger, N Agraït, R D’Agosta and A Castellanos-Gomez Adv. Opt. Mater. 4 1939 (2016)

H Shi et al. Adv. Mater. 32 1907244 (2020).

C-H Ho, X-R Lai, C-A Chuang, W-L Kuo and K-K Tiong Adv. Photon. Res. 2 2000110 (2021).

G Liu, K Chen and J Li J. Am. Ceram. Soc. 101 36 (2018).

C Amory, N Guettari, J C Bernède and M Mebarki Phys. Stat. Sol. 15 3726 (2006).

C Julien, A Chlwy and D Siapkas Phys. Stat. Sol. (a) 118 553 (1990).

S A Elsayed, E A Gaml and M A Nasher Opt. Mater. 84 8 (2018).

M A Nasher, M I Youssif, N A El-Ghamaz and H M Zeyada Optik 178 532 (2019).

H Zeyada, M Youssif, N El-Ghamaz and M Aboderbala Phys. B 506 75 (2017).

W M Desoky, M S Dawood and M M El-Nahass Optik 178 351 (2019).

A A M Farag, I S Yahia and M S Al-Kotb Chin. J. Phys. 64 87 (2020).

T Jadoon, T Bibi, S Muhammad and A Khurshid J. Molecular Graph. Model. 107 107975 (2021).

Y Chi, Z-D Sun, Q-T Xu, H-G Xue, S-P Guo and A C S Appl Mater. Interfaces 12 17699 (2020).

C Chen, N Dong, J Huang, X Chen, H Wang, Z Wang and J Wang Adv. Opt. Mat. 10 2101432 (2022).

P Sharma and S Katyal J. Appl. Phys. 107 113527 (2010).

A A M Farag and I S Yahia Synth. Met. 161 32 (2011).

I M El Radaf and M S El-Bana Physica B 584 412067 (2020).

A A Attia, M M Saadeldin, H S Soliman, A S Gadallah and K Sawaby Opt. Mater. 62 711 (2016).

H Abdel-Khalek, E Shalaan, M Abd-ElSalam and A M El-Mahalawy Synth. Met. 245 223 (2018).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

BE involved in preparing the samples, X-ray measurement, optical spectroscopic measurement, formal analysis of X-ray and optical properties, writing—original draft, and final revision of the manuscript plagiarism. MMEl-N took part in preparing the samples and final revision of the manuscript. NR involved in scanning electron microscope (SEM) measurements. AAMF took part in final analysis of SEM and heterojunction, final revision of all the figures and the manuscript writing and manuscript plagirism.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ebraheem, B., El-Nahass, M.M., Roushdy, N. et al. Nanocrystalline embedded In2Se3 amorphous thin film investigation and optical enhancement characterization for photo-sensing application. Indian J Phys 97, 885–896 (2023). https://doi.org/10.1007/s12648-022-02390-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-022-02390-4