Abstract

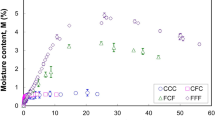

Natural fibre-reinforced polymer composites, recently developed, provide several socioeconomic and sustainability benefits for a wide range of technical applications. The purpose of this study was to look at how natural flax fibre (30 wt%) and silicon dioxide (SiO2 (0, 2.5, 5, 7.5, 10, 12.5 wt%)) affect ternary mixes’ mechanical, combustible, and water absorption qualities. A cone calorimetry investigation revealed that the inclusion of nanosilicon dioxide might reduce the polypropylene (PP) composites made from flax fibre’s total heat release, total smoke release, and heat release rate. Using 10 wt% nanosilicon dioxide, the heat release rate (255 kW/m2 to 161 kW/m2) was considerably reduced. The mechanical characteristics of the composites increased with the addition of nanosilicon dioxide, and the flexural (50.97 MPa) and tensile strength (42.65 MPa) of the materials reached their maximum values at 10 weight% nanosilicon dioxide. Nanosilicon dioxide exhibited homogeneous dispersal in the flax fibre-based PP composites, with an increase in nanosilicon dioxide from 2.5 to 10 wt%, according to scanning electron microscopy observations on the fractured portion of the hybrids. The lack of a recognisable peak in the X-ray diffraction (XRD) after the integration of nano-SiO2 particles suggests that the granules were homogeneous. The highest water absorption in flax/PP hybrids decreases by 13.25, 15.69, 20.16, 23.63 and 19.52% as compared to pure PP and PP with flax fibre with the addition of 2.5, 5, 7.5, 10 and 12.5 wt% of SiO2 filler, respectively. Based on the obtained results in natural flax fibre-based hybrid composites, the nanoSiO2 particles worked as barriers to prevent moisture absorption and increase their rigidity. These outcomes imply that such materials would be appropriate for use in moist settings, like those seen in the maritime, outdoor, and packaging sectors. Additionally, these results imply that such composites may find use in sectors where fire safety is a top priority.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are included in the article. Should further data or information be required, these are available from the corresponding author upon request.

References

Balaji A, Kannan S, Purushothaman R et al (2022) Banana fiber and particle-reinforced epoxy biocomposites: mechanical, water absorption, and thermal properties investigation. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-02829-y

Dahal RK, Acharya B, Dutta A (2022) Mechanical, thermal, and acoustic properties of hemp and biocomposite materials: a review. J Compos Sci 6:373. https://doi.org/10.3390/jcs6120373

Ganesan K, Kailasanathan C, Sanjay MR et al (2020) A new assessment on mechanical properties of jute fiber mat with egg shell powder/nanoclay-reinforced polyester matrix composites. J Nat Fibers 17:482–490. https://doi.org/10.1080/15440478.2018.1500340

Bakhori SNM, Hassan MZ, Bakhori NM et al (2022) Mechanical properties of PALF/Kevlar-reinforced unsaturated polyester hybrid composite laminates. Polymers 14:2468. https://doi.org/10.3390/polym14122468

Prabhu P, Karthikeyan B, Vannan RRRM, Balaji A (2022) Mechanical, thermal and morphological analysis of hybrid natural and glass fiber-reinforced hybrid resin nanocomposites. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-02632-9

Raju GU, Kumarappa S, Gaitonde VN (2012) Mechanical and physical characterization of agricultural waste reinforced polymer composites. J Mater Environ Sci 3:907–916

Dey P, Mahapatra BS, Juyal VK et al (2021) Flax processing waste – a low-cost, potential biosorbent for treatment of heavy metal, dye and organic matter contaminated industrial wastewater. Ind Crops Prod 174:114195. https://doi.org/10.1016/j.indcrop.2021.114195

Ma H, Guna V, Raju T et al (2023) Converting flax processing waste into value added biocomposites. Ind Crops Prod 195:116434. https://doi.org/10.1016/j.indcrop.2023.116434

Srb P, Syrovátková M, Kulhavý P, Tomková B (2018) Study of mechanical properties and modeling of flax reinforced composites. Mater Sci Forum 919:152–159. https://doi.org/10.4028/www.scientific.net/MSF.919.152

Shuvo II, Shadhin M (2019) Biopolymer flax (Linum Usitatissimum L.) and its prospects in biodegradable composite fabrication- a short review. J Text Eng Fashion Technol 5:267–274. https://doi.org/10.15406/jteft.2019.05.00212

Hautala M, Pasila A, Pirila J (2004) Use of hemp and flax in composite manufacture: a search for new production methods. Compos Part A: Appl Sci Manuf 35:11–16. https://doi.org/10.1016/j.compositesa.2003.09.023

Amjad A, Anjang Ab Rahman A, Awais H et al (2022) A review investigating the influence of nanofiller addition on the mechanical, thermal and water absorption properties of cellulosic fibre reinforced polymer composite. J Ind Text 51:65S–100S. https://doi.org/10.1177/15280837211057580

Balaji A, Udhayasankar R, Karthikeyan B et al (2020) Mechanical and thermal characterization of bagasse fiber/coconut shell particle hybrid biocomposites reinforced with cardanol resin. Results in Chemistry 2:100056. https://doi.org/10.1016/j.rechem.2020.100056

Prabhu P, Karthikeyan B, Ravi RM, Vannan R, Balaji A (2022) Investigation on mechanical, dynamic mechanical analysis, thermal conductivity, morphological analysis, and biodegradability properties of hybrid fiber mats reinforced HLCE resin nanocomposites. Polym Compos 43:8850–8859. https://doi.org/10.1002/pc.27066

Samy A, Ismail AM, Ali H (2023) Environmentally friendly mesoporous SiO2 with mixed fiber/particle morphology and large surface area for enhanced dye adsorption. J Mater Sci 58:1586–1607. https://doi.org/10.1007/s10853-022-08119-2

Zaer-Miri S, Khosravi H (2022) Assessment of the wear behavior and interlaminar shear properties of modified nano-TiO2/jute fiber/epoxy multiscale composites. J Ind Text 51:1084–1099. https://doi.org/10.1177/1528083719893718

Nourbakhsh A, Kokta BV, Ashori A, Jahan-Latibari A (2008) Effect of a novel coupling agent, polybutadiene isocyanate, on mechanical properties of wood-fiber polypropylene composites. J Reinf Plast Compos 27:1679–1687. https://doi.org/10.1177/0731684407087377

Hosseini P, Booshehrian A, Madari A (2011) Developing concrete recycling strategies by utilization of nano-SiO 2 particles. Waste Biomass Valoriz 2:347–355. https://doi.org/10.1007/s12649-011-9071-9

Wang A, Wang X, Xian G (2020) Mechanical, low-velocity impact, and hydrothermal aging properties of flax/carbon hybrid composite plates. Polym Test 90:106759. https://doi.org/10.1016/j.polymertesting.2020.106759

Kushwaha PK, Pandey CN, Kumar R (2014) Study on the effect of carbon nanotubes on plastic composite reinforced with natural fiber. J Indian Acad Wood Sci 11:82–86. https://doi.org/10.1007/s13196-014-0121-3

Kumar N, Mireja S, Khandelwal V et al (2017) Light-weight high-strength hollow glass microspheres and bamboo fiber based hybrid polypropylene composite: a strength analysis and morphological study. Compos Part B: Eng 109:277–285. https://doi.org/10.1016/j.compositesb.2016.10.052

Ganesan V, Kaliyamoorthy B (2020) Utilization of Taguchi technique to enhance the interlaminar shear strength of wood dust filled woven jute fiber reinforced polyester composites in cryogenic environment. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1789021

Natrayan L, Kaliappan S, Sethupathy BS et al (2022) Effect of mechanical properties on fibre addition of flax and graphene-based bionanocomposites. Int J Chem Eng 2022. https://doi.org/10.1155/2022/5086365

Engineering BOF effect of filler materials on thermal and mechanical properties of glass fiber reinforced composite materials

Kiguchi M, Kataoka Y, Matsunaga H et al (2007) Surface deterioration of wood-flour polypropylene composites by weathering trials. J Wood Sci 53:234–238. https://doi.org/10.1007/s10086-006-0838-8

Schartel B, Braun U, Schwarz U, Reinemann S (2003) Fire retardancy of polypropylene/flax blends. Polymer 44:6241–6250. https://doi.org/10.1016/S0032-3861(03)00692-X

Liu X, Cui Y, Hao S, Chen H (2018) Influence of depositing nano-SiO2 particles on the surface microstructure and properties of jute fibers via in situ synthesis. Compos Part A: Appl Sci Manufac 109:368–375. https://doi.org/10.1016/j.compositesa.2018.03.026

Mingzhu P, Hailan L, Changtong M (2012) Flammability of nano silicon dioxide – wood fiber – polyethylene composites. J Compos Mater 47:1471–1477. https://doi.org/10.1177/0021998312448499

Becker O, Cheng YB, Varley RJ, Simon GP (2003) Layered silicate nanocomposites based on various high-functionality epoxy resins: the influence of cure temperature on morphology, mechanical properties, and free volume. Macromolecules 36:1616–1625. https://doi.org/10.1021/ma0213448

Sadrmomtazi A, Fasihi A (2010) Influence of polypropylene fibers on the performance of nano-SiO 2-incorporated mortar. Iran J Sci Technol Trans B: Eng 34:385–395

Lakshmaiya N, Ganesan V, Paramasivam P, Dhanasekaran S (2022) Influence of biosynthesized nanoparticles addition and fibre content on the mechanical and moisture absorption behaviour of natural fibre composite. Appl Sci (Switzerland) 12:13030. https://doi.org/10.3390/app122413030

Mukhtar I, Leman Z, Zainudin ES, Ishak MR (2020) Effectiveness of alkali and sodium bicarbonate treatments on sugar palm fiber: mechanical, thermal, and chemical investigations. J Nat Fibers 17:877–889. https://doi.org/10.1080/15440478.2018.1537872

G V, V SS, M KR et al (2023) Experimental investigation of high filler loading of SiO2 on the mechanical and dynamic mechanical analysis of natural PALF fibre-based hybrid composite. Silicon. https://doi.org/10.1007/s12633-023-02464-w

Ponnusamy M, Natrayan L, Patil PP et al (2022) Multiresponse optimization of mechanical behaviour of calotropis gigantea/nano-silicon-based hybrid nanocomposites under cryogenic environment. Adsorpt Sci Technol 2022. https://doi.org/10.1155/2022/4138179

Sanjeevi S, Shanmugam V, Kumar S et al (2021) Effects of water absorption on the mechanical properties of hybrid natural fibre/phenol formaldehyde composites. Sci Rep 11:1–11. https://doi.org/10.1038/s41598-021-92457-9

Arsiya F, Sayadi MH, Sobhani S (2017) Green synthesis of palladium nanoparticles using Chlorella vulgaris. Mater Lett 186:113–115. https://doi.org/10.1016/j.matlet.2016.09.101

García M, Hidalgo J, Garmendia I, García-Jaca J (2009) Wood-plastics composites with better fire retardancy and durability performance. Compos Part A: Appl Sci Manufac 40:1772–1776. https://doi.org/10.1016/j.compositesa.2009.08.010

Matheswaran M, Suresh P, Velmurugan G, Nagaraj M (2023) Evaluation of agrowaste/nanoclay/SiO2-based blended nanocomposites for structural applications: comparative physical and mechanical properties. Silicon. https://doi.org/10.1007/s12633-023-02570-9

Yang X, Sun Y, Shi D, Liu J (2011) Experimental investigation on mechanical properties of a fiber-reinforced silica aerogel composite. Mater Sci Engineering: A 528:4830–4836

Garg M, Abumeri GH, Abdi F (2010) Material properties characterization for multi-scale composites: glass/epoxy/silica nanoparticles. Mater Eval 68:542–547

Devnani GL, Sinha S (2019) Effect of nanofillers on the properties of natural fiber reinforced polymer composites. Mater Today: Proc 18:647–654. https://doi.org/10.1016/j.matpr.2019.06.460

Zhuang C, Chen Y (2019) The effect of nano-SiO2 on concrete properties: a review. Nanatechnol Reviews 8:562–572. https://doi.org/10.1515/ntrev-2019-0050

Maurya AK, Gogoi R, Manik G (2021) Mechano-chemically activated fly-ash and sisal fiber reinforced PP hybrid composite with enhanced mechanical properties. Cellulose 28:8493–8508. https://doi.org/10.1007/s10570-021-03995-4

Wang Y, Xu Z, Wang J et al (2020) Synergistic effect of nano-silica and silica fume on hydration properties of cement-based materials. J Therm Anal Calorim 140:2225–2235. https://doi.org/10.1007/s10973-019-08929-8

Sain M, Park SH, Suhara F, Law S (2004) Flame retardant and mechanical properties of natural fibre-PP composites containing magnesium hydroxide. Polym Degrad Stab 83:363–367. https://doi.org/10.1016/S0141-3910(03)00280-5

Barrera CS, Cornish K (2017) Processing and mechanical properties of natural rubber/waste-derived nano filler composites compared to macro and micro filler composites. Ind Crops Prod 107:217–231. https://doi.org/10.1016/j.indcrop.2017.05.045

Li B, He J (2004) Investigation of mechanical property, flame retardancy and thermal degradation of LLDPE-wood-fibre composites. Polym Degrad Stab 83:241–246. https://doi.org/10.1016/S0141-3910(03)00268-4

Wang C, Cai L, Shi SQ et al (2019) Thermal and flammable properties of bamboo pulp fiber/high-density polyethylene composites: influence of preparation technology, nano calcium carbonate and fiber content. Renew Energy 134:436–445. https://doi.org/10.1016/j.renene.2018.09.051

G V, L N (2023) Experimental investigations of moisture diffusion and mechanical properties of interply rearrangement of glass/Kevlar-based hybrid composites under cryogenic environment. J Mater Res Technol. https://doi.org/10.1016/J.JMRT.2023.02.089

Saha A, Kumar S, Zindani D (2021) Investigation of the effect of water absorption on thermomechanical and viscoelastic properties of flax-hemp-reinforced hybrid composite. Polym Compos 42:4497–4516. https://doi.org/10.1002/pc.26164

Zhao H, Li RKY (2008) Effect of water absorption on the mechanical and dielectric properties of nano-alumina filled epoxy nanocomposites. Compos Part A: Appl Sci Manufac 39:602–611. https://doi.org/10.1016/j.compositesa.2007.07.006

Acknowledgements

The authors thank the Department of Mechanical Engineering, Madanapalle Institute of Technology & Science, Andhra Pradesh, India for the technical assistance.

Author information

Authors and Affiliations

Contributions

Arunkumar D and Latha A: Conceptualization, Methodology; Writing an original draft. Suresh Kumar S and Jasgurpreet Singh Chohan: Investigation, Review. Velmurugan G and Nagaraj M: Testing and Evaluations.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Yes. All permission granted.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

D., A., A., L., S., S. et al. Experimental Investigations of Flammability, Mechanical and Moisture Absorption Properties of Natural Flax/NanoSiO2 Based Hybrid Polypropylene Composites. Silicon 15, 7621–7637 (2023). https://doi.org/10.1007/s12633-023-02611-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02611-3