Abstract

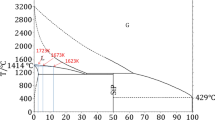

The content of P in industrial silicon affects the photoelectric conversion efficiency of solar-grade silicon. Based on a large amount of actual production data, this paper uses statistical analysis and MIVM model to study the influence of Fe and Al content on P content in the actual production process of Si-P-Fe and Si-P-Al ternary systems. The results showed that statistical analysis (linear regression) were in good agreement with the results of Si-P-Fe and Si-P-Al calculated by the MIVM model.The presence of Fe and Al at the same temperature has a negative impact on the removal of P, and Al has a greater impact on P.The presence of Fe and Al at the same temperature has a negative impact on the removal of P, and Al has a greater impact on P. The MIVM model calculation results provide a theoretical and technical basis for the development of metallurgical methods to prepare solar-grade polysilicon.

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this published article.

Ethics Approval and Consent to Participate.

We don't cover ethics approval and consent to participate.

Consent for Publication.

Not applicable.

References

Ding Z, Yang WJ, Huo KF, Shaw L (2021) Thermodynamics and Kinetics Tuning of LiBH4 for Hydrogen Storage. Progress in Chemistry 33(9):1586–1597

Ding Z, Li SY, Zhou Y, Chen ZQ, Yang WJ, Ma WH, Shaw L (2020) LiBH4 for Hydrogen Storage - New Perspectives. Nano Materials Science 2(2):109–119

Ding Z, Li H, Shaw L (2020) New insights into the solid-state hydrogen storage of nanostructured LiBH4-MgH2 system. Chemical Engineering Journal 385, 123856.

Ding Z, Chen ZQ, Ma TY, Lu C-T, Ma WH, Shaw L (2020) Predicting the hydrogen release ability of LiBH4-based mixtures by ensemble machine learning. Energy Storage Materials 27:466–477

Gao MM, Zhao X, Gao A, Li R, Chen WY, Gao M, Liang S, Li HB (2021) Effect of Si Content on the Morphology Evolution of the Si Primary Dendrites in Al-Si Alloy Solvent Refining Process. SILICON. https://doi.org/10.1007/s12633-021-01233-x

Koehler M, Pomaska M, Lentz F, Finger F, Rau U, Ding K (2018) Wet-Chemical Preparation of Silicon Tunnel Oxides for Transparent Passivated Contacts in Crystalline Silicon Solar Cells. ACS Appl Mater Interfaces 10(17):14259–14263

Ren YS, Wang HP, Morita K (2018) Growth control and enrichment of Si crystals from Si-Sn melt by directional solidification. Vacuum 158:86–92

Li GQ, Lu YS, Xuan QD, Akhlaghi YG, Pei G, Ji J, Zhao XD (2020) Small scale optimization in crystalline silicon solar cell on efficiency enhancement of low-concentrating photovoltaic cell. Sol Energy 202:316–325

Pinto MA, Frate CA, Rodrigues TO, Caldeira-Pires A (2020) Sensitivity analysis of the carbon payback time for a Brazilian photovoltaic power plant. Utilities Policy 63: 101014.

Alemany C, Trassy C, Pateyron B, Li KI, Delannoy Y (2002) Refining of metallurgical-grade silicon by inductive plasma. Sol Energy Mater Sol Cells 72(1–4):41–48

Eger WA, Genest A, Roesch N (2012) Thermal Decomposition of Branched Silanes: A Computational Study on Mechanisms. Chemistry-a European Journal 18(29):9106–9116

Xi FS, Li SY, Ma WH, Chen ZJ, Wei KX, Wu JJ (2021) A review of hydrometallurgy techniques for the removal of impurities from metallurgical-grade silicon. Hydrometallurgy 201: 105553.

Chigondo F (2018) From Metallurgical-Grade to Solar-Grade Silicon: An Overview. SILICON 10(3):789–798

Qian GY, Sun LY, Chen H, Wang Z, Wei KX, Ma WH (2020) Enhancing impurities removal from Si by controlling crystal growth in directional solidification refining with Al-Si alloy. Journal of Alloys and Compounds 820: 153300.

Qian GY, Wang Z, Gong XZ, Cao JW, Ma WH (2020) Design of Refining Slag Based on Raman and NMR Spectroscopy Study for Removing Phosphorus for SoG-Si. SILICON 12(1):171–183

Khajavi LT, Barati M (2017) Thermodynamics of Phosphorus in Solvent Refining of Silicon Using Ferrosilicon Alloys. Metallurgical and Materials Transactions B-Process Metallurgy and Materials Processing Science 48(1):268–275

Liu SN, Huang K, Zhu HM (2016) Removal of Fe, B and P impurities by enhanced separation technique from silicon-rich powder of the multi-wire sawing slurry. Chem Eng J 299:276–281

Lai HX, Sheng ZL, Li JT, Xing PF, Luo XT (2018) Enhanced separation of phosphorus from metallurgical grade silicon by CaAl2Si2 phase reconstruction. Sep Purif Technol 191:257–265

Zhu MY, Yue SY, Wu GX, Tang K, Xu YJ, Safarian J (2021) P removal from Si by Si-Ca-Al alloying-leaching refining: Effect of Al and the CaAl2Si2 phase. Separation and Purification Technology 271.

Jung EJ, Moon BM, Min DJ (2011) Quantitative evaluation for effective removal of phosphorus for SoG-Si. Sol Energy Mater Sol Cells 95(7):1779–1784

Dhamrin M, Ozaki R, Saitoh T (2002) Quality evaluation and improvement of iron-doped electromagnetic multycrystalline silicon wafers. Sol Energy Mater Sol Cells 74(1–4):203–211

Kvande R, Mjos O, Ryningen B (2005) Growth rate and impurity distribution in multicrystalline silicon for solar cells. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing 413:545–549

Fang M, Lu CH, Huang LQ, Lai HX, Chen J, Li JT, Ma WH, Xing PF, Luo XT (2014) Effect of Calcium-Based Slag Treatment on Hydrometallurgical Purification of Metallurgical-Grade Silicon. Ind Eng Chem Res 53(2):972–979

Zhu MY, Azarov A, Monakhov E, Tang K, Safarian J (2020) Phosphorus separation from metallurgical-grade silicon by magnesium alloying and acid leaching. Separation and Purification Technology 240: 116614.

Johnston MD, Khajavi LT, Li M, Sokhanvaran S, Barati M (2012) High-Temperature Refining of Metallurgical-Grade Silicon: A Review. Jom 64(8):935–945

Ma WH, Ogura M, Kobayashi T, Takahashi H (2004) Preparation of solar grade silicon from optical fibers wastes with thermal plasmas. Sol Energy Mater Sol Cells 81(4):477–483

Khattak CP, Joyce DB, Schmid F (2002) A simple process to remove boron from metallurgical grade silicon. Sol Energy Mater Sol Cells 74(1–4):77–89

Green MA (2003) Crystalline and thin-film silicon solar cells: state of the art and future potential. Sol Energy 74(3):181–192

Goswami DY (2007) A review and future prospects of renewable energy in the global energy system. Solar World Congress of the International-Solar-Energy-Society. Beijing, PEOPLES R CHINA, pp 3–10

Evans RC (1952) An Introduction to Crystal Chemistry. University Press. https://doi.org/10.1180/minmag.1965.035.270.31

Iida T, Guthrie R (1988) The Physical Properties of Liquid Metals. Oxford University Press 19–46.

Takamichi I (1993) Physical Properties of Liquid Metals. (I). Characteristic Features of Liquid Metals, and Liquid Metal Processing Operations. Yosetsu Gakkai Shi/Journal of the Japan Welding Society 62(7):508–511.

Hultgren RR (1973) Selected values of the thermodynamic properties of binary alloys. American Society for Met, Selected values of the thermodynamic properties of binary alloys. https://doi.org/10.1017/S0022172400012638

Safarian J, Tangstad M (2012) Kinetics and Mechanism of Phosphorus Removal from Silicon in Vacuum Induction Refining. High Temp Mater Processes (London). https://doi.org/10.1515/htmp.2011.143

Fruehan RJ (1970) The thermodynamic properties of liquid Fe−Si alloys. Metallurgical Transactions 1(4):865–870

Zaitsev AI, Dobrokhotova ZV, Litvina AD, Mogutnov BM (1995) Thermodynamic properties and phase equilibria in the Fe–P system. J Chem Soc, Faraday Trans 91(4):703–712

Zou KH, Tuncali K, Silverman SG (2003) Correlation and simple linear regression. Radiology 227(3):617–622

Wagner C (2002) Thermodynamics of Alloys. Addision-Wesley Press, Cambridge 1(2):245

Dalaker H (2013) Thermodynamic computations of the interaction coefficients between boron and phosphorus and common impurity elements in liquid silicon. Computer Methods in Materials Science 13(3):407–411

Esfahani S, Barati M (2011) Purification of Metallurgical Silicon Using Iron as Impurity Getter, Part II: Extent of Silicon Purification. Met Mater Int 17(6):1009–1015

Li X, Wu JJ, Xu M, Ma WH (2019) Separation and purification of silicon from cutting kerf-loss slurry waste by electromagnetic and slag treatment technology. J Clean Prod 211(20):695–703

Acknowledgements

The authors are grateful for financial support from the National Natural Science Foundation of China (No. 51804147) and Ten Thousand Talent Plans for Young Top-notch Talents of Yunnan Province (No. YNWR-QNBJ-2020-022) and the Major Projects of Yunnan Province (No. 202102AB080013).

Funding

The authors are grateful for financial support from the National Natural Science Foundation of China (No. 51804147) and and the Major Projects of Yunnan Province (No. 202102AB080013).

Author information

Authors and Affiliations

Contributions

Yaqian Zhu: Conceptualization, Resources, Writing—review & editing, Visualization, Validation, Supervision. Zhengjie Chen: Formal analysis, Validation, Data curation, Writing-original draft, Writing-review&editing. Hongmei Zhang: Conceptualization, Resources, Visualization. Wenhui Ma: Writing—review & editing, Visualization, Supervision.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Y., Chen, Z., Zhang, H. et al. Study on Si-P-Fe and Si-P-Al ternary System Interactions Applied by MIVM Model for the Process of Specific Actual Production. Silicon 14, 10571–10579 (2022). https://doi.org/10.1007/s12633-022-01698-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-01698-4