Abstract

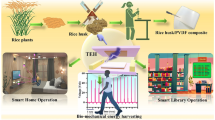

The demand for the development of high-performance and eco-friendly nanocomposites is soaring up. This is because of their desired mechanical, thermal, electrical, magnetic, catalytic, and optical properties and their ecofriendly development. The diversity of nanocomposites has introduced them to a wide variety of applications such as drug delivery, biosensors, bone regeneration, solar cells, super capacitors, fuel cells, automobiles etc. The nanocomposites are deemed competing materials for the sustainable development, this is because of their ecofriendly behavior and value addition. This manuscript reviews the status of the silicon enhanced nanocomposites, various classes of nanocomposites such as ceramic based matrix nanocomposites, metal-based matrix nanocomposites, Polymer based matrix nanocomposites, etc. advanced green polymer-based nanocomposites and sustainable nanofillers for nanocomposites. The applications of nanocomposites in various sectors such as energy, automobiles, packaging, biomedical, environment and safety have been critically reviewed.

Similar content being viewed by others

Data Availability

N/A.

References

Bhagyaraj SM, Oluwafemi OS (2018)Nanotechnology: the science of the invisible, in Synthesis of inorganic nanomaterials. Elsevier, Amsterdam, p 1–18

Ali A et al (2016) Synthesis, characterization, applications, and challenges of iron oxide nanoparticles. Nanotechnol Sci Appl 9:49

Roco MC, Williams RS, Alivisatos P (2000) Nanotechnology research directions: IWGN workshop report: vision for nanotechnology in the next decade. Springer Science & Business Media, Berlin

Jolly R (2017) Synthesis, characterization and application of polymer nanocomposite materials. Aligarh Muslim University, Aligarh

Hadef F (2018) An introduction to nanomaterials. In: Environmental Nanotechnology. Springer, Berlin, p 1–58

Palit S (2020) Recent advances in the application of nanotechnology in food industry and the vast vision for the future. In: Nanoengineering in the Beverage Industry. Elsevier, Amsterdam, p 1–34

Fathy A, et al (2012) Compressive and wear resistance of nanometric alumina reinforced copper matrix composites. Mater Des (1980-2015) 36:100-107

El-Kady O, Fathy A (2014) Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites. Mater Des (1980-2015) 54:348-353

Pottathara YB, et al (2019) Nanomaterials synthesis: design, fabrication and applications. Elsevier Amsterdam

Kalia S et al (2014) Magnetic polymer nanocomposites for environmental and biomedical applications. Colloid Polym Sci 292(9):2025–2052

Chen J et al (2019) An overview of stretchable strain sensors from conductive polymer nanocomposites. J Mater Chem C 7(38):11710–11730

Khalil HA et al (2015) Cellulosic nanocomposites from natural fibers for medical applications: A review. In: Handbook of polymer nanocomposites. Processing, performance and application. Springer, Berlin, p 475–511

Kefeni KK, Mamba BB (2020) Photocatalytic application of spinel ferrite nanoparticles and nanocomposites in wastewater treatment. Sustain Mater Technol 23:e00140

Armentano I et al (2010) Biodegradable polymer matrix nanocomposites for tissue engineering: a review. Polym Degrad Stab 95(11):2126–2146

DeLeon VH et al (2012) Polymer nanocomposites for improved drug delivery efficiency. Mater Chem Phys 132(2–3):409–415

Tekade RK, Maheshwari R, Tekade M (2017) Biopolymer-based nanocomposites for transdermal drug delivery. Biopolymer-Based Composites. Elsevier, Amsterdam, pp 81–106

Naveen MH, Gurudatt NG, Shim Y-B (2017) Applications of conducting polymer composites to electrochemical sensors: A review. Appl Mater Today 9:419–433

Ogawa M (1994) Formation of novel oriented transparent films of layered silica-surfactant nanocomposites. J Am Chem Soc 116(17):7941–7942

Nossol E, Zarbin AJG (2012) Transparent films from carbon nanotubes/Prussian blue nanocomposites: preparation, characterization, and application as electrochemical sensors. J Mater Chem 22(5):1824–1833

Arora A, Padua G (2010) Nanocomposites in food packaging. J Food Sci 75(1):R43–R49

Sorrentino A, Gorrasi G, Vittoria V (2007) Potential perspectives of bio-nanocomposites for food packaging applications. Trends Food Sci Technol 18(2):84–95

Corr SA, Rakovich YP, Gun’ko YK (2008) Multifunctional magnetic-fluorescent nanocomposites for biomedical applications. Nanoscale Res Lett 3(3):87–104

Hule RA, Pochan DJ (2007) Nanocomposites for biomedical applications. MRS Bull 32

Su Y-L, Cheng S-H (2018) A novel electroanalytical assay for sulfamethazine determination in food samples based on conducting polymer nanocomposite-modified electrodes. Talanta 180:81–89

Joshi P et al (2020) Development of polyindole/tungsten carbide nanocomposite-modified electrodes for electrochemical quantification of chlorpyrifos. J Nanostruct Chem 10(1):33–45

Njuguna J, Pielichowski K, Desai S (2008) Nanofiller-reinforced polymer nanocomposites. Polym Adv Technol 19(8):947–959

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers 2(4):728–765

Goh C et al (2008) Ductility improvement and fatigue studies in Mg-CNT nanocomposites. Compos Sci Technol 68(6):1432–1439

Shi Y et al (2013) Self-assembly of hierarchical MoS x/CNT nanocomposites (2< x< 3): towards high performance anode materials for lithium ion batteries. Sci Rep 3:2169

Raja M, Ryu SH, Shanmugharaj A (2013) Thermal, mechanical and electroactive shape memory properties of polyurethane (PU)/poly (lactic acid)(PLA)/CNT nanocomposites. Eur Polymer J 49(11):3492–3500

Abbasi H, Antunes M, Velasco JI (2019) Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog Mater Sci 103:319–373

Loste J et al (2019) Transparent polymer nanocomposites: An overview on their synthesis and advanced properties. Prog Polym Sci 89:133–158

Liu P et al (2019) Recent advancements of polyaniline-based nanocomposites for supercapacitors. J Power Sources 424:108–130

Muhammad A et al (2021) Recent advances and developments in advanced green porous nanomaterial for sustainable energy storage application. J Porous Mater :1–16

Yang Z et al (2019) Long-term antibacterial stable reduced graphene oxide nanocomposites loaded with cuprous oxide nanoparticles. J Colloid Interface Sci 533:13–23

Sheng Y et al (2019) Sol-gel synthesized hexagonal boron nitride/titania nanocomposites with enhanced photocatalytic activity. Appl Surf Sci 465:154–163

Mohammadnezhad G, Keikavousi A, Behbahan (2020) Polymer matrix nanocomposites for heavy metal adsorption: a review. J Iran Chem Soc 17(6):1259–1281

Clancy AJ, Anthony DB, De Luca F (2020) Metal Mimics: Lightweight, strong, and tough nanocomposites and nanomaterial assemblies. ACS Appl Mater Interfaces 12(14):15955–15975

Short K, Buren D (2012) Printable spacecraft: Flexible electronic platforms for NASA missions, vol 2. NASA Innovative Advanced Concepts (NAIC), Phase

Asmatulu E (n.d.) Life cycle analysis of nanocomposites. Adv Nanotechnol :111

Lee SH et al (2011) Tailored assembly of carbon nanotubes and graphene. Adv Func Mater 21(8):1338–1354

Ma P-C et al (2010) Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: a review. Compos Part A: Appl Sci Manufac 41(10):1345–1367

Saba N, Tahir PM, Jawaid M (2014) A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 6(8):2247–2273

Peigney A et al (2002) Aligned carbon nanotubes in ceramic-matrix nanocomposites prepared by high-temperature extrusion. Chem Phys Lett 352(1–2):20–25

Gurnani L, Mukhopadhyay A (2020) Development of carbon nanotube-reinforced ceramic matrix nanocomposites for advanced structural applications. Handbook of Advanced Ceramics and Composites: Defense, Security, Aerospace and Energy Applications, p 929-974

Mohanty P et al (2020) Ultrasonic cavitation: An approach to synthesize uniformly dispersed metal matrix nanocomposites—A review. Nano-Struct Nano-Objects 23:100475

Azarniya A et al (2017) Physicomechanical properties of spark plasma sintered carbon nanotube-containing ceramic matrix nanocomposites. Nanoscale 9(35):12779–12820

Saxena A et al (2017) Effect of ceramic reinforcement on the properties of metal matrix nanocomposites. Mater Today Proc 4(4):5561-5570

Tabandeh-Khorshid M et al (2020) Synthesis, characterization, and properties of graphene reinforced metal-matrix nanocomposites. Compos Part B: Eng 183:107664

Hassanzadeh-Aghdam MK (2019) Micromechanics-based thermal expansion characterization of SiC nanoparticle-reinforced metal matrix nanocomposites. Proc Inst Mech Eng C J Mech Eng Sci 233(1):190-201

Haghgoo M et al (2019) Elastoplastic behavior of the metal matrix nanocomposites containing carbon nanotubes: a micromechanics-based analysis. Proc Inst Mech Eng C J Mech Eng Sci 233(4):676-686

Reddy MP et al (2017) Enhanced performance of nano-sized SiC reinforced Al metal matrix nanocomposites synthesized through microwave sintering and hot extrusion techniques. Prog Nat Sci Mater Int 27(5):606–614

Naskar AK, Keum JK, Boeman RG (2016) Polymer matrix nanocomposites for automotive structural components. Nat Nanotechnol 11(12):1026–1030

Hasnain MS et al (2019) Biodegradable polymer matrix nanocomposites for bone tissue engineering. In: Applications of Nanocomposite Materials in Orthopedics. Elsevier, Amsterdam, p 1–37

Llevot A et al (2016) Renewability is not enough: recent advances in the sustainable synthesis of biomass-derived monomers and polymers. Chem–A Eur J 22(33):11510–11521

Tsujimoto T, Uyama H, Kobayashi S (2003) Green nanocomposites from renewable resources: biodegradable plant oil-silica hybrid coatings. Macromol Rapid Commun 24(12):711–714

Akram D et al (2010) Silica reinforced organic–inorganic hybrid polyurethane nanocomposites from sustainable resource. Macromol Chem Phys 211(4):412–419

Du M, Guo B, Jia D (2010) Newly emerging applications of halloysite nanotubes: a review. Polym Int 59(5):574–582

Lvov Y et al (2016) Halloysite clay nanotubes for loading and sustained release of functional compounds. Adv Mater 28(6):1227–1250

Cavallaro G et al (2014) Halloysite nanotubes as sustainable nanofiller for paper consolidation and protection. J Therm Anal Calorim 117(3):1293–1298

Zhou S, Strømme M, Xu C (2019) Highly transparent, flexible, and mechanically strong nanopapers of cellulose nanofibers@ metal–organic frameworks. Chemistry–A European Journal 25(14):3515–3520

Wang M et al (2015) Hierarchical SnO2/carbon nanofibrous composite derived from cellulose substance as anode material for lithium-ion batteries. Chemistry–A European Journal 21(45):16195–16202

Baran T, Yılmaz N, Baran, Menteş A (2018) Sustainable chitosan/starch composite material for stabilization of palladium nanoparticles: synthesis, characterization and investigation of catalytic behaviour of Pd@ chitosan/starch nanocomposite in Suzuki–Miyaura reaction. Appl Organomet Chem 32(2):e4075

Beeren SR, Meier S, Hindsgaul O (2013) Probing helical hydrophobic binding sites in branched starch polysaccharides using NMR spectroscopy. Chemistry–A European Journal 19(48):16314–16320

Jong L (2013) Natural rubber protein as interfacial enhancement for bio-based nano‐fillers. J Appl Polym Sci 130(3):2188–2197

Zhang L et al (2018) Boosting lithium storage properties of MOF derivatives through a wet-spinning assembled fiber strategy. Chemistry–A European Journal 24(52):13792–13799

Cho C et al (2016) Stable n-type thermoelectric multilayer thin films with high power factor from carbonaceous nanofillers. Nano Energy 28:426–432

Ding J et al (2017) Sustainable graphene suspensions: a reactive diluent for epoxy composite valorization. ACS Sustainable Chemistry & Engineering 5(9):7792–7799

Ellingsen LA-W et al (2016) Nanotechnology for environmentally sustainable electromobility. Nature Nanotechnology 11(12):1039–1051

Fan L-W et al (2013) Effects of various carbon nanofillers on the thermal conductivity and energy storage properties of paraffin-based nanocomposite phase change materials. Appl Energy 110:163–172

Costa P et al (2017) High-performance graphene-based carbon nanofiller/polymer composites for piezoresistive sensor applications. Compos Sci Technol 153:241–252

Zubair M, Ullah A (2020) Recent advances in protein derived bionanocomposites for food packaging applications. Crit Rev Food Sci Nutr 60(3):406–434

Majumdar B, Sarma D, Sarma TK (2019) Development of carbon nanomaterials and their composites for various catalytic applications. In: Carbon-based nanofiller and their rubber nanocomposites. Elsevier, Amsterdam, p 425–439

Kausar A (2021) Green nanocomposites for energy storage. J Compos Sci 5(8):202

Chow CF et al (2016) Combined chemical activation and Fenton degradation to convert waste polyethylene into high-value fine chemicals. Chem Eu J 22(28):9513–9518

Fang Y et al (2018) Thermal-driven self-healing and recyclable waterborne polyurethane films based on reversible covalent interaction. ACS Sustain Chem Eng 6(11):14490–14500

Vieira IRS et al (2019) Waterborne poly (urethane-urea) s films as a sustained release system for ketoconazole. E-Polymers 19(1):168–180

Fang W, Liu L, Guo G (2017) Tunable wettability of electrospun polyurethane/silica composite membranes for effective separation of water-in‐oil and oil‐in‐water emulsions. Chem Eur J 23(47):11253–11260

Dimitry O et al (2011) Studies of particle dispersion in elastomeric polyurethane/organically modified montmorillonite nanocomposites. Int J Green Nanotechnol 3(3):197–212

Ambrosi A, Pumera M (2016) Electrochemically exfoliated graphene and graphene oxide for energy storage and electrochemistry applications. Chem Eur J 22(1):153–159

Vieira IRS et al (2020) Waterborne poly (urethane-urea) s nanocomposites reinforced with clay, reduced graphene oxide and respective hybrids: synthesis, stability and structural characterization. J Polym Environ 28(1):74–90

Singh J, Dhaliwal A (2019) Water retention and controlled release of KCl by using microwave-assisted green synthesis of xanthan gum-cl-poly (acrylic acid)/AgNPs hydrogel nanocomposite. Polym Bull :1–27

Kumar R, Rai B, Kumar G (2019) A simple approach for the synthesis of cellulose nanofiber reinforced chitosan/PVP bio nanocomposite film for packaging. J Polym Environ 27(12):2963–2973

Shen Y et al (2010) Efficient synthesis of lactic acid by aerobic oxidation of glycerol on Au–Pt/TiO2 catalysts. Chem Eur J 16(25):7368–7371

Lee K-Y, Blaker JJ, Bismarck A (2009) Surface functionalisation of bacterial cellulose as the route to produce green polylactide nanocomposites with improved properties. Compos Sci Technol 69(15–16):2724–2733

Chieng BW et al (2012) Graphene nanoplatelets as novel reinforcement filler in poly (lactic acid)/epoxidized palm oil green nanocomposites: Mechanical properties. Int J Mol Sci 13(9):10920–10934

Pathak V, Ambrose RK (2020) Starch-based biodegradable hydrogel as seed coating for corn to improve early growth under water shortage. J Appl Polym Sci 137(14):48523

McGlashan SA, Halley PJ (2003) Preparation and characterisation of biodegradable starch-based nanocomposite materials. Polym Int 52(11):1767–1773

Schwach E, Averous L (2004) Starch-based biodegradable blends: morphology and interface properties. Polym Int 53(12):2115–2124

Kaushik A, Singh M, Verma G (2010) Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr Polym 82(2):337–345

Klemm D et al (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50(24):5438–5466

Cheviron P, Gouanvé F, Espuche E (2014) Green synthesis of colloid silver nanoparticles and resulting biodegradable starch/silver nanocomposites. Carbohydr Polym 108:291–298

Jalal Uddin A, Araki J, Gotoh Y (2011) Toward “strong” green nanocomposites: polyvinyl alcohol reinforced with extremely oriented cellulose whiskers. Biomacromolecules 12(3):617–624

Kang H et al (2014) Using a green method to develop graphene oxide/elastomers nanocomposites with combination of high barrier and mechanical performance. Compos Sci Technol 92:1–8

Doherty WO, Mousavioun P, Fellows CM (2011) Value-adding to cellulosic ethanol: Lignin polymers. Ind Crop Prod 33(2):259–276

Averous L (2004) Biodegradable multiphase systems based on plasticized starch: A review. J Macromol Sci C: Polymer Rev 44(3):231–274

Rinaldi R et al (2016) Paving the way for lignin valorisation: recent advances in bioengineering, biorefining and catalysis. Angew Chem Int Ed 55(29):8164–8215

El-Aghoury A et al (2006) Contribution to the study of fungal attack on some plasticized vinyl formulations. J Polym Environ 14(2):135

Canetti M, Bertini F (2007) Supermolecular structure and thermal properties of poly (ethylene terephthalate)/lignin composites. Compos Sci Technol 67(15–16):3151–3157

Graupner N (2008) Application of lignin as natural adhesion promoter in cotton fibre-reinforced poly (lactic acid)(PLA) composites. J Mater Sci 43(15):5222–5229

Bartolucci C et al (2020) Green nanomaterials fostering agrifood sustainability. TrAC Trends Anal Chem 125:115840

Patwardhan SV, Staniland SS (2019) Green Nanomaterials. IOP Publishing, Bristol

Morsi M et al (2019) Preparation, structural analysis, morphological investigation and electrical properties of gold nanoparticles filled polyvinyl alcohol/carboxymethyl cellulose blend. J Market Res 8(6):5996–6010

Bondarev D et al (2017) Microporous conjugated polymers via homopolymerization of 2, 5-diethynylthiophene. Eur Polym J 92:213–219

Gu C et al (2014) Controlled synthesis of conjugated microporous polymer films: versatile platforms for highly sensitive and label-free chemo‐and biosensing. Angew Chem Int Ed 53(19):4850–4855

Rao Y et al (2002) Novel polymer–ceramic nanocomposite based on high dielectric constant epoxy formula for embedded capacitor application. J Appl Polym Sci 83(5):1084–1090

Cao X et al (2008) Green composites reinforced with hemp nanocrystals in plasticized starch. J Appl Polym Sci 109(6):3804–3810

Chen L et al (2015) White and green light emissions of flexible polymer composites under electric field and multiple strains. Nano Energy 14:372–381

Zhang Q et al (2014) Organic thermoelectric materials: emerging green energy materials converting heat to electricity directly and efficiently. Adv Mater 26(40):6829–6851

Echegoyen Y, Nerín C (2013) Nanoparticle release from nano-silver antimicrobial food containers. Food Chem Toxicol 62:16–22

Ghaderi M et al (2014) All-cellulose nanocomposite film made from bagasse cellulose nanofibers for food packaging application. Carbohydr Polym 104:59–65

Nassar MA, Youssef AM (2012) Mechanical and antibacterial properties of recycled carton paper coated by PS/Ag nanocomposites for packaging. Carbohydr Polym 89(1):269–274

Jatoi AS et al (2020) Improving fermentation industry sludge treatment as well as energy production with constructed dual chamber microbial fuel cell. SN Appl Sci 2(1):1–8

Mann GS et al (2020) Green composites: A review of processing technologies and recent applications. J Thermoplast Compos Mater 33(8):1145–1171

Georgios K, Silva A, Furtado S (2016) Applications of green composite materials. Biodegrad Green Compos 16:312

Furtado SC, Araújo AL, Silva A (2018) Inverse characterization of vegetable fibre-reinforced composites exposed to environmental degradation. Compos Struct 189:529–544

Guo J et al (2013) Conjugated organic framework with three-dimensionally ordered stable structure and delocalized π clouds. Nat Commun 4(1):1–8

Zhuang X et al (2015) Conjugated microporous polymers with dimensionality-controlled heterostructures for green energy devices. Adv Mater 27(25):3789–3796

Yang C et al (2015) Polymer nanocomposites for energy storage, energy saving, and anticorrosion. J Mater Chem A 3(29):14929–14941

Chen S, Skordos A, Thakur VK (2020) Functional nanocomposites for energy storage: chemistry and new horizons. Mater Today Chem 17:100304

Jin J, Shi Z-q, Wang C-y (2014) Electrochemical performance of electrospun carbon nanofibers as free-standing and binder-free anodes for sodium-ion and lithium-ion batteries. Electrochim Acta 141:302–310

Zainab G et al (2020) Electrospun carbon nanofibers with multi-aperture/opening porous hierarchical structure for efficient CO2 adsorption. J Colloid Interface Sci 561:659–667

Mustafov SD et al (2019) Fabrication of conductive Lignin/PAN carbon nanofibers with enhanced graphene for the modified electrodes. Carbon 147:262–275

Chen T et al (2014) Electrospun carbon nanofibers as anode materials for sodium ion batteries with excellent cycle performance. J Mater Chem A 2(12):4117–4121

Tao X et al (2020) Ni@ Ni2P Encapsulation in Interconnected N-doped carbonized cellulose nanofibril network for efficient oxygen evolution reaction. ACS Sustain Chem Eng 8(4):1859–1867

Tang J et al (2019) Compressible cellulose nanofibril (CNF) based aerogels produced via a bio-inspired strategy for heavy metal ion and dye removal. Carbohydr Polym 208:404–412

Dahal B et al (2020) An innovative synthetic approach for core-shell multiscale hierarchically porous boron and nitrogen codoped carbon nanofibers for the oxygen reduction reaction. J Power Sources 453:227883

Zhang Y et al (2019) Bio-based carbon-enhanced tungsten-based bimetal oxides as counter electrodes for dye-sensitized solar cells. J Power Sources 423:339–348

Gurunathan P, Karthick MG, Babu, Ramesha K (2020) Template assisted synthesis of Sn@ C microspheres and SnO2@ C micro bowls as anode for Li-Ion batteries. Energy Storage 2(5):e152

Nie H et al (2019) Nitrogen-doped hierarchical porous CNF derived from fibrous structured hollow ZIF-8 for a high-performance supercapacitor electrode. RSC Adv 9(69):40636–40641

Maruyama J et al (2020) Helical pore alignment on cylindrical carbon. Small 16(2):1905916

Yue L et al (2020) Recent advances in electrospun one-dimensional carbon nanofiber structures/heterostructures as anode materials for sodium ion batteries. J Mater Chem A

Ge X et al (2019) Enabling superior electrochemical properties for highly efficient potassium storage by impregnating ultrafine Sb nanocrystals within nanochannel-containing carbon nanofibers. Angew Chem 131(41):14720–14725

Liu H et al (2020) Direct tuning of meso-/micro-porous structure of carbon nanofibers confining Sb nanocrystals for advanced sodium and potassium storage. J Alloys Compd :155127

Liang S et al (2020) A chronicle review of nonsilicon (Sn, Sb, Ge)-Based Lithium/Sodium‐Ion battery alloying anodes. Small Methods :2000218

Zhang X et al (2018) Nanofibers with MoS2 nanosheets encapsulated in carbon as a binder-free anode for superior lithium storage. New Carbon Mater 33(6):554–561

Wiesberg IL et al (2019) Carbon dioxide management via exergy-based sustainability assessment: Carbon Capture and Storage versus conversion to methanol. Renew Sustain Energy Rev 112:720–732

Stojanovska E et al (2018) Nanofibrous composites for sodium-ion batteries. In: Polymer-based Nanocomposites for Energy and Environmental Applications. Elsevier, Amsterdam, p 333–360

Jamshidian M et al (2010) Poly-lactic acid: production, applications, nanocomposites, and release studies. Compr Rev Food Sci Food Saf 9(5):552–571

Endres H-J (2017) Bio-based thermoplastic and thermosets polymer. Lightweight and sustainable materials for automotive applications, p 139-166

Wei T et al (2012) Tough bio-based elastomer nanocomposites with high performance for engineering applications. Adv Eng Mater 14(1‐2):112–118

Aimer M et al (2016) Reactive extraction of lactic acid by using Tri-n‐octylamine: structure of the ionic phase. Chem Eur J 22(10):3268–3272

Kalita D, Netravali A (2017) Thermoset resin based fiber reinforced biocomposites. Textile Finish 425

Tiwari A (2012) Biotechnology in biopolymers: developments, applications & challenging areas. Smithers Rapra, Shawbury

Hardy JG et al (2016) Responsive biomaterials: advances in materials based on shape-memory polymers. Adv Mater 28(27):5717–5724

Guerra AJ et al (2018) Effects of different sterilization processes on the properties of a novel 3D-printed polycaprolactone stent. Polym Adv Technol 29(8):2327–2335

Nutan B, Singh Chandel AK, Jewrajka SK (2017) Synthesis and multi-responsive self‐assembly of cationic poly (caprolactone)–poly (ethylene glycol) multiblock copolymers. Chem Eur J 23(34):8166–8170

Drzal LT, Mohanty A, Misra M (2001) Bio-composite materials as alternatives to petroleum-based composites for automotive applications. Magnesium 40(60):1

Ray D (2015) 12 state-of-the-art applications of natural fiber composites in the industry. Nat Fiber Compos 5:319

Ashori A (2008) Wood–plastic composites as promising green-composites for automotive industries! Bioresour Technol 99(11):4661–4667

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. Jom 58(11):80–86

Akampumuza O et al (2017) Review of the applications of biocomposites in the automotive industry. Polym Compos 38(11):2553–2569

Rhim J-W, Park H-M, Ha C-S (2013) Bio-nanocomposites for food packaging applications. Prog Polym Sci 38(10):1629–1652

Pillai CKS, Paul W, Sharma CP (2009) Chitin and chitosan polymers: Chemistry, solubility and fiber formation. Prog Polym Sci 34(7):641–678

Tang XZ et al (2012) Recent Advances in Biopolymers and Biopolymer-Based Nanocomposites for Food Packaging Materials. Crit Rev Food Sci Nutr 52(5):426–442

Youssef AM (2013) Polymer Nanocomposites as a New Trend for Packaging Applications. Polym-Plast Technol Eng 52(7):635–660

Sangroniz A et al (2019) Improving the barrier properties of a biodegradable polyester for packaging applications. Eur Polymer J 115:76–85

Simões CL, Viana JC, Cunha AM (2009) Mechanical properties of poly(ε-caprolactone) and poly(lactic acid) blends. J Appl Polym Sci 112(1):345–352

Pandey JK, Singh RP (2005) Green Nanocomposites from Renewable Resources: Effect of Plasticizer on the Structure and Material Properties of Clay-filled Starch. Starch - Stärke 57(1):8–15

Zehetmeyer G et al (2012) Evaluation of polypropylene/montmorillonite nanocomposites as food packaging material. Polym Bull 68(8):2199–2217

Tammaro L, Vittoria V, Bugatti V (2014) Dispersion of modified layered double hydroxides in Poly (ethylene terephthalate) by High Energy Ball Milling for food packaging applications. Eur Polymer J 52:172–180

Shan G-F et al (2011) Effect of multi-walled carbon nanotubes on crystallization behavior of poly (3-hydroxybutyrate-co-3-hydroxyvalerate). Colloid Polym Sci 289(9):1005-1014

Heydari A, Alemzadeh I, Vossoughi M (2013) Functional properties of biodegradable corn starch nanocomposites for food packaging applications. Mater Des 50:954–961

Dehnad D et al (2014) Thermal and antimicrobial properties of chitosan–nanocellulose films for extending shelf life of ground meat. Carbohydr Polym 109:148–154

Galotto MJ et al (2010) Effect of high-pressure food processing on the mass transfer properties of selected packaging materials. Packag Technol Sci 23(5):253–266

Sengupta R et al (2007) A short review on rubber/clay nanocomposites with emphasis on mechanical properties. Polym Eng Sci 47(11):1956–1974

Nair LS, Laurencin CT (2007) Biodegradable polymers as biomaterials. Prog Polym Sci 32(8):762–798

Ngiam M et al (2008) Fabrication of mineralized polymeric nanofibrous composites for bone graft materials. Tissue Eng Part A 15(3):535–546

Qian J et al (2014) Fabrication and in vitro biocompatibility of biomorphic PLGA/nHA composite scaffolds for bone tissue engineering. Mater Sci Eng C 36:95–101

Ramakrishna S et al (2001) Biomedical applications of polymer-composite materials: a review. Compos Sci Technol 61(9):1189–1224

Singh MK et al (2008) Hydroxyapatite modified with carbon-nanotube-reinforced poly(methyl methacrylate): a nanocomposite material for biomedical applications. Adv Func Mater 18(5):694–700

Santo VE et al (2010) Hybrid 3D structure of poly(d,l-lactic acid) loaded with chitosan/chondroitin sulfate nanoparticles to be used as carriers for biomacromolecules in tissue engineering. J Supercrit Fluids 54(3):320–327

Pandey S, Goswami GK, Nanda KK (2012) Green synthesis of biopolymer–silver nanoparticle nanocomposite: An optical sensor for ammonia detection. Int J Biol Macromol 51(4):583–589

La LBT et al (2018) Green lightweight lead-free Gd2O3/epoxy nanocomposites with outstanding X-ray attenuation performance. Compos Sci Technol 163:89–95

Zhang L et al (2018) Boosting lithium storage properties of mof derivatives through a wet-spinning assembled fiber strategy. Chem Eur J 24(52):13792–13799

Abidi N et al (2007) Cotton fabric surface modification for improved UV radiation protection using sol–gel process. J Appl Polym Sci 104(1):111–117

Chow C-F et al (2016) Combined chemical activation and Fenton degradation to convert waste polyethylene into high-value fine chemicals. Chem Eur J 22(28):9513–9518

Zargar V, Asghari M, Dashti A (2015) A review on chitin and chitosan polymers: structure, chemistry, solubility, derivatives, and applications. ChemBioEng Rev 2(3):204–226

Acknowledgements

Authors are thankful to chemical engineering department DUET Karachi for their support.

Author information

Authors and Affiliations

Contributions

All authors discussed the content of the article based on their domain expertise. wrote the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Consent for Publication

N/A.

Ethics Approval and Consent to Participate

N/A.

Conflict of interest

The authors declare that they have no conflict of interest.

Research Involving Human Participants and/or Animals

No applicable.

Informed Consent

The publication is approved by all authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jatoi, A.S., Ahmed, S., Muhammad, A. et al. Comprehensive Review on Silicon-enhanced Green Nanocomposites Towards Sustainable Development. Silicon 14, 7383–7398 (2022). https://doi.org/10.1007/s12633-021-01516-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01516-3