Abstract

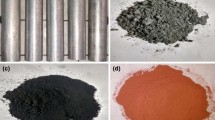

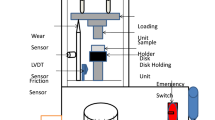

In this work, AA7075 ˗ SiC (0–8 wt.% @ step of 2%) / marble dust (8–0 wt.% @ step of 2%) / graphite (3 wt.%) hybrid alloy composites have been designed and fabricated via high vacuum casting method as per standard procedure, leading to five samples namely SM-08, SM-26, SM-44, SM-62, SM-80 respectively. Thereafter, possible synergistic impact of the complementary combination of SiC/marble dust reinforcing particulates on physical, mechanical, and sliding wear performance of hybrid alloy composites were investigated followed by surface morphology studies. Taguchi approach has been used for sliding wear parametric optimization and hybrid ENTROPY-VIKOR decision-making technique is used for ranking of material based on performance measures. It is observed that with the reinforcing phase the properties like wear performance, coefficient of friction, density, voids content, compressive strength, and impact strength of composites increases considerably while flexural strength diminishes. Thus, SM-62 alloy composite (having 6 wt.% SiC, and 2 wt.% marble dust) shows better improved overall performance relative to others.

Similar content being viewed by others

Data Availability

Additional data available on reasonable request by email to the corresponding author.

References

Wang DZ, Peng HX, Liu J, Yao CK (1995) Wear behavior and microstructural changes of SiCw-Al composite under unlubricated sliding friction. Wear 184:187–192

Harris SJ (1988) Cast metal matrix composites. Mater Sci Technol 4:231–239

Chen W, Liu Y, Yang C, Zhu D, Li Y (2014) (SiCp+ Ti)/7075Al hybrid composites with high strength and large plasticity fabricated by squeeze casting. Mater Sci Eng A 609:250–254

Prabu SB, Karunamoorthy L (2008) Microstructure-based finite element analysis of failure prediction in particle-reinforced metal–matrix composite. J Mater Process Technol 207:53–62

Kumar A, Patnaik A, Bhat IK (2017) Investigation of nickel metal powder on Tribological and Mechanical Properties of al7075Alloy Composites for Gear Material, journal of. Powder Metall 60:371–383

Kumar KR, Kiran K, Balaji VS (2017) Micro structural characteristics and mechanical behavior of aluminium metal matrix composites reinforced with titanium carbides. J Alloys Compd 723:795–801

Kumar KR, Kiran K, Sreebalaji VS (2017) Characterization of mechanical properties of aluminium/tungsten carbide composites. Meas 102:142–149

Alhawari KS, Omar MZ, Ghazali MJ, SallehMS MMN (2013) Wear properties of A356/Al2O3 metal matrix composites produced by semisolid processing. Procedia Eng 68:186–192

Kiran TS, Kumar MP, Basavarajappa S, ViswanathaBM (2014) Dry sliding wear behavior of heat treated hybrid metal matrix composite using Taguchi techniques. Mater Des 63:294–304

Kumar A, Kumar A (2020) Mechanical and dry sliding wear behavior of B4C and rice husk ash reinforced Al 7075 alloy hybrid composite for armors application by using Taguchi techniques. J Mater Today: Proc 27:2617–2625

Bhaskar S, Kumar M, Patnaik A (2019) Application of hybrid AHP-TOPSIS technique in analyzing material performance of sil- icon carbide ceramic particulate reinforced AA2024 alloy compos- ite. Silicon. 12:1075–1084

Kumar M, Kumar A (2020) Application of preference selection index method in performance based ranking of ceramic particulate (SiO2/SiC) reinforced AA2024 composite materials. J Mater Today: Proc 27:2667–2672

Singh T, Patnaik P, Fekete G, Chauhan R, Gangil B (2019) Application of hybrid analytical hierarchy process and complex proportional assessment approach for optimal design of brake friction materials. Polym Compos 40:1602–1608

Satapathy BK, Majumdar A, Tomar BS (2010) Optimal design of flyash filled composite friction materials using combined analytical hierarchy process and technique for order preference by similarity to ideal solutions approach. Mater Des 31:1937–1944

Maniya K, Bhatt MG (2010) A selection of material using a novel type decision –making method: prefence selection index method. Mater Des 31:1785–1789

Maniya KD, Batt MG (2011) An alternative multiple attribute decision making methodology for solving optimal facility layout design selection problems. Comput Int Eng 61:542–549

Jahan A, Kevin L, Edwards MB (2016) Multi criteria decision analysis for supporting the selection of engineering materials in product design .Butterworth-Heinemann. https://doi.org/10.1016/C2012-0-02834-7

Aherwar A, Patnaik A, Bahraminasab M, Singh A (2017) Preliminary evaluations on development of new materials for hip joint femoral head. Mater Des App https://doi.org/10.1177/1464420717714495

Kumar M, Kumar R, Tak Y, Meena RK, Sharma N, Kumar A, Parametric optimization and ranking analysis of hybrid epoxy polymer composites based on mechanical, thermo-mechanical and abrasive wear performance(2020)High Perform. Polym https://doi.org/10.1177/0954008320959412

Kumar A, Patnaik A, Bhat IK (2019) Tribology analysis of cobalt particulate filled Al 7075 alloy for gear materials: a comparative study. Silicon 11:1295–1311

M.Kumar (2020) Mechanical and Sliding Wear Performance of AA356-Al2O3/SiC/Graphite Alloy Composite Materials: Parametric and Ranking Optimization Using Taguchi DOE and Hybrid AHP-GRA Method, Silicon https://doi.org/10.1007/s12633-020-00544-9

Bhaskar S, Kumar M, Patnaik A (2019) Silicon carbide ceramic particulate reinforced AA2024 alloy composite - part I: evaluation of mechanical and sliding tribology performance. Silicon 12:843–865

Kumar M, Kumar A (2019) Sliding wear performance of graphite reinforced AA6061 alloy composites for rotor drum/disk applica- tion. Mater Today Proc https://doi.org/10.1016/j.matpr.2019.09.042

Ramesh CS, Keshavamurthy R, Channabasappa BH (2010) Friction and wear behavior of Ni–P coated Si3N4 reinforced Al6061 composites. Tribol Int 43:623–634

Khorshidi J, Hassani R (2013) A comparative analysis between TOPSIS and PSI method of material selection to achive a desirable combination of strength and workability in Al/SiC composite. Mater Des 52:999–1010

Panahi M, Gitinavard H (2018) Evaluating the sustainable mining contractor selection problems: an imprecise last aggregation preference selection method. J. Sustain Min 16:207–2018

Mesran I, Tampubolon K, Sianturi RD, Waruwu FT (2017) Determination of education scholarship recipients using preference selection index. Sci Technol 3:230–234

Jian SY, Tao SY, Huang XR (2014) Preference selection index method for machine selection in a flexible manufacturing cell. Adv Mater Res 1078:290–293

Jha K, Chamoli S, Tayagi YK, Maurya HO (2018) Characterization of biodegradable composites and application of preference selection index method for deciding optimal phase combination. Mater Today Proc 5:3553–3360

Dev S, Aherwar A, Patnaik A (2019) Material selection for automotive piston component using entropy-VIKOR method. Silicon 12:155–169. https://doi.org/10.1007/s12633-019-00110-y

Moharami A (2020) High-temperature tribological properties of friction stir processed Al-30Mg2Si composites. Mater at High temp https://doi.org/10.1080/09603409.2020.1785792

Moharami A, Razaghian A, Babaei B, OO Ojo4 , lapa ´kova MS (2020) Role of Mg2Si particles on mechanical, wear, and corrosion behaviors of friction stir welding of AA6061-T6 and Al-Mg2Si composite. J Compos Mater0(0):1–23 https://doi.org/10.1177/0021998320925528,54

Moharami A (2020) Improving the dry sliding wear resistance of as cast cu-10Sn-1P alloy through accumulative back extrusion(ABE). J Mater Res Technol (9)5:10091–10096. https://doi.org/10.1016/j.jmrt.2020.07.022

Moharami A, Razaghian A, Paidarc M, Slapakov M, Ojoe OO, Taghiabadib R (2020) Enhancing the mechanical and tribological properties of Mg2Si-rich aluminum alloys by multi-pass friction stir processing. Mater Chem Phys 250:123066. https://doi.org/10.1016/j.matchemphys.2020.123066

Moharami A, Razaghia A, Fmamy M, Taghiabadib R (2019) Effect of tool pin profile on the microstructure and Tribological properties of friction stir processed Al-20 wt% Mg2Si composite. J Tribol 141:122202–122201

Maharani A, Razaghia A (2020) Corrosion behavior of friction stirs processed. Al–Mg2Si composites Mater Sci Technol 36(18):1922–1929. https://doi.org/10.1080/02670836.2020.1852515

Kumar A, Kukshal V, Kiragi (2020) Assessment of Mechanical and Sliding wear performance of Ni particulate filled Al7075 aluminium alloy composite. Mater Today Proc https://doi.org/10.1016/j.matpr.2020.10.556

Kumar M, Bhaskar S, Shakyawal NK, Kuma A (2020) Application of preference selection index method in performance (mechanical properties and sliding wear) based ranking of AA2024-Al2O3/SiC alloy composites. Mater Werkst 51:1662–1685. https://doi.org/10.1002/maw.2019001381662

Li X, Sosa M, Olofsson U (2015) A pin-on-disc study of the tribology characteristics of sintered versus standard steel gear materials. Wear 340:31–40

Acknowledgments

The authors acknowledged the characterization facilities and other infrastructural support given by the Advanced Research Lab for Tribology and Material Research Centre of Malaviya National Institute of Technology Jaipur.

Funding

No funding to declare.

Author information

Authors and Affiliations

Contributions

Ashiwani Kumar: Conceptualization, Methodology, experimentation, Mukesh Kumar: Writing- Reviewing and Editing, Bhavana Pandey: Writing- Original draft preparation.

Corresponding author

Ethics declarations

Conflict of Interests

No potential conflicts of interest concerning the research, authorship, and publication of these articles has been declared by the authors.

Consent to Participate

The author’s consented to participate in this journal.

Consent Publication

The authors consented to publication in this journal.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, A., Kumar, M. & Pandey, B. Investigations on Mechanical and Sliding Wear Performance of AA7075 ˗ SiC/Marble Dust/Graphite Hybrid Alloy Composites Using Hybrid ENTROPY -VIKOR Method. Silicon 14, 2051–2065 (2022). https://doi.org/10.1007/s12633-021-00996-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-00996-7