Abstract

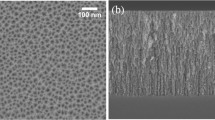

Porous silicon (PSi) has been established as a promising candidate for a variety of applications in many fields of science and technology. Currently, free-standing PSi is receiving an increasing attention for biomedical applications, such as drug delivery carriers and bio-sensing. In this study, fabrication of free-standing PSi film with attractive structural and optical properties for a prospective biomedical uses, is reported. The film is produced in the dark by a pulsed anodic etching of n+- type silicon substrate in an unconventional (HF: HCl: C2H5 OH: H2O2:H2O) electrolyte. The macro-porous nature of the produced film is revealed by scanning electron microscopy (SEM) imaging. X-ray diffraction (XRD) and Raman scattering investigations show both amorphous and nano-crystalline phases coexist in the produced film. On ageing it for two months, Fourier transformation infrared (FTIR) spectroscopy results reveal that the produced film exhibits the characteristic of efficiently oxidized PSi with a good stability. In addition to the strong S-band, the room temperature photoluminescence (PL) spectrum of the film exhibits a weaker F-band, which is attributed to the recombination in SiO2 allocated at surface defects. Moreover, the film adsorption of colchicine drug via immersion process has been investigated by FTIR and UV-spectrophotometric measurements. The results demonstrate that the colchicine is specifically and efficiently adsorbed, with adsorption capacity of around 33%. The results in this study suggest that our fabricated free-standing PSi film can be effectively utilized to prepare PSi nanoparticles for forthcoming drug delivery applications.

Similar content being viewed by others

References

Canham L (2014) Handbook of porous silicon. Springer, Berlin

Korotcenkov G (2016) Porous silicon: from formation to applications: optoelectronics, microelectronics, and energy technology applications3rd edn. CRC Press, Boca Raton

Maniya NH, Patel SR, Murthy Z (2015). Appl Surf Sci 330:358–365

Zhao Y, Gaur G, Retterer ST, Laibinis PE, Weiss SM (2016) Flow-Through Porous Silicon Membranes for Real-Time Label-Free Biosensing. Anal Chem 88:10940–10948

Álvarez J, Bettotti P, Suárez I, Kumar N, Hill D, Chirvony V, Pavesi L, Martínez-Pastor J (2011) Birefringent porous silicon membranes for optical sensing. Opt Express 19:26106–26116

Adiga SP, Jin C, Curtiss LA, Monteiro-Riviere NA, Narayan RJ (2009). Wires Nanomed Nanobi 1:568–581

Anglin EJ, Cheng L, Freeman WR, Sailor MJ (2008) Porous silicon in drug delivery devices and materials. Adv Drug Deliv Rev 60:1266–1277

Kale PG, Solanki CS (2010) Synthesis of si nanoparticles from freestanding porous silicon (PS) film using ultrasonication. IEEE. pp. 003692–003697

López JAL, Román AG, Barojas EG, Gracia JF, Juárez JM, López JC (2014). Nanoscale Res Lett 9:571

Nissinen T, Ikonen T, Lama M, Riikonen J, Lehto V-P (2016). Powder Technol 288:360–365

Solanki C, Bilyalov R, Poortmans J, Celis J-P, Nijs J, Mertens R (2004). J Electrochem Soc 151:C307–C314

Allongue P, Costa-Kieling V, Gerischer H (1993). J Electrochem Soc 140:1018–1026

Frotscher U, Rossow U, Ebert M, Pietryga C, Richter W, Berger M, Arens-Fischer R, Münder H (1996). Thin Solid Films 276:36–39

Fry NL, Boss GR, Sailor MJ (2014). Chem Mater 26:2758–2764

Salem M, Sailor M, Harraz F, Sakka T, Ogata Y (2006). J Appl Phys 100:083520

Pap AE, Kordás K, Tóth G, Levoska J, Uusimäki A, Vähäkangas J, Leppävuori S, George T (2005). Appl Phys Lett 86:041501

Belogorokhov A, Enderlein R, Tabata A, Leite J, Karavanskii V, Belogorokhova L (1997). Phys Rev B 56:10276

Yamani Z, Thompson WH, AbuHassan L, Nayfeh MH (1997). Appl Phys Lett 70:3404–3406

Naddaf M, Almariri A (2014). Appl Phys A Mater Sci Process 116:1337–1345

Naddaf M (2012). J Mater Sci Mater Electron 23:2173–2180

Hou X-Y, H-L Fan X, Lei F-LZ, Li M-Q, Yu M-R, Wang X (1996) Appl Phys Letts 68: 2323–2325

Zheng X, Pan J, Zhang F, Liu E, Shi W, Yan Y (2016). Chem Eng J 284:879–887

Ossicini S, Pavesi L, Priolo F (2003) Light emitting silicon for microphotonics. Springer Science & Business Media

Zou B, Wang J, Liu C, Zhang JZ, El-Sayed MA (2000). Phys Rev B 62:16595

Gupta P, Colvin V, George S (1988). Phys Rev B 37:8234

Borghesi A, Sassella A, Pivac B, Pavesi L (1993). Solid State Commun 87:1–4

Ogata YH, Yoshimi N, Yasuda R, Tsuboi T, Sakka T, Otsuki A (2001). J Appl Phys 90:6487–6492

Ogata YH, Kato F, Tsuboi T, Sakka T (1998). J Electrochem Soc 145:2439–2444

Riikonen J, Salomäki M, van Wonderen J, Kemell M, Xu W, Korhonen O, Ritala M, MacMillan F, Salonen J, Lehto V-P (2012) Surface chemistry, reactivity, and pore structure of porous silicon oxidized by various methods. Langmuir 28:10573–10583

Fritsch E, Mihut L, Baibarac M, Baltog I, Ostrooumov M, Lefrant S, Wery J (2001). J Appl Phys 90:4777–4782

Martín-Palma R, Pascual L, Herrero P, Martínez-Duart J (2005). Appl Phys Lett 87:211906

Vasques A, Torchynska T, Polupan G, Matsumoto-Kuwabara Y, Khomenkova L, Shcherbyna L (2008) Size dependent photoluminescence of Si nano-crystals embedded in amorphous silicon. Trans Tech Publ. pp. 71–76

Cisneros R, Pfeiffer H, Wang C (2010). Nanoscale Res Lett 5:686

Kharin AY, Assilbayeva R, Kargina YV, Timoshenko VY (2019) Comparative analysis of silicon nanostructures by x-ray diffraction technique. IOP Publishing pp 012010

Scherrer P (1912) Bestimmung der inneren Struktur und der Größe von Kolloidteilchen mittels Röntgenstrahlen. Kolloidchemie Ein Lehrbuch Springer pp 387–409

Islam MN, Kumar S (2001). Appl Phys Lett 78:715–717

Richter H, Wang Z, Ley L (1981). Solid State Commun 39:625–629

Edelberg E, Bergh S, Naone R, Hall M, Aydil ES (1997). J Appl Phys 81:2410–2417

Pérez JM, Villalobos J, McNeill P, Prasad J, Cheek R, Kelber J, Estrera J, Stevens P, Glosser R (1992). Appl Phys Lett 61:563–565

Sun Y, Miyasato T (1995). Jpn J Appl Phys 34:L1248

Pusep Y, Rodrigues A, Galzerani J, Arce RD, Koropecki RR, Comedi D (2009). J Electrochem Soc 156:K215–K217

Cullis AG, Canham LT, Calcott PDJ (1997). J Appl Phys 82:909–965

Voloshina T, Zavaritskaya T, Kavetskaya I, Karavanskii V, Romashov D (2002). J Appl Spectrosc 69:275–278

Jane A, Dronov R, Hodges A (2009) Voelcker NH. Trends Biotechnol 27:230–239

Zhang F, Zheng X, Liu E, Yu L, Yan Y (2017). J Ind Eng Chem 46:397–403

Siddiqui S, Dwivedi A, Singh P, Hasan T, Jain S, Prasad O, Misra N (2009). J Struct Chem 50:411–420

Acknowledgements

Authors would like to thank Prof. I. Othman the director general of the AECS and the head of molecular biology and biotechnology department for their support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Naddaf, M., Jarjour, R.A. Free-Standing Porous Silicon Film Produced by a Pulsed Anodic Etching of n+-Silicon Substrate in an HF: HCl: C2H5 OH: H2O2:H2O Electrolyte: Characterization and Adsorption of Colchicine. Silicon 13, 739–746 (2021). https://doi.org/10.1007/s12633-020-00478-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00478-2