Abstract

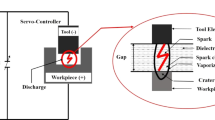

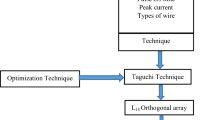

A new composition of Taguchi and the technique for order preference by similarity to ideal solution (TOPSIS) in combination with principal component analysis (PCA) has been explored. A series of experiments were performed in order to acquire an optimal parametric combination during powder mixed electro-discharge machining (PMEDM) of nickel free austenitic stainless steel. Peak current, pulse on time and powder concentration were selected as three process variables, whereas the material removal rate (MRR), tool wear rate (TWR) and over cut (OC) were the major attention. Domain of the investigation was adopted from Taguchi based L16 orthogonal array. The outcomes of the experiment were optimized using TOPSIS method whereas PCA technique was employed to determine the weightage of each response. Response table for S/N ratio was drawn to identify the most influencing machining parameter. Results of the investigation indicated that, peak current was the most effective machining variable followed by pulse on time and powder concentration. The proposed amalgamation of PCA-TOPSIS method was observed to be robust, easily understandable, time saving and modest approach which can help the decision maker to identify an optimal parametric combination with desirable accuracy.

Similar content being viewed by others

Abbreviations

- EDM:

-

Electro discharge machining

- PMEDM:

-

Powder mixed electro-discharge machining

- PCA:

-

Principal component analysis

- DOE:

-

Design of experiment

- MRR:

-

Material removal rate

- TWR:

-

Tool wear rate

- OC:

-

Overcut

- WEDM:

-

Wire electrical discharge machining

- AHP:

-

Analytic hierarchy process

- MOO:

-

Multi-objective optimization

- OA:

-

Orthogonal array

- S/N:

-

Signal to noise ratio

- MPCI:

-

Multi-performance characteristic index

- TOPSIS:

-

Technique for order preference by similarity to ideal solution

References

Paul T, Majumder H, Dey V, Dutta P (2015) Study the effect of material removal rate in die-sinking EDM for Inconel 800 using response surface methodology. J Mater Sci Mech Eng 2:27–31

Majumder H, Maity K (2018) Prediction and optimization of surface roughness and micro-hardness using grnn and MOORA-fuzzy-a MCDM approach for nitinol in WEDM. Measurement 118:1–13

Garg R, Singh K, Sachdeva A, Sharma VS, Ojha K, Singh S (2010) Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int J Adv Manuf Technol 50(1):611–624

Kansal H, Singh S, Kumar P (2005) Parametric optimization of powder mixed electrical discharge machining by response surface methodology. J Mater Process Technol 169(3):427–436

Panda BN, Biswal BB, Deepak B (2014) Integrated AHP and fuzzy TOPSIS approach for the selection of a rapid prototyping process under multi-criteria perspective. http://hdl.handle.net/2080/2234

Majumder H, Maity K (2017) Optimization of machining condition in WEDM for titanium grade 6 using MOORA coupled with PCA—a multivariate hybrid approach. J Adv Manuf Syst 16(02):81–99

Mahapatra SS, Panda BN (2013) Benchmarking of rapid prototyping systems using grey relational analysis. Int J Serv Oper Manage 16(4):460–477

Majumder H, Paul T, Dey V, Dutta P, Saha A (2017) Use of PCA-grey analysis and RSM to model cutting time and surface finish of Inconel 800 during wire electro discharge cutting. Measurement 107:19–30

Khan A, Khan A, Maity K, Maity K (2017) Application of MCDM-based TOPSIS method for the selection of optimal process parameter in turning of pure titanium. Benchmarking: An Int J 24(2):2009–2021

Khan A, Maity K (2016) Application of MCDM-based TOPSIS method for the optimization of multi quality characteristics of modern manufacturing processes. Int J Eng Res Africa 23:33–51

Kumar A, Majumder H, Vivekananda K, Maity K (2017) NSGA-II approach for multi-objective optimization of wire electrical discharge machining process parameter on inconel 718. Mater Today: Proc 4(2):2194–2202

Panda BN, Jena A, Mahapatra S (2010) Prediction of surface finish and material removal rate in wire electrical discharge machining (WEDM) using fuzzy approach. Int J Manuf Technol Ind Eng (IJMTIE) 1(2):109–116

Hwang C-L, Masud ASM (2012) Multiple objective decision making—methods and applications: a state-of-the-art survey, vol 164. Springer Science & Business Media

Opricovic S, Tzeng G -H (2004) Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur J Oper Res 156(2):445–455

Athawale VM, Chakraborty S (2010) A TOPSIS method-based approach to machine tool selection. Proc: Int Conf Ind Eng Oper Manage, 65–70

Chakladar ND, Chakraborty S (2008) A combined TOPSIS-AHP-method-based approach for non-traditional machining processes selection. Proc: Inst Mech Eng Part B: J Eng Manuf 222(12):1613–1623

Singh A, Datta S, Mahapatra SS (2011) Application of TOPSIS in the Taguchi method for optimal machining parameter selection. J Manuf Sci Prod 11(1-3):49–60

Majumder H, Saha A (2018) Application of MCDM based hybrid optimization tool during turning of ASTM A588. Decis Sci Lett 7(2):143–156

Tsui K -L (1992) An overview of Taguchi method and newly deve- loped statistical methods for robust design. IIE Trans 24(1):44–57

Mahapatra S, Patnaik A (2007) Optimization of wire electrical discharge machining (WEDM) process parameters using Taguchi method. Int J Adv Manuf Technol 34(9):911–925

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naik, D.K., Khan, A., Majumder, H. et al. Experimental Investigation of the PMEDM of Nickel Free Austenitic Stainless Steel: A Promising Coronary Stent Material. Silicon 11, 899–907 (2019). https://doi.org/10.1007/s12633-018-9877-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-9877-1