Abstract

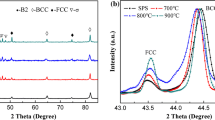

Multicomponent Al20Cr20Fe25Ni25Mn10 alloys were synthesized using spark plasma sintering at different temperatures (800, 900, and 1000°C) and holding times (4, 8, and 12 min) to develop a high entropy alloy (HEA). The characteristics of spark plasma-synthesized (SPSed) alloys were experimentally explored through investigation of microstructures, microhardness, and corrosion using scanning electron microscopy coupled with energy dispersive spectroscopy (EDS), Vickers microhardness tester, and potentiodynamic polarization, respectively. X-ray diffraction (XRD) characterization was employed to identify the phases formed on the developed alloys. The EDS results revealed that the alloys consisted of elements selected in this work irrespective of varying sintering parameters. The XRD, EDS, and scanning electron microscopy collectively provided evidence that the fabricated alloys were characterized by globular microstructures exhibiting face-centered cubic phase, which was formed on a basis of solid solution mechanism. This finding implies that the SPSed alloy showed the features of HEAs. The alloy produced at 1000°C and holding time of 12 min portrayed an optimal microhardness of HV 447.97, but the value decreased to HV 329.47 after heat treatment. The same alloy showed an outstanding corrosion resistance performance. The increase in temperature resulted in an Al20Cr20Fe25Ni25Mn10 alloy with superior density, microhardness, and corrosion resistance over the other alloys developed at different parameters.

Similar content being viewed by others

References

B.S. Murty, J.W. Yeh, and S. Ranganathan, A brief history of alloys and the birth of high-entropy alloys, [in] High Entropy Alloys, Amsterdam: Elsevier, 2014, p. 1.

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes, Adv. Eng. Mater., 6(2004), No. 5, p. 299.

J.W. Yeh, Recent progress in high-entropy alloys, Ann. Chim. Sci. Mat., 31(2006), No. 6, p. 633.

L. Rudolf Kanyane, A. Patricia Popoola, and N. Malatji, Development of spark plasma sintered TiAlSiMoW multicomponent alloy: Microstructural evolution, corrosion and oxidation resistance, Results Phys., 12(2019), p. 1754.

N. Malatji, A.P.I. Popoola, T. Lengopeng, and S. Pityana, Tri-bological and corrosion properties of laser additive manufactured AlCrFeNiCu high entropy alloy, Mater. Today: Proc., 28(2020), p. 944.

K.K. Alaneme, M.O. Bodunrin, and S.R. Oke, Processing, alloy composition and phase transition effect on the mechanical and corrosion properties of high entropy alloys: A review, J. Mater. Res. Technol., 5(2016), No. 4, p. 384.

L.C. Tsao, C.S. Chen, and C.P. Chu, Age hardening reaction of the Al0.3CrFe1.5MnNi0.5 high entropy alloy, Mater. Des. (1980-2015), 36(2012), p. 854.

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys, J. Appl. Phys., 109(2011), No. 10, art. No. 103505.

Z.Q. Fu, W.P. Chen, H.M. Wen, Z. Chen, and E.J. Lavernia, Effects of Co and sintering method on microstructure and mechanical behavior of a high-entropy Al0.6NiFeCrCo alloy prepared by powder metallurgy, J. Alloys Compd., 646(2015), p. 175.

S.Y. Zhang, X.F. Zhang, Q.S. Lu, P. He, T.S. Lin, and H.Y. Geng, Investigation of melt-spinning speed on the property of Yb0.2Ba0.1Al0.1Ga0.1ln0.1La0.05Eu0.05Co3.75Fe0.25Sb12 skutterudites, Mater. Lett., 260(2020), art. No. 126960.

S.Y. Zhang, S.W. Xu, H. Gao, Q.S. Lu, T.S. Lin, P. He, and H.Y. Geng, Characterization of multiple-filled skutterudites with high thermoelectric performance, J. Alloys Compd., 814(2020), art. No. 152272.

G. Popescu, M.M. Adrian, I. Csaki, C.A. Popescu, D. Mitrică, S. Vasile, and I. Carcea, Mechanically alloyed high entropy composite, IOP Conf. Ser.: Mater. Sci. Eng., 145(2016), No. 7, art. No. 072007.

S. Varalakshmi, M. Kamaraj, and B.S. Murty, Synthesis and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying, J. Alloys Compd., 460(2008), No. 1–2, p. 253.

C.S. Babu, K. Sivaprasad, V. Muthupandi, and J.A. Szpunar, Characterization of nanocrystalline AlCoCrCuNiFeZn high entropy alloy produced by mechanical alloying, Procedia Mater. Sci., 5(2014), p. 1020.

S. Riva, S.G.R. Brown, N.P. Lavery, A. Tudball, and K.V. Yusenko, Spark plasma sintering of high entropy alloys, [in] P. Cavaliere, eds., Spark Plasma Sintering of Materials, Springer, Cham, 2019, p. 517.

S. Yadav, K. Biswas, and A. Kumar, Spark plasma sintering of high entropy alloys, [in] P. Cavaliere, eds., Spark Plasma Sintering of Materials, Springer, Cham, 2019, p. 539.

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, and Y. Yang, High-entropy alloy: Challenges and prospects, Mater. Today, 19(2016), No. 6, p. 349.

J.F. Zeng, C.J. Wu, H.P. Peng, Y. Liu, J.H. Wang, and X.P. Su, Microstructure and microhardness of as-cast and 800 °C annealed AlxCr0.2Fe0.2Ni0.6−x and Al0.2Cr0.2FeyNi0.6−y alloys, Vacuum, 152(2018), p. 214.

A. Munitz, L. Meshi, and M.J. Kaufman, Heat treatments’ effects on the microstructure and mechanical properties of an equiatomic Al—Cr—Fe—Mn—Ni high entropy alloy, Mater. Sci. Eng. A, 689(2017), p. 384.

D. Choudhuri, B. Gwalani, S. Gorsse, C.V. Mikler, R.V. Ramanujan, M.A. Gibson, and R. Banerjee, Change in the primary solidification phase from fcc to bcc-based B2 in high entropy or complex concentrated alloys, Scr. Mater., 127(2017), p. 186.

A.J. Zhang, J.S. Han, J.H. Meng, B. Su, and D.L. Pen, Rapid preparation of AlCoCrFeNi high entropy alloy by spark plasma sintering from elemental powder mixture, Mater. Lett., 181(2016), p. 82.

N. Eißmann, B. Klöden, T. Weißgärber, and B. Kieback, High-entropy alloy CoCrFeMnNi produced by powder metallurgy, Powder Metall., 60(2017), No. 3, p. 184.

R.M. German, Coarsening in sintering: Grain shape distribution, grain size distribution, and grain growth kinetics in solidpore systems, Crit. Rev. Solid State Mater. Sci., 35(2010), No. 4, p. 263.

S. Wagner, D. Kahraman, H. Kungl, M.J. Hoffmann, C. Schuh, K. Lubitz, H. Murmann-Biesenecker, and J.A. Schmid, Effect of temperature on grain size, phase composition, and electrical properties in the relaxor-ferroelectric-system Pb(Ni1/3Nb2/3) O3-Pb(Zr, Ti)O3, J. Appl. Phys., 98(2005), No. 2, art. No. 024102.

S. Kennedy, S. Kumaran, and T. Srinivasa Rao, Microstructure and mechanical properties of γ-TiAl consolidated by spark plasma sintering, Integr. Ferroelectr., 185(2017), No. 1, p. 11.

A.V. Adedayo, Development processes of globular microstructure, J. Miner. Mater. Charact. Eng., 10(2011), No. 7, p. 651.

A.G. Atkins, Deformation-mechanism maps (the plasticity and creep of metals and ceramics), J. Mech. Work. Technol., 9(1984), No. 2, p. 224.

S. Elkatatny, M.A.H. Gepreel, A. Hamada, K. Nakamura, K. Yamanaka, and A. Chiba, Effect of Al content and cold rolling on the microstructure and mechanical properties of Al5Cr12 Fe35Mn28Ni20 high-entropy alloy, Mater. Sci. Eng. A, 759(2019), p. 380.

M.H. Xiao, J.W. Chen, J.J. Kang, K. Chen, D. Wu, and N. Gao, Effect of heat treatment process on mechanical properties and microstructure of FeAlCoCrNiTi0.5 alloy, AIP Adv., 8(2018), No. 9, art. No. 095322.

B. Ren, Z.X. Liu, D.M. Li, L. Shi, B. Cai, and M.X. Wang, Effect of elemental interaction on microstructure of CuCrFeNiMn high entropy alloy system, J. Alloys Compd., 493(2010), No. 1–2, p. 148.

Y.P. Wang, B.S. Li, and H.Z. Fu, Solid solution or intermetallics in a high-entropy alloy, Adv. Eng. Mater., 11(2009), No. 8, p. 641.

R.B. Li, W.W. Zhang, Y. Zhang, and P.K. Liaw, The effects of phase transformation on the microstructure and mechanical behavior of FeNiMnCr.75Alx high-entropy alloys, Mater. Sci. Eng. A, 725(2018), p. 138.

B.J. Babalola, N. Maledi, M.B. Shongwe, M.O. Bodunrin, B.A. Obadele, and P.A. Olubambi, Influence of nanocrystalline nickel powder on oxidation resistance of spark plasma sintered Ni-17Cr6.5Co1.2Mo6Al4W7.6Ta alloy, J. King Saud Univ. Eng. Sci., 32(2020), No. 3, p. 198.

A. Mthisi and A.P.I. Popoola, Influence of Al2O3 addition on the hardness and in vitro corrosion behavior of laser synthesized Ti-Al2O3 coatings on Ti-6Al-4V, Int. J. Adv. Manuf. Technol., 100(2019), No. 1–4, p. 917.

R.N. Lumley, Fundamentals of aluminium metallurgy: production, processing, and applications, [in] N. Birbilis and B. Hinton, eds., Corrosion and Corrosion Protection of Aluminium, Woodhead Publishing, Oxford, 2011, p. 574.

T.M. Butler and M.L. Weaver, Oxidation behavior of arc melted AlCoCrFeNi multi-component high-entropy alloys, J. Alloys Compd., 674(2016), p. 229.

K. Masemola, P. Popoola, and N. Malatji, The effect of annealing temperature on the microstructure, mechanical and electrochemical properties of arc-melted AlCrFeMnNi equi-atomic High entropy alloy, J. Mater. Res. Technol., 9(2020), No. 3, p. 5241.

L.R. Kanyane, N. Malatji, A.P.I. Popoola, and M.B. Shongwe, Evolution of microstructure, mechanical properties, electrochemical behaviour and thermal stability of Ti025—Al0.2—Mo0.2—Si0.25W0.1 high entropy alloy fabricated by spark plasma sintering technique, Int. J. Adv. Manuf. Technol., 104(2019), No. 5–8, p. 3163.

Acknowledgements

The authors acknowledge the support from Institute for Nano-Engineering Research and Surface Engineering Research Centre of Tshwane University of Technology and National Research Foundation of South Africa, Pretoria, South Africa.

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Mthisi, A., Malatji, N., Patricia, A. et al. Parametric study of spark plasma sintering of Al20Cr20Fe25Ni25Mn10 high entropy alloy with improved microhardness and corrosion. Int J Miner Metall Mater 29, 119–127 (2022). https://doi.org/10.1007/s12613-020-2200-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2200-3