Abstract

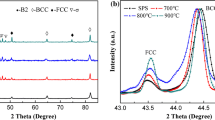

Near Equi-Atomic Ti0.25-Al0.2-Mo0.2-Si0.25W0.1 high entropy alloy (HEA) with enhanced mechanical properties and good corrosion resistance was synthesized by means of spark plasma sintering technology. The influence of spark plasma sintering temperature of developed Ti0.25-Al0.2-Mo0.2-Si0.25W0.1 HEA was investigated at 800 °C, 900 °C and 1000 °C. The analysis of the morphological and microstructural characteristics of the alloy revealed the presence of bcc phase structure along with intermetallic phases of TiSi2 and Mo2Si4. Microhardness, wear and oxidation resistance of the alloy were found to be dependent on sintering temperature. The performance of the samples increased with rise in sintering temperature. The electrochemical behaviour of the alloy was tested in 0.5 M H2SO4 solution and the results showed the alloy to possess good anti-corrosion properties. The subjection of the alloy to annealing conditions at 900 °C induced formation of stable phases that improved the microhardness of the samples.

Similar content being viewed by others

References

Qiu Y, Thomas S, Gibson MA, Fraser HL, Birbilis N (2017) Corrosion of high entropy alloys. Mater Degrad 1(1):15

Fu Z, Chen W, Wen H, Chen Z, Lavernia EJ (2015) Effects of co and sintering method on microstructure and mechanical behavior of a high-entropy Al0. 6NiFeCrCo alloy prepared by powder metallurgy. J Alloys Compd 646:175–182

Lin C-M, Tsai H-L, Bor H-Y (2010) Effect of aging treatment on microstructure and properties of high-entropy Cu0. 5CoCrFeNi alloy. Intermetallics 18(6):1244–1250

Omori M (2000) Sintering, consolidation, reaction and crystal growth by the spark plasma system (SPS). Mater Sci Eng A 287(2):183–188

Chen W, Fu Z, Fang S, Xiao H, Zhu D (2013) Alloying behavior, microstructure and mechanical properties in a FeNiCrCo0. 3Al0. 7 high entropy alloy. Mater Des 51:854–860

Xiao D et al (2017) Microstructure, mechanical and corrosion behaviors of AlCoCuFeNi-(Cr, Ti) high entropy alloys. Mater Des 116:438–447

Sistla HR, Newkirk JW, Liou FF (2015) Effect of Al/Ni ratio, heat treatment on phase transformations and microstructure of AlxFeCoCrNi2− x (x= 0.3, 1) high entropy alloys. Mater Des 81:113–121

Makena MI, Shongwe MB, Ramakokovhu MM, Olubambi PA (2017) Effect of sintering parameters on densification, corrosion and wear behaviour of Ni-50Fe alloy prepared by spark plasma sintering. J Alloys Compd 699:1166–1179

Shongwe MB, Diouf S, Durowoju MO, Olubambi PA (2015) Effect of sintering temperature on the microstructure and mechanical properties of Fe–30% Ni alloys produced by spark plasma sintering. J Alloys Compd 649:824–832

Rudolf L, Kanyane A (2019) Patricia Popoola and NicholusMalatji. Development of spark plasma sintered TiAlSiMoW multicomponent alloy: microstructural evolution, corrosion and oxidation resistance. Results Phys. https://doi.org/10.1016/j.rinp.2019.01.098

Gowon B, Mohammed KS, Jamaluddin SBB, Hussain Z, Evarastics P (2015) The effects of sintering temperature on the densification of mechanically alloyed W-Brass composites. Open J Metal 5(03):19–26

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY (2004) Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6(5):299–303

Yeh J-W, Lin SJ, Chin TS, Gan JY, Chen SK, Shun TT, Tsau CH, Chou SY (2004) Formation of simple crystal structures in cu-co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall Mater Trans A 35(8):2533–2536

Cantor B et al (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A 375:213–218

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK (2008) Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater 10(6):534–538

Senkov O et al (2010) Refractory high-entropy alloys. Intermetallics 18(9):1758–1765

Sheng G, Liu CT (2011) Phase stability in high entropy alloys: formation of solid-solution phase or amorphous phase. Prog Nat Sci: Mater Int 21(6):433–446

Yang X, Zhang Y (2012) Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater Chem Phys 132(2–3):233–238

Zheng B, Liu QB, Zhang LY (2013) Microstructure and properties of MoFeCrTiW high-entropy alloy coating prepared by laser cladding. In Advanced Materials Research. Trans Tech Publ

Zhang Y, Lu ZP, Ma SG, Liaw PK, Tang Z, Cheng YQ, Gao MC (2014) Guidelines in predicting phase formation of high-entropy alloys. Mrs Communications 4(2):57–62

Li C, Li JC, Zhao M, Jiang Q (2009) Effect of alloying elements on microstructure and properties of multiprincipal elements high-entropy alloys. J Alloys Compd 475(1–2):752–757

Wang W-R, Wang WL, Wang SC, Tsai YC, Lai CH, Yeh JW (2012) Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26:44–51

Anselmi-Tamburini U, Garay JE, Munir ZA, Tacca A, Maglia F, Spinolo G (2004) Spark plasma sintering and characterization of bulk nanostructured fully stabilized zirconia: part I. densification studies. J Mater Res 19(11):3255–3262

Kumar D, Maulik O, Sharma VK, Prasad YVSS, Kumar V (2018) Understanding the effect of tungsten on corrosion behavior of AlCuCrFeMnW x high-entropy alloys in 3.5 wt.% NaCl solution. J Mater Eng Perform 27(9):4481–4488

Huang Y, Zhou X, Hua N, Que W, Chen W (2008) High temperature friction and wear behavior of tungsten copper alloys. Int J Refract Met Hard Mater:105–112

Acknowledgements

The authors would like to acknowledge Institute for Nano Engineering Research, Surface Engineering Research Center, Tshwane University of Technology, Department of Chemical Metallurgical and Materials Engineering, Pretoria, South Africa and also Botswana International University of Science and Technology (BIUST).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kanyane, L.R., Malatji, N., Popoola, A.P.I. et al. Evolution of microstructure, mechanical properties, electrochemical behaviour and thermal stability of Ti0.25-Al0.2-Mo0.2-Si0.25W0.1 high entropy alloy fabricated by spark plasma sintering technique. Int J Adv Manuf Technol 104, 3163–3171 (2019). https://doi.org/10.1007/s00170-019-04185-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04185-0