Abstract

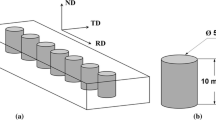

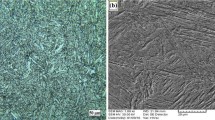

Hot compression tests were performed on AISI 321 austenitic stainless steel in the deformation temperature range of 800–1200°C and constant strain rates of 0.001, 0.01, 0.1, and 1 s−1. Hot flow curves were used to determine the strain hardening exponent and the strain rate sensitivity exponent, and to construct the processing maps. Variations of the strain hardening exponent with strain were used to predict the microstructural evolutions during the hot deformation. Four variations were distinguished reflecting the different microstructural changes. Based on the analysis of the strain hardening exponent versus strain curves, the microstructural evolutions were dynamic recovery, single and multiple peak dynamic recrystallization, and interactions between dynamic recrystallization and precipitation. The strain rate sensitivity variations at an applied strain of 0.8 and strain rate of 0.1 s−1 were compared with the microstructural evolutions. The results demonstrate the existence of a reliable correlation between the strain rate sensitivity values and evolved microstructures. Additionally, the power dissipation map at the applied strain of 0.8 was compared with the resultant microstructures at predetermined deformation conditions. The microstructural evolutions strongly correlated to the power dissipation ratio, and dynamic recrystallization occurred completely at lower power dissipation ratios.

Similar content being viewed by others

References

E. Duncombe, Plastic instability and growth of grooves and patches in plates or tubes, Int. J. Mech. Sci., 14(1972), No. 5, p. 325.

A.K. Ghosh, The influence of strain hardening and strain-rate sensitivity on sheet metal forming, J. Eng. Mater. Technol., 99(1977), No. 3, p. 264.

N. Tahreen, D.L. Chen, M. Nouri, and D.Y. Li, Effects of aluminum content and strain rate on strain hardening behavior of cast magnesium alloys during compression, Mater. Sci. Eng. A, 594(2014), p. 235.

A.K. Ghosh, Tensile instability and necking in materials with strain hardening and strain-rate hardening, Acta Metall., 25(1977), No. 12, p. 1413.

D.H. Kang, D.W. Kim, S. Kim, G.T. Bae, K.H. Kim, and N.J. Kim, Relationship between stretch formability and work-hardening capacity of twin-roll cast Mg alloys at room temperature, Scripta Mater., 61(2009), No. 7, p. 768.

Y.M. Wang, M.W. Chen, F.H. Zhou, and E. Ma, High tensile ductility in a nanostructured metal, Nature, 419(2002), No. 6910, p. 912.

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma, Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals, Mater. Sci. Eng. A, 381(2004), No. 1–2, p. 71.

O.D. Sherby, Advances in superplasticity and in superplastic materials, ISIJ Int., 29(1989), No. 8, p. 698.

I. Charit and R.S. Mishra, High strain rate superplasticity in a commercial 2024 Al alloy via friction stir processing, Mater. Sci. Eng. A, 359(2003), No. 1–2, p. 290.

Y.M. Wang and E. Ma, Three strategies to achieve uniform tensile deformation in a nanostructured metal, Acta Mater., 52(2004), No. 6, p. 1699.

Y.V.R.K. Prasad and K.P. Rao, Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: Anisotropy of hot workability, Mater. Sci. Eng. A, 487(2008), No. 1–2, p. 316.

C.Y. Wang, X.J. Wang, H. Chang, K. Wu, and M.Y. Zheng, Processing maps for hot working of ZK60 magnesium alloy, Mater. Sci. Eng. A, 464(2007), No. 1–2, p. 52.

S.P. Tan, Z.H. Wang, S.C. Cheng, Z.D. Liu, J.C. Han, and W.T. Fu, Processing maps and hot workability of Super304H austenitic heat-resistant stainless steel, Mater. Sci. Eng. A, 517(2009), No. 1–2, p. 312.

S.V.S.N. Murty, B.N. Rao, and B.P. Kashyap, Identification of flow instabilities in the processing maps of AISI 304 stainless steel, J. Mater. Process. Technol., 166(2005), No. 2, p. 268.

B.F. Guo, H.P. Ji, X.G. Liu, L. Gao, R.M. Dong, M. Jin, and Q.H. Zhang, Research on flow stress during hot deformation process and processing map for 316LN austenitic stainless steel, J. Mater. Eng. Perform., 21(2012), No. 7, p. 1455.

M.S. Ghazani and B. Eghbali, A ductile damage criterion for AISI 321 austenitic stainless steel at different temperatures and strain rates, Arabian J. Sci. Eng., 43(2018), No. 9, p. 4855.

M.S. Ghazani, B. Eghbali, and G.R. Ebrahimi, Evaluation of the kinetics of dynamic recovery in AISI 321 austenitic stainless steel using hot flow curves, Trans. Indian Inst. Met., 70(2017), No. 7, p. 1755.

J. Rasti, A. Najafizadeh, and M. Meratian, Correcting the stress-strain curve in hot compression test using finite element analysis and Taguchi method, Int. J. Iron Steel Soc. Iran, 8(2011), No. 1, p. 26.

S.D. Antolovich and R.W. Armstrong, Plastic strain localization in metals: Origins and consequences, Prog. Mater. Sci., 59(2014), p. 1.

M.S. Ghazani and B. Eghbali, Characterization of the hot deformation microstructure of AISI 321 austenitic stainless steel, Mater. Sci. Eng. A, 730(2018), p. 380.

T. Sakai and J.J. Jonas, Overview no. 35 dynamic recrystallization: Mechanical and microstructural considerations, Acta Metall., 32(1984), No. 2, p. 189.

Y.P. Li, E. Onodera, H. Matsumoto, and A. Chiba, Correcting the stress-strain curve in hot compression process to high strain level, Metall. Mater. Trans. A, 40(2009), No. 4, p. 982.

J. May, H.W. Höppel, and M. Göken, Strain rate sensitivity of ultrafine-grained aluminium processed by severe plastic deformation, Scripta Mater., 53(2005), No. 2, p. 189.

Y.V.R.K. Prasad, K.P. Rao, and S. Sasidhar, Hot Working Guide: A Compendium of Processing Maps, 2nd ed., ASM International, Kinsman Road Materials Park, OH, 2015.

A. Momeni and K. Dehghani, Characterization of hot deformation behavior of 410 martensitic stainless steel using constitutive equations and processing maps, Mater. Sci. Eng. A, 527(2010), No. 21–22, p. 5467.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghazani, M.S., Eghbali, B. Strain hardening behavior, strain rate sensitivity and hot deformation maps of AISI 321 austenitic stainless steel. Int J Miner Metall Mater 28, 1799–1810 (2021). https://doi.org/10.1007/s12613-020-2163-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2163-4