Abstract

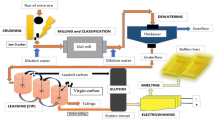

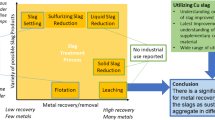

In the newly developed oxygen-enriched bottom-blowing copper smelting process (also known as the SKS copper smelting process), Cu loss in slag is one of the most concerning issues. This paper presents our research results concerning the relationship between the Cu content of the matte and slag in the SKS process; the results are based on actual industrial production in the Dongying Fangyuan copper smelter. The results show that the matte grade strongly influences Cu losses in slag. The dissolved and entrained losses account for 10%–20% and 80%–90% of the total SKS industrial Cu losses in slag, respectively. With increasing matte grade, the dissolved and entrained Cu losses in the SKS slag both increase continuously. When the matte grade is greater than 68%, the content of Cu in the smelting slag increases much more dramatically. To obtain a high direct recovery of copper, the matte grade should be less than 75% in industrial SKS copper production.

Similar content being viewed by others

References

S. Wang, W. Davenport, A. Siegmund, S. Yao, T. Gonzales, G. Walters, and D. George, Copper smelting: 2016 world copper smelting data, [in] 9th International Copper Conference (Copper 2016), Kobe, 2016, p. 322.

W.P. Liu and X.F. Yin, Recovery of copper from copper slag using a microbial fuel cell and characterization of its electrogenesis, Int. J. Miner. Metall. Mater., 24(2017), No. 6, p. 621.

J.S. Deng, S.M. Wen, J.Y. Deng, and D.D. Wu, Extracting copper from copper oxide ore by a zwitterionic reagent and dissolution kinetics, Int. J. Miner. Metall. Mater., 22(2015), No. 3, p. 241.

X.Y. Guo, Y.Z. Zhang, Q.M. Wang, and Z.S. Yuan, Advanced copper smelting technologies used to quadruple China copper production between 2000 and 2015, [in] 9th International Copper Conference (Copper 2016), Kobe, 2016, p. 330.

K.Q. Li, S. Ping, H.Y. Wang, and W. Ni, Recovery of iron from copper slag by deep reduction and magnetic beneficiation, Int. J. Miner. Metall. Mater., 20(2013), No. 11, p. 1035.

Z.Y. Ma, H.Y. Yang, S.T. Huang, Y. Lü, and L. Xiong, Ultra fast microwave-assisted leaching for the recovery of copper and tellurium from copper anode slime, Int. J. Miner. Metall. Mater., 22(2015), No. 6, p. 582.

D.X. Wang, Y. Liu, Z.M. Zhang, T.A. Zhang, and X.L. Li, PIV measurements on physical models of bottom blown oxygen copper smelting furnace, Can. Metall. Q., 56(2017), No. 2, p. 221.

P. Coursol, P.J. Mackey, J.P.T. Kapusta, and N.C. Valencia, Energy consumption in copper smelting: A new Asian horse in the race, JOM, 67(2015), No. 5, p. 1066.

L. Shui, Z.X. Cui, X.D. Ma, M.A. Rhamdhani, A.V. Nguyen, and B.J. Zhao, Understanding of bath surface wave in bottom blown copper smelting furnace, Metall. Mater. Trans. B, 47(2016), No. 1, p. 135.

W.F. Li, J. Zhan, Y.Q. Fan, C. Wei, C.F. Zhang, and J.Y. Hwang, Research and industrial application of a process for direct reduction of molten high-lead smelting slag, JOM, 69(2017), No. 4, p. 784.

W.F. Liu, T.Z. Yang, D.C. Zhang, L. Chen, and Y.F. Liu, A new pyrometallurgical process for producing antimony white from by-product of lead smelting, JOM, 66(2014), No. 9, p. 1694.

Q.M. Wang, X.Y. Guo, and Q.H. Tian, Copper smelting mechanism in oxygen bottom blown furnace, Trans. Nonferrous Met. Soc. China, 27(2017), No. 4, p. 946.

R. Sridhar, J.M. Toguri, and S. Simeonov, Copper losses and thermodynamic considerations in copper smelting, Metall. Mater. Trans. B, 28(1997), No. 2, p. 191.

M. Chen, Z.X. Cui, and B.J. Zhao, Slag chemistry of bottom blown copper smelting furnace at Dongying Fangyuan, [in] 6th International Symposium on High Temperature Metallurgical Processing, Orlando, 2015, p. 257.

H.Q. Liu, Z.X. Cui, M. Chen, and B.J. Zhao, Phase equilibria study of the ZnO-“FeO”-SiO2-Al2O3 System at Po2 10-8 atm, Metall. Mater. Trans. B, 47(2016), No. 2, p. 1113.

P.F. Tan, Modeling and control of copper loss in smelting slag, JOM, 63(2011), No. 12, p. 51.

H. Jalkanen, J. Vehviläinen, and J. Poijärvi, Copper in solidified copper smelter slags, Scand. J. Metall., 32(2003), No. 2, p. 65.

A. Rusen, A. Geveci, Y.A. Topkaya, and B. Derin, Investigation of effect of colemanite addition on copper losses in matte smelting slag, Can. Metall. Q., 51(2012), No. 2, p. 157.

A. Rusen, A. Geveci, Y.A. Topkaya, and B. Derin, Effects of some additives on copper losses to matte smelting slag, JOM, 68(2016), No. 9, p. 2323.

P. Coursol, N.C. Valencia, P. Mackey, S. Bell, and B. Davis, Minimization of copper losses in copper smelting slag during electric furnace treatment, JOM, 64(2012), No. 11, p. 1305.

Q.M. Wang, X.Y. Guo, S.S. Wang, L.L. Liao, and Q.H. Tian, Multiphase equilibrium modeling of oxygen bottom blown copper smelting process, Trans. Nonferrous Met. Soc. China, 27(2017), No. 11, p. 2503.

Q.M. Wang, X.Y. Guo, Q.H. Tian, T. Jiang, M. Chen, and B.J. Zhao, Development and application of SKSSIM simulation software for the oxygen bottom blown copper smelting process, Metals, 7(2017), No. 10, p. 431.

I. Imris, M. Sanchez, and G. Achurra, Copper losses to slags obtained from the El Teniente process, Miner. Process. Extr. Metall., 114(2005), No. 3, p. 135.

A. Yazawa, S. Nakazawa, and Y. Takeda, Distribution behaviour of various elements in copper smelting systems, JOM, 36(1984), No. 8, p. 79.

R. Shimpo, S. Goto, O. Ogawa, and I. Asakuru, A study on equilibrium between copper matte and slag, Can. Metall. Q., 25(1986), No. 2, p. 113.

H.Q. Liu, Z.X. Cui, M. Chen, and B.J. Zhao, Phase equilibria study of the ZnO-‘FeO’-SiO2 System at fixed Po2 10-8 atm, Metall. Mater. Trans. B, 47(2016), No. 1, p.164.

C.W. Bale, E. Belisle, P. Chartrand, S.A. Decterov, G. Eriksson, K. Hack, I.H. Jung, Y.B. Kang, J. Melançon, A.D. Pelton, C. Robelin, and S. Petersen, FactSage thermochemical software and databases-recent developments, Calphad, 33(2009), No. 2, p. 295.

B. Zhao, Phase Equilibria for Copper Smelting and Lead/Zinc Reduction Slags [Dissertations], University of Queensland, Brisbane, 1999, p. 68.

J.Z. Ma, F. Wang, L. Feng, and H.B. Huang, Method improvement for determination of ferrous iron in iron ore by potassium dichromate titrimetry, Chinese J. Inorg. Anal. Chem., 7(2017), No. 1, p. 39.

C. Wang and C.F. Zhang, Study on choosing the best grade matte copper smelting process, World Nonferrous Met., 1002–5065(2016), No. 9, p. 21.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51620105013) and Dongying Fangyuan Nonferrous Metals Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Qm., Wang, Ss., Tian, M. et al. Relationship between copper content of slag and matte in the SKS copper smelting process. Int J Miner Metall Mater 26, 301–308 (2019). https://doi.org/10.1007/s12613-019-1738-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1738-4