Abstract

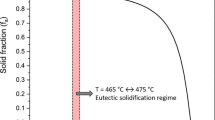

The mechanical properties and constitutive behaviors of as-cast AA7050 in both the solid and semi-solid states were determined using the on-cooling and in situ solidification approaches, respectively. The results show that the strength in the solid state tends to increase with decreasing temperature. The strain rate plays an important role in the stress–strain behaviors at higher temperatures, whereas the influence becomes less pronounced and irregular when the temperature is less than 250°C. The experimental data were fitted to the extended Ludwik equation, which is suitable to describe the mechanical behavior of the materials in the as-cast state. In the semi-solid state, both the strength and ductility of the alloy are high near the solidus temperature and decrease drastically with decreasing solid fraction. As the solid fraction is less than 0.97, the maximum strength only slightly decreases, whereas the post-peak ductility begins to increase. The experimental data were fitted to the modified creep law, which is used to describe the mechanical behavior of semi-solid materials, to determine the equivalent parameter f GBWL, i.e., the fraction of grain boundaries covered by liquid phase.

Similar content being viewed by others

References

W. X. Shu, J. C. Liu, L. G. Hou, H. Cui, J. T. Liu, and J. S. Zhang, Microstructural evolution of Al-8.59Zn-2.00Mg-2.44Cu during homogenization, Int. J. Miner. Metall. Mater., 21 (2014), No. 12, p. 1215.

X. J. Wang, J. Z. Cui, Y. B. Zuo, Z. H. Zhao, and H. T. Zhang, Effects of low-frequency electromagnetic field on the surface quality of 7050 aluminum alloy ingots during the hot-top casting process, Int. J. Miner. Metall. Mater., 18 (2011), No. 2, p. 165.

Z. H. Zhao, Z. Xu, G. S. Wang, Q. F. Zhu, and J. Z. Cui, As-cast structure of DC casting 7075 aluminum alloy obtained under dual-frequency electromagnetic field, Int. J. Miner. Metall. Mater., 21 (2014), No. 2, p. 150.

J.-M. Drezet and M. Rappaz, Modeling of ingot distortions during direct chill casting of aluminum alloys, Metall. Mater. Trans. A, 27A(1996), p. 3214.

M. Lalpoor, D. G. Eskin, and L. Katgerman, Cold-cracking assessment in AA7050 billets during direct-chill casting by thermomechanical simulation of residual thermal stresses and application of fracture mechanics, Metall. Mater. Trans. A, 40 (2009), No. 13, p. 3304.

M. M’hamdi, A. Mo, and H. G. Fjær, TearSim: A two-phase model addressing hot tearing formation during aluminum direct chill casting, Metall. Mater. Trans. A, 37 (2006), p. 3069.

A. J. Williams, T. N. Croft, and M. Cross, Modeling of ingot development during the start-up phase of direct chill casting, Metall. Mater. Trans. B, 34 (2003), No. 5, p. 727.

W. H. Suyitno, W. H. Kool, and L. Katgerman, Finite element method simulation of mushy zone behavior during direct-chill casting of an Al-4.5 pct Cu alloy, Metall. Mater. Trans. A, 35 (2004), No. 9, p. 2917.

J. Sengupta, S. L. Cockcroft, D. M. Maijer, M. A. Wells, and A. Larouche, On the development of a three-dimensional transient thermal model to predict ingot cooling behavior during the start-up phase of the direct chill-casting process for an AA5182 aluminum alloy ingot, Metall. Mater. Trans. B, 35 (2004), No. 3, p. 523.

F. D’Elia, C. Ravindran, D. Sediako, K. U. Kainer, and N. Hort, Hot tearing mechanisms of B206 aluminum-copper alloy, Mater. Des., 64 (2014), p. 44.

J. F. Song, Z. Wang, Y. D. Huang, A. Srinivasan, F. Beckmann, K. U. Kainer, and N. Hort, Effect of Zn addition on hot tearing behaviour of Mg-0.5Ca-xZn alloys, Mater. Des., 87 (2015), p. 157.

M. Lalpoor, D. G. Eskin, D. Ruvalcaba, H. G. Fjær, A. T. Cate, N. Ontijt, and L. Katgerman, Cold cracking in DC-cast high strength aluminum alloy ingots: an intrinsic problem intensified by casting process parameters, Mater. Sci. Eng. A, 528 (2011), No. 6, p. 2831.

A. B. Phillion, S. Thompson, S. L. Cockcroft, and M. A. Wells, Tensile properties of as-cast aluminum alloys AA3104, AA6111 and CA31218 at above solidus temperatures, Mater. Sci. Eng. A, 497 (2008), No. 1-2, p. 388.

K. M. Chang and B. Kang, Cracking control in DC casting of high-strength aluminum alloys, J. Chin Inst. Eng., 22 (1999), No. 1, p. 27.

J. F. Grandfield, J. A. Taylor, and C. J. Davidson, Tensile coherency in semi-solid AZ91 alloy, Magnesium Technol., (2002), p. 207.

L. J. Colley, M. A. Wells, and D. M. Maijer, Tensile properties of as-cast AA5182Close to the solidus temperature, Mater. Sci. Eng. A, 386 (2004), No. 1-2, p. 140.

W. M. van Haaften, W. H. Kool, and L. Katgerman, Tensile behaviour of semi-solid industrial aluminium alloys AA3104 and AA5182, Mater. Sci. Eng. A, 336 (2002), No. 1-2, p. 1.

W. M. van Haaften, W. H. Kool, and L. Katgerman, Hot tearing studies in AA5182, J. Mater. Eng. Perform., 11 (2002), No. 5, p. 537.

A. B. Phillion, S. L. Cockcroft, and P. D. Lee, A new methodology for measurement of semi-solid constitutive behavior and its application to examination of as-cast porosity and hot tearing in aluminum alloys, Mater. Sci. Eng. A, 491 (2008), No. 1-2, p. 237.

B. Magnin, L. Maenner, L. Katgerman, and S. Engler, Ductility and rheology of an Al-4. 5% Cu alloy from room temperature to coherency temperature, Mater. Sci. Forum, 217-222 (1996), p. 1209.

T. Nakagawa, P. Suvanchai, T. Okane, and T. Umeda, Deformation behavior during solidification of steels and aluminium alloys, Mater. Sci. Forum, 215-216 (1996), p. 377.

H. Nagaumi and T. Umeda, Study of the crack sensitivity of 6××× and 7××× aluminum alloys, Mater. Sci. Forum, 426 (2003), p. 465.

H. Nagaumi, S. Suzuki, T. Okane, and T. Umeda, Effect of iron content on hot tearing of high-strength Al-Mg-Si alloy, Mater. Trans., 47 (2006), No. 11, p. 2821.

H. Nagaumi, P. Suvanchai, T. Okane, and T. Umeda, Mechanical properties of high strength Al-Mg-Si alloy during solidification, Mater. Trans., 47 (2006), No. 12, p. 2918.

H. Nagaumi, S. Suzuki, T. Okane, and T. Umeda, Hot tearing of machinability improved 2××× aluminum alloy of high tin content with manganese and chromium addition, Mater. Trans., 49 (2008), No. 2, p. 324.

V. Mathier, P. D. Grasso, and M. Rappaz, A new tensile test for aluminum alloys in the mushy state: experimental method and numerical modeling, Metall. Mater. Trans. A, 39 (2008), No. 6, p. 1399.

A. K. Dahle, T. Sumitomo, and S. Instone, Relationship between tensile and shear strengths of the mushy zone in solidifying aluminum alloys, Metall. Mater. Trans. A, 34 (2003), No. 1, p. 105.

D. Fabrègue, A. Deschamps, M. Suéry, and W. J. Poole, Rheological behavior of Al-Mg-Si-Cu alloys in the mushy state obtained by partial remelting and partial solidification at high cooling rate, Metall. Mater. Trans. A, 37 (2006), No. 5, p. 1459.

A. Alankar and M. A. Wells, Constitutive behavior of as-cast aluminum alloys AA3104, AA5182 and AA6111 at below solidus temperatures, Mater. Sci. Eng. A, 527 (2010), No. 29-30, p. 7812.

M. Lalpoor, D. G. Eskin, and L. Katgerman, Fracture behavior and mechanical properties of high strength aluminum alloys in the as-cast condition, Mater. Sci. Eng. A, 497 (2008), No. 1-2, p. 186.

A. R. Alhassan-Abu and M. A. Wells, Determination of constitutive behaviour of as cast AA5182 for deformations that occur during direct chill casting using the Gleeble 1500 machine, Mater. Sci. Technol., 19 (2003), No. 1, p. 55.

W. M. van Haaften, B. Magnin, W. H. Kool, and L. Katgerman, Constitutive behavior of as-cast AA1050, AA3104, and AA5182, Metall. Mater. Trans. A, 33 (2002), No. 7, p. 1971.

T. Subroto, A. Miroux, D. G. Eskin, A. Marson, K. Ellingsen, and L. Katgerman, Tensile mechanical behavior of as-cast AA7050 alloy in the supersolidus temperature range, [in] 13th International Conference on Fracture, Beijing, 2013, p. 1.

Q. L. Bai, H. X. Li, Q. Du, J. S. Zhang, and L. Z. Zhuang, Mechanical properties and constitutive behaviors of as-cast high strength AA7××× alloys below solidus temperature, Mater. Sci. Forum, 794-796 (2014), p. 467.

I. I. Novikov, Hot Shortness of Non Ferrous Metals and Alloys, Nauka, Moscow, 1968.

Q. L. Bai, J. C. Liu, H. X. Li, Q. Du, L. Katgerman, and J. S. Zhang, L. Z. Zhuang, A modified hot tearing criterion for direct chill casting of aluminium alloys, Mater. Sci. Technol., 32 (2016), No. 8, p. 846.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bai, Ql., Li, Hx., Du, Q. et al. Mechanical properties and constitutive behaviors of as-cast 7050 aluminum alloy from room temperature to above the solidus temperature. Int J Miner Metall Mater 23, 949–958 (2016). https://doi.org/10.1007/s12613-016-1311-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1311-3