Abstract

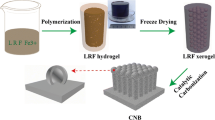

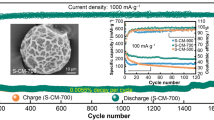

Hard carbon (HC) has emerged as one of the superior anode materials for sodium-ion batteries (SIBs), with its electrochemical performance significantly influenced by the presence of oxygen functional groups and its closed pore structure. However, current research on the structural adjustment of these oxygen functional groups and the closed pore architecture within HC remains limited. Herein, energy-efficient and contamination-free spark plasma sintering technology was employed to tune the structure of coconut-shell HC, resulting in significant adjustments to the content of carboxyl (decreasing from 5.71 at% to 2.12 at%) and hydroxyl groups (decreasing from 7.73 at% to 6.26 at%). Crucially, these modifications reduced the irreversible reaction of oxygen functional groups with Na+. Simultaneously, a substantial number of closed pores with an average diameter of 1.22 nm were generated within the HC, offering an ideal environment for efficient Na+ accommodation. These structural changes resulted in a remarkable improvement in the electrochemical performance of the modified HC. The reversible specific capacity of the modified HC surged from 73.89 mAh·g−1 to an impressive 251.97 mAh·g−1 at a current density of 50 mA·g−1. Even at 400 mA·g−1, the reversible specific capacity increased significantly from 14.55 to 85.44 mAh·g−1. Hence, this study provides a novel perspective for designing tailored HC materials with the potential to develop high-performance SIBs.

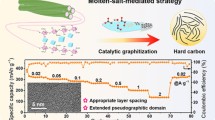

Graphical abstract

摘要

硬炭 (HC) 作为钠离子电池中的优良负极材料, 其储钠性能受到氧官能团和闭孔结构的显著影响。本文采用高效快速的放电等离子体烧结技术对椰壳炭进行了表面改性和孔结构调控, 将羧基含量从5.71 at%降低到2.12 at%和羟基从7.73 at%降低到6.26 at%。这些调控减少了氧官能团与Na+的不可逆反应。与此同时, 在HC内产生了大量的闭孔, 平均孔径为1.22 nm, 为高效储钠提供了理想的空间, 使其电化学性能有了显著的提升。在电流密度为50 mA·g−1时, 可逆储钠容量从73.89 mAh·g−1增长到251.97 mAh·g−1。因此, 本研究为设计和开发高性能钠离子电池负极材料的制备提供了新的视角。

Similar content being viewed by others

References

Choi JW, Aurbach D. Promise and reality of post-lithium-ion batteries with high energy densities. Nat Rev Mater. 2016;1:16013. https://doi.org/10.1038/natrevmats.2016.13.

Liu J, Bao ZN, Cui Y, Dufek EJ, Goodenough JB, Khalifah P, Li QY, Liaw BY, Liu P, Manthiram A, Meng YS, Subramanian VR, Toney MF, Viswanathan VV, Whittingham MS, Xiao J, Xu W, Yang JH, Yang XQ, Zhang JG. Pathways for practical high-energy long-cycling lithium metal batteries. Nat Energy. 2019;4:180. https://doi.org/10.1038/s41560-019-0338-x.

Luo XY, Zheng H, Lai WD, Yuan P, Li SW, Li D, Chen Y. Defect engineering of carbons for energy conversion and storage applications. Energy Environ Mater. 2023;6(3): e12402. https://doi.org/10.1002/eem2.12402.

Chen JX, Su ZL, Zhao T, Pu GG, Li A, Wang L. Performance of cathode material of high-power lithium-ion battery. Chin J Rare Met. 2023;47(12):1756. https://doi.org/10.13373/j.cnki.cjrm.XY21010027.

Li L, Jia SF, Cao MH, Ji YQ, Qiu HW, Zhang D. Progress in research on metal-based materials in stabilized Zn anodes. Rare Met. 2023. https://doi.org/10.1007/s12598-023-02441-7.

Zhu CL, Wang HL, Fan WJ, Zhai SL, Wang XJ, Shi J, Huang MH, Liu S, Li Z, Chen JW. Large-scale doping-engineering enables boron/nitrogen dual-doped porous carbon for high-performance zinc ion capacitors. Rare Met. 2022;41(7):2505. https://doi.org/10.1007/s12598-022-01975-6.

Luo XY, Chen SR, Hu TZ, Chen Y, Li F. Renewable biomass-derived carbons for electrochemical capacitor applications. SusMat. 2021;1(2):211. https://doi.org/10.1002/sus2.8.

Zhan HB, Liu SQ, Wang Q, Cao ML, Ma YA, Zhang CK, Li J. Development of lithium manganese iron phosphate cathode material for lithium-ion batteries. Chin J Rare Met. 2023;47(12):1669. https://doi.org/10.13373/j.cnki.cjrm.XY23060002.

Kim SW, Seo DH, Ma XH, Ceder G, Kang K. Electrode materials for rechargeable sodium-ion batteries: potential alternatives to current lithium-ion batteries. Adv Energy Mater. 2012;2(7):710. https://doi.org/10.1002/aenm.201200026.

Hwang JY, Myung ST, Sun YK. Sodium-ion batteries: present and future. Chem Soc Rev. 2017;46(12):3529. https://doi.org/10.1039/C6CS00776G.

Tang Z, Zhou SY, Huang YC, Wang H, Zhang R, Wang Q, Sun D, Tang YG, Wang HY. Improving the initial coulombic efficiency of carbonaceous materials for Li/Na-ion batteries: origins, solutions, and perspectives. Electrochem Energy R. 2023;6(1):8. https://doi.org/10.1007/s41918-022-00178-y.

Dou XW, Hasa I, Saurel D, Vaalma C, Wu LM, Buchholz D, Bresser D, Komaba S, Passerini S. Hard carbons for sodium-ion batteries: structure, analysis, sustainability, and electrochemistry. Mater Today. 2019;23:87. https://doi.org/10.1016/j.mattod.2018.12.040.

Xiao BW, Rojo T, Li XL. Hard carbon as sodium-ion battery anodes: progress and challenges. ChemSusChem. 2019;12(1):133. https://doi.org/10.1002/cssc.201801879.

Chen MH, Luo FQ, Liao YC, Liu CR, Xu DW, Wang Z, Liu Q, Wang D, Ye YY, Li SR, Wang DC, Zheng ZF. Hard carbon derived for lignin with robust and low-potential sodium ion storage. Electroanal Chem. 2022;919:116526. https://doi.org/10.1016/j.jelechem.2022.116526.

Chen XY, Tian JY, Li P, Fang YL, Fang YJ, Liang XM, Feng JW, Dong J, Ai XP, Yang HX, Cao YL. An overall understanding of sodium storage behaviors in hard carbons by an “adsorption-intercalation/filling” hybrid mechanism. Adv Energy Mater. 2022;12(24):2200886. https://doi.org/10.1002/aenm.202200886.

Xu C, Yang W, Ma G, Che S, Li Y, Jia Y, Chen N, Huang GY, Li YF. Edge-nitrogen enriched porous carbon nanosheets anodes with enlarged interlayer distance for fast charging sodium-ion batteries. Small. 2022;18(48):2204375. https://doi.org/10.1002/smll.202204375.

Qiu YY, Fu F, Hu M, Shen PK, Zhu JL. Tailored chemically bonded metal phosphide@carbon nanowire arrays on foam metal as an all-in-one anode for ultrahigh-area-capacity sodium-ion batteries. Chem Eng J. 2023;454:140402. https://doi.org/10.1016/i.cej.2022.140402.

Fu F, Hu M, Key JL, Shen KP, Zhu JL. Carbon encapsulated FeS nanosheet-nanoribbon interwoven sandwich structure as efficient sodium-ion battery anodes. Carbon. 2023;215:118469. https://doi.org/10.1016/j.carbon.2023.118469.

Nie W, Cheng HW, Liu XL, Sun QC, Tian F, Yao WL, Liang SQ, Lu XG, Zhou J. Surface organic nitrogen-doping disordered biomass carbon materials with superior cycle stability in the sodium-ion batteries. J Power Sources. 2022;522:230994. https://doi.org/10.1016/j.jpowsour.2022.230994.

Lu ZX, Wang J, Feng WL, Yin XP, Feng XC, Zhao SY, Li CX, Wang RX, Huang QA, Zhao YF. Zinc single-atom-regulated hard carbons for high-rate and low-temperature sodium-ion batteries. Adv Mater. 2023;35(26):2211461. https://doi.org/10.1002/adma.202211461.

Zhao YH, Hu Z, Fan CL, Liu ZX, Zhang RS, Han SC, Liu JS, Liu JL. Constructing high-performance N-doped carbon nanotubes anode by tuning interlayer spacing and the compatibility mechanism with ether electrolyte for sodium-ion batteries. Chem Eng J. 2022;446(4):137427. https://doi.org/10.1016/j.cej.2022.137427.

Gao XM, Zhao HQ, Zhang SJ, Shen HT, Li Z. Mechanochemical sodification of oxygen/nitrogen species on surface of hard carbon for improved sodium storage. ACS Sustain Chem Eng. 2022;10(1):23. https://doi.org/10.1021/acssuschemeng.1c07661.

Shen C, Wang C, Jin T, Zhang XG, Jiao LF, Xie KY. Tailoring the surface chemistry of hard carbon towards high-efficiency sodium ion storage. Nanoscale. 2022;14(25):8959. https://doi.org/10.1039/D2NR00172A.

Wu XH, Wu S, Wu CH, Zhang XT, Jiang ZB, Liu SF, Li N. Plasma-promoted surface regulation of a novel integrative carbon network for boosting the long-cycle capability of sodium-ion storage. Carbon. 2022;191:112. https://doi.org/10.1016/j.carbon.2022.01.025.

Yang HS, Park MW, Kim KH, Li OL, Jeon TI, Kang J. Facile in situ synthesis of dual-heteroatom-doped high-rate capability carbon anode for rechargeable seawater-batteries. Carbon. 2022;189:251. https://doi.org/10.1016/j.carbon.2021.12.066.

Zhen YC, Chen Y, Li F, Guo ZY, Hong ZS, Titirici MM. Ultrafast synthesis of hard carbon anodes for sodium-ion batteries. Proc Natl Acad Sci USA. 2021;118(42):e2111119118. https://doi.org/10.1073/pnas.2111119118.

Yuan P, Xiao HM, Li JY, Luo JH, Luo XY, Chen DM, Li D, Chen Y. Optimizing oxygen substituents of a carbon cathode for improved capacitive behavior in ethanol-based zinc-ion capacitors. New Carbon Mater. 2023;38(3):522. https://doi.org/10.1016/S1872-5805(23)60733-4.

Zhang P, Shu YR, Wang Y, Ye JH, Yang L. Simple and efficient synthesis methods for fabricating anode materials of sodium-ion batteries and their sodium-ion storage mechanism study. J Mater Chem A. 2023;11(6):2920. https://doi.org/10.1039/d2ta09051a.

Oh JAS, Deysher G, Ridley P, Chen YT, Cheng DY, Cronk A, Ham SY, Tan DHS, Jang JY, Nguyen LHB, Meng YS. High-performing all-solid-state sodium-ion batteries enabled by the presodiation of hard carbon. Adv Energy Mater. 2023;13(26):2300776. https://doi.org/10.1002/aenm.202300776.

Zhang X, Chen WL, Peng JY, Guo YX, Cheng LH, Chen N, Rui D, Huang YH, Xue LH, Zhang WX. Pore structure modification of pitch-derived hard carbon for enhanced pore filling sodium storage. Energy Technol. 2022;10(11):2200612. https://doi.org/10.1002/ente.202200612.

Zhang MZ, Liang YZ, Liu F, An XG, Feng JK, Xi BJ, Xiong SL. Ni2P immobilized on N, P-codoped porous carbon sheets for alkali metal ion batteries and storage mechanism. J Mater Chem A. 2023;11:8162. https://doi.org/10.1039/D2TA09890C.

Luo XY, Yuan P, Luo JH, Xiao HM, Li JY, Zheng H, Du BD, Li D, Chen Y. The enhancing effect of stable oxygen functional groups on porous-carbon-supported Pt catalysts for alkaline hydrogen evolution. Nanomaterials. 2023;13(8):1415. https://doi.org/10.3390/nano13081415.

Jing WF, Wang M, Li Y, Li HR, Zhang HN, Hu SL, Wang HQ, He YB. Pore structure engineering of wood-derived hard carbon enables their high-capacity and cycle-stable sodium storage properties. Electrochim Acta. 2021;391:139000. https://doi.org/10.1016/j.electacta.2021.139000.

Han GF, Li F, Zou W, Karamad M, Jeon JP, Kim SW, Bu YF, Fu ZP, Lu YL, Siahrostami S, Baek JB. Building and identifying highly active oxygenated groups in carbon materials for oxygen reduction to H2O2. Nat Commun. 2020;11:2209. https://doi.org/10.1038/s41467-020-15782-z.

Fanning PE, Vannice MA. A DRIFTS study of the formation of surface groups on carbon by oxidation. Carbon. 1993;31(5):721. https://doi.org/10.1016/0008-6223(93)90009-Y.

Shi NX, Liu GZ, Xi BJ, An XG, Sun CH, Liu XZ, Xiong CL. MoSe2/TiO2 heterostructure integrated in N-doped carbon nanosheets assembled porous core-shell microspheres for enhanced sodium storage. Nano Res. 2023;16:9398. https://doi.org/10.1007/s12274-023-5604-3.

Xu R, Yi ZL, Song MX, Chen JP, Wei XX, Su FY, Dai LQ, Sun GH, Yang F, Xie LJ, Chen CM. Boosting sodium storage performance of hard carbons by regulating oxygen functionalities of the cross-linked asphalt precursor. Carbon. 2023;206:94. https://doi.org/10.1016/j.carbon.2023.02.004.

Pan XN, Xi BJ, Lu HB, Zhang ZCY, An XG, Liu J, Feng JK, Xiong SL. Molybdenum oxynitride atomic nanoclusters bonded in nanosheets of N-doped carbon hierarchical microspheres for efficient sodium storage. Nano-Micro Lett. 2022;14:163. https://doi.org/10.1007/s40820-022-00893-7.

Xu TY, Qiu X, Zhang X, Xia YY. Regulation of surface oxygen functional groups and pore structure of bamboo-derived hard carbon for enhanced sodium storage performance. Chem Eng J. 2023;452(4):139514. https://doi.org/10.1016/j.cej.2022.139514.

Sun F, Wang H, Qu ZB, Wang KF, Wang LJ, Gao JH, Gao JM, Liu SQ, Lu YF. Carboxyl-dominant oxygen rich carbon for improved sodium ion storage: Synergistic enhancement of adsorption and intercalation mechanisms. Adv Energy Mater. 2021;11(1):2002981. https://doi.org/10.1002/aenm.202002981.

Luo XY, Xiao HM, Li JY, Yuan P, Du BD, Zheng H, Li D, Chen Y. Cyclic ether on Pt-based carbon support for enhanced alkaline hydrogen evolution. Electroanal Chem. 2023;939:117476. https://doi.org/10.1016/j.jelechem.2023.117476.

Tang Z, Zhou SY, Wu PF, Wang H, Huang YC, Zhang YM, Sun D, Tang YG, Wang HY. Engineering surface oxygenated functionalities on commercial hard carbon toward superior sodium storage. Chem Eng J. 2022;441:135899. https://doi.org/10.1016/j.cej.2022.135899.

Xia JL, Yan D, Guo LP, Dong XL, Li WC, Lu AH. Hard carbon nanosheets with uniform ultramicropores and accessible functional groups showing high realistic capacity and superior rate performance for sodium-ion storage. Adv Mater. 2020;32(21):2000447. https://doi.org/10.1002/adma.202000447.

Sun D, Luo B, Wang HY, Tang YG, Ji XB, Wang LZ. Engineering the trap effect of residual oxygen atoms and defects in hard carbon anode towards high initial Coulombic efficiency. Nano Energy. 2019;64:103937. https://doi.org/10.1016/j.nanoen.2019.103937.

Ilic IK, Schutjajew K, Zhang W, Oschatz M. Changes of porosity of hard carbons during mechanical treatment and the relevance for sodium-ion anodes. Carbon. 2022;186:55. https://doi.org/10.1016/j.carbon.2021.09.063.

Dahbi M, Kiso M, Kubota K, Horiba T, Chafik T, Hida K, Matsuyama T, Komaba S. Synthesis of hard carbons from argan shell for Na-ion batteries. J Mater Chem A. 2017;5:9917. https://doi.org/10.1039/C7TA01394A.

Meng QW, Chen BY, Jian WB, Zhang XS, Sun SR, Wang TJ, Zhang WL. Hard carbon anodes for sodium-ion batteries: dependence of the microstructure and performance on the molecular structure of lignin. J Power Sources. 2023;581:233475. https://doi.org/10.1016/j.jpowsour.2023.233475.

Zhao JH, He XX, Lai WH, Yang Z, Liu XH, Li L, Qiao Y, Xiao Y, Li L, Wu XQ, Chou SL. Catalytic defect-repairing using manganese ions for hard carbon anode with high-capacity and high-initial-coulombic-efficiency in sodium-ion batteries. Adv Energy Mater. 2023;13(18):2300444. https://doi.org/10.1002/aenm.202300444.

Yin XP, Lu ZX, Wang J, Feng XC, Roy S, Liu XS, Yang Y, Zhao YF, Zhang JJ. Enabling fast Na+ transfer kinetics in the whole-voltage-region of hard-carbon anodes for ultrahigh-rate sodium storage. Adv Mater. 2022;34(13):2109282. https://doi.org/10.1002/adma.202109282.

Surendran V, Hema RK, Hassan MSO, Vijayan V, Shaijumon MM. Open or closed? Elucidating the correlation between micropore nature and sodium storage mechanisms in hard carbon. Batteries Supercaps. 2022;5(11):e202200316. https://doi.org/10.1002/batt.202200316.

Song MH, Song Q, Zhang T, Huo XM, Lin ZZ, Hu ZW, Lei D, Jin T, Shen C, Xie KY. Growing curly graphene layer boosts hard carbon with superior sodium-ion storage. Nano Res. 2023;16:9299. https://doi.org/10.1007/s12274-023-5539-8.

Song MX, Yi ZL, Xu R, Chen JP, Cheng JY, Wang ZF, Liu QL, Guo QG, Xie LJ, Chen CM. Towards enhanced sodium storage of hard carbon anodes: regulating the oxygen content in precursor by low-temperature hydrogen reduction. Energy Storage Mater. 2022;51:620. https://doi.org/10.1016/j.ensm.2022.07.005.

Tratnik B, van de Velde N, Jerman I, Kapun G, Tchernychova E, Tomsic M, Jamnik A, Genorio B, Vizintin A, Dominko R. Correlating structural properties with electrochemical behavior of non-graphitizable carbons in Na-ion batteries. ACS Appl Energy Mater. 2022;5(9):10667. https://doi.org/10.1021/acsaem.2c01390.

Chen DQ, Zhang W, Luo KY, Song Y, Zhong YJ, Liu YX, Wang GK, Zhong BH, Wu ZG, Guo XD. Hard carbon for sodium storage: mechanism and optimization strategies toward commercialization. Energy Environ Sci. 2021;14(4):2244. https://doi.org/10.1039/D0EE03916K.

Lu HY, Ai FX, Jia YL, Tang CY, Zhang XH, Huang YH, Yang HX, Cao YL. Exploring sodium-ion storage mechanism in hard carbons with different microstructure prepared by ball-milling method. Small. 2018;14(39):1802694. https://doi.org/10.1002/smll.201802694.

Zhou HY, Sun N, Yu JX, Soomro RA, Zhang SH, Xu B. Microstructure regulation of resin-based hard carbons via esterification cross-linking for high-performance sodium-ion batteries. Inorg Chem Front. 2023;10(8):2404. https://doi.org/10.1039/D3QI00052D.

Fan LL, Zhang X, Fan LP, Yan L, Wang ZJ, Lei WH, Ruan D, Shi ZQ. Boosting the high capacitance-controlled capacity of hard carbon by using surface oxygen functional groups for fast and stable sodium storage. ACS Appl Energy Mater. 2021;4(10):11436. https://doi.org/10.1021/acsaem.1c02214.

Hu JZ, Liu WJ, Zheng JH, Li GC, Bu YF, Qiao F, Lian BJ, Zhao Y. Coral-like cobalt selenide/carbon nanosheet arrays attached on carbon nanofibers for high-rate sodium-ion storage. Rare Met. 2023;42(3):916. https://doi.org/10.1007/s12598-022-02146-3.

Huang G, Kong QQ, Yao WT, Wang QY. High proportion of active nitrogen-doped hard carbon based on mannich reaction as anode material for high-performance sodium-ion batteries. ChemSusChem. 2023;16(7):e202202070. https://doi.org/10.1002/cssc.202202070.

Liu Y, Wan YH, Zhang JY, Zhang XM, Hung CT, Lv ZR, Hua WM, Wang YG, Chao DL, Li W. Surface stretching enables highly disordered graphitic domains for ultrahigh rate sodium storage. Small. 2023;19(28):2301203. https://doi.org/10.1002/smll.202301203.

Zhang GF, Zhang LJ, Ren QJ, Yan L, Zhang FM, Lv WJ, Shi ZQ. Tailoring a phenolic resin precursor by facile pre-oxidation tactics to realize a high-initial-coulombic-efficiency hard carbon anode for sodium-ion batteries. ACS Appl Mater Interfaces. 2021;13(27):31650. https://doi.org/10.1021/acsami.1c06168.

Yuan M, Cao B, Liu H, Meng CY, Wu JP, Zhang S, Li A, Chen XH, Song HH. Sodium storage mechanism of nongraphitic carbons: a general model and the function of accessible closed pores. Chem Mater. 2022;34(7):3489. https://doi.org/10.1021/acs.chemmater.2c00405.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 52062012), Guangdong Province Key Discipline Construction Project (No. 2021ZDJS102), the Innovation Team of Universities of Guangdong Province (No. 2022KCXTD030), the Special Fund for Science and Technology Innovation Cultivation of Guangdong University Students (No. pdjh2023b0549) and the Student Academic Fund of Foshan University (No. xsjj202206kjb02).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiao, HM., Zheng, H., Yuan, P. et al. Structural engineering of hard carbon through spark plasma sintering for enhanced sodium-ion storage. Rare Met. (2024). https://doi.org/10.1007/s12598-024-02716-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12598-024-02716-7