Abstract

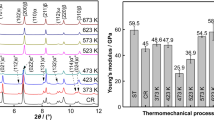

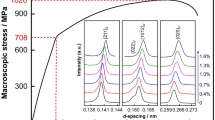

In this work, the underlying mechanism responsible for the near-linear elastic deformation behavior of a dual-phase Ti-Nb alloy consisting of β and α″ phase with large recoverable strain was systematically elucidated. Based on in situ synchrotron X-ray diffraction (SXRD) analyses, it was found that besides intrinsic elastic deformation, a slight reversible β ↔ α″ stress-induced martensitic (SIM) transformation, which proceeded in a consecutive mode under the retarding effect of micro-defects, took place during the near-linear elastic deformation. After unloading, a small amount of residual macroscopic strain remained in the specimen due to the incomplete reverse α″ → β transformation on unloading. The high near-linear elastic deformability of the cold drawing (CD) Ti-Nb alloy has been revealed to be attributed to the coupling actions of intrinsic elasticity as well as the consecutive and reversible β ↔ α″ SIM transformation. Our research may contribute to a new avenue for the design and development of novel dual-phase Ti-based alloys with desirable elastic deformability.

Graphical abstract

摘要

本文系统地阐明了β和α″相双相Ti-Nb合金大可恢复应变的近线弹性变形行为的潜在机制。基于原位同步X射线衍射分析发现, 在近线性弹性变形过程中, 除了固有的弹性变形外, 还发生了轻微的可逆β ↔ α″应力诱导马氏体(SIM)相变, 该相变在微缺陷的延缓作用下以连续模式进行。卸载后, 由于不完全α″ → β逆相变, 试样中仍有少量残余应变。冷拔 Ti-Nb合金具有较高的近线弹性变形性能, 这是由于其固有弹性和连续可逆的β ↔ α″SIM相变的耦合作用所致。本研究为设计和开发具有良好弹性变形性能的新型双相钛基合金开辟了新的途径。

Similar content being viewed by others

References

Wang JW, Sansoz F, Deng C, Xu G, Han GR, Mao SX. Strong Hall-Petch type behavior in the elastic strain limit of nanotwinned gold nanowires. Nano Lett. 2015;15(6):3865. https://doi.org/10.1021/acs.nanolett.5b00694.

Wu FF, Chan KC, Jiang SS, Chen SH, Wang G. Bulk metallic glass composite with good tensile ductility, high strength and large elastic strain limit. Sci Rep. 2014;4:5302. https://doi.org/10.1038/srep05302.

Dal Bó MR, Salvador CAF, Mello MG, Lima DD, Faria GA, Ramirez AJ, Caram R. The effect of Zr and Sn additions on the microstructure of Ti-Nb-Fe gum metals with high elastic admissible strain. Mater Des. 2018;160:1186. https://doi.org/10.1016/j.matdes.2018.10.040.

Zhu JM, Wang D, Gao YP, Zhang TY, Wang YZ. Linear-superelastic metals by controlled strain release via nanoscale concentration-gradient engineering. Mater Today. 2020;33:17. https://doi.org/10.1016/j.mattod.2019.10.003.

Sun Z, Hao SJ, Kang GF, Ren Y, Liu JP, Yang Y, Kong XG, Feng B, Wang C, Zhao K, Cui LS. Exploiting ultra-large linear elasticity over a wide temperature range in nanocrystalline NiTi alloy. J Mater Sci Technol. 2020;57:197. https://doi.org/10.1016/j.jmst.2020.01.073.

Liu YL, Sun YH, Zhao Y, Li CL, Zhao FL, Yao XH, Hang RQ, Chu PK. Selective inhibition effects on cancer cells and bacteria of Ni-Ti-O nanoporous layers grown on biomedical NiTi alloy by anodization. Rare Met. 2022;41(1):78. https://doi.org/10.1007/s12598-021-01707-2.

Tanaka Y, Himuro Y, Kainuma R, Sutou Y, Omori T, Ishida K. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science. 2010;327(5972):1488. https://doi.org/10.1126/science.1183169.

Lee SW, Kim JH, Park CH, Hong JK, Yeom JT. Alloy design of metastable α+β titanium alloy with high elastic admissible strain. Mater Sci Eng A. 2021;802:140621. https://doi.org/10.1016/j.msea.2020.140621.

Ozan S, Lin JX, Li YC, Ipek R, Wen C. Development of Ti-Nb-Zr alloys with high elastic admissible strain for temporary orthopedic devices. Acta Biomater. 2015;20:176. https://doi.org/10.1016/j.actbio.2015.03.023.

Plaine AH, Silva MRD, Bolfarini C. Microstructure and elastic deformation behavior of β-type Ti-29Nb-13Ta-4.6Zr with promising mechanical properties for stent applications. J Mater Res Technol. 2019;8(5):3852. https://doi.org/10.1016/j.jmrt.2019.06.047.

Qu WT, Gong H, Wang J, Nie YS, Li Y. Martensitic transformation, shape memory effect and superelasticity of Ti-xZr-(30–x)Nb-4Ta alloys. Rare Met. 2019;38(10):965. https://doi.org/10.1007/s12598-019-01305-3.

Kim HY, Miyazaki S. Ni-Free Ti-Based Shape Memory Alloys. Oxford: ButterworthHeinemann; 2018. p. 53.

Guo S, Shang Y, Zhang JS, Meng QK, Cheng XN, Zhao XQ. In situ synchrotron X-ray diffraction study of deformation behaviour of a metastable β-type Ti-33Nb-4Sn alloy. Mater Sci Eng A. 2017;692:81. https://doi.org/10.1016/j.msea.2017.03.061.

Chen LB, Huang CW, Li ZD, Xu Y, He F, Li JH. Solution temperature in biphasic region on microstructure and mechanical properties of Ti-55531 alloy. Chin J Rare Met. 2021;45(2):147. https://doi.org/10.13373/j.cnki.cjrm.xy19020008.

Church NL, Talbot CEP, Wise GJ, Shah OYI, Jones NG. Development of ultra-high strength Ti-Nb-Sn alloys through grain-refinement by in situ Zener pinning. Scr Mater. 2022;218: 114809. https://doi.org/10.1016/j.scriptamat.2022.114809.

Al-Zain Y, Kim HY, Koyano T, Hosoda H, Nam TH, Miyazaki S. Anomalous temperature dependence of the superelastic behavior of Ti-Nb-Mo alloys. Acta Mater. 2011;59:1464. https://doi.org/10.1016/j.actamat.2010.11.008.

Xiong CY, Li Y, Zhang J, Wang Y, Qu WT, Ji YC, Cui LS, Ren XB. Superelasticity over a wide temperature range in metastable β-Ti shape memory alloys. J Alloys Compd. 2021;853:157090. https://doi.org/10.1016/j.jallcom.2020.157090.

Cai S, Schaffer JE, Ehle AL, Ren Y. A Ni-free β-Ti alloy with large and stable room temperature super-elasticity. Mater Today Commun. 2021;26:101838. https://doi.org/10.1016/j.mtcomm.2020.101838.

Guo S, Wang W, Shen BG, Tan L, Liu HX, Ma W, Xie ZM, Cheng XN, Shi P. Uniaxial tensile deformation behavior of a sandwich-like structural TiNb-NiTi composite for biomedical applications. Rare Met. 2021;40(12):3627. https://doi.org/10.1007/s12598-021-01779-0.

Chen X, Qiu C. Development of a novel metastable beta titanium alloy with ultrahigh yield strength and good ductility based on laser power bed fusion. Addit Manuf. 2022;49:102501. https://doi.org/10.1016/j.addma.2021.102501.

Otsuka K, Ren X. Physical metallurgy of Ti-Ni-based shape memory alloys. Prog Mater Sci. 2005;50(5):511. https://doi.org/10.1016/j.pmatsci.2004.10.001.

Guo S, Meng QK, Cheng XN, Zhao XQ. Deformation behavior of metastable β-type Ti-25Nb-2Mo-4Sn alloy for biomedical applications. J Mech Behav Biomed Mater. 2014;38:26. https://doi.org/10.1016/j.jmbbm.2014.06.006.

Guo S, Shi YL, Liu GL, Wu RT, Luo R, Peng CT, Meng QK, Cheng XN, Zhao XQ. Design and fabrication of a (β+α′′) dual-phase Ti-Nb-Sn alloy with linear deformation behavior for biomedical applications. J Alloys Compd. 2019;805:517. https://doi.org/10.1016/j.jallcom.2019.07.109.

Guo S, Ding W, Zhang HH, Lu WQ, Liu GL, Liu HX, Cheng XN, Zhao XQ. Mechanisms of near-linear elastic deformation behavior in a binary metastable β-type Ti-Nb alloy with large recoverable strain. Mater Charact. 2022;187:111858. https://doi.org/10.1016/j.matchar.2022.111858.

Hou YP, Guo S, Qiao XL, Tian T, Meng QK, Cheng XN, Zhao XQ. Origin of ultralow Young’s modulus in a metastable β-type Ti-33Nb-4Sn alloy. J Mech Behav Biomed Mater. 2016;59:220. https://doi.org/10.1016/j.jmbbm.2015.12.037.

Inamura T, Shimizu R, Kim HY, Miyazaki S, Hosoda H. Optimum rolling ratio for obtaining {001}<110> recrystallization texture in Ti-Nb-Al biomedical shape memory alloy. Mat Sci Eng C. 2016;61:499. https://doi.org/10.1016/j.msec.2015.12.086.

Zhang YW, Li SJ, Obbard EG, Wang H, Wang SC, Hao YL, Yang R. Elastic properties of Ti-24Nb-4Zr-8Sn single crystals with bcc crystal structure. Acta Mater. 2011;59(8):3081. https://doi.org/10.1016/j.actamat.2011.01.048.

Naka S, Marty M, Thomas M, Khan T. Variation in the degree of order and its influence on mechanical behavior in complex B2 aluminides of refractory metals. Mater Sci Eng A. 1995;192:69. https://doi.org/10.1016/0921-5093(94)03205-X.

Hanada S, Masahashi N, Jung TK, Yamada N, Yamako G, Itoi E. Fabrication of a high-performance hip prosthetic stem using β Ti-33.6Nb-4Sn. J Mech Behav Biomed Mater. 2014;30:140. https://doi.org/10.1016/j.jmbbm.2013.11.002.

Hanada S, Masahashi N, Semboshi S, Jung TK. Low Young’s modulus of cold groove-rolled β Ti-Nb-Sn alloys for orthopedic applications. Mater Sci Eng A. 2021;802:140645. https://doi.org/10.1016/j.msea.2020.140645.

Zafari A, Xia K. Grain refinement in a metastable beta Ti alloy deformed to large strains at high strain rates. Acta Mater. 2018;157:174. https://doi.org/10.1016/j.actamat.2018.07.030.

Ahmend M, Pereloma EV. Observation of simultaneous operation of deformation twins in both α and β phases in metastable β titanium alloy. J Alloys Compd. 2022;910:164794. https://doi.org/10.1016/j.jallcom.2022.164794.

Xu W, Kim KB, Das J, Calin M, Rellinghaus B, Eckert J. Deformation-induced nanostructuring in a Ti-Nb-Ta-In β alloy. Appl Phys Lett. 2006;89:31906. https://doi.org/10.1063/1.2222239.

He BB, Hu B, Yen HW, Cheng GJ, Wang ZK, Luo HW, Huang MX. High dislocation density-induced large ductility in deformed and partitioned steels. Science. 2017;357:1029. https://doi.org/10.1126/science.aan0177.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 52175410), the Six Talent Peaks Project in Jiangsu Province (No. 2019-XCL-113), Zhenjiang Science & Technology Program (No. GY2020001) and the Project of Faculty of Agricultural Equipment of Jiangsu University (No. NZXB20200101). This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract (No. DE-AC02-06CH11357).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, Y., Ding, W., Ma, W. et al. Mechanism of a dual-phase Ti-Nb alloy exhibiting near-linear elastic deformation. Rare Met. 43, 2282–2289 (2024). https://doi.org/10.1007/s12598-023-02610-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02610-8