Abstract

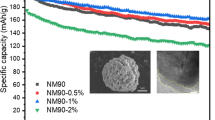

Ultra-high nickel layered oxide cathode material with high energy density is the most promising material to improve the electrochemical performance of lithium-ion batteries (LIBs). However, the poor structural stability and severe surface/interface side reactions of the material lead to poor rate performance and cyclic stability, which limits its application in practice. In this paper, the dual-modification strategy of Co doping and La2O3 coating is used to meet the above challenges. Co doping can effectively widen layer spacing and reduce Li+/Ni2+ mixing, and La2O3 coating can effectively eliminate the residual alkali on the surface of active material, inhibit the thickening of cathode electrolyte interphase (CEI) film and reduce surface/interface side reactions. Therefore, the modified material (NM90-CL) with excellent electrochemical properties is achieved through the synergistic enhancement of Co doping and La2O3 coating. Its capacity retention rate can reach 77.9% after 200 cycles at 1.0 °C and 75.7% after 200 cycles at 5.0 °C. Its reversible capacity can up to 153.5 mAh·g–1 at 10.0 °C. This dual-modification strategy will provide theoretical guidance and technical support for the synthesis of other high-performance electrode materials.

Graphical abstract

摘要

具有高能量密度的超高镍层状氧化物正极材料是提高锂离子电池电化学性能最有希望的材料。但该材料的结构稳定性差, 表/界面副反应严重, 导致该材料的倍率性能和循环稳定性较差, 从而限制了该材料在实际中的广泛应用。本文采用Co3+掺杂和La2O3包覆双重改性的策略来应对上述挑战。Co3+掺杂可有效拓宽层间距, 减少Li+/Ni2+混排, La2O3包覆可有效消除活性材料的表面残碱, 抑制CEI膜增厚, 减少表面/界面副反应。因此, 通过Co3+掺杂和La2O3包覆的协同增强, 获得了具有优异电化学性能的NM90-CL材料。其在1.0C下200次循环后容量保持率可达77.9%, 在5.0C下200次循环后容量保持率可达75.7%, 在10.0C下可逆容量可达153.5 mAh·g−1, 这种双重改性的策略将为其它高性能电极材料的合成提供理论指导和技术支持。

Similar content being viewed by others

References

Myung ST, Maglia F, Park KJ, Yoon CS, Lamp P, Kim SJ, Sun YK. Nickel-rich layered cathode materials for automotive lithium-ion batteries: achievements and perspectives. ACS Energy Lett. 2017;2(1):196. https://doi.org/10.1021/acsenergylett.6b00594.

Zhu XF, Li X, Liang TQ, Liu XH, Ma JM. Electrolyte perspective on stabilizing LiNi0.8Co0.1Mn0.1O2 cathode for lithium-ion batteries. Rare Met. 2022;42(2):387. https://doi.org/10.1007/s12598-022-02101-2.

Lin QL, Qian ZF, Dai XY, Sun YL, Wang RH. Regulation of electronic structure of monolayer MoS2 by pressure. Rare Met. 2022;41(5):1761. https://doi.org/10.1007/s12598-021-01888-w.

Lin QL, Liang H, Zhou CQ, Qian ZF, Sun YL, Wang XY, Wang RH. Defect-induced magnetism in χ3 borophene. Rare Met. 2022;41(10):3486. https://doi.org/10.1007/s12598-022-02041-x.

Li WB, Wu K, Feng H, Wang N, Zhang JH, Wang JJ, Li XF. Atomic layer deposition of ultrafine Pd nanoparticles for enhancing the rate capability of LiNi0.8Co0.1Mn0.1O2 cathode. Tungsten. 2022;4(4):346. https://doi.org/10.1007/s42864-022-00178-x.

Wang JH, Wang Y, Guo YZ, Liu CW, Dan LL. Electrochemical characterization of AlPO4 coated LiNi1/3Co1/3Mn1/3O2 cathode materials for high temperature lithium battery application. Rare Met. 2021;40(1):78. https://doi.org/10.1007/s12598-014-0247-x.

Ryu HH, Park NY, Yoon DR, Kim UH, Yoon CS, Sun YK. New class of Ni-rich cathode materials LiNixCoyB1-x-yO2 for next lithium batteries. Adv Energy Mater. 2020;10(25):2000495. https://doi.org/10.1002/aenm.202000495.

Park GT, Namkoong B, Kim SB, Liu J, Yoon CS, Sun YK. Introducing high-valence elements into cobalt-free layered cathodes for practical lithium-ion batteries. Nat Energy. 2022;7(10):946. https://doi.org/10.1038/s41560-022-01106-6.

Liu SY, Zhou YH, Zhang YB, Xia SJ, Li Y, Zhou X, Qiu B, Shao GJ, Liu ZP. Surface yttrium-doping induced by element segregation to suppress oxygen release in Li-rich layered oxide cathodes. Tungsten. 2022;4(4):336. https://doi.org/10.1007/s42864-022-00165-2.

Qiu Z, Zhang Y, Liu Z, Gao Y, Liu J, Zeng Q. Stabilizing Ni-rich LiNi0.92Co0.06Al0.02O2 cathodes by boracic polyanion and tungsten cation Co-doping for high-energy lithium-ion batteries. ChemElectroChem. 2020;7(18):3811. https://doi.org/10.1002/celc.202000927.

Ryu HH, Park GT, Yoon CS, Sun YK. Microstructural degradation of Ni-rich LiNixCoyMn1-x-yO2 cathodes during accelerated calendar aging. Small. 2018;14(45):1803179. https://doi.org/10.1002/smll.201803179.

Yuan K, Ning RQ, Zhou LJ, Shen C, Zhou SS, Li J, Jin T, Zhang XG, Xie KY. A low-carbon strategy for revival of degraded single crystal LiNi0.6Co0.2Mn0.2O2. Rare Met. 2022;42(2):459. https://doi.org/10.1007/s12598-022-02147-2.

Wang R, Dai X, Qian Z, Sun Y, Fan S, Xiong K, Zhang H, Wu F. In situ surface protection for enhancing stability and performance of LiNi0.5Mn0.3Co0.2O2 at 4.8 V: the working mechanisms. ACS Mater Lett. 2020;2(4):280. https://doi.org/10.1021/acsmaterialslett.9b00476.

Park GT, Ryu HH, Park NY, Yoon CS, Sun YK. Tungsten doping for stabilization of Li[Ni0.90Co0.05Mn0.05]O2 cathode for Li-ion battery at high voltage. J Power Sources. 2019;442:227242. https://doi.org/10.1016/j.jpowsour.2019.227242.

Kasim MF, Azizan W, Elong KA, Kamarudin N, Yaakob MK, Badar N. Enhancing the structural stability and capacity retention of Ni-rich LiNi0.7Co0.3O2 cathode materials via Ti doping for rechargeable Li-ion batteries: Experimental and computational approaches. J Alloys Compd. 2021;888:161559. https://doi.org/10.1016/j.jallcom.2021.161559.

Savaş UC, Aydınol MK. Effect of calcium or yttrium doping on cation ordering and electrochemical performance of Li(Ni0.80−xCo0.15Al0.05Mx)O2 (M = Ca, Y) as a Li-ion battery cathode. Mater Sci Eng B. 2021;264:114925. https://doi.org/10.1016/j.mseb.2020.114925.

Park KJ, Jung HG, Kuo LY, Kaghazchi P, Yoon CS, Sun YK. Improved cycling stability of Li[Ni0.90Co0.05Mn0.05]O2 through microstructure modification by boron doping for Li-ion batteries. Adv Energy Mater. 2018;8(25):1801202. https://doi.org/10.1002/aenm.201801202.

Yu H, Cao Y, Chen L, Hu Y, Duan X, Dai S, Li C, Jiang H. Surface enrichment and diffusion enabling gradient-doping and coating of Ni-rich cathode toward Li-ion batteries. Nat Commun. 2021;12(1):4564. https://doi.org/10.1038/s41467-021-24893-0.

Xie Y, Guo F, Zhang Y. One-step calcination reaction to synthesize Li2MnO3 coating layers for LiNi0.8Co0.1Mn0.1O2 to improve cycling performances under high-voltage for Li-ion batteries. Appl Surf Sci. 2022;595:153479. https://doi.org/10.1016/j.apsusc.2022.153479.

Zhang Z, Zhou P, Meng H, Chen C, Cheng F, Tao Z, Chen J. Amorphous Zr(OH)4 coated LiNi0.915Co0.075Al0.01O2 cathode material with enhanced electrochemical performance for lithium ion batteries. J Energy Chem. 2017;26(3):481. https://doi.org/10.1016/j.jechem.2016.12.003.

He R, Wei A, Bai X, Zhang L, Li X, Jin M, Zhang X, Ge J, Liu Z. Enhanced cycling performance of Li ion batteries based on Ni-rich cathode materials with LaPO4/Li3PO4 co-modification. Ceram Int. 2021;47(24):34585. https://doi.org/10.1016/j.ceramint.2021.08.373.

Chu M, Huang Z, Zhang T, Wang R, Shao T, Wang C, Zhu W, He L, Chen J, Zhao W, Xiao Y. Enhancing the electrochemical performance and structural stability of Ni-rich layered cathode materials via dual-site doping. ACS Appl Mater Interfaces. 2021;13(17):19950. https://doi.org/10.1021/acsami.1c00755.

Yu H, Zhu H, Yang Z, Liu M, Jiang H, Li C. Bulk Mg-doping and surface polypyrrole-coating enable high-rate and long-life for Ni-rich layered cathodes. Chem Eng J. 2021;412:128625. https://doi.org/10.1016/j.cej.2021.128625.

Li W, Erickson EM, Manthiram A. High-nickel layered oxide cathodes for lithium-based automotive batteries. Nat Energy. 2020;5(1):26. https://doi.org/10.1038/s41560-019-0513-0.

Li W, Lee S, Manthiram A. High-nickel NMA: a cobalt-free alternative to NMC and NCA cathodes for lithium-ion batteries. Adv Mater. 2020;32(33):2002718. https://doi.org/10.1002/adma.202002718.

Turcheniuk K, Bondarev D, Singhal V, Yushin G. Ten years left to redesign lithium-ion batteries reserves of rare metals used in electric-vehicle cells are dwindling, so boost research on iron and silicon alternatives, urge Kostiantyn Turcheniuk and colleagues. Nature. 2018;559(7715):467. https://doi.org/10.1038/d41586-018-05752-3.

Huang Z, Wang Z, Guo H, Li X. Influence of Mg2+ doping on the structure and electrochemical performances of layered LiNi0.6Co0.2Mn0.2MgO2 cathode materials. J Alloys Compd. 2016;671:479. https://doi.org/10.1016/j.jallcom.2016.02.119.

Kim SB, Kim H, Park DH, Kim JH, Shin JH, Jang JS, Moon SH, Choi JH, Park KW. Li-ion diffusivity and electrochemical performance of Ni-rich cathode material doped with fluoride ions. J Power Sources. 2021;506:230219. https://doi.org/10.1016/j.jpowsour.2021.230219.

Kim UH, Park GT, Son BK, Nam GW, Liu J, Kuo LY, Kaghazchi P, Yoon CS, Sun YK. Heuristic solution for achieving long-term cycle stability for Ni-rich layered cathodes at full depth of discharge. Nat Energy. 2021;6(1):115. https://doi.org/10.1038/s41560-020-00693-6.

Yang Z, Guo X, Xiang W, Hua W, Zhang J, He F, Wang K, Xiao Y, Zhong B. K-doped layered LiNi0.5Co0.2Mn0.3O2 cathode material: Towards the superior rate capability and cycling performance. J Alloys Compd. 2017;699:358. https://doi.org/10.1016/j.jallcom.2016.11.245.

Zhao L, Chen G, Weng Y, Yan T, Shi L, An Z, Zhang D. Precise Al2O3 coating on LiNi0.5Co0.2Mn0.3O2 by atomic layer deposition restrains the shuttle effect of transition metals in Li-ion capacitors. Chem Eng J. 2020;401:126138. https://doi.org/10.1016/j.cej.2020.126138.

Li M, Lu J. Cobalt in lithium-ion batteries. Science. 2020;367:979. https://doi.org/10.1126/science.aba9168.

Wang J, Nie Y, Miao C, Tan Y, Wen M, Xiao W. Enhanced electrochemical properties of Ni-rich layered cathode materials via Mg2+ and Ti4+ co-doping for lithium-ion batteries. J Colloid Interface Sci. 2021;601:853. https://doi.org/10.1016/j.jcis.2021.05.167.

Zhu H, Yu H, Jiang H, Hu Y, Jiang H, Li C. High-efficiency Mo doping stabilized LiNi0.9Co0.1O2 cathode materials for rapid charging and long-life Li-ion batteries. Chem Eng Sci. 2020;217:115518. https://doi.org/10.1016/j.ces.2020.115518.

Noh M, Cho J. Optimized synthetic conditions of LiNi0.5Co0.2Mn0.3O2 cathode materials for high rate lithium batteries via Co-precipitation method. J Electrochem Soc. 2013;160(1):A105. https://doi.org/10.1149/2.004302jes.

Wu F, Li Q, Chen L, Lu Y, Su Y, Bao L, Chen R, Chen S. Use of Ce to reinforce the interface of Ni-Rich LiNi0.8Co0.1Mn0.1O2 cathode materials for lithium-ion batteries under high operating voltage. Chemsuschem. 2019;12(4):935. https://doi.org/10.1002/cssc.201802304.

Yao S, Wang Y, Liang Y, Yu H, Majeed A, Shen X, Li T, Qin S. Modified polysulfides conversion catalysis and confinement by employing La2O3 nanorods in high performance lithium-sulfur batteries. Ceram Int. 2021;47(19):27012. https://doi.org/10.1016/j.ceramint.2021.06.114.

Sattar T, Lee SH, Sim SJ, Jin BS, Kim HS. Understanding the combined effect of Ca doping and phosphate coating on Ni-rich LiNi0.91Co0.06Mn0.03O2 cathode material for Li-ion batteries. Electrochim Acta. 2021;399:139417. https://doi.org/10.1016/j.electacta.2021.139417.

Li X, Cheng L, Chen L, Huang B, Yang J, Li Y, Li W. Stabilizing the surface of LiNi0.815Co0.15Al0.035O2 by a facile pre-oxidation-coating strategy on the precursor. Solid State Ionics. 2022;386:116028. https://doi.org/10.1016/j.ssi.2022.116028.

Min K, Park K, Park SY, Seo SW, Choi B, ChoE. Improved electrochemical properties of LiNi0.91Co0.06Mn0.03O2 cathode material via Li-reactive coating with metal phosphates. Sci Rep. 2017;7(1):7151. https://doi.org/10.1038/s41598-017-07375-6.

Qiu L, Xiang W, Tian W, Xu CL, Li YC, Wu ZG, Chen TR, Jia K, Wang D, He FR, Guo XD. Polyanion and cation co-doping stabilized Ni-rich Ni–Co–Al material as cathode with enhanced electrochemical performance for Li-ion battery. Nano Energy. 2019;63:103818. https://doi.org/10.1016/j.nanoen.2019.06.014.

Park KJ, Choi MJ, Maglia F, Kim SJ, Kim KH, Yoon CS, Sun YK. High-capacity concentration gradient LiNi0.865Co0.120Al0.015O2 cathode for lithium-ion batteries. Adv Energy Mater. 2018;8(19):1703612. https://doi.org/10.1002/aenm.201703612.

Wu F, Liu N, Chen L, Su Y, Tan G, Bao L, Zhang Q, Lu Y, Wang J, Chen S, Tan J. Improving the reversibility of the H2–H3 phase transitions for layered Ni-rich oxide cathode towards retarded structural transition and enhanced cycle stability. Nano Energy. 2019;59:50. https://doi.org/10.1016/j.nanoen.2019.02.027.

Li L, Han Y, Zhao B, Zhao G, Qiang W, Huang B. Enhancing the cycle stability of Zr-doped LiNi0.83Co0.12Mn0.05O2 by co-precipitation. Ionics. 2022;28(3):1037. https://doi.org/10.1007/s11581-021-04386-2.

Li L, Fu L, Li M, Wang C, Zhao Z, Xie S, Lin H, Wu X, Liu H, Zhang L, Zhang Q, Tan L. B-doped and La4NiLiO8-coated Ni-rich cathode with enhanced structural and interfacial stability for lithium-ion batteries. J Energy Chem. 2022;71:588. https://doi.org/10.1016/j.jechem.2022.04.037.

Yao J, Wu J, Yang Y, Xiao S, Li Y. Lithium storage performance of coralline-like FeMnO3 anode materials prepared by a facile chemical co-precipitation method. J Alloys Compd. 2020;848:156444. https://doi.org/10.1016/j.jallcom.2020.156444.

Lan G, Zhou H, Xing L, Chen J, Li Z, Guo R, Che Y, Li W. Insight into the interaction between Ni-rich LiNi0.8Co0.1Mn0.1O2 cathode and BF4-- introducing electrolyte at 4.5 V high voltage. J Energy Chem. 2019;39:235. https://doi.org/10.1016/j.jechem.2019.04.011.

Shi CG, Shen CH, Peng XX, Luo CX, Shen LF, Sheng WJ, Fan JJ, Wang Q, Zhang SJ, Xu BB, Xian JJ, Wei YM, Huang L, Li JT, Sun SG. A special enabler for boosting cyclic life and rate capability of LiNi0.8Co0.1Mn0.1O2: green and simple additive. Nano Energy. 2019;65:104084. https://doi.org/10.1016/j.nanoen.2019.104084.

Acknowledgements

This work was financially supported by the National Science Foundation of China (Nos. 22169007 and 22362011), the Science and Technology Major Project of Guangxi (No. AA19046001), the Open Research Fund of Guangxi Key Laboratory of Electrochemical and Magnetochemical Functional Materials (Nos. EMFM20201105 and EMFM20181119), the Characteristic Innovation Projects of Universities in Guangdong Province (No. 2022KTSCX324), the Science and Technology Innovation Commission of Shenzhen (No. JCYJ20190808173815205) and the University Teachers' Characteristic Innovation Research Project (No. 2021XJZZ11).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Peng, JQ., Wei, YY., Liu, DM. et al. Enhanced cycling stability and rate performance of Co-doped and La2O3-coated LiNi0.9Mn0.1O2 toward power battery. Rare Met. 43, 658–670 (2024). https://doi.org/10.1007/s12598-023-02470-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02470-2