Abstract

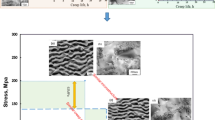

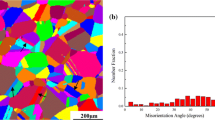

Design of heat treatments is related to the key technology for development of nickel-based single crystal superalloys (Ni-SXs). Based on the full understanding of the solidification characteristics, this work applies optimization design of heat treatments for a second-generation Ni-SX. Microstructure evolution and creep properties are compared in the material under conventional/standard (Std.) and optimized (Opt.) treatments. For the Std. sample, strong dendritic segregations determine inconsistent microstructure evolution in the dendritic (D) and interdendritic region (ID), while the latter serves as weak area to have the prior microcrack initiation, damaging overall performance of the alloy. The Opt. treatment applies higher homogenization temperature, leading to overall reduced segregations, while not inducing incipient melting. A lower temperature of first-step ageing is used to lower the size of γ′ particles. These help to form the more uniform microstructure in dendritic and interdendritic region and relieve the inconsistent microstructure evolution. The balanced local strength makes ID no longer as the weak area, thus restricting microcrack initiation. Great improvement of high temperature and low stress property is obtained by this progress, leading to the pronounced increase of creep rupture life under 1100 °C /140 MPa.

摘要

热处理工艺设计是发展先进镍基单晶高温合金的关键技术。本文基于对一种第二代镍基单晶高温合金凝固特性的深入分析,进行了热处理工艺的优化设计,并系统的对比了材料在标准及优化热处理条件下的显微结构与蠕变性能。标准热处理后材料仍具有较强的枝晶偏析,使得枝晶核与枝晶间区域在蠕变过程中的组织演化存在不一致,而后者则作为薄弱点使微裂纹集中在该区域产生,损害合金的整体性能。优化热处理通过工艺设计提高了均匀化处理的温度,在不发生初熔的前提下有效减轻了枝晶偏析;同时采用了更低的第一步时效热处理温度,以减小γ′沉淀相处尺寸。这些办法使得枝晶核与枝晶间区域形成了更一致的热处理组织,同时也抑制了蠕变组织演化的不一致性。得益于此,枝晶核与枝晶间的局部强度更加均衡,有效抑制了枝晶间的微裂纹萌生,提高了材料在高温低应力条件下的蠕变抗性,延长了1100 ℃/140 MPa持久寿命。

Graphical Abstract

Similar content being viewed by others

References

Betteridge W, Shaw SWK. Development of superalloys. Mater Sci Technol. 1987;3(9):682. https://doi.org/10.1179/mst.1987.3.9.682.

Versnyder FI, Shank ME. The development of columnar grain and single crystal high temperature materials through directional solidification. Mater Sci Eng. 1970;6(4):231. https://doi.org/10.1016/0025-5416(70)90050-9.

Schafrik R, Sprague R. Saga of gas turbine materials part I. Adv Mater Processes. 2004;162(3):33.

Xu KD, Ren ZM, Li CJ. Progress in application of rare metals in superalloys. Rare Met. 2014;33(2):111. https://doi.org/10.1007/s12598-014-0256-9.

Yang FM, Lian LX, Liu Y, Gong XF. Mechanism of adding rhenium to improve hot corrosion resistance of nickel-based single-crystal superalloys. Rare Met. 2021;40(8):2076. https://doi.org/10.1007/s12598-020-01584-1.

Reed RC. The Superalloys: Fundamentals and Applications. Cambridge: Cambridge University Press. 2006. 1.

Xia W, Zhao X, Yue L, Zhang Z. A review of composition evolution in Ni-based single crystal superalloys. J Mater Sci Technol. 2020;44(9):76. https://doi.org/10.1016/j.jmst.2020.01.026.

Pollock TM, Tin S. Nickel-based superalloys for advanced turbine engines: chemistry, microstructure, and properties. J Propul Power. 2006;22(2):361. https://doi.org/10.2514/1.18239.

Elliott AJ, Pollock TM, Tin S, King WT, Huang SC, Gigliotti MFX. Directional solidification of large superalloy castings with radiation and liquid-metal cooling: a comparative assessment. Metall Mater Trans a-Phys Metall Mater Sci. 2004;35(10):3221. https://doi.org/10.1007/s11661-004-0066-z.

Feng W, Chang J, Zhu S. Nickel-based single crystal superalloys with different Rhenium contents. Chin J Rare Met. 2021;45(3):353. https://doi.org/10.13373/j.cnki.cjrm.XY20050020.

Ma Z, Pei YL, Luo L, Qin L, Li SS, Gong SK. Partitioning behavior and lattice misfit of γ/γ′ phases in Ni-based superalloys with different Mo additions. Rare Met. 2021;40(4):920. https://doi.org/10.1007/s12598-019-01309-z.

Wang XY, Wang JJ, Zhang CJ, Tong WW, Jiang B, Lu GX, Wen ZX, Feng T. Creep prediction model for nickel-based single-crystal superalloys considering precipitation of TCP phase. Rare Met. 2021;40(10):2892. https://doi.org/10.1007/s12598-020-01670-4.

Pang HT, Zhang L, Hobbs RA, Stone HJ, Rae CMF. Solution heat treatment optimization of fourth-generation single-crystal nickel-base superalloys. Metall Mater Trans a-Phys Metall Mater Sci. 2012;43A(9):3264. https://doi.org/10.1007/s11661-012-1146-0.

Hegde SR, Kearsey RM, Beddoes JC. Designing homogenization-solution heat treatments for single crystal superalloys. Mater Sci Eng a-Struct Mater Prop Microstruct Process. 2010;527(21/22):5528. https://doi.org/10.1016/j.msea.2010.05.019.

Kearsey R, Hegde S, Beddoes J. Design of solutionizing heat treatments for an experimental single crystal superalloy. Superalloys. 2008;2008:310. https://doi.org/10.7449/2008/Superalloys_2008_301_310.

Fuchs GE. Improvement of creep strength of a third generation, single-crystal Ni-base superalloy by solution heat treatment. J Mater Eng Perform. 2002;11(1):19. https://doi.org/10.1007/s11665-002-0003-5.

Fuchs GE. Solution heat treatment response of a third generation single crystal Ni-base superalloy. Mater Sci Eng, A. 2001;300(1/2):52. https://doi.org/10.1016/S0921-5093(00)01776-7.

Kou Z, Feng T, Lan S, Tang S, Yang L, Yang Y, Wilde G. Observing dislocations transported by twin boundaries in al thin film: unusual pathways for dislocation-twin boundary interactions. Nano Lett. 2022;22(15):6229. https://doi.org/10.1021/acs.nanolett.2c01763.

Xia W, Zhao X, Yue L, Yue Q, Wang J, Ding Q, Bei H, Zhang Z. Inconsistent creep between dendrite core and interdendritic region under different degrees of elemental inhomogeneity in nickel-based single crystal superalloys. J Mater Sci Technol. 2021;92(33):88. https://doi.org/10.1016/j.jmst.2021.03.033.

Caron P, Henderson PJ, Khan T, McLean M. On the effects of heat treatments on the creep behaviour of a single crystal superalloy. Scr Metall. 1986;20(6):875. https://doi.org/10.1016/0036-9748(86)90458-8.

Caron P, Khan T. Improvement of creep strength in a nickel-base single-crystal superalloy by heat treatment. Mater Sci Eng. 1983;61(2):173. https://doi.org/10.1016/0025-5416(83)90199-4.

Lai KW, Shi SJ, Yan ZW, Li YS, Jin SS, Wang D, Maqbool S. Phase-field simulation of re-dissolution of γ′ phase in Ni–Al alloy by continuous and second-order aging treatment. Rare Met. 2021;40(3):1155. https://doi.org/10.1007/s12598-020-01624-w.

Murakumo T, Kobayashi T, Koizumi Y, Harada H. Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction. Acta Mater. 2004;52(12):3737. https://doi.org/10.1016/j.actamat.2004.04.028.

Van Sluytman JS, Pollock TM. Optimal precipitate shapes in nickel-base γ–γ′ alloys. Acta Mater. 2012;60(4):1771. https://doi.org/10.1016/j.actamat.2011.12.008.

Singh ARP, Nag S, Hwang JY, Viswanathan GB, Tiley J, Srinivasan R, Fraser HL, Banerjee R. Influence of cooling rate on the development of multiple generations of γ′ precipitates in a commercial nickel base superalloy. Mater Charact. 2011;62(9):878. https://doi.org/10.1016/j.matchar.2011.06.002.

Li JR, Zhong Z, Liu SZ, Tang D, Wei P, Wei P, Wu ZT, Huang D, Han MJS. A low-cost second generation single crystal superalloy DD6. Superalloys. 2000;2000:777. https://doi.org/10.7449/2000/Superalloys_2000_777_783.

Long HB, Mao SC, Liu YN, Zhang Z, Han XD. Microstructural and compositional design of Ni-based single crystalline superalloysd—a review. J Alloy Compd. 2018;743:203. https://doi.org/10.1016/j.jallcom.2018.01.224.

Kawagishi K, Yeh AC, Yokokawa T, Kobayashi T, Koizumi Y, Harada H. Development of an oxidation-resistant high-strength sixth-generation single-crystal superalloy TMS-238. Superalloys. 2012;2012:189. https://doi.org/10.1002/9781118516430.ch21.

Janotti A, Krcmar M, Fu CL, Reed RC. Solute diffusion in metals: larger atoms can move faster. Phys Rev Lett. 2004;92(8):085901. https://doi.org/10.1103/physrevlett.92.085901.

Matan N, Cox DC, Rae CMF, Reed RC. On the kinetics of rafting in CMSX-4 superalloy single crystals. Acta Mater. 1999;47(7):2031. https://doi.org/10.1016/s1359-6454(99)00093-2.

Jiang L, Dou X, Wu M, Cai M. Creep anisotropy of single crystal alloy IC6SX at 980 °C/230 MPa. Chin J Rare Met. 2021;45(5):632. https://doi.org/10.13373/j.cnki.cjrm.XY20080038.

Pollock TM, Argon AS. Directional coarsening in nickel-base single crystals with high volume fractions of coherent precipitates. Acta Metall et Mater. 1994;42(6):1859. https://doi.org/10.1016/0956-7151(94)90011-6.

Reed RC, Cox DC, Rae CMF. Kinetics of rafting in a single crystal superalloy: effects of residual microsegregation. Mater Sci Technol. 2013;23(8):893. https://doi.org/10.1179/174328407x192723.

Milhet X, Arnoux M, Cormier J, Mendez J, Tromas C. On the influence of the dendritic structure on the creep behavior of a Re-containing superalloy at high temperature/low stress. Mater Sci Eng, A. 2012;546:139. https://doi.org/10.1016/j.msea.2012.03.041.

Epishin A, Link T. Mechanisms of high-temperature creep of nickel-based superalloys under low applied stresses. Phil Mag. 2004;84(19):1979. https://doi.org/10.1080/14786430410001663240.

Epishin A, Link T, Brückner U, Portella PD. Kinetics of the topological inversion of the γ/γ′-microstructure during creep of a nickel-based superalloy. Acta Mater. 2001;49(19):4017. https://doi.org/10.1016/S1359-6454(01)00290-7.

He J, Cao L, Makineni SK, Gault B, Eggeler G. Effect of interface dislocations on mass flow during high temperature and low stress creep of single crystal Ni-base superalloys. Scripta Mater. 2021;191:23. https://doi.org/10.1016/j.scriptamat.2020.09.016.

Wu X, Makineni SK, Liebscher CH, Dehm G, Rezaei Mianroodi J, Shanthraj P, Svendsen B, Bürger D, Eggeler G, Raabe D, Gault B. Unveiling the Re effect in Ni-based single crystal superalloys. Nat Commun. 2020;11(1):389. https://doi.org/10.1038/s41467-019-14062-9.

Kontis P, Li ZM, Collins DM, Cormier J, Raabe D, Gault B. The effect of chromium and cobalt segregation at dislocations on nickel-based superalloys. Scripta Mater. 2018;145:76. https://doi.org/10.1016/j.scriptamat.2017.10.005.

Barba D, Smith TM, Miao J, Mills MJ, Reed RC. Segregation-sssisted plasticity in Ni-based superalloys. Metall and Mater Trans A. 2018;49(9):4173. https://doi.org/10.1007/s11661-018-4567-6.

Tang YL, Huang M, Xiong JC, Li JR, Zhu J. Evolution of superdislocation structures during tertiary creep of a nickel-based single-crystal superalloy at high temperature and low stress. Acta Mater. 2017;126:336. https://doi.org/10.1016/j.actamat.2016.12.072.

Srinivasan R, Eggeler GF, Mills MJ. γ′-cutting as rate-controlling recovery process during high-temperature and low-stress creep of superalloy single crystals. Acta Mater. 2000;48(20):4867. https://doi.org/10.1016/S1359-6454(00)00292-5.

Qi D, Wang L, Zhao P, Qi L, He S, Qi Y, Ye H, Zhang J, Du K. Facilitating effect of interfacial grooves on the rafting of nickel-based single crystal superalloy at high temperature. Scripta Mater. 2019;167:71. https://doi.org/10.1016/j.scriptamat.2019.04.001.

Pollock TM. The growth and elevated temperature stability of high refractory nickel-base single crystals. Mater Sci Eng B. 1995;32(3):255. https://doi.org/10.1016/0921-5107(95)03016-6.

Rae CMF, Reed RC. Primary creep in single crystal superalloys: origins, mechanisms and effects. Acta Mater. 2007;55(3):1067. https://doi.org/10.1016/j.actamat.2006.09.026.

Reed RC, Matan N, Cox DC, Rist MA, Rae CMF. Creep of CMSX-4 superalloy single crystals: effects of rafting at high temperature. Acta Mater. 1999;47(12):3367. https://doi.org/10.1016/S1359-6454(99)00217-7.

Zhang JX, Murakumo T, Koizumi Y, Harada H. The influence of interfacial dislocation arrangements in a fourth generation single crystal TMS-138 superalloy on creep properties. J Mater Sci. 2003;38(24):4883. https://doi.org/10.1023/B:JMSC.0000004409.70156.6a.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 91960201), the Key Basic Research Program of Zhejiang Province (No. 2020C01002), Zhejiang Provincial Natural Science Foundation of China (Nos. LR22E010003 and Q23E010029), the National Science and Technology Major Project of China (No. J2019-III-0008-0051) and the Fundamental Research Funds for the Central Universities (No. 226-2022-00050).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xia, WS., Zhao, XB., Xu, JC. et al. Improvement for creep strength of a second-generation single crystal superalloy by design of heat treatments. Rare Met. 43, 342–350 (2024). https://doi.org/10.1007/s12598-023-02361-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02361-6