Abstract

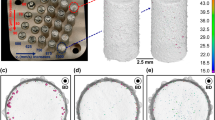

The Cu-based shape memory alloy (SMA) with highly oriented columnar crystals is an ideal candidate for the commercial application, especially the ones obtained through rapid cooling via additive manufacturing method. In this work, Cu71Al18Mn11 (at%) shape memory alloy with strong <001> texture columnar grains was successfully prepared by selective laser melting (SLM). An L27(313) orthogonal array was designed to systematically investigate the effects of laser power, scanning speed, scanning spacing, layer thickness and their interactions on the forming quality of Cu71Al18Mn11 alloys. Cu71Al18Mn11 alloys with density of 7.3204 g·cm−3 and relative density of 99.18% were successfully prepared when the laser power, scanning speed, scanning distance and layer thickness were 240 W, 1000 mm·s−1, 0.11 mm and 25 µm, the transformation onset temperature (Ms), martensite phase transformation termination temperature (Mf), austenite phase transformation onset temperature (As) and austenite phase transformation termination temperature (Af) are −21.84, −26.04, −15.75 and −12.36 °C, respectively. The compression strength and fracture strain along the building direction (BD) were significantly superior to the scanning direction (SD), while the superelasticity of compression along the SD reached 2.50%, which was better than that of 2.32% along BD. The mechanical property and superelasticity anisotropy due to the formation of columnar grains and texture were discussed. This study shows that SLM is a proposed method for the preparation of Cu-Al-Mn SMAs with high superelasticity, which provides a new strategy for enhancing the shape memory alloy superelasticity.

Graphical Abstract

摘要

具有高取向柱状晶的铜基形状记忆合金是商业应用的理想候选材料。在这项工作中,通过选择性激光熔化(SLM)成功制备了具有强<001>织构柱状晶的Cu71Al18Mn11(at%)形状记忆合金。设计了L27(313)正交阵列,系统地研究了激光功率、扫描速度、扫描间距、层厚及它们之间的相互作用对Cu71Al18Mn11合金成型质量的影响。当激光功率、扫描速度、扫描间距和层厚分别为240 W、1000 mm·s−1、0.11 mm和25 μm时,成功制备了密度为7.3204 g·cm-3,相对密度为99.18%的Cu71Al18Mn11合金,其Ms,Mf,As和Af分别为−21.84、−26.04、−15.75和−12.36 °C。沿生长方向(BD)的压缩强度和断裂应变明显优于扫描方向(SD),而沿SD的压缩超弹性达到2.50%,优于沿BD的2.32%。讨论了由于柱状晶和织构的形成而产生的力学性能和超弹性的各向异性。本研究表明,SLM是一种拟制具有高超弹性的Cu-Al-Mn SMA的方法,它为提高形状记忆合金的超弹性提供了一种新的策略。

Similar content being viewed by others

References

Chen ZW, Gan CL, Qian JP, Nong D. Effect of Cr content on phase transition characteristics and microhardness of near equiatomic NiTi SMA. Chin J of Rare Met. 2021;45(9):1034. https://doi.org/10.13373/j.cnki.cjrm.XY20080009

Feng X, Zhao LM, Mi XJ, Huang GJ, Xie HF, Yin XQ, Peng LJ, Yang Z. Improving interface adhesion in TiNi wire/shape memory epoxy composites using carbon nanotubes. Rare Met. 2021;40(4):934. https://doi.org/10.1007/s12598-018-1029-7.

Yang R, Li S, Zhang N, Wang C, Wang TM, Wang QH. Tribology behaviors of Ti–Ni51.5 at% shape memory alloy with different microstructures and textures. Rare Met. 2021;40(12):3616. https://doi.org/10.1007/S12598-021-01706-3.

Sun YH, Zhao Y, Zhao YY, Rong YJ, Yao RH, Yao XH, Hang RQ, Chu PK. Improving exposure of anodically ordered Ni–Ti–O and corrosion resistance and biological properties of NiTi alloys by substrate electropolishing. Rare Met. 2021;40(12):3575. https://doi.org/10.1007/s12598-021-01757-6.

Liu XJ, Wang QZ, Kondrat’ev SY, Ji PG, Yin FX, Cui CX, Hao GL. Microstructural, mechanical, and damping properties of a Cu-based shape memory alloy refined by an in situ LaB6/Al Inoculant. Metall Mater Trans. 2019. https://doi.org/10.1007/s11661-019-05153-9.

Jani JM, Leary M, Subic A, Gibson MA. A review of shape memory alloy research, applications and opportunities. Mater Des. 2014;56:1078. https://doi.org/10.1016/j.matdes.2013.11.084.

Toshihiro O, Tomoe K, Shingo K, Ikuo O, Yuji S, Yoshikazu A, Kiyohito I, Ryosuke K. Abnormal grain growth induced by cyclic heat treatment. Science. 2013;341(6153):1500. https://doi.org/10.1126/science.1238017.

Yang SY, Zhang JX, Chi MY, Yang MJ, Wang CP, Liu XJ. Excellent superelasticity of Cu-Al-Mn-Cr shape memory single crystal obtained only through annealing cast polycrystalline alloy. Scripta Mater. 2019;165:20. https://doi.org/10.1016/j.scriptamat.2019.02.011.

Liu JL, Huang HY, Xie JX. The roles of grain orientation and grain boundary characteristics in the enhanced superelasticity of Cu71.8Al17.8Mn10.4 shape memory alloys. Mater Des. 2014;64:427. https://doi.org/10.1016/j.matdes.2014.07.070.

Wang Y, Huang HY, Xie JX. Texture evolution and flow stress of columnar-grained polycrystalline copper during intense plastic deformation process at room temperature. Mater Sci Eng, A. 2011;530:418. https://doi.org/10.1016/j.msea.2011.09.105.

Yang R, Li S, Zhang N, Wang C, Wang TM, Wang QH. Tribology behaviors of Ti-Ni51.5 at% shape memory alloy with different microstructures and textures. Rare Met. 2021;40(12):3616. https://doi.org/10.1007/s12598-021-01706-3.

Huang YJ, Liu J, Hu QD, Liu QH, Karaman I, Li JG. Applications of the directional solidification in magnetic shape memory alloys. IOP Conf Ser Mater Sci Eng. 2016;117(1):1. https://doi.org/10.1088/1757-899X/117/1/012029.

Fu H, Song S, Zhuo L, Zhang Z, Xie J. Enhanced mechanical properties of polycrystalline Cu-Al-Ni alloy through grain boundary orientation and composition control. Mater Sci Eng, A. 2015;650:218. https://doi.org/10.1016/j.msea.2015.10.037.

Shen Y, Wei ZY, Sun W, Zhang YF, Liu E, Liu J. Large elastocaloric effect in directionally solidified all- d -metal Heusler metamagnetic shape memory alloys. Acta Mater. 2020;188:677. https://doi.org/10.1016/j.actamat.2020.02.045.

Ni JT, Zhou QJ, Yi F, Dong P, Li Q, Yan ZY. Development of Laser Additive Manufacturing Technology and Its Application Progress in Aerospace Field. Chin J of Rare Met. 2022,46(10):1365. https://doi.org/10.13373/j.cnki.cjrm.XY22050021

Kusama T, Omori T, Saito T, Kise S, Tanaka T, Araki Y, Kainuma R. Ultra-large single crystals by abnormal grain growth. Nat Commun. 2017;8(1):354. https://doi.org/10.1038/s41467-017-00383-0.

Xu S, Kusama T, Xu X, Huang HY, Omori T, Xie JX, Kainuma R. Large [001] single crystals via abnormal grain growth from columnar polycrystal. Materialia. 2019;6:100336. https://doi.org/10.1016/j.mtla.2019.100336.

Lauhoff C, Fischer A, Sobrero C, Liehr A, Krooß P, Brenne F, Richter J, Kahlert M, Böhm S, Niendorf T. Additive manufacturing of Co-Ni-Ga high-temperature shape memory alloy: processability and phase transformation behavior. Metall Mater Trans. 2020;51(3):1056. https://doi.org/10.1007/s11661-019-05608-z.

Tan Z, Zhang XY, Zhou ZL, Zhou Z, Yang Y, Guo XY, Wang ZJ, Wu X, Wang GH, He DY. Thermal effect on the microstructure of the lattice structure Cu-10Sn alloy fabricated through selective laser melting. J Alloy Compd. 2019;787:1. https://doi.org/10.1016/j.jallcom.2019.02.196.

Zhang JS, Wu Y, Cheng X, Zhang SQ, Wang HM. Study of microstructure evolution and preference growth direction in a fully laminated directional micro-columnar TiAl fabricated using laser additive manufacturing technique. Mater Lett. 2019;243:62. https://doi.org/10.1016/j.matlet.2019.01.137.

PérezCerrato M, Fraile I, GómezCortés JF, Urionabarrenetxea E, RuizLarrea I, González I, Nó ML, Burgos N, San JJM. Designing for shape memory in additive manufacturing of Cu–Al–Ni shape memory alloy processed by laser powder bed fusion. Materials. 2022;15(18):6284. https://doi.org/10.3390/MA15186284.

Chen Y, Zhang XX, David CD, Christopher AS. Shape memory and superelasticity in polycrystalline Cu-Al-Ni microwires. Appl Phys Lett. 2009;95(17):296. https://doi.org/10.1063/1.3257372.

Zhuo LR, Song B, Li RD, Wei QS, Yan CZ, Shi YS. Effect of element evaporation on the microstructure and properties of CuZnAl shape memory alloys prepared by selective laser melting. Opt Laser Technol. 2020;127:106164. https://doi.org/10.1016/j.optlastec.2020.106164.

Gargarella P, Kiminami CS, Mazzer EM, Cava RD, Basilio LA, Bolfarini C, Botta WJ, Eckert J, Gustmann T, Pauly S. Phase formation, thermal stability and mechanical properties of a Cu-Al-Ni-Mn shape memory alloy prepared by selective laser melting. Mater Res-Ibero-Am J Mater. 2015;18:35. https://doi.org/10.1590/1516-1439.338914.

Gustmann T, Neves A, Kühn U, Gargarella P, Kiminami CS, Bolfarini C, Eckert J, Pauly S. Influence of processing parameters on the fabrication of a Cu-Al-Ni-Mn shape-memory alloy by selective laser melting. Addit Manuf. 2016;11:23. https://doi.org/10.1016/j.addma.2016.04.003.

Mazzer EM, Claudio SK, Gargarella P, Cava RD, Basilio LA, Bolfarini C, Botta WJ, Eckert J, Gustmann T, Pauly S. Atomization and selective laser melting of a Cu-Al-Ni-Mn shape memory alloy. Mater Sci Forum. 2014;3692(802–802):343. https://doi.org/10.4028/www.scientific.net/MSF.802.343.

Wang HY, Huang JL, Xu D, Gu H, Feng JC, Zhu J, Mao JZ. Comparison of microstructure and shape memory properties between two Cu-Al-Mn alloys produced by additive manufacturing technology. Materialia. 2022;26:101594. https://doi.org/10.1016/J.MTLA.2022.101594.

Babacan N, Pauly S, Gustmann T. Laser powder bed fusion of a superelastic Cu-Al-Mn shape memory alloy. Mater Des. 2021;203:109625. https://doi.org/10.1016/J.MATDES.2021.109625.

Chen JG, Wang XB, Pan YC. Influence of laser power and scan speed on the microstructure and properties of GH4169 alloy prepared by selective laser melting. IOP Conf Ser Mater Sci Eng. 2019;688(3):1. https://doi.org/10.1088/1757-899X/688/3/033064.

Bi J, Chen YB, Chen X, Starostenkov MD, Dong GJ. Densification, microstructural features and tensile properties of selective laser melted AlMgSiScZr alloy from single track to block specimen. J Cent South Univ. 2021;28(4):1129. https://doi.org/10.1007/S11771-021-4685-Y.

Greco S, Cutzeit K, Hotz H, Kirsch B, Aurich JC. Selective laser melting (SLM) of AISI 316L—impact of laser power, layer thickness, and hatch spacing on roughness, density, and microhardness at constant input energy density. Int J Adv Manuf Technol. 2020;108:1. https://doi.org/10.1007/s00170-020-05510-8.

Alagha AN, Hussain S, Zaki W. Additive manufacturing of shape memory alloys: A review with emphasis on powder bed systems. Mater Des. 2021;204:109654. https://doi.org/10.1016/J.MATDES.2021.109654.

Thijs L, Kempen K, Kruth JP, Van Humbeek J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013;61(5):1809. https://doi.org/10.1016/j.actamat.2012.11.052.

Tian J, Zhu WZ, Wei QS, Wen SF, Li S, Song B, Shi YS. Process optimization, microstructures and mechanical properties of a Cu-based shape memory alloy fabricated by selective laser melting. J Alloy Compd. 2019;785:754. https://doi.org/10.1016/j.jallcom.2019.01.153.

Kainuma R, Takahashi S, Ishida K. Ductile shape memory alloys of the Cu-Al-Mn system. Eur Phys J Spec Top. 1995;05(C8):961. https://doi.org/10.1051/jp4/199558961.

Kainuma R, Takahashi S, Ishida K. Thermoelastic martensite and shape memory effect in ductile Cu-Al-Mn alloys. Metall Mater Trans A. 1996;27(8):2187. https://doi.org/10.1007/BF02651873.

Leuders S, Thone M, Riemer A, Niendorf T, Troster T, Richard HA, Maier HJ. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: fatigue resistance and crack growth performance. Int J Fatigue. 2013;48:300. https://doi.org/10.1016/j.ijfatigue.2012.11.011.

Jaber H, Konya J, Kulcsar K, Kovacs T. Effects of annealing and solution treatments on the microstructure and mechanical properties of Ti6Al4V manufactured by selective laser melting. Materials. 2022;15(5):1978. https://doi.org/10.3390/MA15051978.

Tonelli L, Liverani E, Morri A, Ceschini L. Role of direct aging and solution treatment on hardness, microstructure and residual stress of the A357 (AlSi7Mg0.6) alloy produced by powder bed fusion. Metall Mater Trans B. 2021;52(4):1. https://doi.org/10.1007/S11663-021-02179-6.

Sutou Y, Omori T, Yamauchi K, Ono N, Kainuma R, Ishida K. Effect of grain size and texture on pseudoelasticity in Cu–Al–Mn-based shape memory wire. Acta Mater. 2005;53(15):4121. https://doi.org/10.1016/j.actamat.2005.05.013.

Beth EC, Todd AP, Allison MB. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015;87:309. https://doi.org/10.1016/j.actamat.2014.12.054.

Ladani L, Razmi J, Farhan CS. Mechanical anisotropy and strain rate dependency behavior of Ti6Al4V produced using E-beam additive fabrication. J Eng Mater Technol. 2014;136(3):1. https://doi.org/10.1115/1.4027729.

Kok Y, Tan XP, Wang P, Nai MLS, Loh NH, Liu E, Tor SB. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: a critical review. Mater Des. 2018;139:565. https://doi.org/10.1016/j.matdes.2017.11.021.

Liu JL, Huang HY, Xie JX. Superelastic anisotropy characteristics of columnar-grained Cu–Al–Mn shape memory alloys and its potential applications. Mater Des. 2015;85:211. https://doi.org/10.1016/j.matdes.2015.06.114.

Miyazaki S, Kawai T, Otsuka K. On the origin of intergranular fracture in β phase shape memory alloys. Scr Metall. 1982;16(4):431. https://doi.org/10.1016/0036-9748(82)90167-3.

Liu JL, Yan WX, Li MH. Tension–compression asymmetry of superelasticity in unidirectionally solidified Cu-Al-Mn shape memory alloy. J Mater Eng Perform. 2020;29(1):289. https://doi.org/10.1007/s11665-020-04588-1.

Petr Š, Václav N. Anisotropy of martensitic transformations in modeling of shape memory alloy polycrystals. Int J Plast. 2000;16(10):1243. https://doi.org/10.1016/S0749-6419(00)00009-7.

Yuan WQ, Wang JN. Anisotropy of the phase-transformation plasticity in textured CuZnAl shape-memory sheets. J Mater Process Tech. 2002;123(1):31. https://doi.org/10.1016/S0924-0136(02)00039-0.

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (No. 52272258), Fundamental Research Funds for the Central Universities (No. 2023ZKPYJD07), Key R&D and transformation projects in Qinghai Province (No. 2021-HZ-808) and Hebei Province (No. 21314401D). Acknowledgement is made to the American Chemical Society Petroleum Research Fund for the support (No. PRF-59722-ND10).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, MW., Hu, ZF., Yang, BB. et al. Additive manufacturing of Cu-Al-Mn shape memory alloy with enhanced superelasticity. Rare Met. 42, 4234–4245 (2023). https://doi.org/10.1007/s12598-023-02353-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02353-6