Abstract

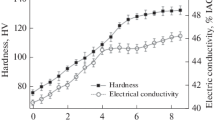

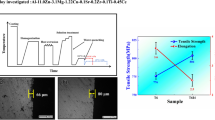

Sn microalloying can depress the adverse effect of natural aging after quenching (i.e., room-temperature storage) of Al–Mg–Si alloys. However, the other effect of Sc micro-addition to the Al–Mg–Si–Sn alloys remains elusive. Here, the optimal room-temperature storage time, properties and micromechanisms of Al–0.43 Mg–1.2Si–0.1Sn–0.1Sc (wt%) alloy are investigated by atomic-resolution scanning transmission electron microscopy (STEM), microhardness and corrosion resistance tests. The results show that the peak-aging Al–Mg–Si–Sn–Sc alloy exhibits vastly shortened peak hardening time, increased thermal stability and corrosion resistance compared with its Sc-free counterpart after a long room-temperature storage time of 1 week. Under such a designed double-stage aging regime (1-week room-temperature storage + artificial aging at 180 °C), the addition of Sc to Al–Mg–Si–Sn alloy induces a decrease in diameter but an increase in length of peak-hardening β”-based precipitates. In addition, a suppressed over-aging phase transition from Sc/Sn-containing β” to β’ is identified in the Al–Mg–Si–Sn–Sc alloy. The Sn tends to segregate to the Si site in the low-density cylinder of β” and the central site of sub-B' in the precipitate can be occupied by Sn/Sc. Further study reveals that Sc and Sn coexist in the precursors of β”. Both reduced width of precipitation free zones and protective corrosion product film easily formed on the material contribute to the improved corrosion resistance of Al–Mg–Si–Sn–Sc alloy. The results provide important insight into the development of high-performance Al alloys.

Graphical abstract

摘要

Sn 微合金化可以抑制 Al Mg Si 合金淬火后自然时效 即室温储存 的不利影响。然而, Sc 微添加到 Al Mg Si Sn 合金的其他影响仍然是难 以捉摸的。通过原子分辨率扫描透射电镜、显微硬度和耐蚀性测试,研究了 Al 0.43Mg 1.2Si 0.1Sn 0.1Sc (wt%) 合金的最佳室温储存 时间、 性能和微观机理。结果表明 经峰时效处理的 Al Mg Si Sn Sc 合金在长时间室温储存 1 周后,其峰时效时间明显 缩短,热稳定性和耐蚀性 明显提高 在设计的双级 时效 室温储存 1 周 180 人工时效 条件下, Sc 的加入使 Al Mg Si Sn 合金的 β" 基峰硬析出相直径减小,长度 增加。此外, Al Mg Si Sn Sc 合金还发生了从含 Sc/ S n 的 β" 到 β' 的抑制过时效相变。 Sn 倾向于在 β" 低密度柱中偏析到 Si 位,析出相中 sub B 中心位置被 Sn/Sc 占据。进一步的研究表明, Sc 和 Sn 同时存在于 β" 的前 驱 体中。 Al Mg Si Sn Sc 合金的耐蚀性因 前驱晶界无析出带 宽 度减小和易在材料上形成保护腐蚀产物膜而提高。研究结果为高性能铝合金的发展提供了重要的理论依据。

Similar content being viewed by others

References

Matsuda K, Sakaguchi Y, Miyata Y, Uetani Y, Sato T, Kamio A, Ikeno S. Precipitation sequence of various kinds of metastable phases in Al-1.0mass% Mg2Si-0.4mass% Si alloy. J Mater Sci. 2000;35(1):179. https://doi.org/10.1023/A:1004769305736.

Marioara CD, Andersen SJ, Jansen J, Zandbergen HW. The influence of temperature and storage time at RT on nucleation of the β” phase in a 6082 Al–Mg–Si alloy. Acta Mater. 2003. https://doi.org/10.1016/S1359-6454(02)00470-6.

Li Y, Wang QP, Gao GJ, Li JD, Wang ZD, Xu GM. Texture evolution and mechanical properties of Al–Mg–Si alloys at different intermediate annealing temperatures. Rare Met. 2019;38(10):937. https://doi.org/10.1007/s12598-019-01315-1.

Hu J, Teng J, Ji X, Fu D, Zhang W, Zhang H. Enhanced mechanical properties of an Al–Mg–Si alloy by repetitive continuous extrusion forming process and subsequent aging treatment. Mater Sci Eng A. 2017;695:35. https://doi.org/10.1016/j.msea.2017.04.013.

Chen JH, Costan E, van Huis MA, Xu Q, Zandbergen HW. Atomic pillar-based nanoprecipitates strengthen AlMgSi alloys. Science. 2006;312(5772):416. https://doi.org/10.1126/science.1124199.

Wu S, Luo T, Kou Z, Tang S, Shan G, Yan M, Wang J, Fu S, Liu S, Lan S, Feng T. Unconventional structure evolution stabilizes the ultrahigh specific strength in a nanostructured Al–Mg–Li alloy. Mater Sci Eng A. 2022;860:144282. https://doi.org/10.1016/j.msea.2022.144282.

Wu S, Luo T, Kou Z, Tang S, Yan M, Wang J, Fu S, Ying H, Liu S, Wilde G, Lai Q, Lan S, Feng T. Origin of strain softening in a nanograined Al alloy. Scr Mater. 2023;226:115235. https://doi.org/10.1016/j.scriptamat.2022.115235.

Banhart J, Chang CST, Liang Z, Wanderka N, Lay MDH, Hill AJ. Natural aging in Al–Mg–Si alloys-a process of unexpected complexity. Adv Eng Mater. 2010;12(7):559. https://doi.org/10.1002/adem.201000041.

Birol Y, Karlík M. Bake hardening of twin roll cast Al–Mg–Si sheet. Mater Sci Technol. 2013;21(2):153. https://doi.org/10.1179/174328405x20905.

Ding L, Jia Z, Zhang Z, Sanders RE, Liu Q, Yang G. The natural aging and precipitation hardening behaviour of Al–Mg–Si–Cu alloys with different Mg/Si ratios and Cu additions. Mater Sci Eng A. 2015;627:119. https://doi.org/10.1016/j.msea.2014.12.086.

Tu W, Tang J, Zhang Y, Cao L, Ma L, Zhu Q, Ye L, Liu S. Influence of Sn on the precipitation and hardening response of natural aged Al-0.4Mg-1.0Si alloy artificial aged at different temperatures. Mater Sci Eng A. 2019;765:138250. https://doi.org/10.1016/j.msea.2019.138250.

Weng Y, Ding L, Xu Y, Jia Z, Sun Q, Chen F, Sun X, Cong Y, Liu Q. Effect of In addition on the precipitation behavior and mechanical property for Al–Mg–Si alloys. J Alloys Compd. 2022;895:162685. https://doi.org/10.1016/j.jallcom.2021.162685.

Tu W, Tang J, Ye L, Cao L, Zeng Y, Zhu Q, Zhang Y, Liu S, Ma L, Lu J, Yang B. Effect of the natural aging time on the age-hardening response and precipitation behavior of the Al-0.4Mg-1.0Si-(Sn) alloy. Mater Des. 2021;198:109307. https://doi.org/10.1016/j.matdes.2020.109307.

Tu W, Tang J, Zhang Y, Ye L, Liu S, Lu J, Zhan X, Li C. Effect of Sn and Cu addition on the precipitation and hardening behavior of Al-1.0Mg-0.6Si alloy. Mater Sci Eng A. 2020;770:138515. https://doi.org/10.1016/j.msea.2019.138515.

Liu M, Zhang X, Körner B, Elsayed M, Liang Z, Leyvraz D, Banhart J. Effect of Sn and In on the natural ageing kinetics of Al–Mg–Si alloys. Materialia. 2019;6:100261. https://doi.org/10.1016/j.mtla.2019.100261.

Prach O, Trudonoshyn O, Randelzhofer P, Körner C, Durst K. Effect of Zr, Cr and Sc on the Al–Mg–Si–Mn high-pressure die casting alloys. Mater Sci Eng A. 2019;759:603. https://doi.org/10.1016/j.msea.2019.05.038.

Zhang JY, Gao YH, Yang C, Zhang P, Kuang J, Liu G, Sun J. Microalloying Al alloys with Sc: a review. Rare Met. 2020;39(6):636. https://doi.org/10.1007/s12598-020-01433-1.

He C, Luo B, Zheng Y, Yin Y, Bai Z, Ren Z. Effect of Sn on microstructure and corrosion behaviors of Al–Mg–Si alloys. Mater Charact. 2019;156:109836. https://doi.org/10.1016/j.matchar.2019.109836.

Weng Y, Xu Y, Ding L, Jia Z, Zhang Z, Chen J, Xie M, Liu Q. Effect of Sn contents on natural aging and precipitation hardening in Al–Mg–Si alloys. Mater Charact. 2021;179:111383. https://doi.org/10.1016/j.matchar.2021.111383.

Werinos M, Antrekowitsch H, Ebner T, Prillhofer R, Uggowitzer PJ, Pogatscher S. Hardening of Al–Mg–Si alloys: effect of trace elements and prolonged natural aging. Mater Des. 2016;107:257. https://doi.org/10.1016/j.matdes.2016.06.014.

Werinos M, Antrekowitsch H, Kozeschnik E, Ebner T, Moszner F, Löffler JF, Uggowitzer PJ, Pogatscher S. Ultrafast artificial aging of Al–Mg–Si alloys. Scr Mater. 2016;112:148. https://doi.org/10.1016/j.scriptamat.2015.09.037.

Zhang X, Liu M, Sun H, Banhart J. Influence of Sn on the age hardening behavior of Al–Mg–Si alloys at different temperatures. Materialia. 2019;8:100441. https://doi.org/10.1016/j.mtla.2019.100441.

Saga M, Kikuchi M. Effect of Sn Addition on the two-step aging behavior in Al–Mg–Si Alloys for automotive application. In: Proceedings of the 9th International Conference on Aluminium Alloys. Brisbane; 2004. 2.

Werinos M, Antrekowitsch H, Ebner T, Prillhofer R, Curtin WA, Uggowitzer PJ, Pogatscher S. Design strategy for controlled natural aging in Al–Mg–Si alloys. Acta Mater. 2016;118:296. https://doi.org/10.1016/j.actamat.2016.07.048.

Liu Y, Lai YX, Chen ZQ, Chen SL, Gao P, Chen JH. Formation of β”-related composite precipitates in relation to enhanced thermal stability of Sc-alloyed Al–Mg–Si alloys. J Alloys Compd. 2021. https://doi.org/10.1016/j.jallcom.2021.160942.

Wang SB, Pan CF, Wei B, Zheng X, Lai YX, Chen JH. Nano-phase transformation of composite precipitates in multicomponent Al–Mg–Si(–Sc) alloys. J Mater Sci Technol. 2022;110:216. https://doi.org/10.1016/j.jmst.2021.09.037.

Jiang S, Wang R. Grain size-dependent Mg/Si ratio effect on the microstructure and mechanical/electrical properties of Al–Mg–Si–Sc alloys. J Mater Sci Technol. 2019;35(7):1354. https://doi.org/10.1016/j.jmst.2019.03.011.

Wei B, Pan S, Liao G, Ali A, Wang S. Sc-containing hierarchical phase structures to improve the mechanical and corrosion resistant properties of Al–Mg–Si alloy. Mater Des. 2022;218:110699. https://doi.org/10.1016/j.matdes.2022.110699.

Sun Y, Luo Y, Pan Q, Liu B, Long L, Wang W, Ye J, Huang Z, Xiang S. Effect of Sc content on microstructure and properties of Al–Zn–Mg–Cu–Zr alloy. Mater Today Commun. 2021;26:101899. https://doi.org/10.1016/j.mtcomm.2020.101899.

Li K, Béché A, Song M, Sha G, Lu X, Zhang K, Du Y, Ringer SP, Schryvers D. Atomistic structure of Cu-containing β” precipitates in an Al–Mg–Si–Cu alloy. Scr Mater. 2014;75:86. https://doi.org/10.1016/j.scriptamat.2013.11.030.

Yang W, Wang M, Zhang R, Zhang Q, Sheng X. The diffraction patterns from β” precipitates in 12 orientations in Al–Mg–Si alloy. Scr Mater. 2010;62(9):705. https://doi.org/10.1016/j.scriptamat.2010.01.039.

Han X, Wang S, Wei B, Pan S, Liao G, Li W, Wei Y. Influence of Sc addition on precipitation behavior and properties of Al–Cu–Mg alloy. Acta Metall Sin (Engl Lett). 2022. https://doi.org/10.1007/s40195-021-01328-9.

Hirosawa S, Sato T, Kamio A, Flower HM. Classification of the role of microalloying elements in phase decomposition of Al based alloys. Acta Mater. 2000;48(8):1797. https://doi.org/10.1016/S1359-6454(99)00475-9.

Zhang X, Zhou X, Nilsson JO. Corrosion behaviour of AA6082 Al–Mg–Si alloy extrusion: the influence of quench cooling rate. Corros Sci. 2019;150:100. https://doi.org/10.1016/j.corsci.2019.01.030.

Zeng FL, Wei ZL, Li JF, Li CX, Tan X, Zhang Z, Zheng ZQ. Corrosion mechanism associated with Mg2Si and Si particles in Al–Mg–Si alloys. Trans Nonferrous Met Soc China. 2011;21(12):2559. https://doi.org/10.1016/S1003-6326(11)61092-3.

Wu X-F, Wang K-Y, Wu F-F, Zhao R-D, Chen M-H, Xiang J, Ma S-N, Zhang Y. Simultaneous grain refinement and eutectic Mg2Si modification in hypoeutectic Al-11Mg2Si alloys by Sc addition. J Alloys Compd. 2019;791:402. https://doi.org/10.1016/j.jallcom.2019.03.326.

Liu S, Wang X, Zu Q, Han B, Han X, Cui C. Significantly improved particle strengthening of Al–Sc alloy by high Sc composition design and rapid solidification. Mater Sci Eng A. 2021;800:140304. https://doi.org/10.1016/j.msea.2020.140304.

Liang Z, Pan QL, He YB, Wang CZ, Liang WJ. Effect of minor Sc and Zr addition on microstructures and mechanical properties of Al–Zn–Mg–Cu alloys. Trans Nonferrous Met Soc China. 2007;17(2):340. https://doi.org/10.1016/S1003-6326(07)60095-8.

Huang X, Pan Q, Li B, Liu Z, Huang Z, Yin Z. Microstructure, mechanical properties and stress corrosion cracking of Al–Zn–Mg–Zr alloy sheet with trace amount of Sc. J Alloys Compd. 2015;650:805. https://doi.org/10.1016/j.jallcom.2015.08.011.

Zandbergen H, Andersen S, Jansen J. Structure determination of Mg5Si6 particles in Al by dynamic electron diffraction studies. Science. 1997;277(5330):1221. https://doi.org/10.1126/science.277.5330.1221.

Ravi C, Wolverton C. First-principles study of crystal structure and stability of Al–Mg–Si–(Cu) precipitates. Acta Mater. 2004;52(14):4213. https://doi.org/10.1016/j.actamat.2004.05.037.

Chen H, Lu J, Kong Y, Li K, Yang T, Meingast A, Yang M, Lu Q, Du Y. Atomic scale investigation of the crystal structure and interfaces of the B′ precipitate in Al–Mg–Si alloys. Acta Mater. 2020;185:193. https://doi.org/10.1016/j.actamat.2019.11.059.

Pennycook S, Jesson D. High-resolution incoherent imaging of crystals. Phys Rev Lett. 1990;64(8):938. https://doi.org/10.1103/PhysRevLett.64.938.

Liu C, Ma P, Zhan L, Huang M, Li J. Solute Sn-induced formation of composite β’/β” precipitates in Al–Mg–Si alloy. Scr Mater. 2018;155:68. https://doi.org/10.1016/j.scriptamat.2018.06.028.

Andersen SJ, Marioara CD, Frøseth A, Vissers R, Zandbergen HW. Crystal structure of the orthorhombic U2-Al4Mg4Si4 precipitate in the Al–Mg–Si alloy system and its relation to the β’ and β” phases. Mater Sci Eng A. 2005;390(1–2):127. https://doi.org/10.1016/j.msea.2004.09.019.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 52061003 and U20A20274), the Natural Science Foundation of Guangxi (No. 2018GXNSFAA050012) and Guangxi Science and Technology Project (Nos. AA17204036-1, AA18118030 and AA17204100).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pan, S., Chen, XJ., Liao, GZ. et al. Developing a high-performance Al–Mg–Si–Sn–Sc alloy for essential room-temperature storage after quenching: aging regime design and micromechanisms. Rare Met. 42, 3814–3828 (2023). https://doi.org/10.1007/s12598-023-02342-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02342-9