Abstract

Cu-based composites with multiscale configuration for electrical contact applications are fabricated via a ball milling (BM)-spark plasma sintering (SPS)-aging process. Synergistic strengthening of the Cu alloy matrix by micro-scale metallic glass particles and nanoscale intracrystalline precipitation phases is realized. The annealing technique achieves the decomposition of solute atoms in the Cu alloy, ensuring the excellent electrical properties of the matrix conductive network. The composite with multiscale configuration achieves an outstanding combination of ultimate compressive strength of (1114 ± 15) MPa and electrical conductivity of 33.0% ± 1.1% International Annealed Copper Standard (IACS) after annealing at 400 °C for 10.0 h. Investigation of the strengthening and conductivity mechanisms suggests that the precipitation of the Cr-rich phase within the matrix crystals is a critical contributor to the concerted enhancement of strength and conductivity. In addition, the positive role of nanocrystals precipitated at the edges of metallic glass particles on the interfacial bonding of composites is addressed.

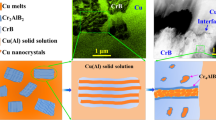

Graphical abstract

摘要

通过球磨—放电等离子体烧结—时效工艺制备了用于电接触应用的多尺度结构的铜基复合材料。实现了微米级 金属玻璃颗粒和纳米级晶内沉淀相对铜合金基体的协同强化。退火工艺实现了铜合金中溶质原子的脱溶,确保 了基体导电网络的优异电性能。具有多尺度结构的复合材料在400 °C 退火10 h 后达到了(1114±15) MPa 的极 限抗压强度和33.0%±1.1% IACS 的电导率的出色性能组合。对强化机制和导电机制的研究表明,基体晶体中 富铬相的析出是协同增优化强度和导电性的关键因素。此外,还讨论了在金属玻璃颗粒边缘析出的纳米晶体对 复合材料界面结合的积极作用。

Similar content being viewed by others

References

Yang YH, Li SY, Cui ZS, Li Z, Li YP, Lei Q. Microstructure and properties of high-strength Cu-Ni-Si-(Ti) alloys. Rare Met. 2021;40(11):3251. https://doi.org/10.1007/s12598-020-01699-5.

Zhang XH, Zhang Y, Tian BH, Jia YL, Liu Y, Song KX, Volinsky AA, Xue HH. Cr effects on the electrical contact properties of the Al2O3-Cu/15W composites. Nanotechnol Rev. 2019;8:128. https://doi.org/10.1021/10.1515/ntrev-2019-0012.

Liu XL, Cai ZB, Xiao Q, Shen MX, Yang WB, Chen DY. Fretting wear behavior of brass/copper-graphite composites as a contactor material under electrical contact. Int J Mech Sci. 2020;184:1703. https://doi.org/10.1016/j.ijmecsci.2020.105703.

Dong ZL, Peng YF, Tan ZQ, Fan GL, Guo Q, Li ZQ, Xiong DB. Simultaneously enhanced electrical conductivity and strength in Cu/graphene/Cu sandwiched nanofilm. Scr Mater. 2020;187:296. https://doi.org/10.1016/j.scriptamat.2020.06.051.

Li WJ, Chen ZY, Jiang H, Sui XH, Zhao CF, Zhen L, Shao WZ. Effects of interfacial wettability on arc erosion behavior of Zn2SnO4/Cu electrical contacts. J Mater Sci Technol. 2022;109:64. https://doi.org/10.1016/j.jmst.2021.08.045.

Cheng BW, Bao R, Yi JH, Li CJ, Tao JM, Liu YC, Tan SL, You X. Interface optimization of CNT/Cu composite by forming TiC nanoprecipitation and low interface energy structure via spark plasma sintering. J Alloys Compd. 2017;722:852. https://doi.org/10.1016/j.jallcom.2017.06.186.

Qian SY, Xu ZH, Xie HN, Shi CS, Zhao NQ, He CN, Liu EZ. Effect of rare metal element interfacial modulation in graphene/Cu composite with high strength, high ductility and good electrical conductivity. Appl Surf Sci. 2020;533:147489. https://doi.org/10.1016/j.apsusc.2020.147489.

Guo XH, Song KX, Xua W, Li GH, Zhang ZL. Effect of TiB2 particle size on the material transfer behaviour of Cu-TiB2 composites. Mater Sci Technol. 2020;36:1685. https://doi.org/10.1080/02670836.2020.1821964.

Zhou DS, Geng HW, Zeng W, Zhang DL, Kong C, Munroe P. Suppressing Al2O3 nanoparticle coarsening and Cu nanograin growth of milled nanostructured Cu-5vol.%Al2O3 composite powder particles by doping with Ti. J Mater Sci Technol. 2017;22:1323. https://doi.org/10.1016/j.jmst.2017.03.010.

Zeng W, Xie JW, Zhou DS, Fu ZQ, Zhang DL, Lavernia EJ. Bulk Cu-NbC nanocomposites with high strength and high electrical conductivity. J Alloys Compd. 2018;745:55. https://doi.org/10.1016/j.jallcom.2018.02.215.

Zhang DD, He XY, Liu Y, Bai F, Wang JG. The effect of in situ nano-sized particle content on the properties of TiCx/Cu composites. J Mater Res Technol. 2021;10:453. https://doi.org/10.1016/j.jmrt.2020.12.037.

Zhang XZ, Chen TJ, Ma SM, Qin H, Ma JY. Overcoming the strength-ductility trade-off of an aluminum matrix composite by novel core-shell structured reinforcing particulates. Compos Part B-Eng. 2021;206:1541. https://doi.org/10.1016/j.compositesb.2020.108541.

Pu BW, Zhang X, Chen XF, Lin XB, Zhao DD, Shi CS, Liu EZ, Sha JW, He CN, Zhao NQ. Exceptional mechanical properties of aluminum matrix composites with heterogeneous structure induced by in-situ graphene nanosheet-Cu hybrids. Compos Part B-Eng. 2022;234:109731. https://doi.org/10.1016/j.compositesb.2020.108541.

Yang P, You X, Yi JH, Fang D, Bao R, Shen T, Liu YC, Tao JM, Li CJ, Tan SL, Guo SD. Simultaneous achievement of high strength, excellent ductility and good electrical conductivity in carbon nanotube/copper composites. J Alloy Compd. 2018;752:431. https://doi.org/10.1016/10.1016/j.jallcom.2018.03.341.

Chu K, Jia CC, Jiang LK, Li WS. Improvement of interface and mechanical properties in carbon nanotube reinforced Cu-Cr matrix composites. Mater Des. 2013;45:407. https://doi.org/10.1016/j.matdes.2012.09.027.

Cho S, Kikuchi K, Miyazaki T, Kawasaki A, Arami Y, Silvain JF. Epitaxial growth of chromium carbide nanostructures on multiwalled carbon nanotubes (MWCNTs) in MWCNT copper composites. Acta Mater. 2013;61:708. https://doi.org/10.1016/j.actamat.2012.10.022.

Tong Y, Chen D, Han B, Wang J, Feng R, Yang T, Zhao C, Zhao YL, Guo W, Shimizu Y, Liu CT, Liaw PK, Inoue K, Nagai Y, Hu A, Kai JJ. Outstanding tensile properties of a precipitation-strengthened FeCoNiCrTi0.2 high-entropy alloy at room and cryogenic temperatures. Acta Mater. 2019;165:228. https://doi.org/10.1016/j.actamat.2012.10.022.

Lan S, Wu ZD, Wei XY, Zhou J, Lu ZP, Neuefeind J, Wang XL. Structure origin of a transition of classic-to-avalanche nucleation in Zr-Cu-Al bulk metallic glasses. Acta Mater. 2018;149:108. https://doi.org/10.1016/j.actamat.2018.02.028.

Bao WZ, Yan H, Chen J, Xie GQ. High strength conductive bulk Cu-based alloy metallic glass composites fabricated by spark plasma sintering. Mater Sci Eng A. 2021;825:141919. https://doi.org/10.1016/j.msea.2021.141919.

Bao WZ, Chen J, Yang XX, Xiang T, Cai ZY, Xie GQ. Improved strength and conductivity of metallic-glass-reinforced nanocrystalline CuCrZr alloy. Mater Des. 2022;214:110420. https://doi.org/10.1016/j.matdes.2022.110420.

Liu YZ, Chen J, Li Z, Wang XH, Zhang P, Liu JN. AlCoCrFeNi high entropy alloy reinforced Cu-based composite with high strength and ductility after hot extrusion. Vacuum. 2021;184:109882. https://doi.org/10.1016/j.vacuum.2020.109882.

Xie GQ, Huang ZW. Optimizing mechanical and electrical properties of Cu-coated Cu-Zr-Al bulk metallic glass composites by adjusting glassy powder size. Intermetallics. 2022;146:107570. https://doi.org/10.1016/j.intermet.2022.107570.

Huang ZW, Wu ZW, Cheng X, Zhang ZW, Xie GQ. Bulk metallic glass composites with high strength and electrical conductivity by sintering Cu-coated CuZrAl glassy powder. J Alloys Compd. 2020;841:155723. https://doi.org/10.1016/j.jallcom.2020.155723.

Bao WZ, Chen J, Xie GQ. Optimized strength and conductivity of multi-scale cooper alloy/metallic glass composites tuned by a one-step SPS process. J Mater Sci Technol. 2022;128:22. https://doi.org/10.1016/j.jmst.2022.04.024.

Yan F, Liu L, Li M, Zhang M, Shang L, Xiao L, Ao Y. One-step electrodeposition of Cu/CNT/CF multiscale reinforcement with substantially improved thermal/electrical conductivity and interfacial properties of epoxy composites. Compos Part A Appl Sci Manuf. 2019;125:105530. https://doi.org/10.1016/j.compositesa.2019.105530.

Sadoun AM, Abdallah AW, Najjar IMR, Basha M, Elmahdy M. Effect of lattice structure evolution and stacking fault energy on the properties of Cu-ZrO2/GNP nanocomposites. Ceram Int. 2019;47:29598. https://doi.org/10.1016/j.compositesa.2019.105530.

Wu X, Zhu Y. Heterogeneous materials: a new class of materials with unprecedented mechanical properties. Math Res Lett. 2017;5:527. https://doi.org/10.1080/21663831.2017.1343208.

Zhang ZY, Sun LX, Tao NR. Nanostructures and nanoprecipitates induce high strength and high electrical conductivity in a CuCrZr alloy. J Mater Sci Technol. 2020;48:18. https://doi.org/10.1016/j.jmst.2019.12.022.

Wu G, Liu C, Brognara A, Ghidelli M, Raabe D, Li ZM. Symbiotic crystal-glass alloys via dynamic chemical partitioning. Mater Today. 2021;51:6. https://doi.org/10.1016/j.mattod.2021.10.025.

Xu WQ, Zheng RK, Laws KJ, Ringer SP, Ferry M. In situ formation of crystalline flakes in Mg-based metallic glass composites by controlled inoculation. Acta Mater. 2011;59:7776. https://doi.org/10.1016/j.actamat.2011.08.044.

Chen ZH, Hui HY, Li CL, Chen F, Mei XM, Ma Y, Li JY, Choi SW, Mei QS. GNPs/Al nanocomposites with high strength and ductility and electrical conductivity fabricated by accumulative roll-compositing. Rare Met. 2021;40(10):2593. https://doi.org/10.1007/s12598-020-01695-9.

Alizadeh R, LLorca J. Interactions between basal dislocations and β1′ precipitates in Mg-4Zn alloy: mechanisms and strengthening. Acta Mater. 2020;186:475. https://doi.org/10.1016/j.actamat.2020.01.028.

Huang JZ, Xiao Z, Dai J, Li Z, Jiang HY, Wang W, Zhang XX. Microstructure and properties of a novel Cu-Ni-Co-Si-Mg alloy with super-high strength and conductivity. Mater Sci Eng A. 2019;744:754. https://doi.org/10.1016/j.msea.2018.12.075.

Barnett MR, Wang H, Guo TT. An Orowan precipitate strengthening equation for mechanical twinning in Mg. Int J Plasticity. 2019;122:108. https://doi.org/10.1016/j.ijplas.2018.08.010.

Jiang JF, Huang MJ, Wang Y, Liu YZ, Zhang Y. Microstructure evolution and formation mechanism of CoCrCu1.2FeNi high entropy alloy during the whole process of semi-solid billet preparation. J Mater Sci Technol. 2022;120:172. https://doi.org/10.1016/j.jmst.2021.12.044.

Zhang Z, Topping TD, Li Y, Vogt R, Zhou Y, Haines C, Paras J, Kapoor D, Schoenung JM, Lavernia EJ. Mechanical behavior of ultrafine-grained Al composites reinforced with B4C nanoparticles. Scr Mater. 2011;65:652. https://doi.org/10.1016/j.scriptamat.2011.06.

Zhang Y, Topping TD, Yang H, Lavernia EJ, Schoenung JM, Nutt SR. Micro-strain evolution and toughening mechanisms in a trimodal Al-based metal matrix composite. Metall Mater Trans A. 2015;46:1196. https://doi.org/10.1007/s11661-014-2729-8.

Esawi AMK, Aboulkhair NT. Bi-modally structured pure aluminum for enhanced strength and ductility. Mater Des. 2015;83:493. https://doi.org/10.1016/j.matdes.2015.06.062.

Park JY, Lee JS, Choi BK, Hong BG, Jeong YH. Effect of cooling rate on mechanical properties of aged ITER-grade CuCrZr. Fusion Eng Des. 2008;83:1503. https://doi.org/10.1016/j.fusengdes.2008.07.006.

Kim YJ, Lee JU, Kim YM, Park SH. Microstructural evolution and grain growth mechanism of pre-twinned magnesium alloy during annealing. J Magnes Alloys. 2021;9:1233. https://doi.org/10.1016/j.jma.2020.11.015.

Sauvage X, Bobruk EV, Murashkin MY, Nasedkina Y, Enikeev NA, Valiev RZ. Optimization of electrical conductivity and strength combination by structure design at the nanoscale in Al-Mg-Si alloys. Acta Mater. 2015;98:355. https://doi.org/10.1016/j.actamat.2015.07.039.

Murashkin MY, Sabirov I, Sauvage X, Valiev RZ. Nanostructured Al and Cu alloys with superior strength and electrical conductivity. J Mater Sci. 2016;51:33. https://doi.org/10.1007/s10853-015-9354-9.

Zhang MX, Kelly PM. Crystallographic features of phase transformations in solids. Prog Mater Sci. 2009;54:1101. https://doi.org/10.1016/j.pmatsci.2009.06.001.

Vidyuk TM, Dudina DV, Korchagin MA, Gavrilov AI, Ukhina AV, Bulanova UE, Legan MA, Novoselov AN, Esikov MA, Anisimov AG. Manufacturing of TiC-Cu composites by mechanical milling and spark plasma sintering using different carbon sources. Surf Interfaces. 2021;27:101445. https://doi.org/10.1016/j.surfin.2021.101445.

Zhang DD, Bai F, Wang Y, Wang JG, Wang WQ. Grain refinement and mechanical properties of Cu-Cr-Zr alloys with different nano-sized TiCp addition. Materials. 2017;10(8):919. https://doi.org/10.3390/ma10080919.

Dudina DV, Grigoreva TF, Kvashnin VI, Devyatkina ET, Vosmerikov SV, Ukhina AV, Novoselov AN, Legan MA, Esikov MA, Lukyanov YL, Anisimov AG, Kovaleva SA, Lyakhov NZ. Microstructure and properties of Cu-10 wt% Al bronze obtained by high-energy mechanical milling and spark plasma sintering. Mater Lett. 2022;312:131671. https://doi.org/10.1016/j.matlet.2022.131671.

Zhang DD, Bai F, Sun LP, Wang Y, Wang JG. Compression properties and electrical conductivity of in-situ 20 vol.% nano-sized TiCx/Cu composites with different particle size and morphology. Materials. 2017;10(5):499. https://doi.org/10.3390/ma10050499.

Zhang DD, He XY, Zhao H, Gao YL. Properties of TiCp/Cu composites fabricated by powder metallurgy and electrodeless copper plating. Mater Sci Technol. 2022;38:5. https://doi.org/10.1080/02670836.2021.2015838.

Shaik MA, Golla BR. Two body abrasion wear behaviour of Cu-ZrB2 composites against SiC emery paper. Wear. 2020;450–451:203260. https://doi.org/10.1016/j.wear.2020.203260.

Shaik MA, Golla BR. Mechanical, tribological and electrical properties of ZrB2 reinforced Cu processed via milling and high-pressure hot pressing. Ceram Int. 2020;46:20226. https://doi.org/10.1016/j.ceramint.2020.05.104.

Fathy A, Shehata F, Abdelhameed M, Elmahdy M. Compressive and wear resistance of nanometric alumina reinforced copper matrix composites. Mater Des. 2012;36:100. https://doi.org/10.1016/j.dt.2018.05.003.

Asgharzadeh H, Eslami S. Effect of reduced graphene oxide nanoplatelets content on the mechanical and electrical properties of copper matrix composite. J Alloys Compd. 2019;806:553. https://doi.org/10.1016/j.jallcom.2019.07.183.

Luo GQ, Guo JW, Hu JN, Li PB, Sun Y, Shen Q. Microstructure and properties of W-Ag matrix composites by designed dual-metal-layer coated powders. Mater Des. 2022;219:110733. https://doi.org/10.1016/j.matdes.2022.110733.

Zou QC, Wu D, An XZ, Li M, Xu CY, Zhou XL, Jie JC, Dong ZH. Fabrication of W–20Cu composite with optimization of particle packing in PM route. J Mater Res Technol. 2022;19:2895. https://doi.org/10.1016/j.jmrt.2022.06.068.

Wang LD, Yang ZY, Cui Y, Wei B, Xu SC, Sheng J, Wang M, Zhu YP, Fei WD. Graphene-copper composite with micro-layered grains and ultrahigh strength. Sci Rep. 2017;7:41896. https://doi.org/10.1038/srep41896.

Chen J, Li BH, Bao WZ, Cai ZY, Xie GQ. Achieving high strength and high conductivity of bulk metallic glass composites by controlled milling process. J Alloys Compd. 2022;902:163849. https://doi.org/10.1016/j.jallcom.2022.163849.

Wu ZD, Lan S, Wei XY, Olds D, Page K, Shen BL, Wang XL. Heterogeneous nucleation in Zr-Cu-Al-Ag metallic glasses triggered by quenched-in metastable crystals-a time-resolved neutron diffraction study. Physica B Condens Matter. 2018;551:60. https://doi.org/10.1016/j.physb.2017.12.030.

Acknowledgements

The work was financially supported by Shenzhen Knowledge Innovation Plan—Fundamental Research (Discipline Distribution) (No. JCYJ20180507184623297), the National Natural Science Foundation of China (No. 51871077), Guangdong Basic and Applied Basic Research Foundation (No. 2021A1515012626), Shenzhen Science and Technology Plan—Technology Innovation (No. KQJSCX20180328165656256), Development and Reform Commission of Shenzhen Municipality-Shenzhen R&D Center for Al-based Hydrogen Hydrolysis Materials (No. ZX20190229), Startup Foundation from Shenzhen and Startup Foundation from Harbin Institute of Technology (Shenzhen).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bao, WZ., Chen, J., Li, JZ. et al. Outstanding strength and conductivity of metallic glass composites with multiscale configuration. Rare Met. 42, 3099–3113 (2023). https://doi.org/10.1007/s12598-023-02308-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02308-x