Abstract

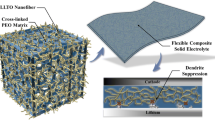

In the polyoxyethylene (PEO)-based solid-state electrolytes, the low ionic conductivity of lithium ions limits its application in solid-state lithium batteries, so optimizing the conduction path of lithium ions is beneficial to improve the ionic conductivity. In this work, we report the use of hydrothermal carbon nano-sphere (HCS) modified glass fibers (GF) as a functional filler (GF@HCS) to improve the ionic conductivity of PEO composite solid-state electrolytes. The oxygen atoms in the hydroxyl groups on the surface of HCS can be complexed with Li ions as its transport sites, which means that it can promote the long-distance transport of Li ions along the glass fiber surface. With addition of 2 wt% GF@HCS fillers, the degree of crystallinity of PEO composite solid-state electrolyte is the smallest, and the ionic conductivity is significantly increased from 8.9 × 10–5 to 4.4 × 10–4 S·cm−1 at 60 °C. Moreover, the PEO composite solid-state electrolyte exhibits better lithium–metal interface stability in symmetric lithium batteries and superior rate performance in LiFePO4 solid-state batteries.

Graphical abstract

摘要

在PEO基全固态电解质中, 由于它的锂离子离子电导率太低限制了其在固态锂电池中的应用, 因此优化锂离子的传导路径有利于提高它的离子电导率。在这项工作中, 我们报告了使用水热碳纳米球 (HCS) 改性玻璃纤维 (GF) 作为功能填料 (GF@HCS) 来提高PEO复合电解质的离子电导率。HCS表面羟基中的氧原子可以与锂离子络合作为它的传输位点, 即它可以促进锂离子沿玻璃纤维表面长距离传输。添加质量分数2 %的GF@HCS填料后, PEO复合固态电解质的结晶度最小而且它的离子电导率在 60 °C时从 8.9×10–5 S·cm–1提高到 4.4×10–4 S·cm–1。此外, 复合固态电解质在锂金属对称电池中表现出更好的界面稳定性, 在LiFePO4固态电池中表现出优异的倍率性能。

Similar content being viewed by others

References

Zheng Y, Yao Y, Ou J, Li M, Luo D, Dou H, Li Z, Amine K, Yu A, Chen Z. A review of composite solid-state electrolytes for lithium batteries: fundamentals, key materials and advanced structures. Chem Soc Rev. 2020;49(23):8790. https://doi.org/10.1039/d0cs00305k.

Cui J, Chen X, Zhou Z, Zuo M, Xiao Y, Zhao N, Shi C, Guo X. Effect of continuous pressures on electrochemical performance of Si anodes. Mater Today Energy. 2021;20:100632. https://doi.org/10.1016/j.mtener.2020.100632.

Wei WQ, Liu BQ, Gan YQ, Ma HJ, Cui DW. Protecting lithium metal anode in all-solid-state batteries with a composite electrolyte. Rare Met. 2021;40(2):409. https://doi.org/10.1007/s12598-020-01501-6.

Zhang XD, Yue FS, Liang JY, Shi JL, Li H, Guo YG. Structure design of cathode electrodes for solid-state batteries: challenges and progress. Small Struct. 2020;1(3):2000042. https://doi.org/10.1002/sstr.202000042.

Zhou Q, Ma J, Dong SM, Li XF, Cui GL. Intermolecular chemistry in solid polymer electrolytes for high-energy-density lithium batteries. Adv Mater. 2019;31(50):1902029. https://doi.org/10.1002/adma.201902029.

Ratner MA, Shriver DF. Ion-transport in solvent-free polymers. Chem Rev. 1988;88(1):109. https://doi.org/10.1021/cr00083a006.

Wang Z, Shen L, Deng S, Cui P, Yao X. 10 μm-thick high-strength solid polymer electrolytes with excellent interface compatibility for flexible all-solid-state lithium-metal batteries. Adv Mater. 2021;33(25):2100353. https://doi.org/10.1002/adma.202100353.

Guo Q, Xu F, Shen L, Wang Z, Wang J, He H, Yao X. Poly(ethylene glycol) brush on Li6.4La3Zr1.4Ta0.6O12 towards intimate interfacial compatibility in composite polymer electrolyte for flexible all-solid-state lithium metal batteries. J Power Sources. 2021;498:229934. https://doi.org/10.1016/j.jpowsour.2021.229934.

Yang S, Zhang Z, Shen L, Chen P, Gu Z, Chang M, Zhao Y, He H, Yao X. Gravity-driven poly(ethylene glycol)@Li1.5Al0.5Ge1.5(PO4)3 asymmetric solid polymer electrolytes for all-solid-state lithium batteries. J Power Sources. 2022;518:23075. https://doi.org/10.1016/j.jpowsour.2021.230756.

Papke BL, Ratner MA, Shriver DF. Vibrational spectroscopy and structure of polymer electrolytes, poly(ethylene oxide) complexes of alkali-metal salts. J Phys Chem Solids. 1981;42(6):493. https://doi.org/10.1016/0022-3697(81)90030-5.

Adebahr J, Gavelin P, Jannasch P, Ostrovskii D, Wesslen B, Jacobsson P. Cation coordination in ion-conducting gels based on PEO-grafted polymers. Solid State Ionics. 2000;135(1–4):149. https://doi.org/10.1016/s0167-2738(00)00294-0.

Mullerplathe F, Vangunsteren WF. Computer-simulation of a polymer electrolyte—lithium iodide in amorphous poly(ethylene oxide). J Chem Phys. 1995;103(11):4745. https://doi.org/10.1063/1.470611.

Maitra A, Heuer A. Cation transport in polymer electrolytes: a microscopic approach. Phys Rev Lett. 2007;98(22):227802. https://doi.org/10.1103/PhysRevLett.98.227802.

Dygas JR, Misztal-Faraj B, Floljanczyk Z, Krok F, Marzantowicz M, Zygadlo-Monikowska E. Effects of inhomogeneity on ionic conductivity and relaxations in PEO and PEO-salt complexes. Solid State Ion. 2003;157(1–4):249. https://doi.org/10.1016/s0167-2738(02)00217-5.

Neat R, Glasse M, Linford R, Hooper A. Thermal history and polymer electrolyte structure—implications for solid-state battery design. Solid State Ion. 1986;18:1088. https://doi.org/10.1016/0167-2738(86)90314-0.

Huang B, Li ZH, Zhu YM, Che Y, Wang CA. Tailored lithium metal/polymer electrolyte interface with LiTa2PO8 fillers in PEO-based composite electrolyte. Rare Met. 2022. https://doi.org/10.1007/s12598-021-01951-6.

Jayathilaka P, Dissanayake M, Albinsson I, Mellander BE. Effect of nano-porous Al2O3 on thermal, dielectric and transport properties of the (PEO)9LiTFSI polymer electrolyte system. Electrochim Acta. 2002;47(20):3257. https://doi.org/10.1016/s0013-4686(02)00243-8.

Dissanayake M, Jayathilaka P, Bokalawala RSP, Albinsson I, Mellander BE. Effect of concentration and grain size of alumina filler on the ionic conductivity enhancement of the (PEO)9LiCF3SO3:Al2O3 composite polymer electrolyte. J Power Sources. 2003;119:409. https://doi.org/10.1016/s0378-7753(03)00262-3.

Croce F, Appetecchi GB, Persi L, Scrosati B. Nanocomposite polymer electrolytes for lithium batteries. Nature. 1998;394(6692):456. https://doi.org/10.1038/28818.

Cheng Z, Liu T, Zhao B, Shen F, Jin H, Han X. Recent advances in organic-inorganic composite solid electrolytes for all-solid-state lithium batteries. Energy Storage Mater. 2021;34:388. https://doi.org/10.1016/j.ensm.2020.09.016.

Chua S, Fang RP, Sun ZH, Wu MJ, Gu Z, Wang YZ, Hart JN, Sharma N, Li F, Wang DW. Hybrid solid polymer electrolytes with two-dimensional inorganic nanofillers. Chem A Eur J. 2018;24(69):18180. https://doi.org/10.1002/chem.201804781.

Fan R, Liu C, He KQ, Cheng SHS, Chen DZ, Liao CZ, Li RKY, Tang JN, Lu ZG. Versatile strategy for realizing flexible room-temperature all-solid-state battery through a synergistic combination of salt affluent PEO and Li6.75La3Zr1.75Ta0.25O12 nanofibers. ACS Appl Mater Interfaces. 2020;12(6):7222. https://doi.org/10.1021/acsami.9b20104.

Liu W, Lee SW, Lin D, Shi F, Wang S, Sendek AD, Cui Y. Enhancing ionic conductivity in composite polymer electrolytes with well-aligned ceramic nanowires. Nat Energy. 2017;2(5):17035. https://doi.org/10.1038/nenergy.2017.35.

Sheng OW, Jin CB, Luo JM, Yuan HD, Huang H, Gan YP, Zhang J, Xia Y, Liang C, Zhang WK, Tao XY. Mg2B2O5 nanowire enabled multifunctional solid-state electrolytes with high ionic conductivity, excellent mechanical properties, and flame-retardant performance. Nano Lett. 2018;18(5):3104. https://doi.org/10.1021/acs.nanolett.8b00659.

Lin Y, Wang XM, Liu J, Miller JD. Natural halloysite nano-clay electrolyte for advanced all-solid-state lithium-sulfur batteries. Nano Energy. 2017;31:478. https://doi.org/10.1016/j.nanoen.2016.11.045.

Wang X, Hua H, Xie X, Zhang P, Zhao J. Hydroxyl on the filler surface promotes Li+ conduction in PEO all-solid-state electrolyte. Solid State Ion. 2021;372:115768. https://doi.org/10.1016/j.ssi.2021.115768.

Baccile N, Laurent G, Babonneau F, Fayon F, Titirici MM, Antonietti M. Structural characterization of hydrothermal carbon spheres by advanced solid-state MAS C-13 NMR investigations. J Phys Chem C. 2009;113(22):9644. https://doi.org/10.1021/jp901582x.

Evans J, Vincent CA, Bruce PG. Electrochemical measurement of transference numbers in polymer electrolytes. Polymer. 1987;28(13):2324. https://doi.org/10.1016/0032-3861(87)90394-6.

Sun XM, Li YD. Colloidal carbon spheres and their core/shell structures with noble-metal nanoparticles. Angew Chem Int Ed. 2004;43(5):597. https://doi.org/10.1002/anie.200352386.

Chen Z, Ma LJ, Li SQ, Geng JX, Song Q, Liu J, Wang CL, Wang H, Li J, Qin Z, Li SJ. Simple approach to carboxyl-rich materials through low-temperature heat treatment of hydrothermal carbon in air. Appl Surf Sci. 2011;257(20):8686. https://doi.org/10.1016/j.apsusc.2011.05.048.

Song XH, Gunawan P, Jiang RR, Leong SSJ, Wang KA, Xu R. Surface activated carbon nanospheres for fast adsorption of silver ions from aqueous solutions. J Hazard Mater. 2011;194:162. https://doi.org/10.1016/j.jhazmat.2011.07.076.

Gong YT, Xie L, Li HR, Wang Y. Sustainable and scalable production of monodisperse and highly uniform colloidal carbonaceous spheres using sodium polyacrylate as the dispersant. Chem Commun. 2014;50(84):12633. https://doi.org/10.1039/c4cc04998e.

Vignarooban K, Dissanayake MAKL, Albinsson I, Mellander BE. Effect of TiO2 nano-filler and EC plasticizer on electrical and thermal properties of poly(ethylene oxide) (PEO) based solid polymer electrolytes. Solid State Ion. 2014;266:25. https://doi.org/10.1016/j.ssi.2014.08.002.

Lu Y, Zhao CZ, Yuan H, Cheng XB, Huang JQ, Zhang Q. Critical current density in solid-state lithium metal batteries: mechanism, influences, and strategies. Adv Funct Mater. 2021;31(18):2009925. https://doi.org/10.1002/adfm.202009925.

Nakayama M, Wada S, Kuroki S, Nogami M. Factors affecting cyclic durability of all-solid-state lithium polymer batteries using poly(ethylene oxide)-based solid polymer electrolytes. Energy Environ Sci. 2010;3(12):1995. https://doi.org/10.1039/c0ee00266f.

Banerjee A, Wang X, Fang C, Wu EA, Meng YS. Interfaces and interphases in all-solid-state batteries with inorganic solid electrolytes. Chem Rev. 2020;120(14):6878. https://doi.org/10.1021/acs.chemrev.0c00101.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 21875195, 22021001 and 52172184).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Shen, X., Zhang, P. et al. Promoted Li+ conduction in PEO-based all-solid-state electrolyte by hydroxyl-modified glass fiber fillers. Rare Met. 42, 875–884 (2023). https://doi.org/10.1007/s12598-022-02218-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-02218-4