Abstract

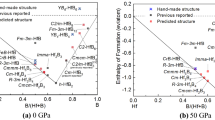

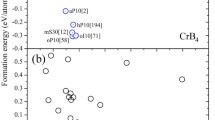

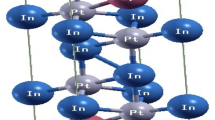

High-entropy diborides (HEBs) have attracted extensive research due to their potential ultra-high hardness. In the present work, the effects of transition metals (TM) on lattice parameters, electron work function (EWF), bonding charge density, and hardness of HEBs are comprehensively investigated by the first-principles calculations, including (TiZrHfNbTa)B2, (TiZrHfNbMo)B2, (TiZrHfTaMo)B2, (TiZrNbTaMo)B2, and (TiHfNbTaMo)B2. It is revealed that the disordered TM atoms result in a severe local lattice distortion and the formation of weak spots. In view of bonding charge density, it is understood that the degree of electron contribution of TM atoms directly affects the bonding strength of the metallic layer, contributing to the optimized hardness of HEBs. Moreover, the proposed power-law-scaled relationship integrating the EWF and the grain size yields an excellent agreement between our predicted results and those reported experimental ones. It is found that the HEBs exhibit relatively high hardness which is higher than those of single transition metal diborides. In particular, the hardness of (TiZrNbTaMo)B2 and (TiHfNbTaMo)B2 can be as high as 29.15 and 28.02 GPa, respectively. This work provides a rapid strategy to discover/design advanced HEBs efficiently, supported by the coupling hardening mechanisms of solid solution and grain refinement based on the atomic and electronic interactions.

Graphical abstract

摘要

高熵二硼化物(HEBs)因其潜在的超高硬度而引起了广泛的研究。本文采用第一原理计算方法,以(TiZrHfNbTa)B2、(TiZrHfNbMo)B2、(TiZrHfTaMo)B2、(TiZrNbTaMo)B2和(TiHfNbTaMo)B2五种高熵二硼化物为例,全面研究了过渡金属对高熵二硼化物晶格参数、电子功函数、键合电子密度和硬度的影响。结果表明,不同元素之间的原子大小差异导致了严重的局域晶格畸变和薄弱点的形成。结合键合电子密度可知,金属原子的电子贡献程度直接影响金属层的键合强度,进而优化了高熵二硼化物的硬度。此外,本工作建立了耦合电子功函数和晶粒尺寸预测硬度的三参数幂律模型,预测的硬度值与实验值吻合较好。预测结果表明,高熵二硼化物具有较高的硬度,并且高于单金属二硼化物的硬度。其中,(TiZrNbTaMo)B2和(TiHfNbTaMo)B2的硬度分别高达29.15和28.02 GPa。本工作阐明了高熵二硼化物固溶强化与细晶强化的耦合强化机制,为先进超硬高熵硼化物的设计提供了一种有效的预测方法。

Similar content being viewed by others

References

Yeh JW, Chen SK, Gan JY, Lin SJ, Chin TS, Shun TT, Tsau CH, Chang SY. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall Mater Trans A-Phys Metall Mater Sci. 2004;35A(8):2533. https://doi.org/10.1007/s11661-006-0234-4.

Cantor B, Chang ITH, Knight P, Vincent AJB. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A. 2004;375:213. https://doi.org/10.1016/j.msea.2003.10.257.

Wang Y, Yan M, Zhu Q, Wang WY, Wu Y, Hui X, Otis R, Shang SL, Liu ZK, Chen LL. Computation of entropies and phase equilibria in refractory V-Nb-Mo-Ta-W high-entropy alloys. Acta Mater. 2018;143:88. https://doi.org/10.1016/j.actamat.2017.10.017.

Zhang Y, Zuo TT, Tang Z, Gao MC, Dahmen KA, Liaw PK, Lu ZP. Microstructures and properties of high-entropy alloys. Prog Mater Sci. 2014;61:1. https://doi.org/10.1016/j.pmatsci.2013.10.001.

Miracle DB, Senkov ON. A critical review of high entropy alloys and related concepts. Acta Mater. 2017;122:448. https://doi.org/10.1016/j.actamat.2016.08.081.

Huang C, Zhang Y, Vilar R, Shen J. Dry sliding wear behavior of laser clad TiVCrAlSi high entropy alloy coatings on Ti–6Al–4V substrate. Mater Des. 2012;41:338. https://doi.org/10.1016/j.matdes.2012.04.049.

Zhao YJ, Qiao JW, Ma SG, Gao MC, Yang HJ, Chen MW, Zhang Y. A hexagonal close-packed high-entropy alloy: the effect of entropy. Mater Des. 2016;96:10. https://doi.org/10.1016/j.matdes.2016.01.149.

Zou Y, Ma H, Spolenak R. Ultrastrong ductile and stable high-entropy alloys at small scales. Nat Commun. 2015;6:7748. https://doi.org/10.1038/ncomms8748.

Senkov ON, Miller JD, Miracle DB, Woodward C. Accelerated exploration of multi-principal element alloys with solid solution phases. Nat Commun. 2015;6:6529. https://doi.org/10.1038/ncomms7529.

Lu SY, Miao JW, Lu YP. Strengthening and toughening of multi-principal high-entropy alloys. Chin J Rare Met. 2021;45(5):530. https://doi.org/10.13373/j.cnki.cjrm.XY20080042.

Nong Z, Zhu J, Zhao R. Prediction of structure and elastic properties of AlCrFeNiTi system high entropy alloys. Intermetallics. 2017;86:134. https://doi.org/10.1016/j.intermet.2017.03.014.

Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO. A fracture-resistant high-entropy alloy for cryogenic applications. Science. 2014;345(6201):1153. https://doi.org/10.1126/science.1254581.

Guo YX, Liu QB, Shang XJ. In situ TiN-reinforced CoCr2FeNiTi0.5 high-entropy alloy composite coating fabricated by laser cladding. Rare Met. 2020;39(10):1190. https://doi.org/10.1007/s12598-018-1194-8.

Wang YX, Yang YJ, Yang HJ, Zhang M, Qiao JW. Effect of nitriding on the tribological properties of Al1.3CoCuFeNi2 high-entropy alloy. J Alloy Compd. 2017;725:365. https://doi.org/10.1016/j.jallcom.2017.07.132.

Rost CM, Sachet E, Borman T, Moballegh A, Dickey EC, Hou D, Jones JL, Curtarolo S, Maria JP. Entropy-stabilized oxides. Nat Commun. 2015;6:8485. https://doi.org/10.1038/ncomms9485.

Mangaiyarkkarasi J, Saravanan R. Charge distribution around Ba–O and Ti–O bonds in BaTi1−xZrxO3 through powder X-ray diffraction. Rare Met. 2021;40(12):3660. https://doi.org/10.1007/s12598-016-0812-6.

Chen H, Xiang HM, Dai FZ, Liu JC, Zhou YC. Porous high entropy ((Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)B2: a novel strategy towards making ultrahigh temperature ceramics thermal insulating. J Mater Sci Technol. 2019;35(10):2404. https://doi.org/10.1016/j.jmst.2019.05.059.

Qin MD, Yan QZ, Wang HR, Hu CZ, Vecchio KS, Luo J. High-entropy monoborides: towards superhard materials. Scr Mater. 2020;189:101. https://doi.org/10.1016/j.scriptamat.2020.08.018.

Yu D, Yin J, Zhang B, Liu X, Huang Z. Recent development of high-entropy transitional carbides: a review. J Ceram Soc JPN. 2020;128(7):329. https://doi.org/10.2109/jcersj2.19242.

Vyatskikh AL, MacDonald BE, Dupuy AD, Lavernia EJ, Schoenung JM, Hahn H. High entropy silicides: CALPHAD-guided prediction and thin film fabrication. Scr Mater. 2021;201:113914. https://doi.org/10.1016/j.scriptamat.2021.113914.

Xiang HM, Xing Y, Dai FZ, Wang HJ, Su L, Miao L, Zhang GJ, Wang YG, Qi XW, Yao L, Wang HL, Zhao B, Li JQ, Zhou YC. High-entropy ceramics: present status, challenges, and a look forward. J Adv Ceram. 2021;10(3):385. https://doi.org/10.1007/s40145-021-0477-y.

Feng L, Fahrenholtz WG, Hilmas GE. Processing of dense high-entropy boride ceramics. J Eur Ceram Soc. 2020;40(12):3815. https://doi.org/10.1016/j.jeurceramsoc.2020.03.065.

Ye YF, Wang Q, Lu J, Liu CT, Yang Y. High-entropy alloy: challenges and prospects. Mater. 2016;19(6):349. https://doi.org/10.1016/j.mattod.2015.11.026.

Zhang Y, Sun SK, Guo WM, Zhang W, Xu L, Yuan JH, Guan DK, Wang W, You Y, Lin HT. Fabrication of textured (Hf0.2Zr0.2Ta0.2Cr0.2Ti0.2)B2 high-entropy ceramics. J Eur Ceram Soc. 2021;41(1):1015. https://doi.org/10.1016/j.jeurceramsoc.2020.08.071.

Feng L, Monteverde F, Fahrenholtz WG, Hilmas GE. Superhard high-entropy AlB2-type diboride ceramics. Scr Mater. 2021;199:113855. https://doi.org/10.1016/j.scriptamat.2021.113855.

Kvashnin AG, Allahyari Z, Oganov AR. Computational discovery of hard and superhard materials. J Appl Phys. 2019;126(4): 040901. https://doi.org/10.1063/1.5109782.

Solozhenko VL, Dub SN, Novikov NV. Mechanical properties of cubic BC2N, a new superhard phase. Diam Relat Mat. 2001;10(12):2228. https://doi.org/10.1016/s0925-9635(01)00513-1.

Zhang Y, Jiang ZB, Sun SK, Guo WM, Chen QS, Qiu JX, Plucknett K, Lin HT. Microstructure and mechanical properties of high-entropy borides derived from boro/carbothermal reduction. J Eur Ceram Soc. 2019;39(13):3920. https://doi.org/10.1016/j.jeurceramsoc.2019.05.017.

Zhang Y, Guo WM, Jiang ZB, Zhu QQ, Sun SK, You Y, Plucknett K, Lin HT. Dense high-entropy boride ceramics with ultra-high hardness. Scr Mater. 2019;164:135. https://doi.org/10.1016/j.scriptamat.2019.01.021.

Qin MD, Gild J, Wang HR, Harrington T, Vecchio KS, Luo J. Dissolving and stabilizing soft WB2 and MoB2 phases into high-entropy borides via boron-metals reactive sintering to attain higher hardness. J Eur Ceram Soc. 2020;40(12):4348. https://doi.org/10.1016/j.jeurceramsoc.2020.03.063.

Dai FZ, Sun YJ, Wen B, Xiang HM, Zhou YC. Temperature dependent thermal and elastic properties of high entropy ((Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2: molecular dynamics simulation by deep learning potential. J Mater Sci Technol. 2021;72:8. https://doi.org/10.1016/j.jmst.2020.07.014.

Wang YP, Gan GY, Wang W, Yang Y, Tang BY. Ab initio prediction of mechanical and electronic properties of ultrahigh temperature high-entropy ceramics (Hf0.2Zr0.2Ta0.2M0.2Ti0.2)B2 (M=Nb, Mo, Cr). Phys Status Solidi B-Basic Solid State Phys. 2018;255(8):1800011. https://doi.org/10.1002/pssb.201800011.

Wang WY, Darling KA, Wang Y, Shang SL, Kecskes LJ, Hui XD, Liu ZK. Power law scaled hardness of Mn strengthened nanocrystalline AlMn non-equilibrium solid solutions. Scr Mater. 2016;120:31. https://doi.org/10.1016/j.scriptamat.2016.04.003.

Feng L, Fahrenholtz WG, Hilmas GE, Monteverde F. Effect of Nb content on the phase composition, densification, microstructure, and mechanical properties of high-entropy boride ceramics. J Eur Ceram Soc. 2021;41(1):92. https://doi.org/10.1016/j.jeurceramsoc.2020.08.058.

Ma MD, Ye BL, Han YJ, Sun L, He JL, Chu YH. High-pressure sintering of ultrafine-grained high-entropy diboride ceramics. J Am Ceram Soc. 2020;103(12):6655. https://doi.org/10.1111/jace.17387.

Zou C, Li J, Wang WY, Zhang Y, Tang B, Wang H, Lin D, Wang J, Kou H, Xu D. Revealing the local lattice strains and strengthening mechanisms of Ti alloys. Comp Mater Sci. 2018;152:169. https://doi.org/10.1016/j.commatsci.2018.05.028.

Liu JX, Shen XQ, Wu Y, Li F, Liang YC, Zhang GJ. Mechanical properties of hot-pressed high-entropy diboride-based ceramics. J Adv Ceram. 2020;9(4):503. https://doi.org/10.1007/s40145-020-0383-8.

Trinkle DR, Woodward C. The chemistry of deformation: how solutes soften pure metals. Science. 2005;310(5754):1665. https://doi.org/10.1126/science.1118616.

Zou C, Li J, Wang WY, Zhang Y, Lin D, Yuan R, Wang X, Tang B, Wang J, Gao X, Kou H, Hui X, Zeng X, Qian M, Song H, Liu ZK, Xu D. Integrating data mining and machine learning to discover high-strength ductile titanium alloys. Acta Mater. 2021;202:211. https://doi.org/10.1016/j.actamat.2020.10.056.

Mellor WM, Kaufmann K, Dippo OF, Figueroa SD, Schrader GD, Vecchio KS. Development of ultrahigh-entropy ceramics with tailored oxidation behavior. J Eur Ceram Soc. 2021;41(12):5791. https://doi.org/10.1016/j.jeurceramsoc.2021.05.010.

Wang WY, Shang SL, Wang Y, Han F, Darling KA, Wu Y, Xie X, Senkov ON, Li J, Hui XD, Dahmen KA, Liaw PK, Kecskes LJ, Liu ZK. Atomic and electronic basis for the serrations of refractory high-entropy alloys. NPJ Comput Mater. 2017;3(1):23. https://doi.org/10.1038/s41524-017-0024-0.

Lu H, Hua G, Li D. Dependence of the mechanical behavior of alloys on their electron work function-an alternative parameter for materials design. Appl Phys Lett. 2013;103(26): 261902. https://doi.org/10.1063/1.4852675.

Hua G, Li D. The correlation between the electron work function and yield strength of metals. Phys Status Solidi B-Basic Res. 2012;249(8):1517. https://doi.org/10.1002/pssb.201248051.

Gao FM, He JL, Wu ED, Liu SM, Yu DL, Li DC, Zhang SY, Tian YJ. Hardness of covalent crystals. Phys Rev Lett. 2003;91(1): 015502. https://doi.org/10.1103/PhysRevLett.91.015502.

Wang Y, Wang WY, Chen LQ, Liu ZK. Bonding charge density from atomic perturbations. J Comput Chem. 2015;36(13):1008. https://doi.org/10.1002/jcc.23880.

Tian F, Lin DY, Gao X, Zhao YF, Song HF. A structural modeling approach to solid solutions based on the similar atomic environment. J Chem Phys. 2020;153(3): 034101. https://doi.org/10.1063/5.0014094.

Song H, Tian F, Hu QM, Vitos L, Wang Y, Shen J, Chen N. Local lattice distortion in high-entropy alloys. Phys Rev Mater. 2017;1(2):023404. https://doi.org/10.1103/PhysRevMaterials.1.023404.

van de Walle A, Asta M, Ceder G. The alloy theoretic automated toolkit: a user guide. Calphad: Comput Coupling Ph Diagr Thermochem. 2002;26(4):539. https://doi.org/10.1016/s0364-5916(02)80006-2.

Kresse G, Furthmuller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B. 1996;54(16):11169. https://doi.org/10.1103/PhysRevB.54.11169.

Kresse G, Furthmuller J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp Mater Sci. 1996;6(1):15. https://doi.org/10.1016/0927-0256(96)00008-0.

Kresse G, Joubert D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys Rev B. 1999;59(3):1758. https://doi.org/10.1103/PhysRevB.59.1758.

Wang Y, Perdew JP. Correlation hole of the spin-polarized electron-gas, with exact small-wave-vector and high density scaling. Phys Rev B. 1991;44(24):13298. https://doi.org/10.1103/PhysRevB.44.13298.

Methfessel M, Paxton AT. High-precision sampling for brillouin-zone integration in matals. Phys Rev B. 1989;40(6):3616. https://doi.org/10.1103/PhysRevB.40.3616.

Blochl PE, Jepsen O, Andersen OK. Improved tetrahedron method for brillouin-zone integrations. Phys Rev B. 1994;49(23):16223. https://doi.org/10.1103/PhysRevB.49.16223.

Birch F. Finite elastic strain of cubic crystals. Phys Rev. 1947;71(11):809. https://doi.org/10.1103/PhysRev.71.809.

Murnaghan FD. The compressibility of media under extreme pressures. Proc Natl Acad Sci USA. 1944;30:244. https://doi.org/10.1073/pnas.30.9.244.

Momma K, Izumi F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J Appl Crystallogr. 2011;44:1272. https://doi.org/10.1107/s0021889811038970.

Halas S, Durakiewicz T. Work functions of elements expressed in terms of the fermi energy and the density of free electrons. J Phys Condens Matter. 1998;10(48):10815. https://doi.org/10.1088/0953-8984/10/48/005.

Wang WY, Shang SL, Wang Y, Kim H, Darling KA, Kecskes LJ, Mathaudhu SN, Hui XD, Liu ZK. Solid-solution hardening in Mg-Gd-TM (TM = Ag, Zn, and Zr) alloys: an integrated density functional theory and electron work function study. Jom. 2015;67(10):2433. https://doi.org/10.1007/s11837-015-1555-9.

Ding QQ, Zhang Y, Chen X, Fu XQ, Chen DK, Chen SJ, Gu L, Wei F, Bei HB, Gao YF, Wen MR, Li JX, Zhang Z, Zhu T, Ritchie RO, Yu Q. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature. 2019;574(7777):223. https://doi.org/10.1038/s41586-019-1617-1.

Lei ZF, Liu XJ, Wu Y, Wang H, Jiang SH, Wang SD, Hui XD, Wu YD, Gault B, Kontis P, Raabe D, Gu L, Zhang QH, Chen HW, Wang HT, Liu JB, An K, Zeng QS, Nieh TG, Lu ZP. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature. 2018;563(7732):546. https://doi.org/10.1038/s41586-018-0685-y.

Santodonato LJ, Zhang Y, Feygenson M, Parish CM, Gao MC, Weber RJK, Neuefeind JC, Tang Z, Liaw PK. Deviation from high-entropy configurations in the atomic distributions of a multi-principal-element alloy. Nat Commun. 2015;6:5964. https://doi.org/10.1038/ncomms6964.

Harrington TJ, Gild J, Sarker P, Toher C, Rost CM, Dippo OF, McElfresh C, Kaufmann K, Marin E, Borowski L, Hopkins PE, Luo J, Curtarolo S, Brenner DW, Vecchio KS. Phase stability and mechanical properties of novel high entropy transition metal carbides. Acta Mater. 2019;166:271. https://doi.org/10.1016/j.actamat.2018.12.054.

Liu D, Wen TQ, Ye BL, Chu YH. Synthesis of superfine high-entropy metal diboride powders. Scr Mater. 2019;167:110. https://doi.org/10.1016/j.scriptamat.2019.03.038.

Gild J, Zhang Y, Harrington T, Jiang S, Hu T, Quinn MC, Mellor WM, Zhou N, Vecchio K, Luo J. High-entropy metal diborides: a new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Sci Rep. 2016;6(1):37946. https://doi.org/10.1038/srep37946.

Shein IR, Ivanovskii AL. Elastic properties of mono- and polycrystalline hexagonal AlB2-like diborides of s, p and d metals from first-principles calculations. J Phys Condens Matter. 2008;20(41):415218. https://doi.org/10.1088/0953-8984/20/41/415218.

Blaha P, Schwarz K, Dederichs PH. Electrinic-structure of hcp metals. Phys Rev B. 1988;38(14):9368. https://doi.org/10.1103/PhysRevB.38.9368.

Dirras G, Lilensten L, Djemia P, Laurent-Brocq M, Tingaud D, Couzinie JP, Perriere L, Chauveau T, Guillot I. Elastic and plastic properties of as-cast equimolar TiHfZrTaNb high-entropy alloy. Mater Sci Eng A-Struct Mater Prop Microstruct Process. 2016;654:30. https://doi.org/10.1016/j.msea.2015.12.017.

Tallarita G, Licheri R, Garroni S, Orru R, Cao G. Novel processing route for the fabrication of bulk high-entropy metal diborides. Scr Mater. 2019;158:100. https://doi.org/10.1016/j.scriptamat.2018.08.039.

Sun L, Gao Y, Xiao B, Li Y, Wang G. Anisotropic elastic and thermal properties of titanium borides by first-principles calculations. J Alloy Compd. 2013;579:457. https://doi.org/10.1016/j.jallcom.2013.06.119.

Zhang X, Luo X, Han J, Li J, Han W. Electronic structure, elasticity and hardness of diborides of zirconium and hafnium: first principles calculations. Comp Mater Sci. 2008;44(2):411. https://doi.org/10.1016/j.commatsci.2008.04.002.

Vajeeston P, Ravindran P, Ravi C, Asokamani R. Electronic structure, bonding, and ground-state properties of AlB2-type transition-metal diborides. Phys Rev B. 2001;63(4):045115. https://doi.org/10.1103/PhysRevB.63.045115.

Post B, Glaser FW, Moskowitz D. Transition metal diborides. Acta Metall. 1954;2(1):20. https://doi.org/10.1016/0001-6160(54)90090-5.

Chen XL, Tu QY, Dai L, Xu YP. A note on the AlB2 type structure. Mod Phys Lett B. 2002;16(3):73. https://doi.org/10.1142/s021798490200349x.

Oses C, Toher C, Curtarolo S. High-entropy ceramics. Nat Rev Mater. 2020;5(4):295. https://doi.org/10.1038/s41578-019-0170-8.

Wang WY, Wang J, Lin D, Zou C, Wu Y, Hu Y, Shang SL, Darling KA, Wang Y, Hui X, Li J, Kecskes LJ, Liaw PK, Liu ZK. Revealing the microstates of body-centered-cubic (BCC) equiatomic high entropy alloys. J Phase Equilib Diffus. 2017;38(4):404. https://doi.org/10.1007/s11669-017-0565-4.

Gilman JJ. Why diamond is very hard. Philos Mag A. 2002;82(10):1811. https://doi.org/10.1080/01418610208235692.

Licheri R, Musa C, Orru R, Cao G, Sciti D, Silvestroni L. Bulk monolithic zirconium and tantalum diborides by reactive and non-reactive spark plasma sintering. J Alloy Compd. 2016;663:351. https://doi.org/10.1016/j.jallcom.2015.12.096.

Wang YL, Kang YL, Wang WY, Ding QQ, Zhou JG, Yang SK. Circumventing silver oxidation induced performance degradation of silver surface-enhanced Raman scattering substrates. Nanotechnology. 2018;29(41): 414001. https://doi.org/10.1088/1361-6528/aad678.

Chen XL, Tu QY, He M, Dai L, Wu L. The bond ionicity of MB2 (M = Mg, Ti, V, Cr, Mn, Zr, Hf, Ta, Al and Y). J Phys Condens Matter. 2001;13(29):L723. https://doi.org/10.1088/0953-8984/13/29/105.

Lu J, Ravichandran G, Johnson WL. Deformation behavior of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass over a wide range of strain-rates and temperatures. Acta Mater. 2003;51(12):3429. https://doi.org/10.1016/s1359-6454(03)00164-2.

Ogata S, Li J, Yip S. Ideal pure shear strength of aluminum and copper. Science. 2002;298(5594):807. https://doi.org/10.1126/science.1076652.

Meyer JC, Kurasch S, Park HJ, Skakalova V, Kunzel D, Gross A, Chuvilin A, Algara-Siller G, Roth S, Iwasaki T, Starke U, Smet JH, Kaiser U. Experimental analysis of charge redistribution due to chemical bonding by high-resolution transmission electron microscopy. Nat Mater. 2011;10(3):209. https://doi.org/10.1038/nmat2941.

Luo K, Li W, Zhang HY, Su HL. Changes of hardness and electronic work function of Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass on annealing. Philos Mag Lett. 2011;91(4):237. https://doi.org/10.1080/09500839.2010.539989.

Gild J, Wright A, Quiambao-Tomko K, Qin M, Tomko JA, bin Hoque MS, Luo J. Thermal conductivity and hardness of three single-phase high-entropy metal diborides fabricated by borocarbothermal reduction and spark plasma sintering. Ceram Int. 2020;46(5):6906. https://doi.org/10.1016/j.ceramint.2019.11.186.

Yu Q, Shan ZW, Li J, Huang XX, Xiao L, Sun J, Ma E. Strong crystal size effect on deformation twinning. Nature. 2010;463(7279):335. https://doi.org/10.1038/nature08692.

Liu XC, Zhang HW, Lu K. Strain-induced ultrahard and ultrastable nanolaminated structure in nickel. Science. 2013;342(6156):337. https://doi.org/10.1126/science.1242578.

Gupta RK, Fabijanic D, Zhang R, Birbilis N. Corrosion behaviour and hardness of in situ consolidated nanostructured Al and Al-Cr alloys produced via high-energy ball milling. Corros Sci. 2015;98:643. https://doi.org/10.1016/j.corsci.2015.06.011.

Bhaumik SK, Divakar C, Singh AK, Upadhyaya GS. Synthesis and sintering of TiB2 and TiB2-TiC composite under high pressure. Mater Sci Eng A-Struct Mater Prop Microstruct Process. 2000;279(1–2):275. https://doi.org/10.1016/s0921-5093(99)00217-8.

Chakraborty S, Mallick AR, Debnath D, Das PK. Densification, mechanical and tribological properties of ZrB2 by SPS: effect of pulsed current. Int J Refract Hard Met. 2015;48:150. https://doi.org/10.1016/j.ijrmhm.2014.09.004.

Ni DW, Zhang GJ, Kan YM, Wang PL. Hot pressed HfB2 and HfB2-20 vol%SiC ceramics based on HfB2 powder synthesized by borothermal reduction of HfO2. Int J Appl Ceram. 2010;7(6):830. https://doi.org/10.1111/j.1744-7402.2009.02404.x.

Gu Q, Krauss G, Steurer W. Transition metal borides: superhard versus ultra-incompressihle. Adv Mater. 2008;20(19):3620. https://doi.org/10.1002/adma.200703025.

Chung HY, Weinberger MB, Levine JB, Kavner A, Yang JM, Tolbert SH, Kaner RB. Synthesis of ultra-incompressible superhard rhenium diboride at ambient pressure. Science. 2007;316(5823):436. https://doi.org/10.1126/science.1139322.

Wada T, Yamashita N. Formation of CBN films by ion-beam assisted deposition. J Vac Sci Technol A. 1992;10(3):515. https://doi.org/10.1116/1.578181.

Mukhopadhyay A, Raju GB, Basu B, Suri AK. Correlation between phase evolution, mechanical properties and instrumented indentation response of TiB2-based ceramics. J Eur Ceram Soc. 2009;29(3):505. https://doi.org/10.1016/j.jeurceramsoc.2008.06.030.

Chakraborty S, Debnath D, Mallick AR, Das PK. Mechanical and thermal properties of hot pressed ZrB2 system with TiB2. Int J Refract Met Hard Mat. 2014;46:35. https://doi.org/10.1016/j.ijrmhm.2014.05.004.

Zapata Solvas E, Jayaseelan DD, Lin HT, Brown P, Lee WE. Mechanical properties of ZrB2- and HfB2-based ultra-high temperature ceramics fabricated by spark plasma sintering. J Eur Ceram Soc. 2013;33(7):1373. https://doi.org/10.1016/j.jeurceramsoc.2012.12.009.

Sairam K, Sonber JK, Murthy TSRC, Subramanian C, Fotedar RK, Hubli RC. Reaction spark plasma sintering of niobium diboride. Int J Refract Hard Met. 2014;43:259. https://doi.org/10.1016/j.ijrmhm.2013.12.011.

Musa C, Orrù R, Licheri R, Cao G. Spark plasma synthesis and densification of TaB2 by pulsed electric current sintering. Mater Lett. 2011;65(19–20):3080. https://doi.org/10.1016/j.matlet.2011.06.094.

Locci AM, Licheri R, Orru R, Cao G. Reactive spark plasma sintering of rhenium diboride. Ceram Int. 2009;35(1):397. https://doi.org/10.1016/j.ceramint.2007.11.012.

Hebbache M, Stuparević L, Živković D. A new superhard material: osmium diboride OsB2. Solid State Commun. 2006;139(5):227. https://doi.org/10.1016/j.ssc.2006.05.041.

Mohammadi R, Lech AT, Xie M, Weaver BE, Yeung MT, Tolbert SH, Kaner RB. Tungsten tetraboride, an inexpensive superhard material. Proc Natl Acad Sci USA. 2011;108(27):10958. https://doi.org/10.1073/pnas.1102636108.

Simunek A, Vackar J. Hardness of covalent and ionic crystals: first-principle calculations. Phys Rev Lett. 2006;96(8): 085501. https://doi.org/10.1103/PhysRevLett.96.085501.

Li KY, Wang XT, Zhang FF, Xue DF. Electronegativity identification of novel superhard materials. Phys Rev Lett. 2008;100(23):235504. https://doi.org/10.1103/PhysRevLett.100.235504.

Chen XQ, Niu HY, Li DZ, Li YY. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics. 2011;19(9):1275. https://doi.org/10.1016/j.intermet.2011.03.026.

Dai FZ, Wen B, Sun Y, Xiang H, Zhou Y. Theoretical prediction on thermal and mechanical properties of high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C by deep learning potential. J Mater Sci Technol. 2020;43:168. https://doi.org/10.1016/j.jmst.2020.01.005.

Tian YJ, Xu B, Zhao ZS. Microscopic theory of hardness and design of novel superhard crystals. Int J Refract Met Hard Mat. 2012;33:93. https://doi.org/10.1016/j.ijrmhm.2012.02.021.

Ma D, Stoica AD, Wang XL. Power-law scaling and fractal nature of medium-range order in metallic glasses. Nat Mater. 2009;8(1):30. https://doi.org/10.1038/nmat2340.

Acknowledgements

This study was financially supported by the Science Challenge Project (No. TZ 2018002). First-principles calculations were carried out on the clusters at the Northwestern Polytechnical University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yao, G., Wang, WY., Li, PX. et al. Electronic structures and strengthening mechanisms of superhard high-entropy diborides. Rare Met. 42, 614–628 (2023). https://doi.org/10.1007/s12598-022-02152-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-02152-5