Abstract

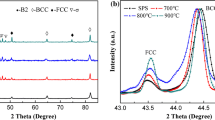

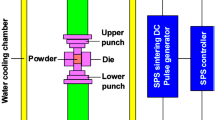

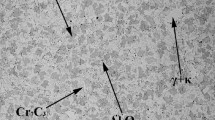

2024 aluminum alloys were consolidated by using spark plasma sintering (SPS) method, and then heat treated by solid solution treatment (SST) and aging treatment (AT) procedures. The average grain size of bulk samples sintered with 5, 20 and 50 μm powders was 3.72, 4.73 and 8.11 μm, respectively. The difference between the average grain size and original powder size was attributed to the recrystallization during short sintering process. The number of the inclusion phases in these samples decreased after SST and increased after subsequent AT. Besides, it was observed that intergranular corrosion (IGC) cracks initiated from stable pits due to the electrochemical inhomogeneity between the intermetallic particles (IMPs) and the aluminum matrix (176.02, 110.83 and 164.80 mV for as-SPS, as-SST and as-AT samples, respectively). Besides, the cracks would propagate along the grain boundaries (GBs) and bypass the IMPs at GBs during propagation. It was revealed that the sample after SST presented the best IGC resistance, and this was ascribed to the reduce of IMPs, both in size and number.

Graphical abstact

摘要

本文采用放电等离子烧结法制备了2024铝合金, 并对铝合金进行固溶和时效热处理, 研究了2024铝合金的晶间腐蚀行为随热处理过程的演变规律。结果表明, 烧结的 2024铝合金的晶间腐蚀敏感性在固溶处理后提升, 而在时效处理后降低。分析表明这是由于固溶处理后的试样中的析出相的数量减少, 尺寸降低。铝合金表面的晶间腐蚀裂纹起源于稳定的点蚀坑, 而点蚀萌生是由于析出相的存在, 析出相的数量减少使得点蚀萌生位点减少。同时, 研究发现裂纹沿晶界拓展, 固溶后试样的晶间腐蚀敏感性降低是由于析出相与铝基体间电势差降低 (烧结后, 固溶后和时效后的电势差分别为: 176.02, 110.83以及164.80 mV), 从而降低了裂纹拓展驱动力。

Similar content being viewed by others

References

Zhang X, Jiao Y, Yu Y, Liu B, Hashimoto T, Liu H, Dong Z. Intergranular corrosion in AA2024-T3 aluminium alloy: the influence of stored energy and prediction. Corros Sci. 2019;155:1.

Hao XL, Zhao N, Jin HH, Ma W, Zhang DH. Nickel-free sealing technology for anodic oxidation film of aluminum alloy at room temperature. Rare Met. 2021;40(4):968.

Ralston K, Virtanen S, Birbilis N. Effect of processing on grain size and corrosion of AA2024-T3. Corrosion. 2011;67(10):105001.

Song F, Zhang X, Liu S, Tan Q, Li D. The effect of quench rate and overageing temper on the corrosion behaviour of AA7050. Corros Sci. 2014;78(8):276.

Li XQ, Chen WP, Long Y, Hu LX, Wang ED. Unique microstructure and property of a 2024 aluminum aIloy subjected to upsetting extrusion multiple processing. Rare Met. 2004;23(1):74.

Aydn H, Bayram A, Uguz A, Akay KS. Tensile properties of friction stir welded joints of 2024 aluminum alloys in different heat-treated-state. Mater Des. 2009;30(6):2211.

Khoshnaw FM, Gardi RH. Effect of aging time and temperature on exfoliation corrosion of aluminum alloys 2024–T3 and 7075–T6. Werkst Korros. 2007;58(5):345.

Xu HB, Sun HB, Yang H, Chi LX, Chen J. Microstructure and properties of joint for stirring brazing of dissimilar Al/Mg alloy during heating processes. Rare Met. 2015;34(4):245.

Zou XL, Yan H, Chen XH. Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment. Trans Nonferrous Metal Soc. 2017;27(10):2146.

Jia SF, Zhan LH, Zhang J. Influence of solid solution treatment on microstructure and mechanical properties of 2219 aluminium alloy. Mater Res Innov. 2014;18(sup2):52.

Zhang XX, Liu B, Zhou XR, Zhang T, Gao YJ, Dong ZH, Wang JJ, Nilsson J. The influence of room temperature storage on intergranular corrosion susceptibility of AA6082 Al-Mg-Si alloy. Corros Commun. 2021. https://doi.org/10.1016/j.corcom.2021.09.004.

Pan Y, Zhang D, Liu H, Zhuang L, Zhang J. Precipitation hardening and intergranular corrosion behavior of novel Al-Mg-Zn(-Cu) alloys. J Alloy Compd. 2021;853:157199.

Liu YH, Yan LM, Hou XH, Huang DN, Zhang JB, Shen J. Precipitates and corrosion resistance of an Al-Zn-Mg-Cu-Zr plate with different percentage reduction per passes. Rare Met. 2018;37(5):381.

Tian W, Li S, Wang B, Liu J, Yu M. Pitting corrosion of naturally aged AA 7075 aluminum alloys with bimodal grain size. Corros Sci. 2016;113(9):1.

Zhang B, Ma XL. A review—pitting corrosion initiation investigated by TEM. J Mater Sci Technol. 2019;35(7):1455.

Ilevbare G, Kelly R, Scully J. Role of intermetallic phases in localized corrosion of AA5083. J Electrochem Soc. 2004;151(8):B453.

Yasakau K, Zheludkevich M, Lamaka S, Ferreira M. Role of intermetallic phases in localized corrosion of AA5083. Electrochim Acta. 2007;52(27):7651.

Boag A, Taylor R, Muster T, Goodman N, McCulloch D, Ryan C, Route B, Jamieson D, Hughes AE. Stable pit formation on AA2024-T3 in a NaCl environment. Corros Sci. 2010;52(1):90.

Ghanbari E, Saatchi A, Lei X, Macdonald DD. Studies on pitting corrosion of Al-Cu-Li alloys Part II: breakdown potential and pit initiation. Mater (Basel). 2019;12(11):1786.

Boag A, Hughes A, Glenn A, Muster T, McCulloch D. Corrosion of AA2024-T3 Part I: localised corrosion of isolated IM particles. Corros Sci. 2011;53(1):17.

Sun Y, Pan Q, Sun Y, Wang W, Zhuang Z, Wang X, Hu Q. Localized corrosion behavior associated with Al7Cu2Fe intermetallic in Al-Zn-Mg-Cu-Zr alloy. J Alloy Compd. 2019;783(12):329.

Chang SH, Lee SC, Huang KT, Liang C. Effects of solid-solution treatment on microstructure and mechanical properties of HIP treated alloy 718. Appl Mech Mater. 2011;117–119:1315.

Zhang X, Zhang K, Li X, Deng X, Li Y, Ma M, Shi Y. Effect of solid-solution treatment on corrosion and electrochemical behaviors of Mg-15Y alloy in 3.5 wt.% NaCl solution. J Rare Earth. 2012;30(11):1158.

Xu DK, Birbilis N, Lashansky D, Rometsch PA, Muddle BC. Effect of solution treatment on the corrosion behaviour of aluminium alloy AA7150: optimisation for corrosion resistance. Corros Sci. 2011;53(1):217.

Zander D, Schnatterer C, Altenbach C, Chaineux V. Microstructural impact on intergranular corrosion and the mechanical properties of industrial drawn 6056 aluminum wires. Mater Des. 2015;83(D22):49.

Ma Q, Zhang D, Zhuang L, Zhang J. Intergranular corrosion resistance of Zn modified 5××× series Al alloy during retrogression and re-aging treatment. Mater Charact. 2018;144:264.

Lin YC, Jiang YQ, Xia YC, Zhang XC, Zhou HM, Deng J. Effects of creep-aging processing on the corrosion resistance and mechanical properties of an Al-Cu-Mg alloy. Mat Sci Eng A. 2014;605:192.

Liu G, Lin YC, Zhang XC, Jiang YQ. Effects of two-stage creep-aging on precipitates of an Al-Cu-Mg alloy. Mat Sci Eng A. 2014;614:45.

Ly R, Karayan A, Hartwig K, Castaneda H. Insights into the electrochemical response of a partially recrystallized Al-Mg-Si alloy and its relationship to corrosion events. Electrochim Acta. 2019;308:35.

Li H, Zhang X, Chen M, Li YF, Liang X. Effect of pre-deformation on the stress corrosion cracking susceptibility of aluminum alloy 2519. Rare Met. 2007;26(4):385.

Vikas G. Effect of ageing time and temperature on corrosion behaviour of aluminum alloy 2014. IOP Conf Ser Mat Sci Eng. 2018;338(1):012008.

Zheng R, Ma C. Novel fabrication of bulk fine-grained Al-Cu-Mg alloy with superior mechanical properties. Adv Eng Mater. 2016;18(6):1027.

Olivier G, Benjamin D, Tobias K, Gabi S, Mathias H. Field-assisted sintering technology/spark plasma sintering: mechanisms, materials, and technology development. Adv Eng Mater. 2014;16(7):830.

Saheb N. Spark plasma and microwave sintering of Al6061 and Al2124 alloys. Int J Min Met Mater. 2013;20(2):152.

Cabrini M, Lorenzi S, Pastore T, Testa C, Manfredi D, Lorusso M, Calignano F, Pavese M, Andreatta F. Corrosion behavior of AlSi10Mg alloy produced by laser powder bed fusion under chloride exposure. Corros Sci. 2019;152(3):101.

Revilla R, Liang J, Godet S, Graeve ID. Local corrosion behavior of additive manufactured AlSiMg alloy assessed by SEM and SKPFM. J Electrochem Soc. 2016;164(2):C27.

Senöz C, Borodin S, Stratmann M, Rohwerder M. In situ detection of differences in the electrochemical activity of Al2Cu IMPs and investigation of their effect on FFC by scanning Kelvin probe force microscopy. Corros Sci. 2012;58(5):307.

Deng Y, Ye R, Xu G, Yang J, Pan Q, Bing P, Cao X, Duan Y, Wang Y, Lu L. Corrosion behaviour and mechanism of new aerospace Al-Zn-Mg alloy friction stir welded joints and the effects of secondary Al3ScxZr1−x nanoparticles. Corros Sci. 2015;90:359.

Tian W, Li S, Chen X, Liu J, Yu M. Intergranular corrosion of spark plasma sintering assembled bimodal grain sized AA7075 aluminum alloys. Corros Sci. 2016;107:211.

Thierry G, SeBastien L. Processing dense hetero-nanostructured metallic materials by spark plasma sintering. Scr Mater. 2007;57(6):525.

Srinivasarao B, Ohkubo T, Mukaib T, Hono K. Synthesis of high-strength bimodally grained iron by mechanical alloying and spark plasma sintering. Scr Mater. 2008;58(9):759.

Lin YC, Liu G, Chen MS, Zhang JL, Chen ZG, Jiang YQ, Li J. Corrosion resistance of a two-stage stress-aged Al-Cu-Mg alloy: effects of external stress. J Alloy Compd. 2016;661:221.

Niu PL, Li WY, Li N, Xu YX, Chen DL. Exfoliation corrosion of friction stir welded dissimilar 2024-to-7075 aluminum alloys. Mater Charact. 2019;147:93.

Rai P, Shekhar S, Mondal K. Development of gradient microstructure in mild steel and grain size dependence of its electrochemical response. Corros Sci. 2018;138:85.

Luo C, Zhang XX, Zhou XR, Sun ZH, Zhang XY, Tang ZH, Lu F, Thompson GE. Characterization of localized corrosion in an Al-Cu-Li alloy. J Mater Eng Perform. 2016;25(5):1811.

Navaser M, Atapour M. Effect of friction stir processing on pitting corrosion and intergranular attack of 7075 aluminum alloy. J Mater Sci Technol. 2017;33(2):155.

Bach LX, Son DL, Phong MT, Thang LV, Bian MZ, Nam ND. A study on Mg and AlN composite in microstructural and electrochemical characterizations of extruded aluminum alloy. Compo Part B-Eng. 2019;156:332.

Zhang X, Lv Y, Hashimoto T, Nilsson JO, Zhou XR. Intergranular corrosion of AA6082 Al-Mg-Si alloy extrusion: the influence of trace Cu and grain boundary misorientation. J Alloy Compd. 2021;853:157228.

Luo C, Zhou X, Thompson GE, Hughes AE. Observations of intergranular corrosion in AA2024-T351: the influence of grain stored energy. Corros Sci. 2012;61(8):35.

Zheng YY, Luo BH, He C, Gao Y, Bai ZH. Corrosion evolution and behaviour of Al–2.1Mg–1.6Si alloy in chloride media. Rare Met. 2021;40(4):908.

Li QA, Li X, Zhang Q, Chen J. Effect of rare-earth element Sm on the corrosion behavior of Mg-6Al-1.2Y-0.9Nd alloy. Rare Met. 2010;29(6):557.

Zhu Y, Sun K, Frankel GS. Intermetallic phases in aluminum alloys and their roles in localized corrosion. J Electrochem Soc. 2018;165(11):C807.

Lu Y, Bradshaw AR, Chiu YL, Jones IP. Effects of secondary phase and grain size on the corrosion of biodegradable Mg-Zn-Ca alloys. Mater Sci Eng C Mater Biol Appl. 2015;48:480.

Miranda G, Carvalho O, Soares D, Silva FS. Properties assessment of nickel particulate-reinforced aluminum composites produced by hot pressing. J Compos Mater. 2015;50(4):523.

Rohwerder M, Turcu F. High-resolution Kelvin probe microscopy in corrosion science: scanning Kelvin probe force microscopy (SKPFM) versus classical scanning Kelvin probe (SKP). Electrochim Acta. 2007;53(2):290.

Li W, Cai M, Wang Y, Yu S. Influences of tensile strain and strain rate on the electron work function of metals and alloys. Scr Mater. 2006;54(5):921.

Huo WG, Hu JJ, Cao HH, Du Y, Zhang W. Simultaneously enhanced mechanical strength and inter-granular corrosion resistance in high strength 7075 Al alloy. J Alloy Compd. 2019;781:680.

Yuan R, Gu Y, Wu H. Effect of surface Volta potential of Cr-containing steel on uniform corrosion and pitting corrosion. Mater Corros. 2021;72(11):1774.

Meng YB, Li SM, Liu JH, Yu M, Chen MJ. Pitting of 2024 alloys prepared by spark plasma sintering using powders with different sizes. Corros Sci. 2020;170:108525.

Acknowledgements

This research was financially supported by the National Nature Science Foundations of China (Nos. 51271012 and 51671013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interests.

Rights and permissions

About this article

Cite this article

Meng, YB., Li, SM., Liu, JH. et al. Intergranular corrosion of spark plasma sintered 2024 aluminum alloy at different heat treatment states. Rare Met. 41, 3865–3877 (2022). https://doi.org/10.1007/s12598-022-01990-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-01990-7