Abstract

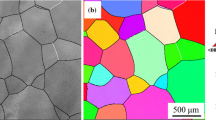

High strength titanium alloys suffer from a limited combination of strength and ductility. Considering their microstructure, the coarse β grain is a detrimental factor. In the present study, the effects of hot deformation and annealing treatment on the β grain refinement of Ti–5Al–5Mo–5V–1Cr–1Fe (TC18) titanium alloy have been investigated by using electronic backscattered diffraction (EBSD) and transmission electric microscopy (TEM). Hot compression tests of TC18 alloy were performed between 1073 and 1223 K at strain rates of 0.01 and 0.10 s−1. Subsequent annealing treatments were conducted to investigate the effect of deformation microstructure on the recrystallization behavior of β grains. The results indicate that dynamic recovery (DRV) is the dominant restoration mechanism during hot deformation. Discontinuous dynamic recrystallization (dDRX) is significantly limited at a higher temperature in the β region, whereas continuous dynamic recrystallization (cDRX) of the β phase is observed at a higher strain rate in the (α + β) region. The final annealing microstructure is highly dependent on the deformation microstructure. Limited dDRX during hot deformation could not effectively refine the β grains. The refined and uniform β grains with an average grain size of 12 μm are achieved by combining hot deformation and subsequent annealing in the (α + β) region. This study provides a guide for the β grain refinement of high strength titanium alloys.

Graphic abstract

Similar content being viewed by others

References

Lütjering G, Williams JC. Titanium. 2nd ed. Berlin Heidelberg: Springer; 2007. 251.

Banerjee D. Perspectives on titanium science and technology. Acta Mater. 2013;61(3):844.

Zhang K, Dong HB, Jiang ZY, Shi S, Liu HX. Effects of cold-deformation and aging process on microstructure and properties of TB8 titanium alloy. Chin J Rare Met. 2019;43(9):904.

Gottstein G. Physical Foundations of Materials Science. Berlin: Springer; 2013. 260.

Ivasishin OM, Markovsky PE, Matviychuk YV, Semiatin SL, Ward CH, Fox S. A comparative study of the mechanical properties of high-strength β-titanium alloys. J Alloys Compd. 2008;457(1):296.

Cui YM, Li CH, Zhang CS, Li RG, Ren Y, Zheng WW, Wang YD. Effect of initial microstructure on the micromechanical behavior of Ti-55531 titanium alloy investigated by in-situ high-energy X-ray diffraction. Mater Sci Eng A. 2020. https://doi.org/10.1016/j.msea.2019.138806.

Xia QF, Liang YL, Yang CL, Zhang S, Ou MG. Tensile deformation behavior of TC4 titanium alloy. Chin J Rare Met. 2019;43(7):765.

Weiss I, Alvarado PJ, Fitzsimons G, DeArdo AJ. Grain refinement and coarsening during dynamic recrystallization in plain carbon steel. Scr Metall. 1983;17(6):693.

Chen YJ, Li YJ, Walmsley JC, Dumoulin S, Gireesh SS, Armada S, Skaret PC, Roven HJ. Quantitative analysis of grain refinement in titanium during equal channel angular pressing. Scr Mater. 2011;64(9):904.

Luo R, Zheng Q, Zhu J, Guo S, Li DS, Xu GF, Cheng XN. Dynamic recrystallization behavior of Fe–20Cr–30Ni–06Nb–2Al–Mo alloy. Rare Met. 2019;38(2):181.

Zhao J, Zhong J, Yan F, Chai F, Dargusch M. Deformation behaviour and mechanisms during hot compression at supertransus temperatures in Ti-10V-2Fe-3Al. J Alloys Compd. 2017;710:616.

Li LF, Yang WY, Sun ZQ. Dynamic recrystallization of ferrite in a low-carbon steel. Metall Mater Trans A. 2006;37(3):609.

Wang K, Wu M, Yan Z, Li D, Xin R, Liu Q. Dynamic restoration and deformation heterogeneity during hot deformation of a duplex-structure TC21 titanium alloy. Mater Sci Eng. 2018;712:440.

Doherty RD, Hughes DA, Humphreys FJ, Jonas JJ, Jensen DJ, Kassner ME, King WE, Mcnelley TR, McQueen HJ, Rollett AD. Current issues in recrystallization: a review. Mater Sci Eng. 1997;238(2):219.

Dong R, Li J, Kou H, Tang B, Hua K, Liu S. Characteristics of a hot-rolled near β titanium alloy Ti-7333. Mater Charact. 2017;129:135.

Li L, Li MQ, Luo J. Mechanism in the β phase evolution during hot deformation of Ti–5Al–2Sn–2Zr–4Mo–4Cr with a transformed microstructure. Acta Mater. 2015;94:36.

Zherebtsov S, Murzinova M, Salishchev G, Semiatin S. Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 2011;59(10):4138.

Wang YL, Song XY, Ma W, Zhang WJ, Ye WJ, Hui SX. Microstructure and tensile properties of Ti-62421S alloy plate with different annealing treatments. Rare Met. 2018;36(7):568.

Lu ZD, Zhang CJ, Du ZX, Han JC, Zhang SZ, Yang F, Chen YY. Relationship between microstructure and tensile properties on a near-β titanium alloy after multidirectional forging and heat treatment. Rare Met. 2019;36(4):336.

Gottstein G, Molodov D, Shvindlerman L. Grain boundary migration in metals: recent developments. Interface Sci. 1998;6(1):7.

Humphreys FJ, Hatherly M. Recrystallization and Related Annealing Phenomena. 2nd ed. Amsterdam: Elsevier; 2004. 220.

Dillamore IL, Roberts WT. Rolling textures in fcc and bcc metals. Acta Metall. 1964;12(3):281.

Huang K, Logé RE. A review of dynamic recrystallization phenomena in metallic materials. Mater Des. 2016;111:548.

Li LF, Yang WY, Sun ZQ. Dynamic recrystallization of ferrite with particle-stimulated nucleation in a low-carbon steel. Metall Mater Trans A. 2013;44(5):2060.

Warchomicka F, Poletti C, Stockinger M. Study of the hot deformation behaviour in Ti–5Al–5Mo–5V–3Cr–1Zr. Mater Sci Eng. 2011;528(28):8277.

Dikovits M, Poletti C, Warchomicka F. Deformation mechanisms in the near-β titanium alloy Ti-55531. Metall Mater Trans A. 2013;45(3):1586.

Godfrey A, Cao WQ, Hansen N, Liu Q. Stored energy, microstructure, and flow stress of deformed metals. Metall Mater Trans A. 2005;36(9):2371.

Fei Y, Wang XN, Zhu ZS, Li J, Shang GQ, Zhu LW. β grain growth kinetics of a new metastable β titanium alloy. Mater Sci Forum. 2016;747:844.

Ouyang DL, Du HM, Cui X, Lu SQ, Dong XJ. Grain growth behavior of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy during isothermal β heat treatments. Rare Met. 2019;36(3):233.

Shim HS, Na TW, Chung JS, Kwon SB, Gil K, Park JT, Hwang NM. Synchrotron X-ray microdiffraction of Fe–3wt%Si steel focusing on sub-boundaries within Goss grains. Scr Mater. 2016;116:71.

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci. 2014;60(60):13.

Acknowledgements

This study was financially supported by the National Key Research and Development Program of China (No. 2016YFB0701302).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, YM., Zheng, WW., Li, CH. et al. Effectiveness of hot deformation and subsequent annealing for β grain refinement of Ti–5Al–5Mo–5V–1Cr–1Fe titanium alloy. Rare Met. 40, 3608–3615 (2021). https://doi.org/10.1007/s12598-020-01677-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01677-x